Recyclable high-oxygen-barrier film material and preparation method thereof

A film, high-resistance technology, applied in chemical instruments and methods, applications, household appliances, etc., can solve the problems of difficult to process interlayer anti-peel strength composite films, high cost, and restricting the application of all-plastic composite films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

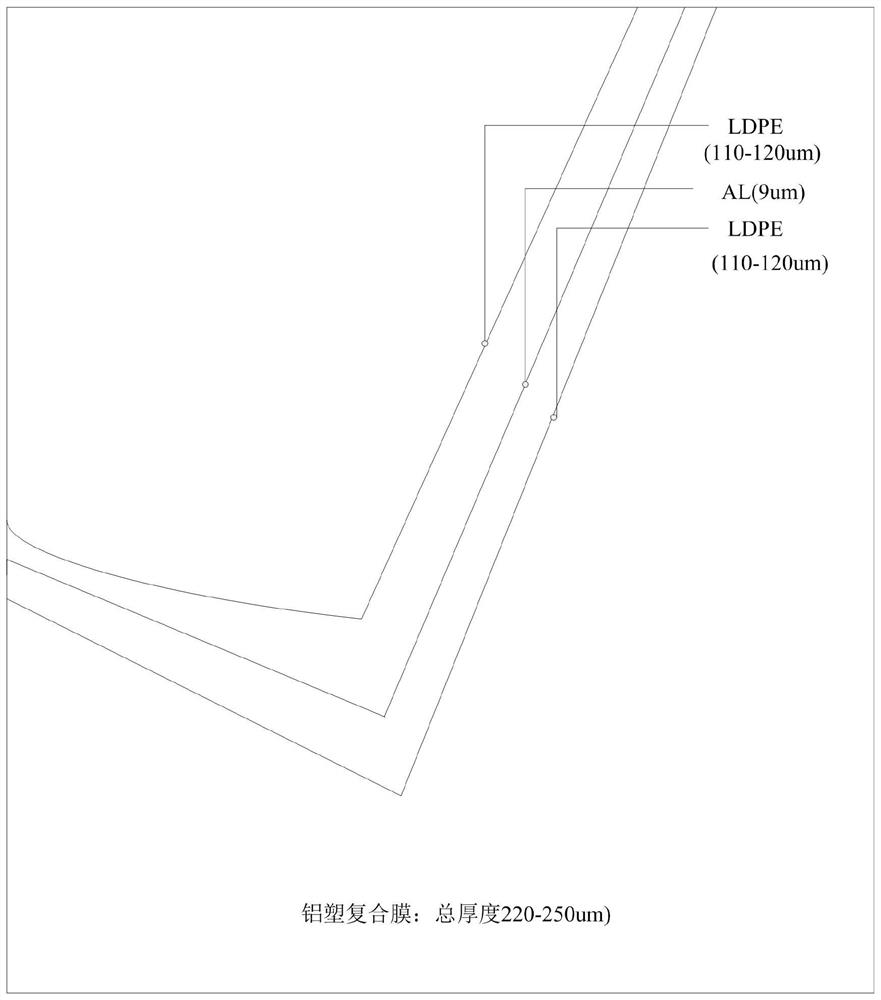

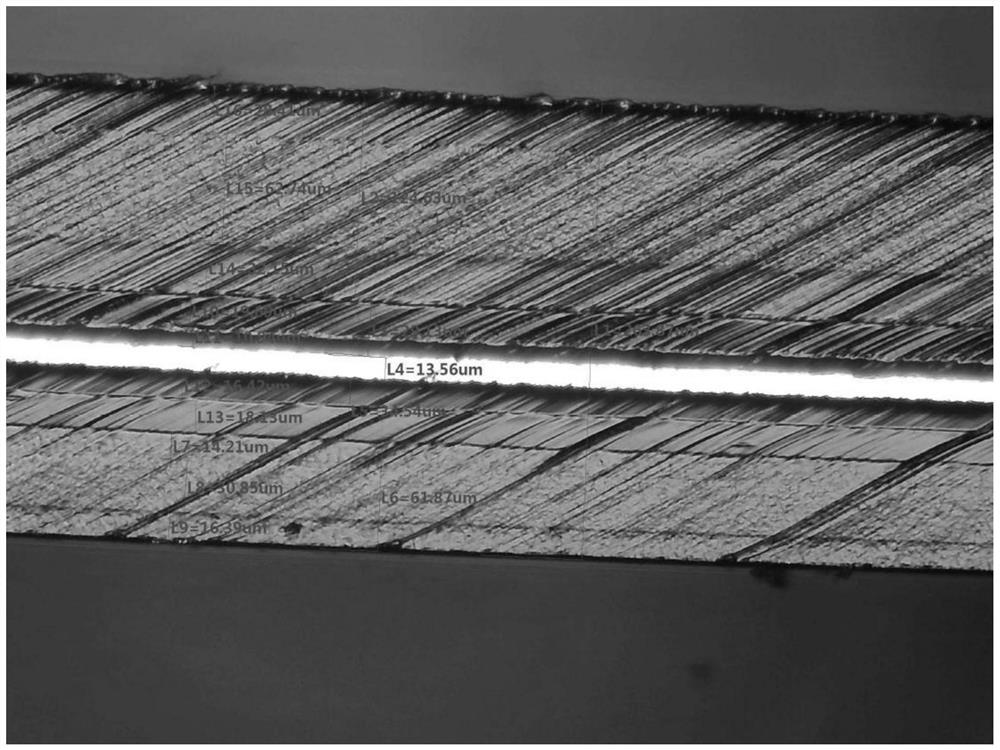

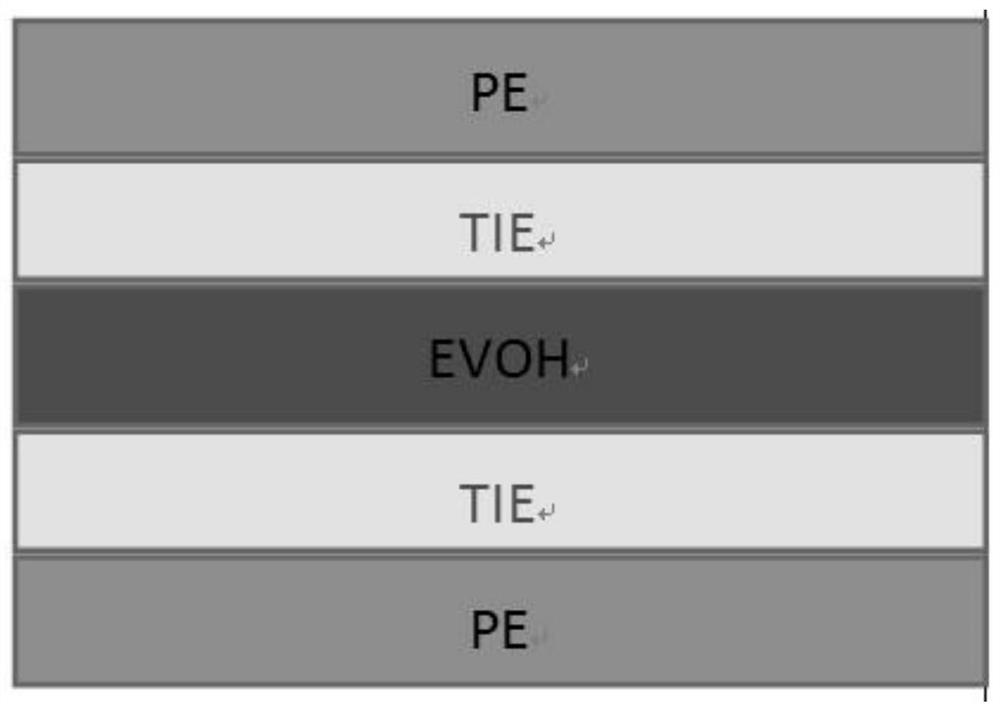

[0069] A recyclable high oxygen barrier film material of the present invention, comprising the first polyethylene functional layer (the first HDPE monolayer + the third HDPE monolayer + the first outer PE layer are used in this embodiment), ethylene-vinyl alcohol Copolymer intermediate barrier layer (EVOH co-extruded film is selected in this embodiment) and the second polyethylene functional layer (the fourth HDPE single layer + second HDPE single layer + second outer PE layer is used in this embodiment), ethylene-ethylene The two sides of the alcohol copolymer intermediate barrier layer are finally respectively combined with the first polyethylene functional layer and the second polyethylene functional layer through the adhesive resin layer. The oxygen transmission rate test value of the high oxygen barrier film material is less than 1cm 3 / m 2 .day (specifically 0.54cm 3 / m 2 .day). The water vapor transmission rate (37.8°C, 90%RH) of the high oxygen barrier film materia...

Embodiment 2

