Patents

Literature

55results about How to "Catalyst content reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

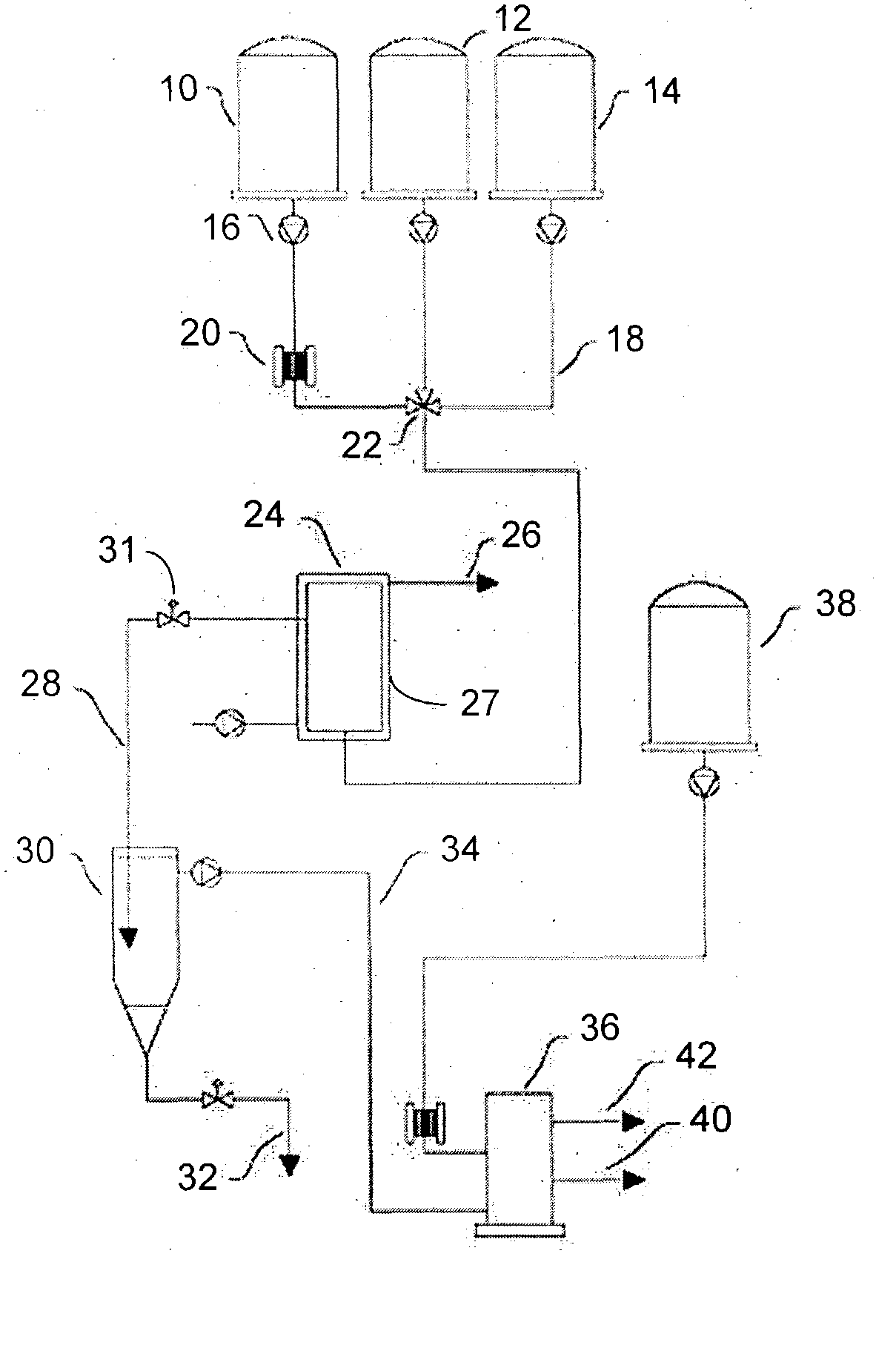

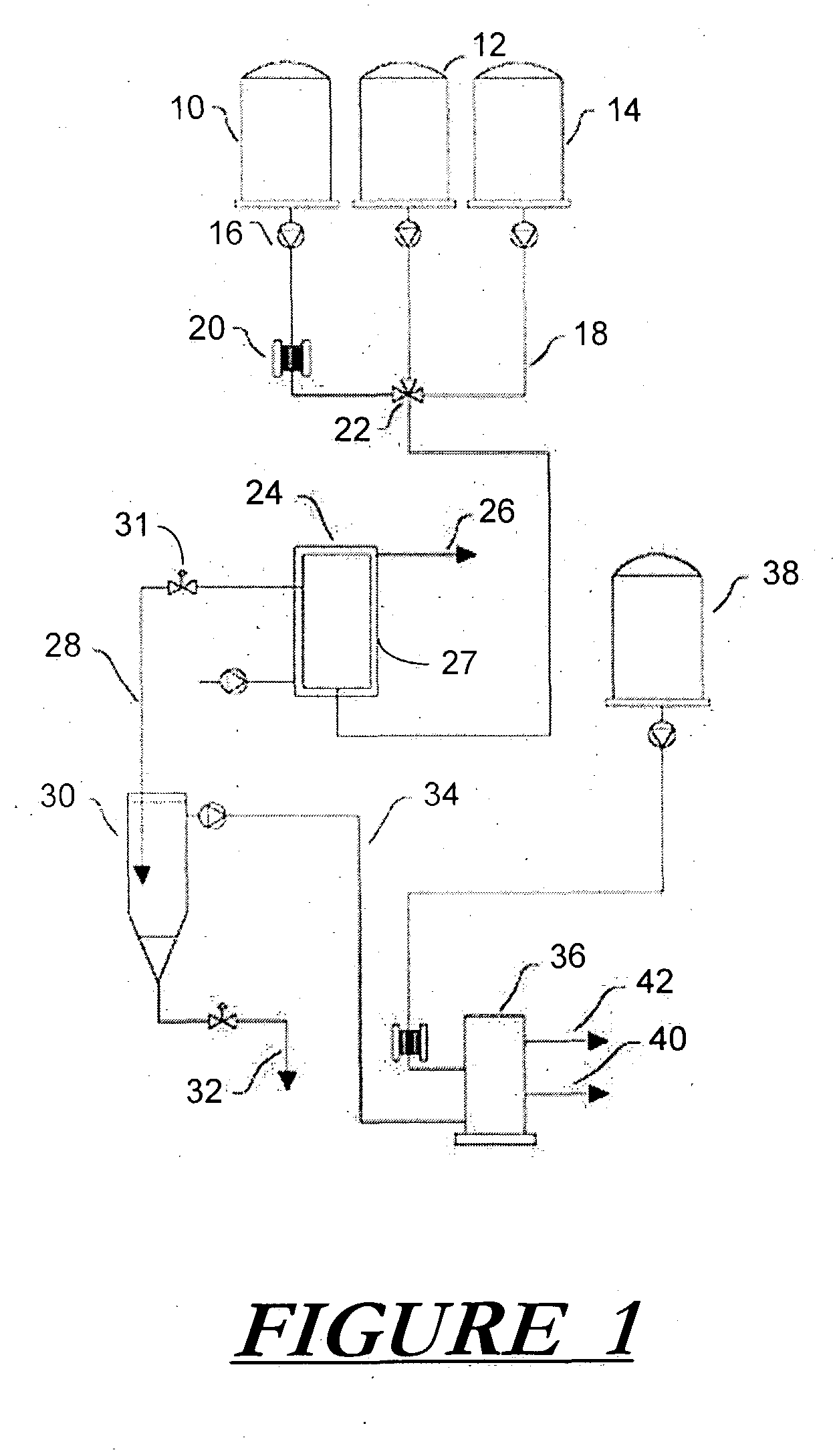

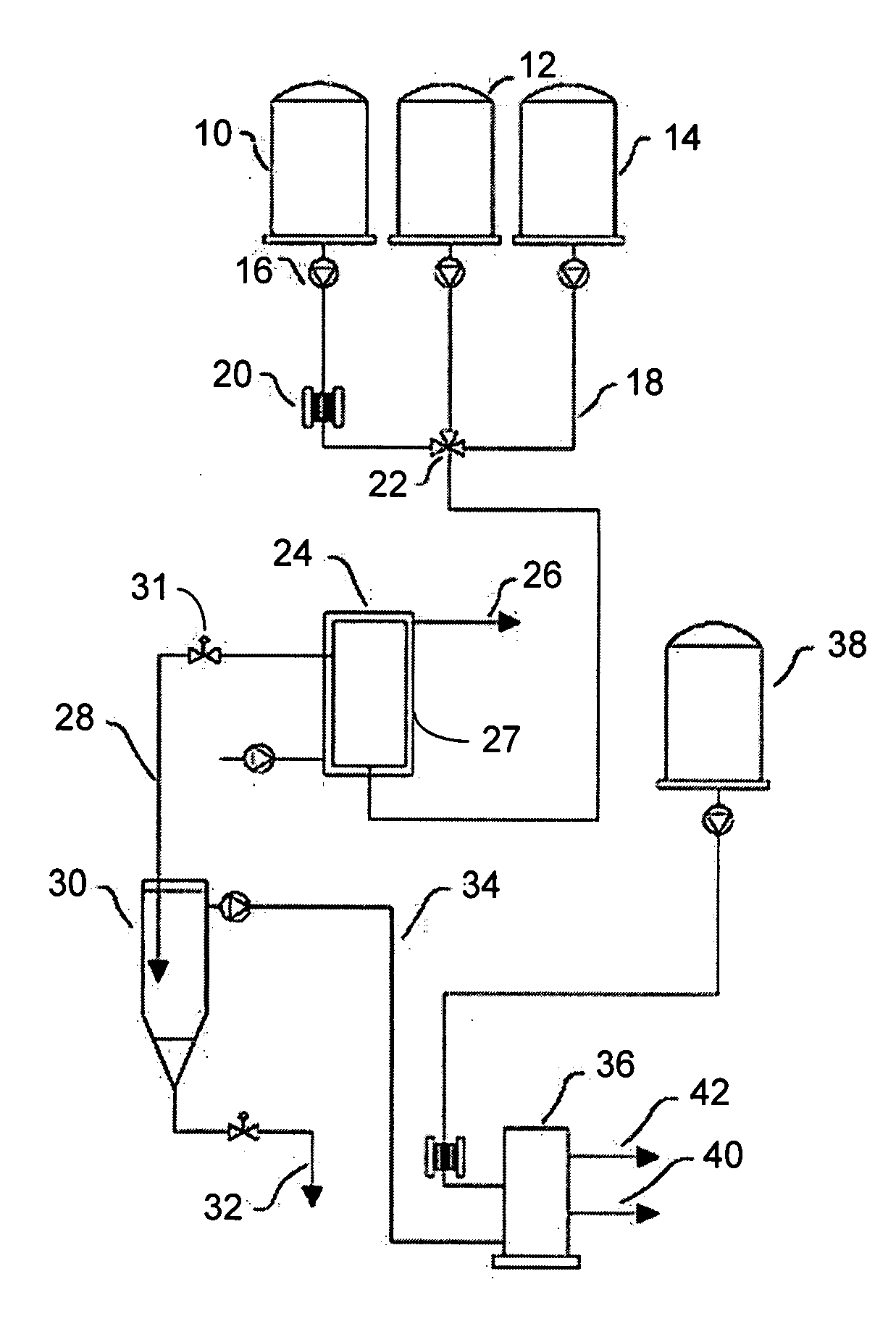

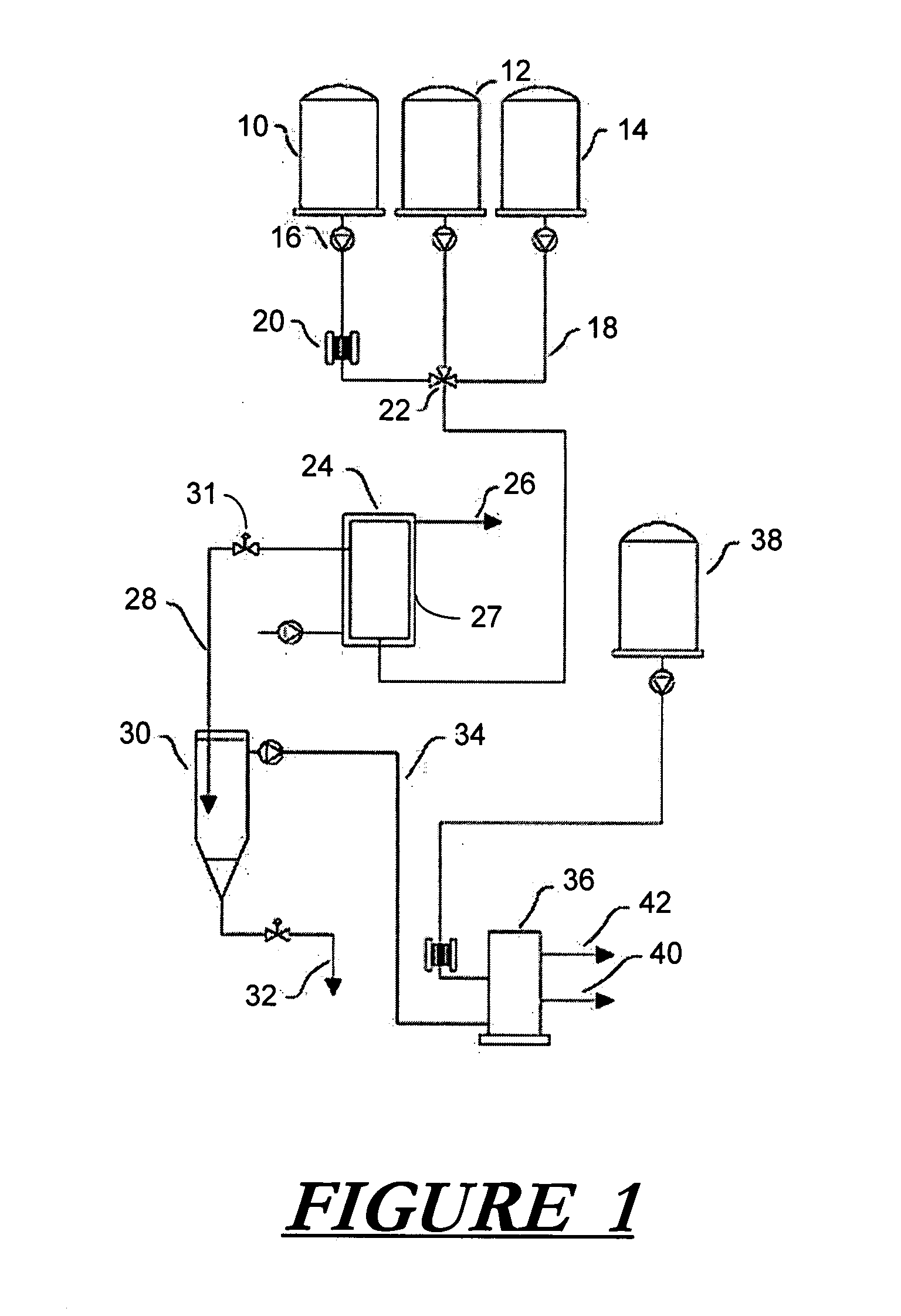

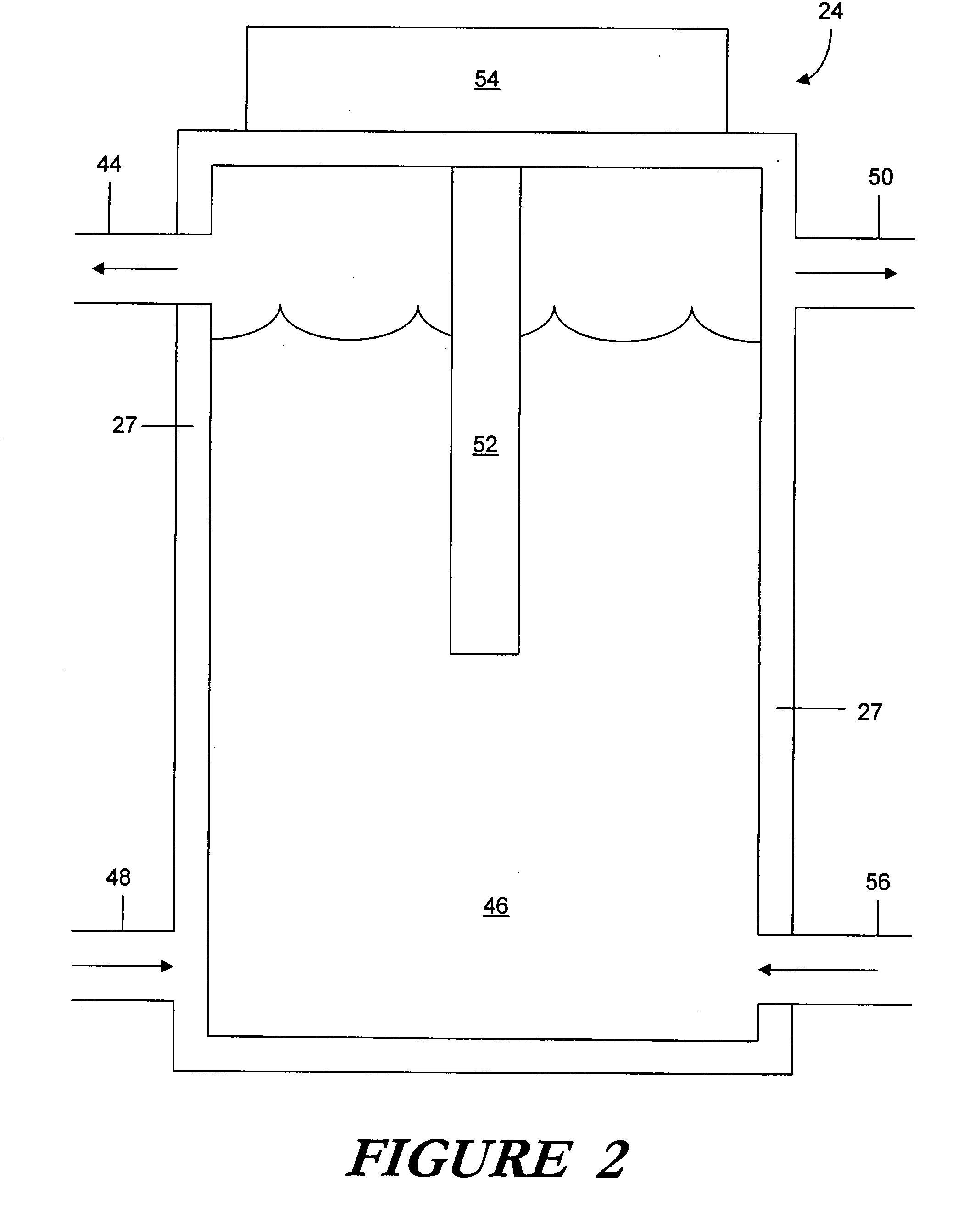

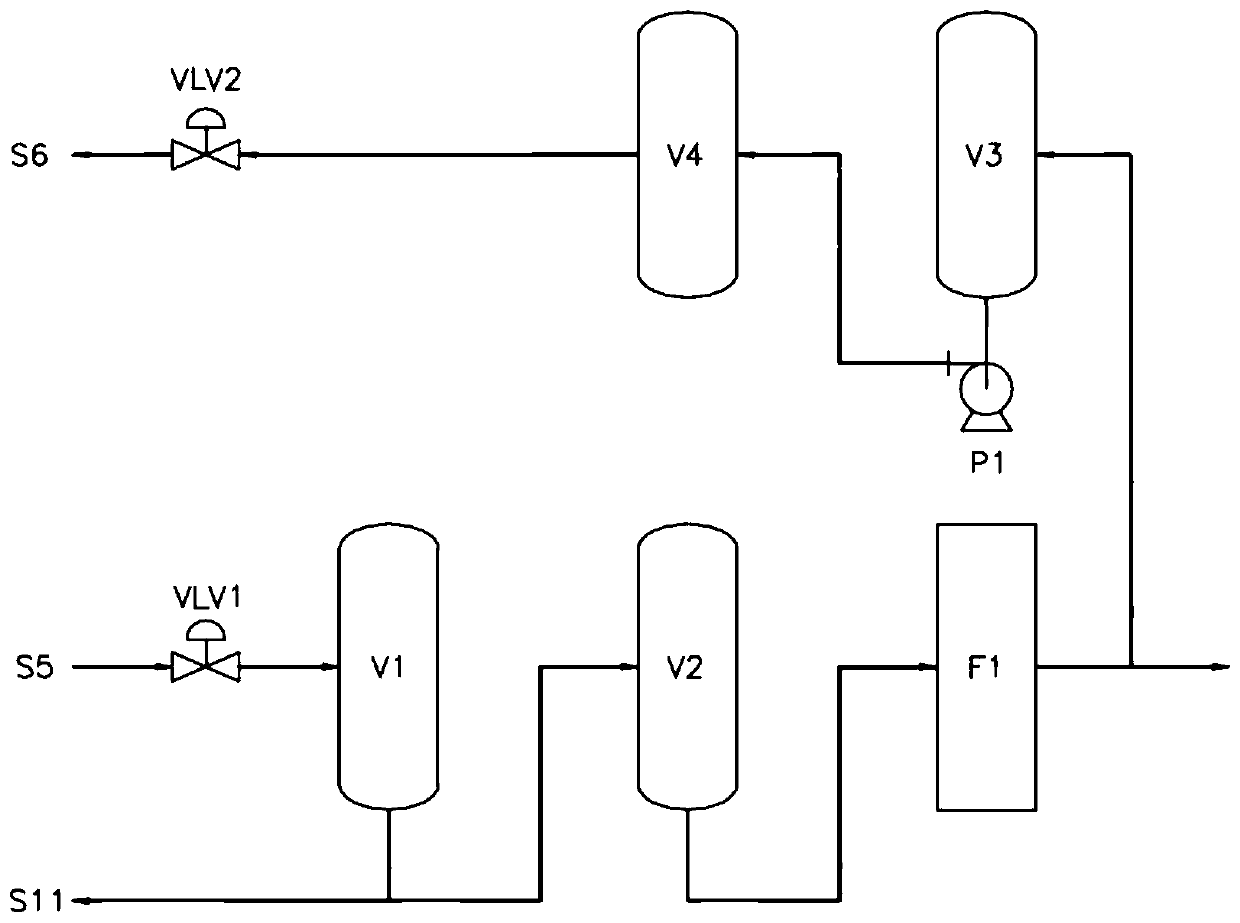

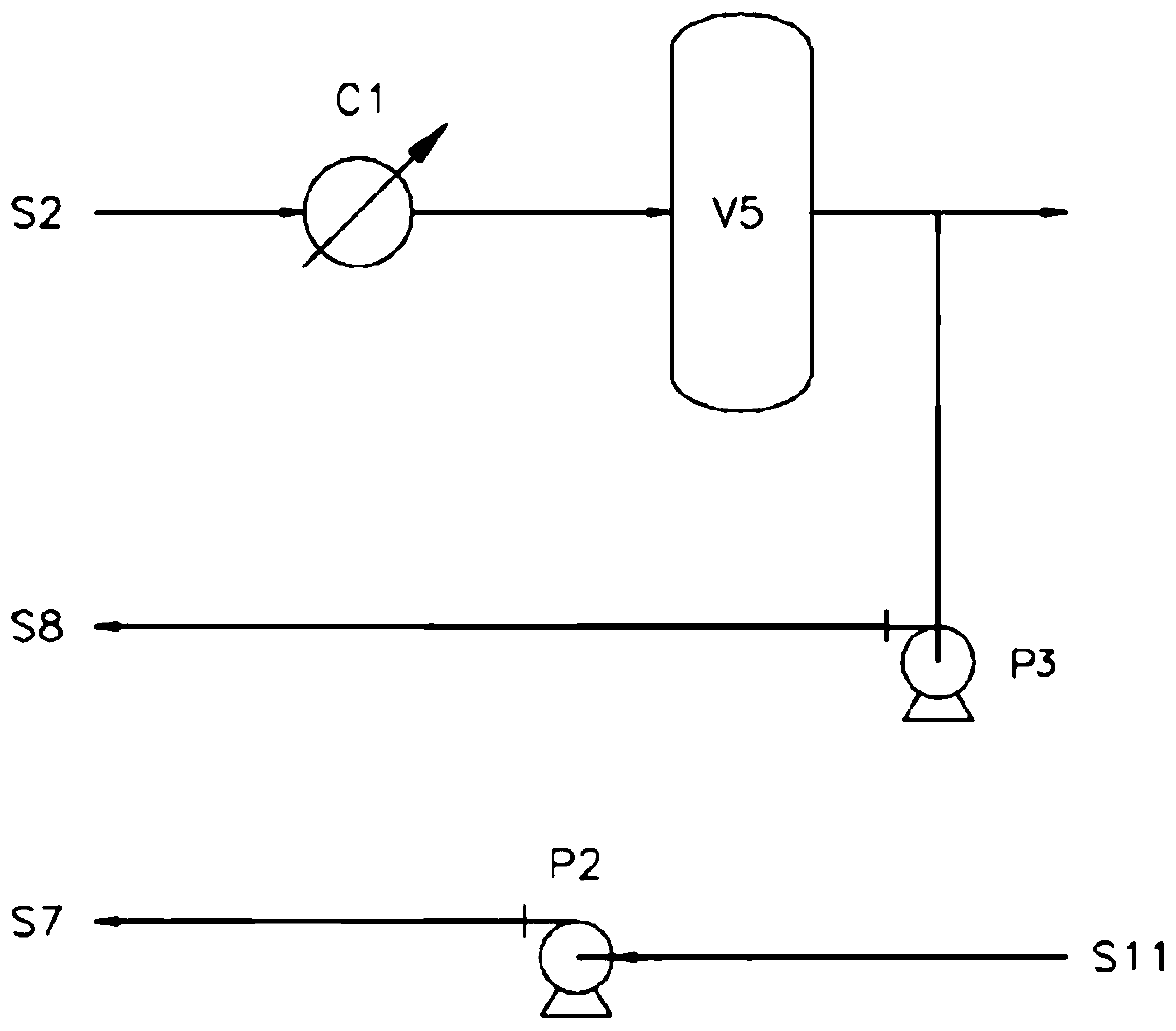

Apparatus and method for the production of fatty acid alkyl ester

InactiveUS20050027137A1Eliminate operationShort possible reaction timeFatty oils/acids recovery from wasteAnalysis using chemical indicatorsAlcoholVegetable oil

An apparatus and method for producing fatty acid alkyl esters from fatty acids derived from vegetable oils and animal fats with an alkaline solution dissolved in stoichiometric or near stoichiometric levels of a monoalkyl alcohol to form a mixture. The method further comprises emulsifying the mixture as a means to reach a completed chemical