Section structure of motorcycle tire

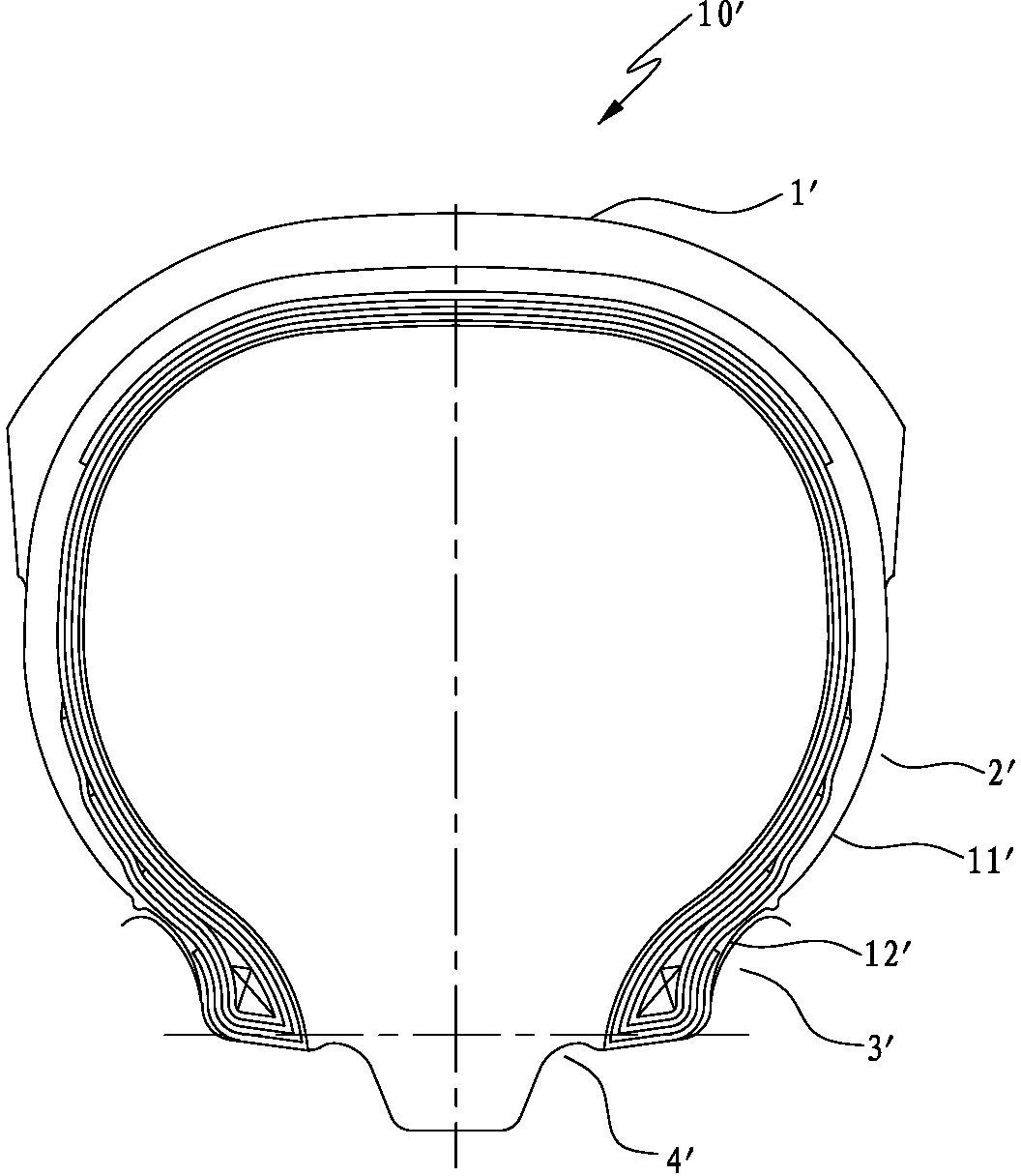

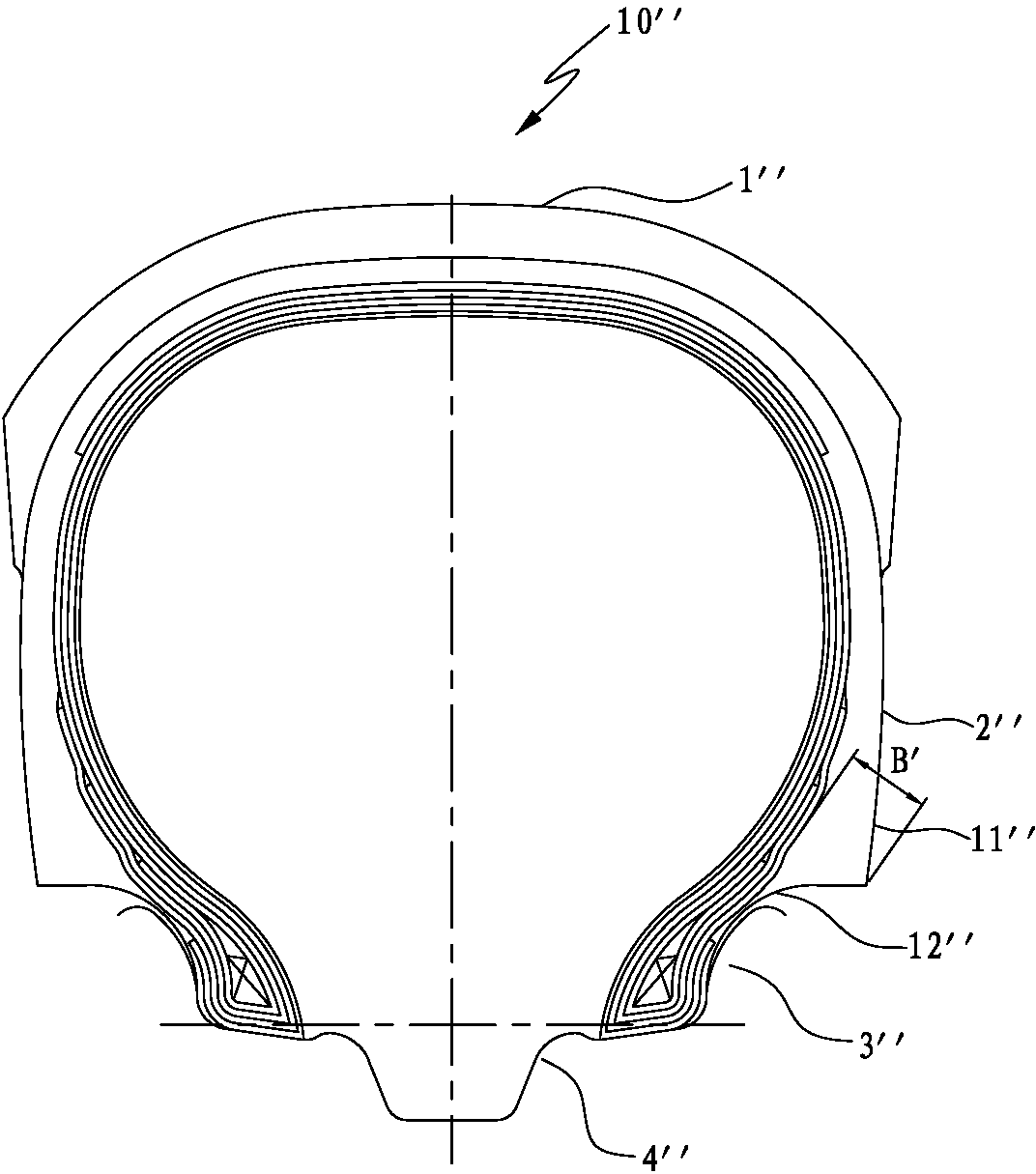

A technology for motorcycle tires and cross-sections, which is applied to tire parts, reinforcing layers of pneumatic tires, tire edges, etc., and can solve problems such as weak rigidity of the bead 2', weakened extrusion pressure, and detachment of the bead 3' , to achieve the effect of improving air retention performance, reducing weight and ensuring rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