[0075] a kind of like Figure 9 The recyclable high oxygen barrier film material of the present invention comprises the first polyethylene functional layer (the first outer PE layer+the first HDPE single layer is used in this embodiment), an ethylene-vinyl alcohol copolymer intermediate barrier layer (this embodiment The embodiment selects the EVOH layer) and the second polyethylene functional layer (this embodiment adopts the second HDPE single layer + the second outer PE layer), and the two sides of the ethylene-vinyl alcohol copolymer intermediate barrier layer are respectively separated by the adhesive resin layer. Combined with the first polyethylene functional layer and the second polyethylene functional layer, the first polyolefin functional layer, the ethylene-vinyl alcohol copolymer intermediate barrier layer and the second polyolefin functional layer are closely connected by an adhesive resin layer Adhesive as a whole, and when using conventional composite film mater...

Embodiment 3

[0088] a kind of like Figure 10 The recyclable white high oxygen barrier film material of the present invention is shown, comprising the first polyethylene functional layer (the first outer PE layer + the first HDPE single layer is used in this embodiment), an ethylene-vinyl alcohol copolymer intermediate barrier layer (this embodiment selects EVOH layer) and the second polyethylene functional layer (this embodiment adopts the second HDPE single layer + second outer PE layer), and the two sides of the ethylene-vinyl alcohol copolymer intermediate barrier layer are bonded The resin layer is respectively combined with the first polyethylene functional layer and the second polyethylene functional layer, and the first polyolefin functional layer, the ethylene-vinyl alcohol copolymer intermediate barrier layer and the second polyolefin functional layer are bonded The resin layer is tightly bonded into a whole, and the peel strength test of conventional composite film materials (su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com