reaction state in a reactor section, wherein the oils or fats are transesterified into fatty acid alkyl esters. The transesterification occurs when the natural boundary surfaces of the immiscible mixture are enlarged by ultrasonic cavitation in the reaction section and the transesterification is performed at, or near atmospheric pressure. The method finally includes, after reaching the chemical reaction state, separating residues from the fatty acid alkyl ester in a gravitational phase separation section.

Owner:HOOKER JEFFREY D

Rapid-cure, one-component mixtures, which contain alkoxysilane-terminated polymers

InactiveUS7153923B2Fast curingCatalyst content reductionOther chemical processesPolyureas/polyurethane adhesivesPolymer scienceHeteroatom

One-component, moisture curing compositions which exhibit rapid curing, even with exceptionally low levels of catalyst or with no catalyst at all, can be formulated from alkoxysilane-terminated polymers having alkoxysilane groups bonded to an electronegative, free electron-pair-containing heteroatom via a methylene linking group. Polymer blends containing the alkoxysilane-terminated polymers exhibit rapid cure, even at room temperature, and allow the use of nitrogen containing components such as adhesion promoters.

Owner:WACKER CHEM GMBH +1

Catalysts for production of biodiesel fuel and glycerol

InactiveUS20090119979A1Inexpensive and commercially availableSimplifies evacuationFatty acid esterificationNitrogen-metal/silicon/boron binary compoundsTrans esterificationBiodiesel

A method of producing biodiesel through the trans-esterification of a triglyceride, comprising mixing a triglyceride, an alcohol, and a catalyst to form a mixture, where said catalyst is non-metal quaternary ammonium hydroxide or non-metal quaternary phosphonium hydroxide, removing volatile components from said mixture, and allowing the remaining mixture to separate into a biodiesel-rich layer and a glycerol-rich layer.