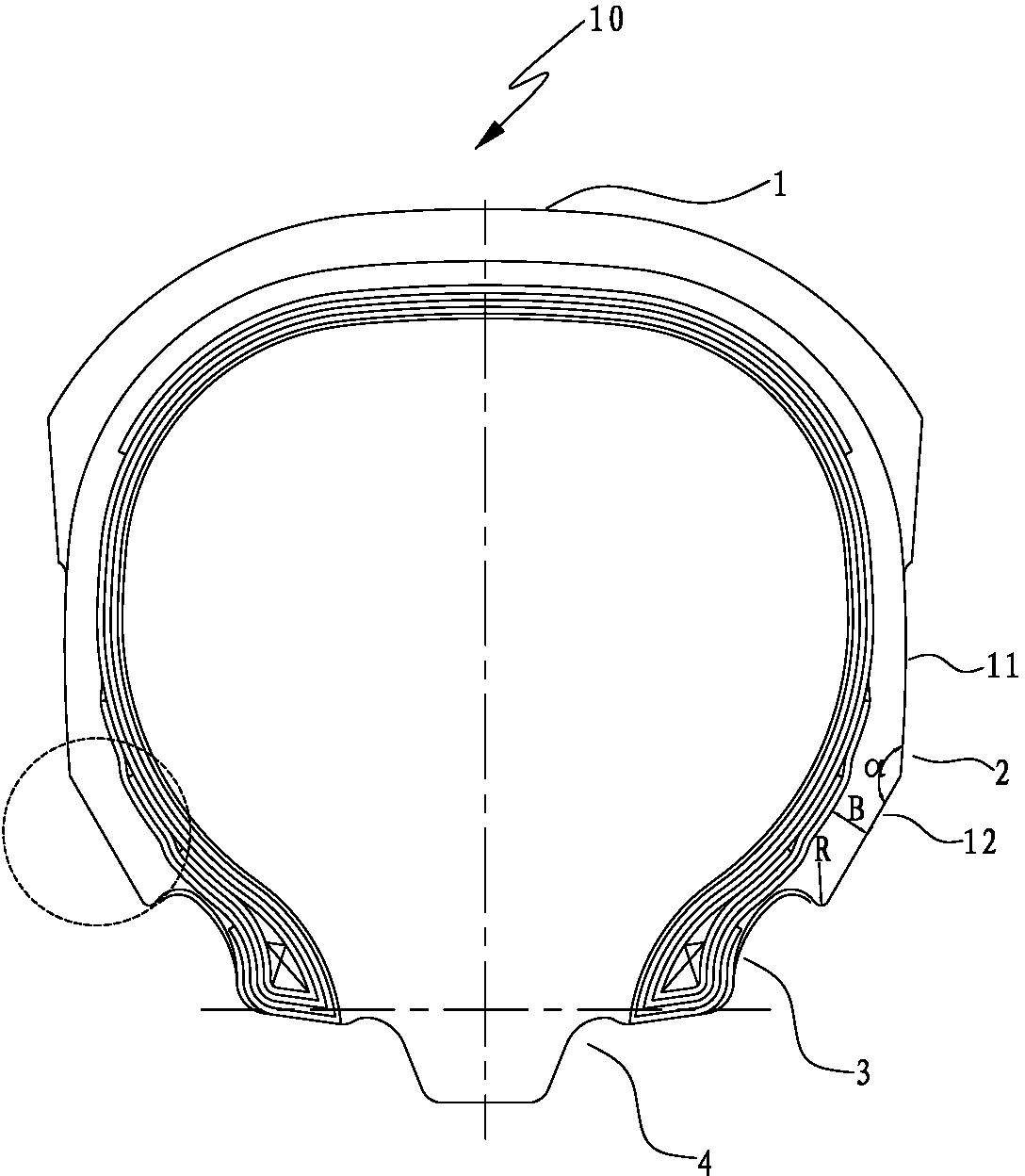

[0017] Such as image 3 , 4 As shown, the present invention discloses a section structure of a motorcycle tire, the vertical direction is radial, and the horizontal direction is axial. The tire 10 includes a tread portion 1, a bead portion 2 and a bead portion 3, and the profile of the bead portion 2 of the tire is adjusted and designed, that is, the tire bead portion 2 is composed of an upper arc line 11 and a lower straight line 12 , the arc line 11 and the straight line 12 form an obtuse angle α, the angle α is set to 140°~160°, so that the bead portion 2 is roughly a broken line, so that the rigidity of the bead portion 2 can be effectively ensured, and the tire 10 Better fitting with the rim 4 to prevent the bead lip 3 from detaching from the rim 4; in addition, the design of the sawtooth pattern 13 is added to the entire circumference of the straight line 12. The sawtooth pattern can be set parallel to the axial or radial direction, and the sawtooth pattern 13 The dept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com