Pneumatic Tubeless Tires

An inflatable inner tube technology, applied in the field of tire structure, can solve the problems of air leakage, poor tire rigidity and support, high manufacturing and maintenance costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

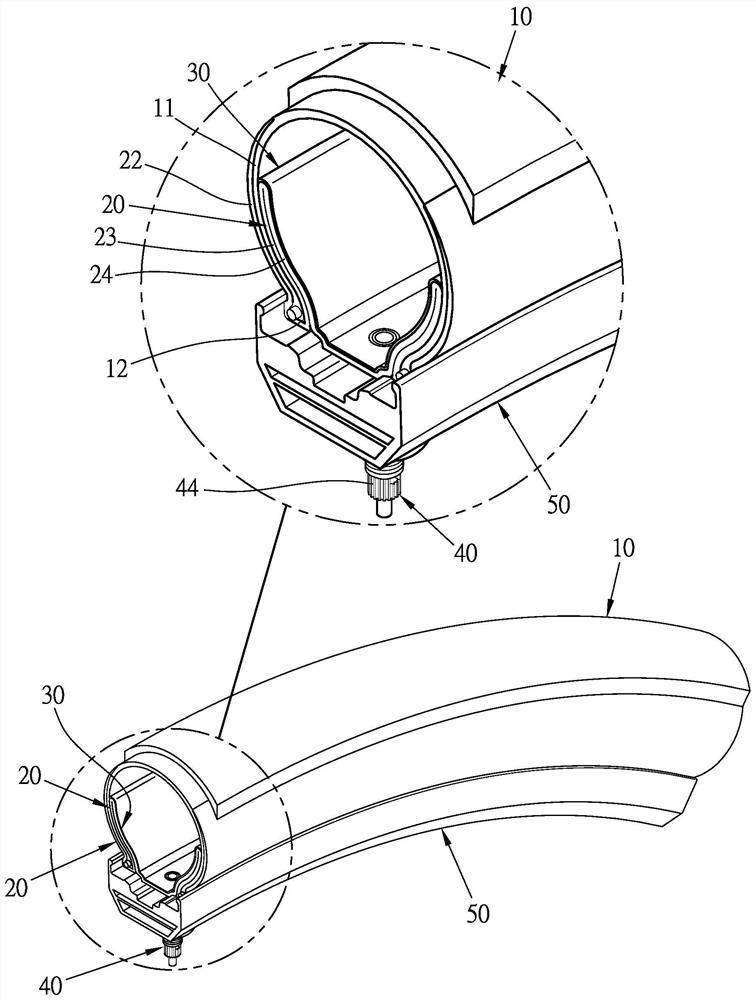

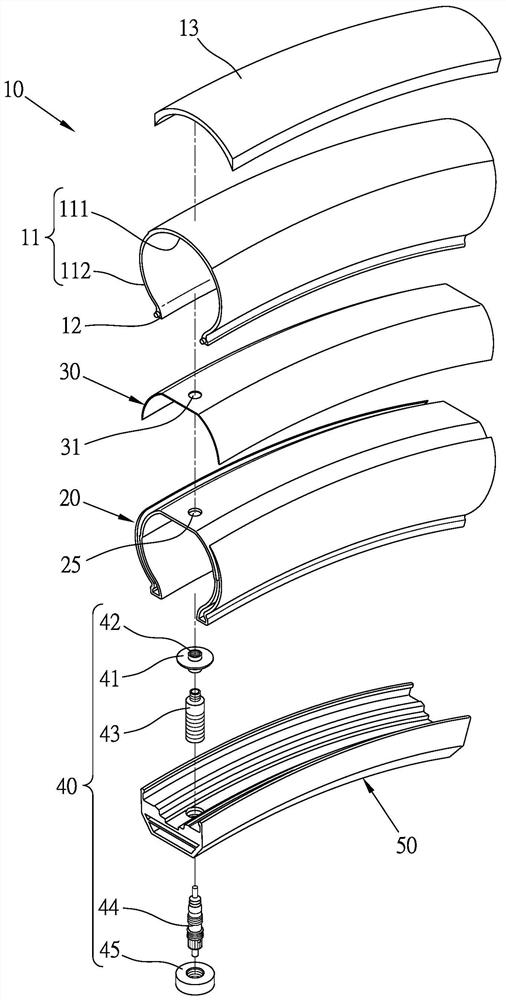

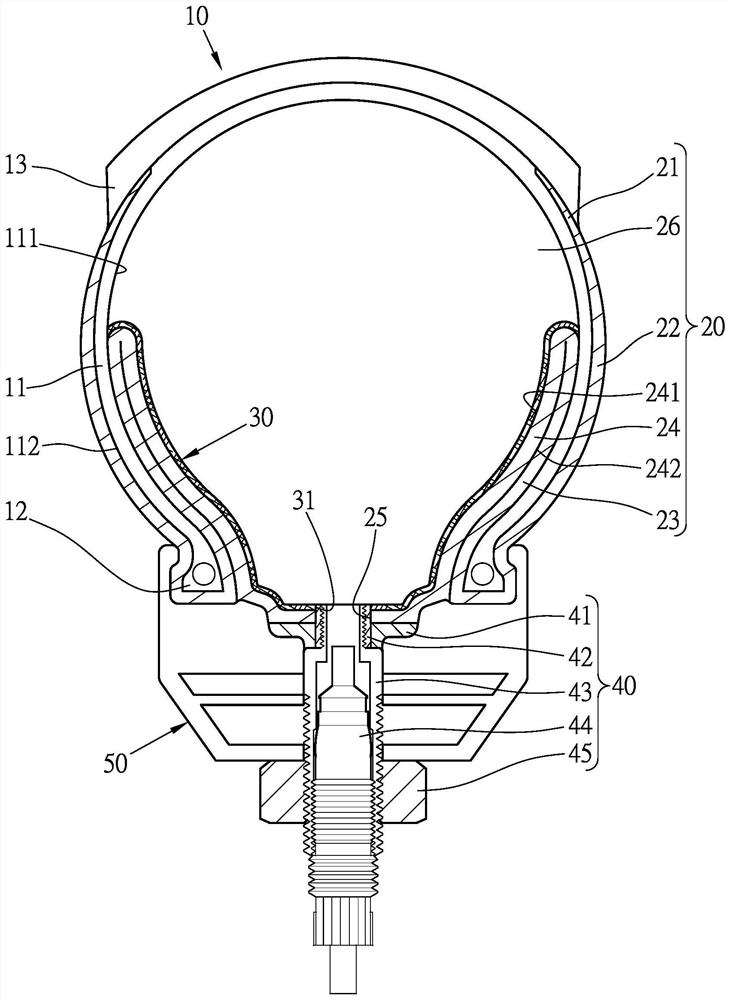

[0093] First please refer to Figure 1-3 , a pneumatic tubeless tire 10 provided by the present invention includes: a carcass 11 can move due to different inflation states, so that the gas chamber 26 can form different sizes of spaces.

[0094] The spacer 30 of the present invention can be one of a single spacer, a plurality of spacers, spacer liquid or spacer powder; Ethylene formate, acrylonitrile-butadiene-styrene copolymer, polyethylene, polypropylene, low-density styrene, polystyrene, polyethylene terephthalate, polyamide, polyoxymethylene, polycarbonate, One of the materials such as polyphenylene ether, ethylene-vinyl acetate, polyimide, polyphenylene sulfide or polytetrafluoroethylene; when the separator 30 is in powder form, it can be one of the materials such as silicon and magnesium oxide ; When the separator 30 is liquid, it may be a solvent containing silicon.

[0095] The installation method of the isolator 30 of the present invention can be installed on the wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com