Owner:IMPERIAL PETROLUEM

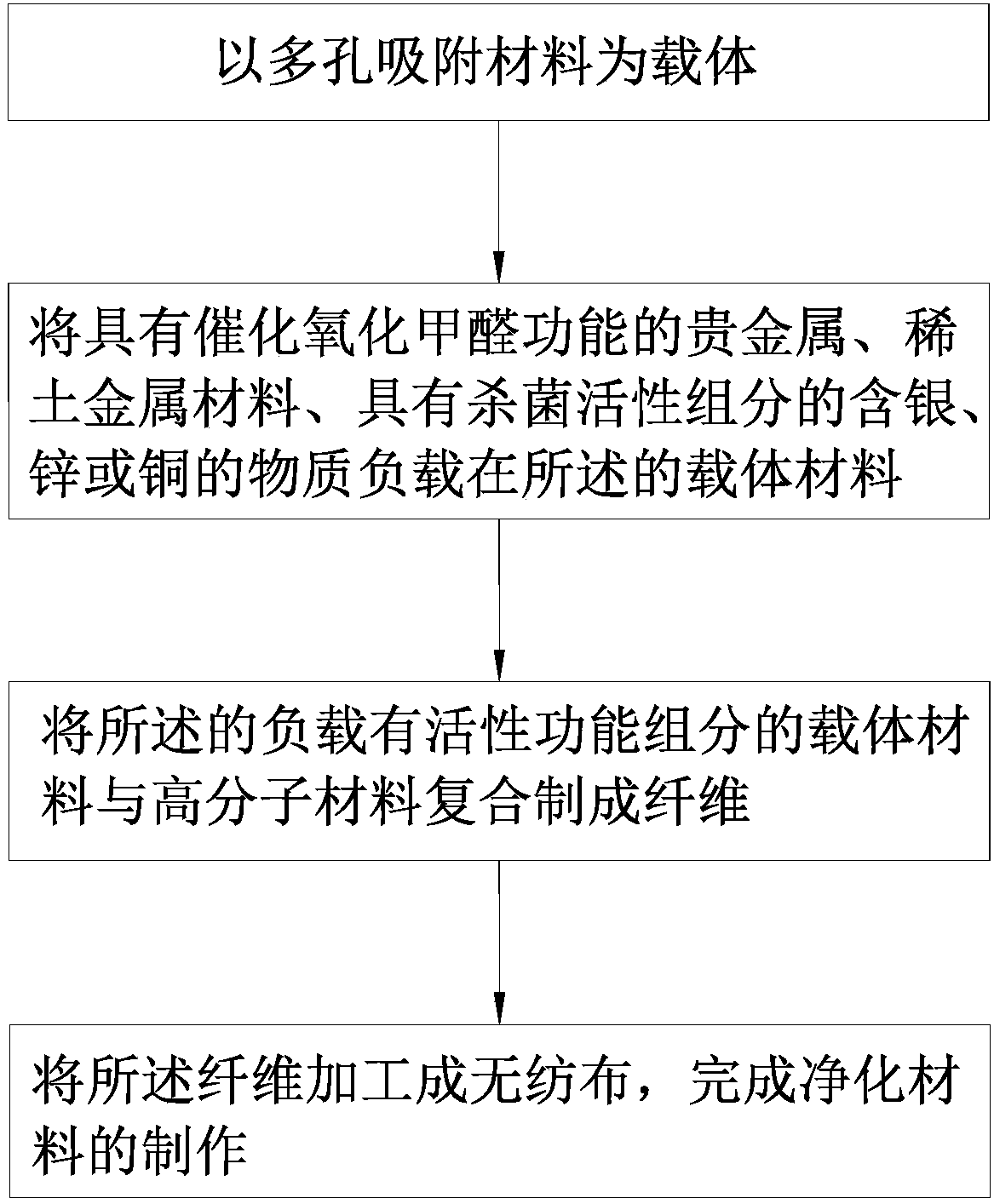

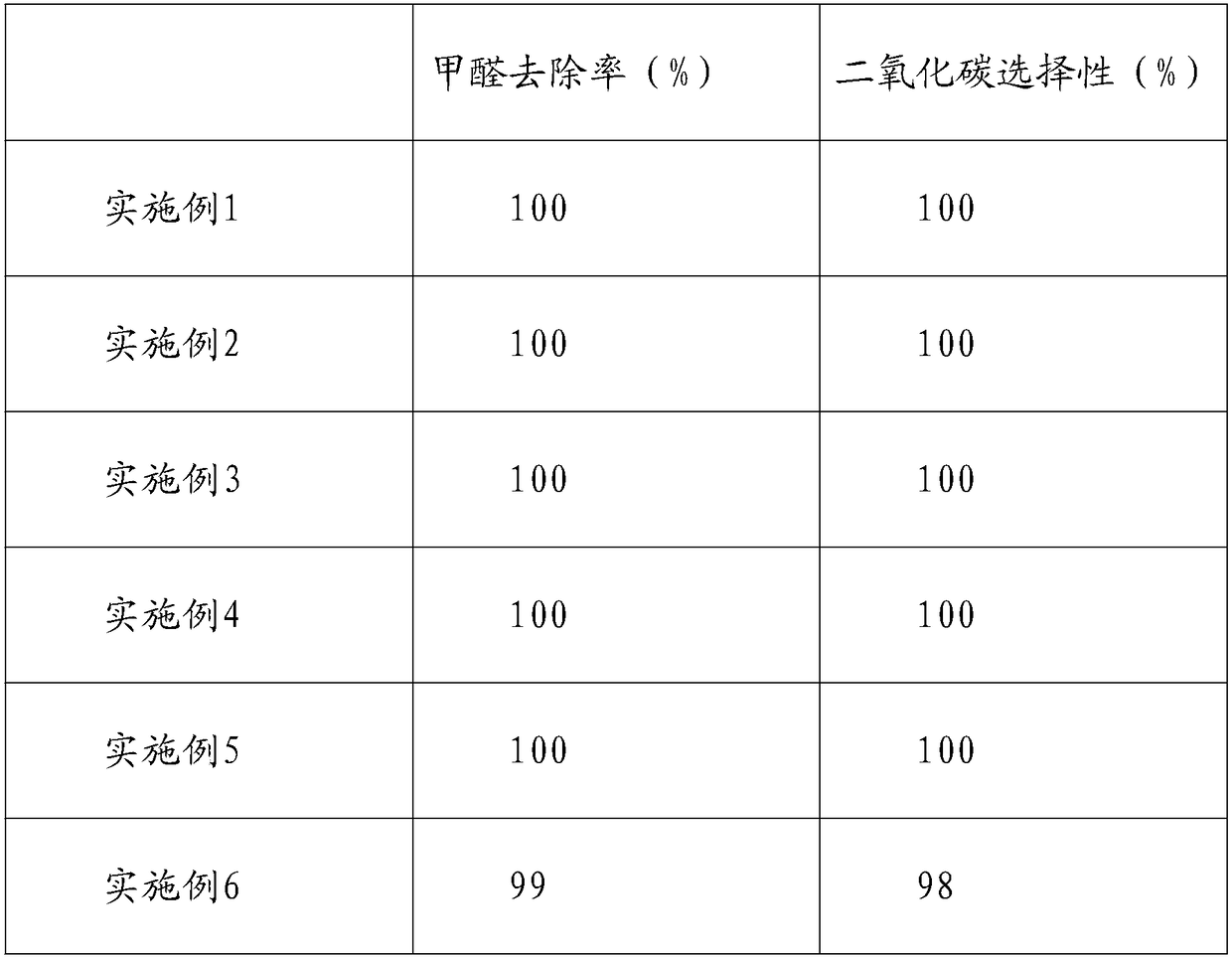

Preparation method for new purification material with catalytic oxidation of formaldehyde and sterilization function

The invention relates to a preparation method of new purification material with catalytic oxidation formaldehyde and sterilization function. The preparation method comprises the following steps of: 1,taking a porous adsorption material as a carrier; step 2, loading noble metal with a catalytic oxidation formaldehyde function, rare-earth metal material, substance containing silver, zinc or copperwith sterilizing active component on a carrier material; step 3, synthetizing the carrier material loaded with the active functional component with the high molecular material to form the fiber; step4, processing the fiber into a non-woven fabric to finish the preparation of the purification material. By bonding the carrier material containing formaldehyde catalytic oxidation active component andsterilizing active component with high-molecular material such as polyester, polyethylene, polypropylene and nylon, after heating and melting, bonding the active component with the fiber, and forminga strong active layer inside and outside the fiber, the new purification material with catalytic oxidation formaldehyde and sterilization function has the advantages that the specific surface area ofthe material is increased, the dispersion of the active component is facilitated, the formaldehyde can be fully contacted with the catalyst, and the formaldehyde has good purification function.

