Catalytic conversion method for improving cetane number and yield of diesel

A catalytic conversion method and cetane number technology, applied in the field of catalytic conversion, can solve the problems of improving the properties of diesel oil and low cetane number of light diesel oil, etc., and achieve performance improvement, catalyst content reduction, and reduction of fragmentation tendency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

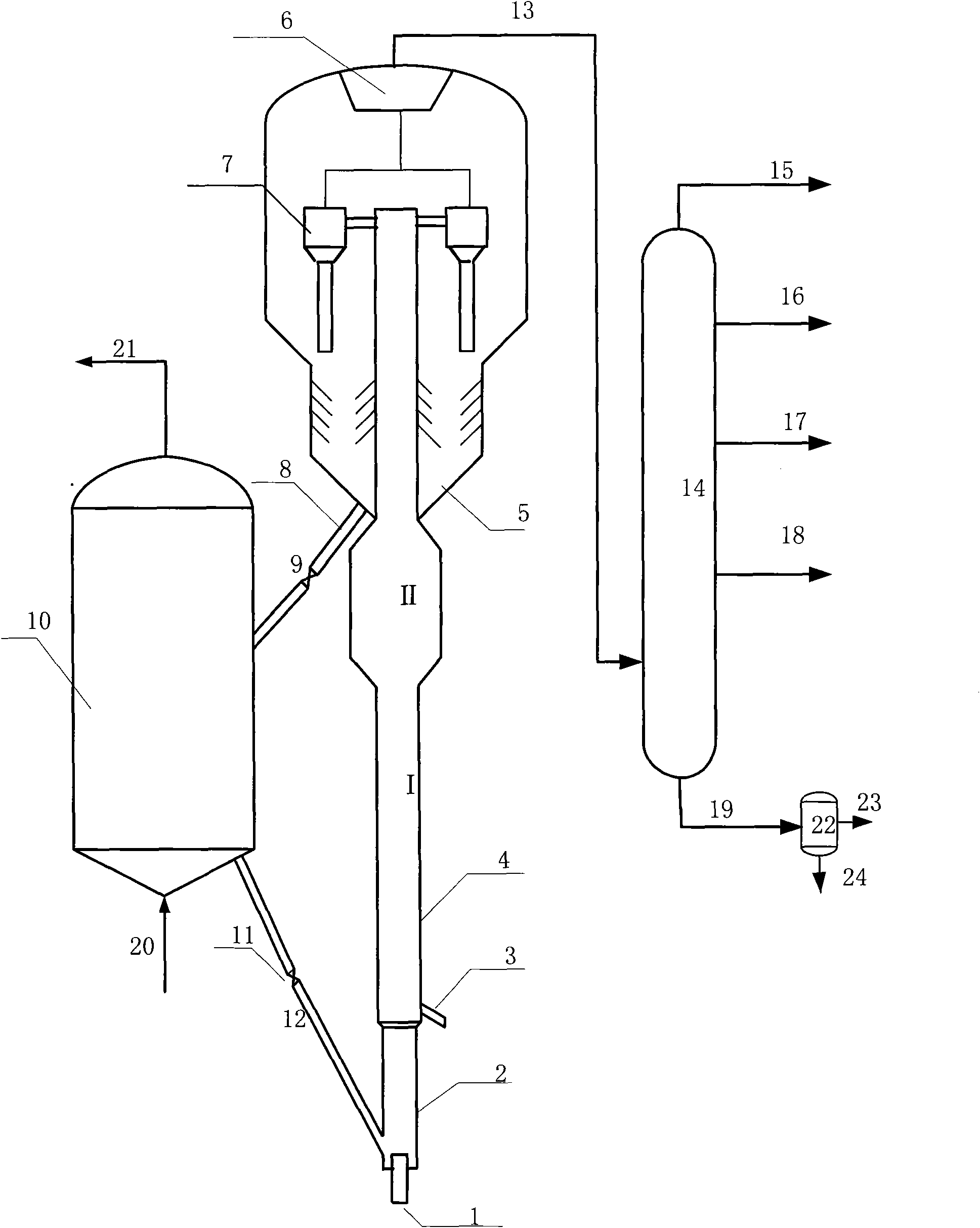

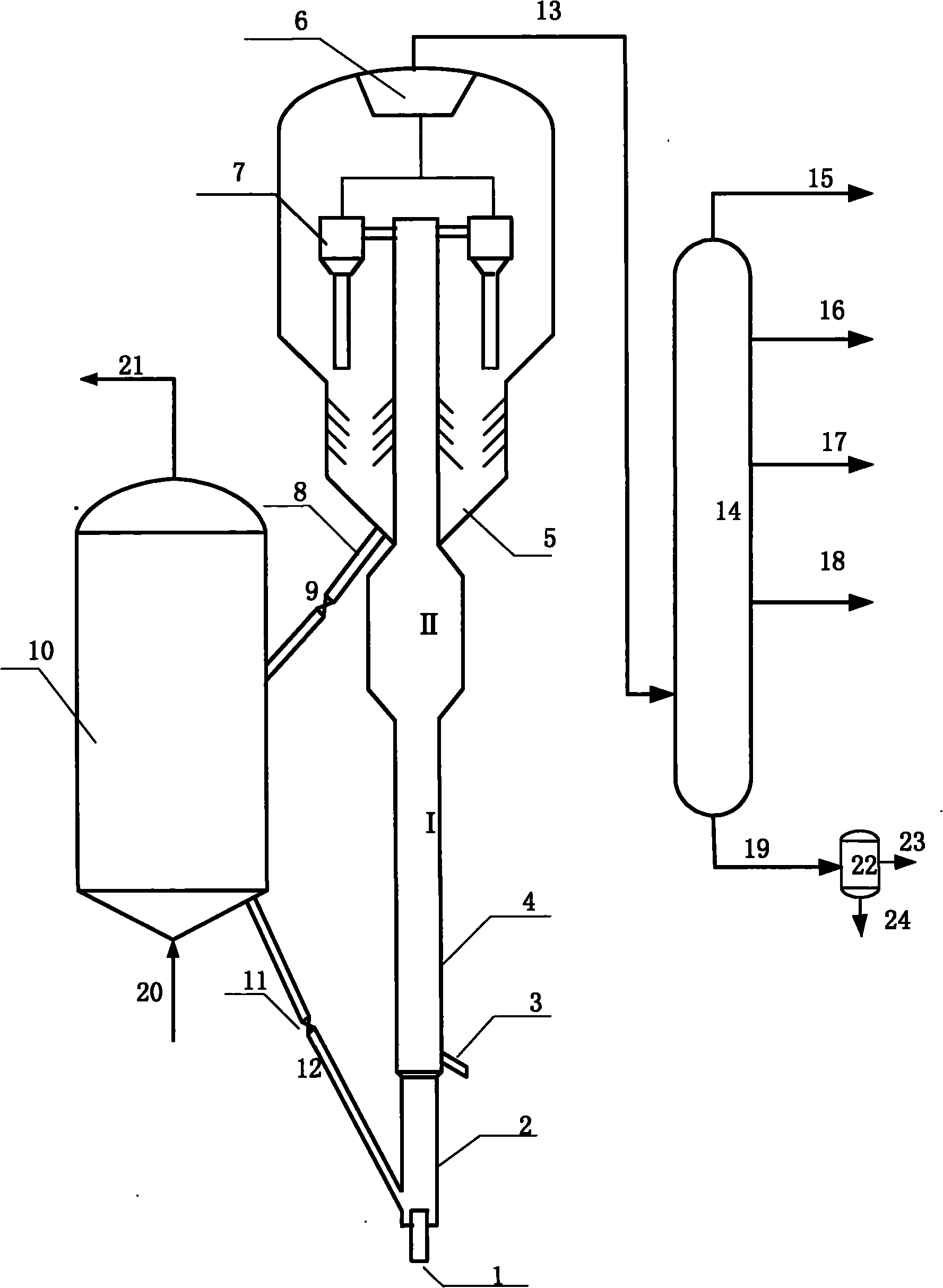

[0048] This example illustrates the situation of producing high-quality diesel oil by selective cracking reaction using the method provided by the present invention.

[0049] The flow chart of the medium-sized catalytic cracking unit is shown in the attached figure. The feedstock oil is injected into the reaction zone I of the riser reactor through the pipeline 3, and it contacts and reacts with the catalyst A lifted by water vapor at the lower part of the riser reactor, and reacts in the riser reactor. The weight ratio of catalyst A and raw oil in the reactor is 3:1, the residence time of raw oil in the riser reactor is 1.6 seconds, and the reaction temperature is 450°C. The pressure of the gas collection chamber is 0.2 MPa. After the oil and gas come out of the riser, they are separated by the cyclone separator and then enter the rear fractionation system. The spent catalyst with carbon enters the stripping section, and the spent catalyst after stripping goes to the regenera...

Embodiment 2

[0052] Adopt the riser reactor identical with above-mentioned embodiment 1 to carry out test, used stock oil is identical with above-mentioned embodiment, test procedure and method are exactly the same as embodiment, just the catalyst that adopts is changed into by the conventional particle size catalyst A of embodiment 1 Coarse particle size catalyst B. The test conditions and test results are listed in Table 3, and the properties of diesel oil are listed in Table 4.

[0053] As can be seen from Table 3, the yield of diesel oil in this embodiment is as high as 46.15% by weight; as can be seen from Table 4, the cetane number of diesel oil in this embodiment is as high as 52, and the cetane number barrel of diesel oil is as high as 2399.8.

[0054] It can also be seen from Table 3 that the dry gas and coke yields of this embodiment are significantly lower than those in Example 1, indicating that the cracking catalyst B with a coarse particle size can reduce the dry gas and coke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com