Owner:SHENZHEN PUREMATE TECH

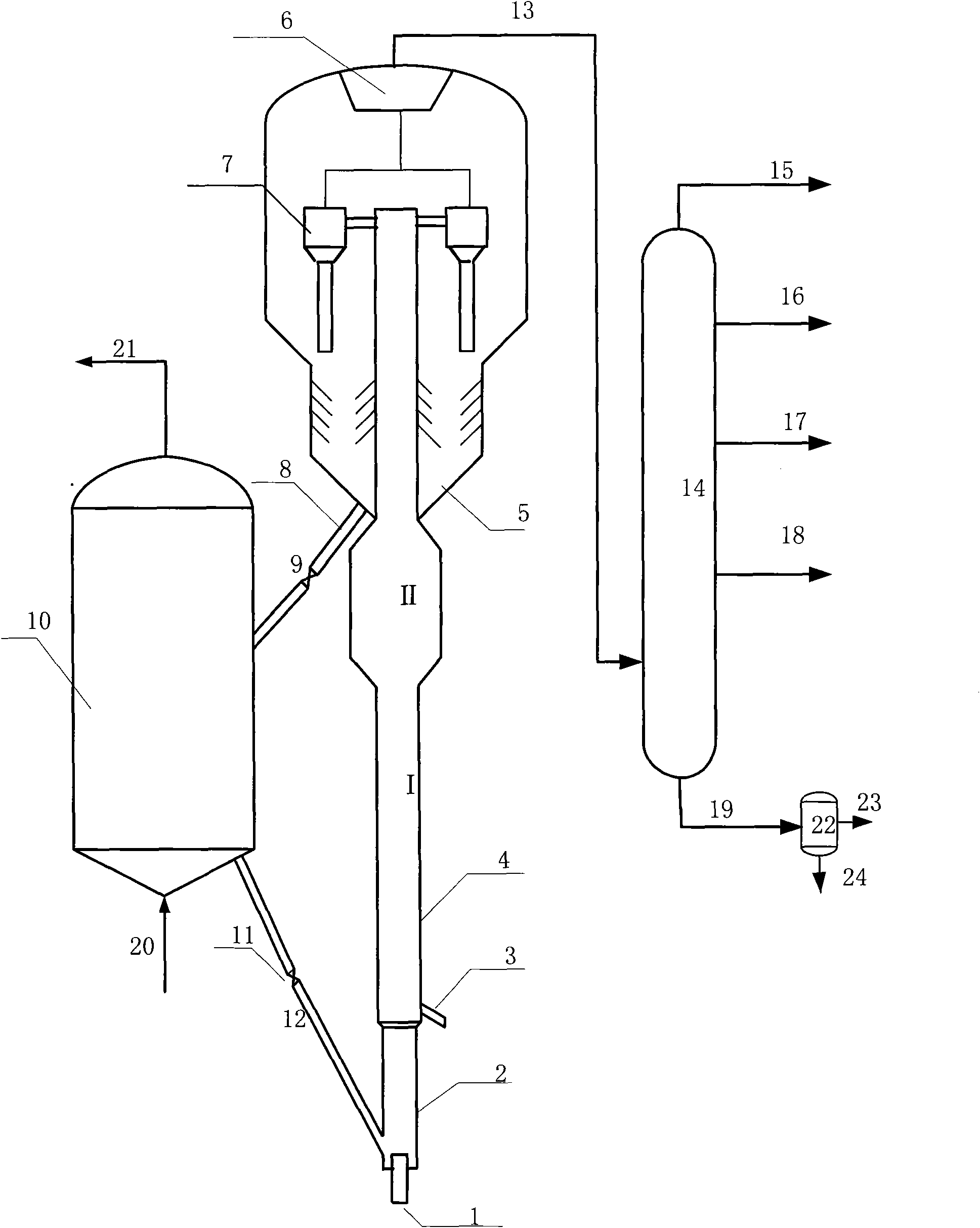

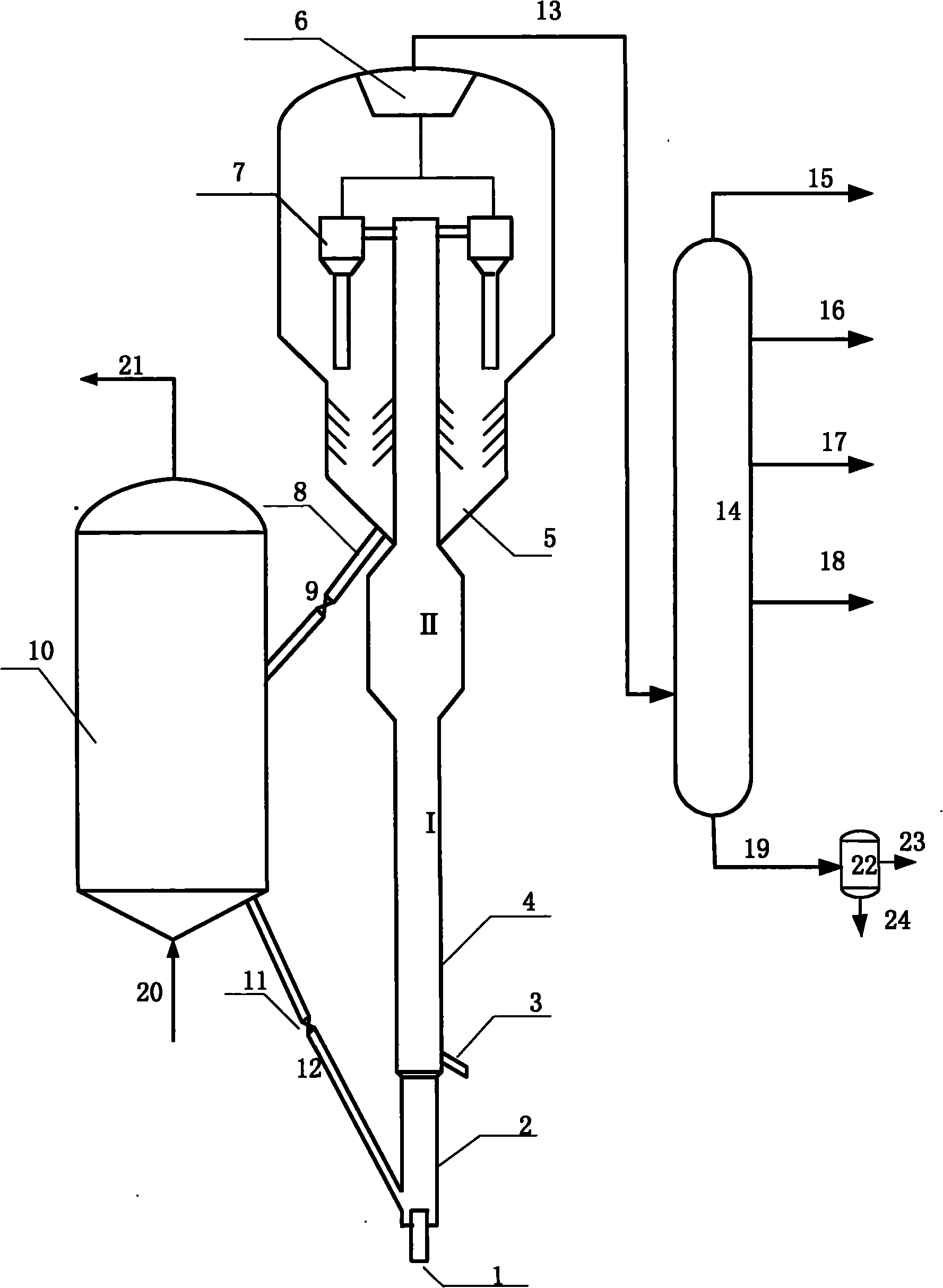

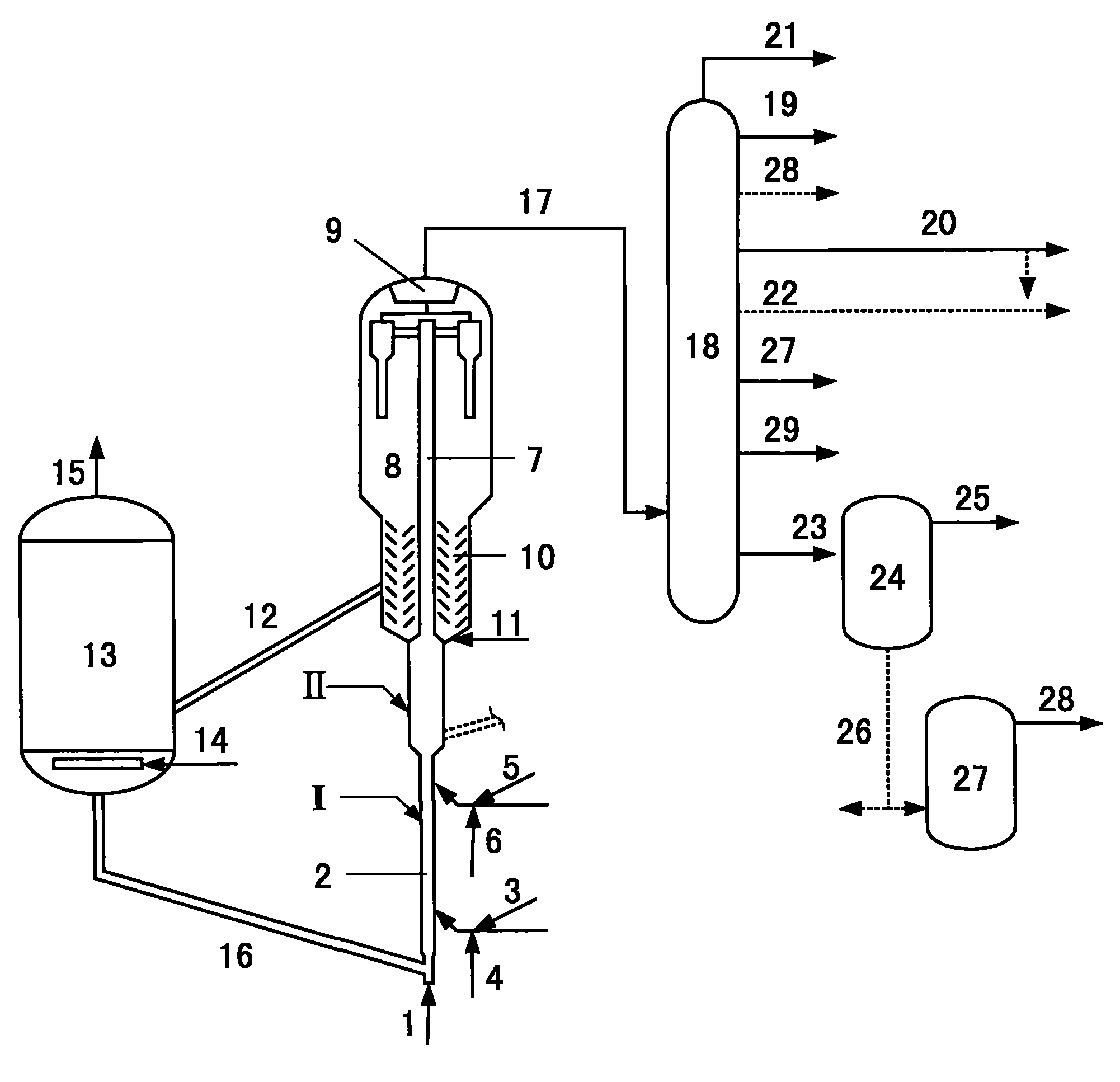

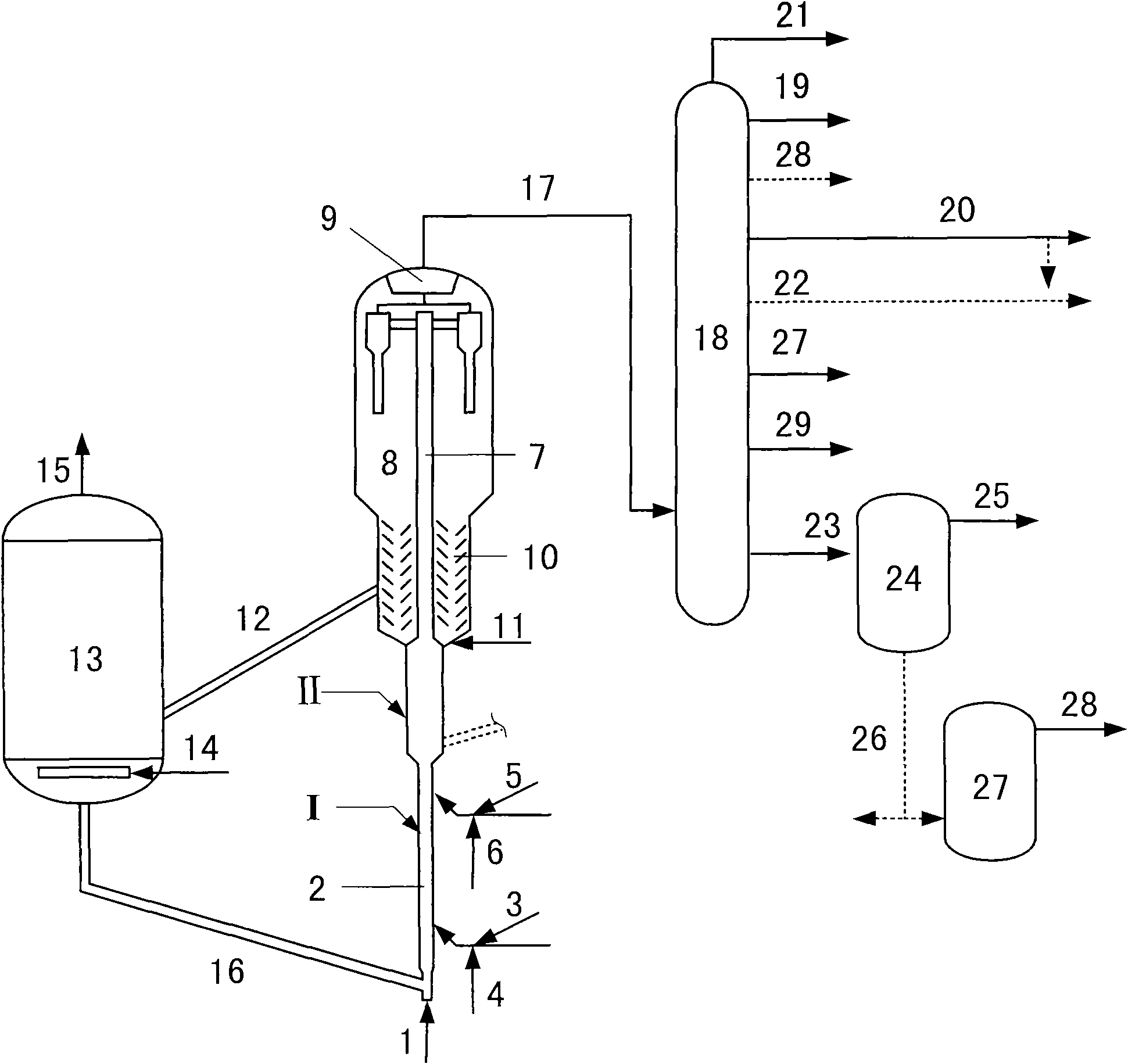

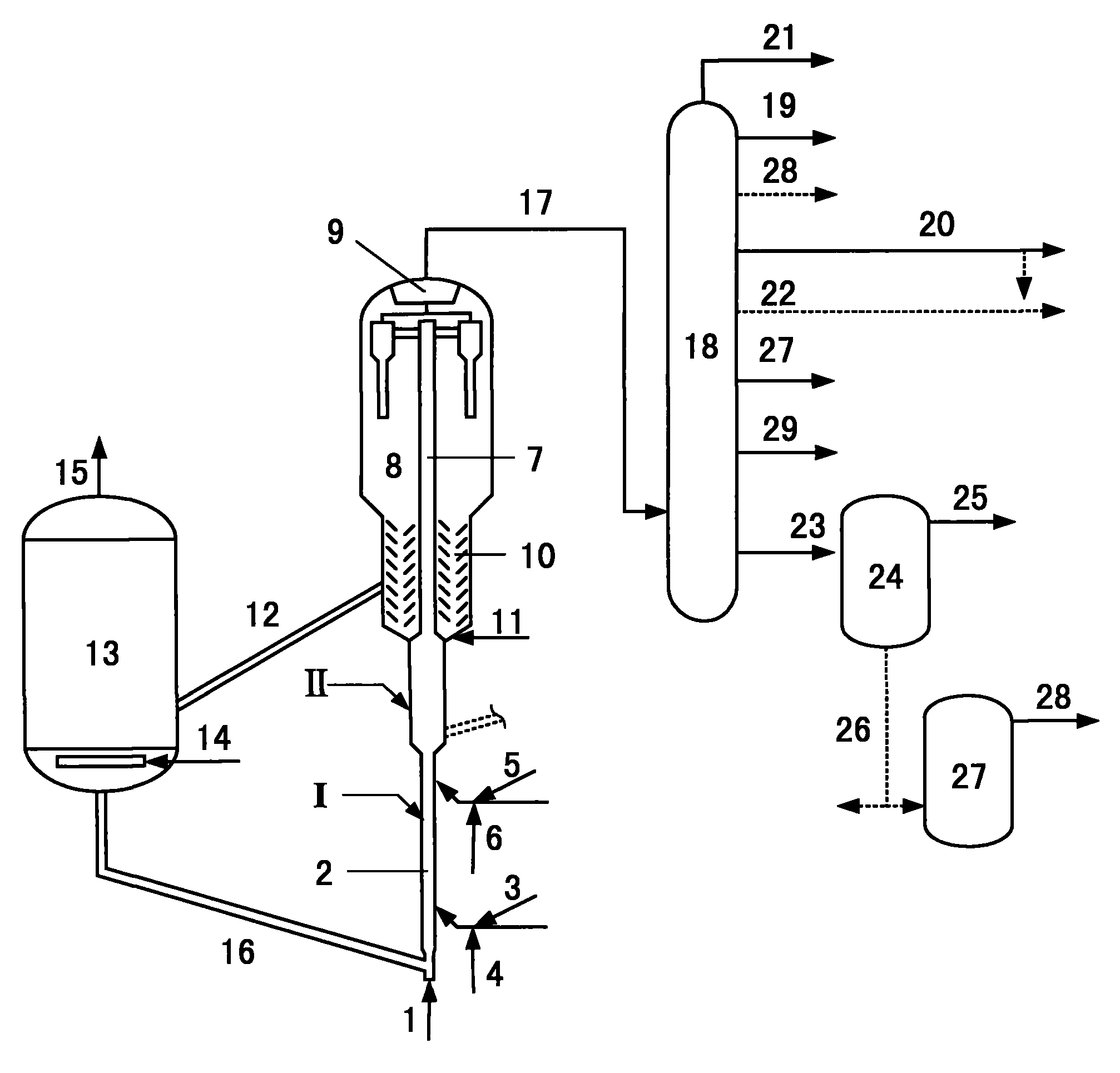

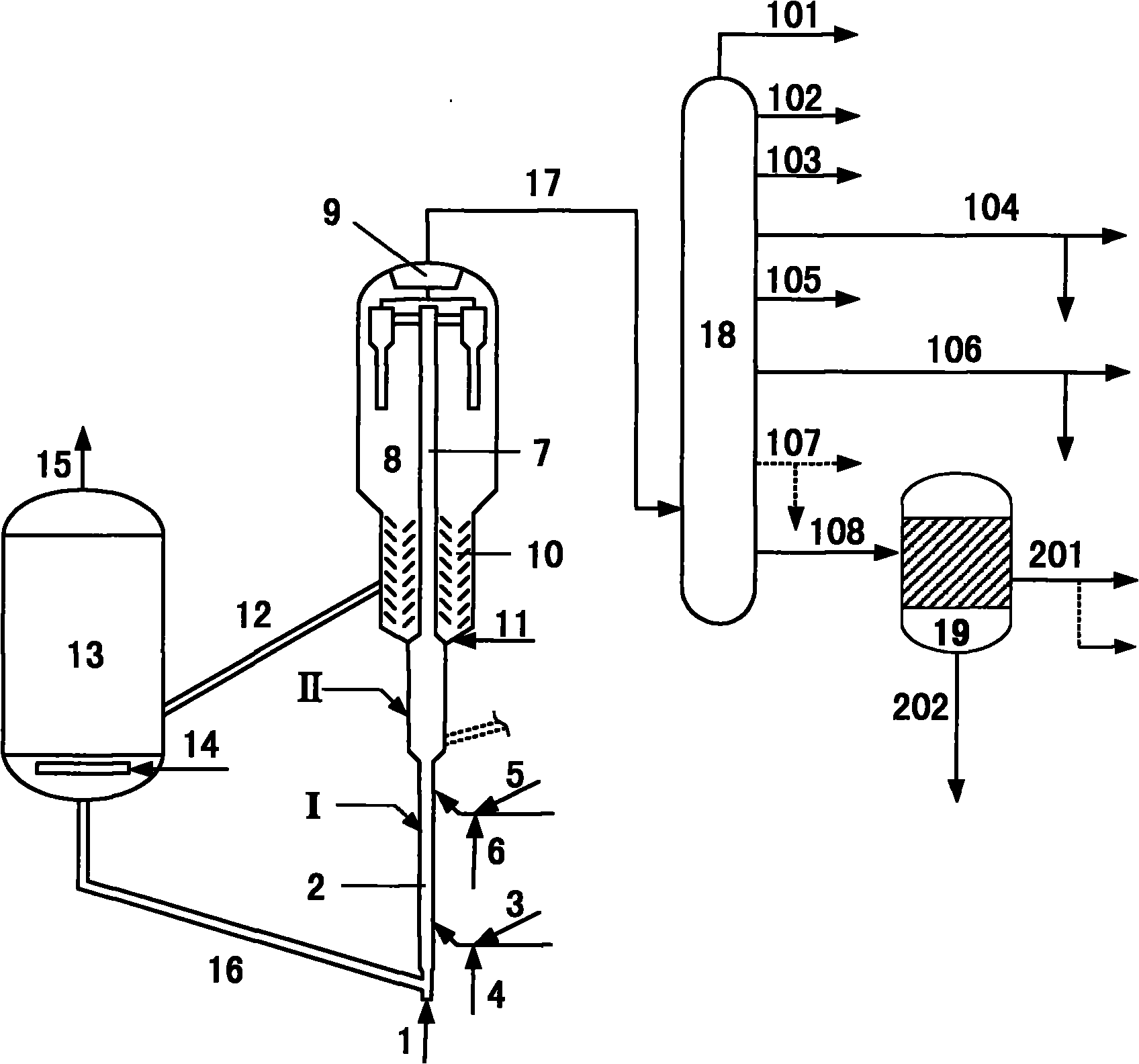

Catalytic conversion method for preparing propylene and high-octane value gasoline

ActiveCN101935266AHigh yieldImprove octaneCatalytic crackingBulk chemical productionWaxReaction temperature

The invention discloses a catalytic conversion method for preparing propylene and high-octane value gasoline. Crude oil contacts a catalyst rich in mesoporous zeolite and with coarse particle size distribution for reaction; and reaction temperature, weight hourly space velocity and the weight ratio of the catalyst to the crude oil are sufficiently proper for preparing a reaction product comprising 12 to 60 percent of catalytic wax oil based on the weight of the crude oil in the reaction, wherein the weight hourly space velocity is 25 to 100 h<-1>; the reaction temperature is 450 to 600 DEG C;and the weight ratio of the catalyst to the crude oil is 1 to 30. The invention provides the catalytic conversion method based on the prior art, which particularly has the advantages of greatly reducing dry gas yield and coke yield at the same time of converting the heavy crude oil into the high-octane value gasoline and the propylene so as to realize the high-efficiency utilization of oil resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

Purification method of polyether polyol with low degree of unsaturation

InactiveCN101962441AShort time spentThe process is simpleEther separation/purificationDegree of unsaturationAdsorption method

The invention discloses a method for removing residual bimetallic catalyst in a polyether polyol product with low degree of unsaturation, which is characterized by adopting the adsorption method to remove the catalyst, and can greatly simplify the process flow, reduce impurities introduced into the product, realize high purification rate, improve the stability of late-stage storage of the polyether polyol with low degree of unsaturation, improve the product quality and be widely applied in the purification of the polyether polyol with low degree of unsaturation.

Owner:NANJING UNIV OF SCI & TECH

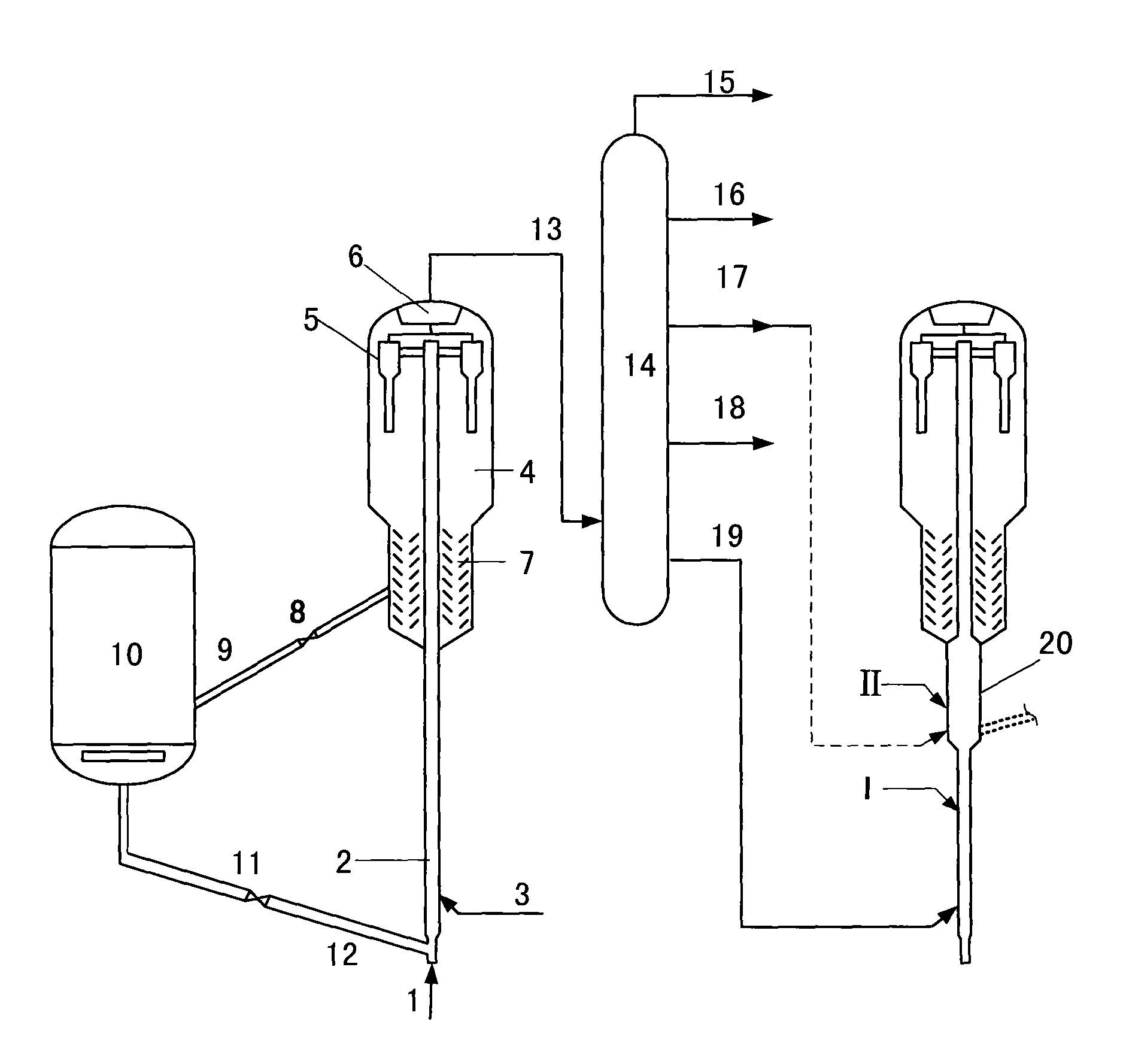

Method for the production of fatty acid alkyl ester

InactiveUS20070199238A1Efficient and economically viable productionImprove scalabilityFatty acid chemical modificationPreparation by ester-hydroxy reactionAlcoholVegetable oil

An apparatus and method for producing fatty acid alkyl esters from fatty acids derived from vegetable oils and animal fats with an alkaline solution dissolved in stoichiometric or near-stoichiometric levels of a monoalkyl alcohol to form a mixture. The method further comprises emulsifying the mixture as a means to reach a completed chemical reaction state in a reactor section, wherein the oils or fats are transesterified into fatty acid alkyl esters. The transesterification occurs when the natural boundary surfaces of the immiscible mixture are enlarged by ultrasonic cavitation in the reaction section and the transesterification is performed at, or near atmospheric pressure. The method finally includes, after reaching the chemical reaction state, separating residues from the fatty acid alkyl ester in a gravitational phase separation section.

Owner:HOOKER JEFFREY D

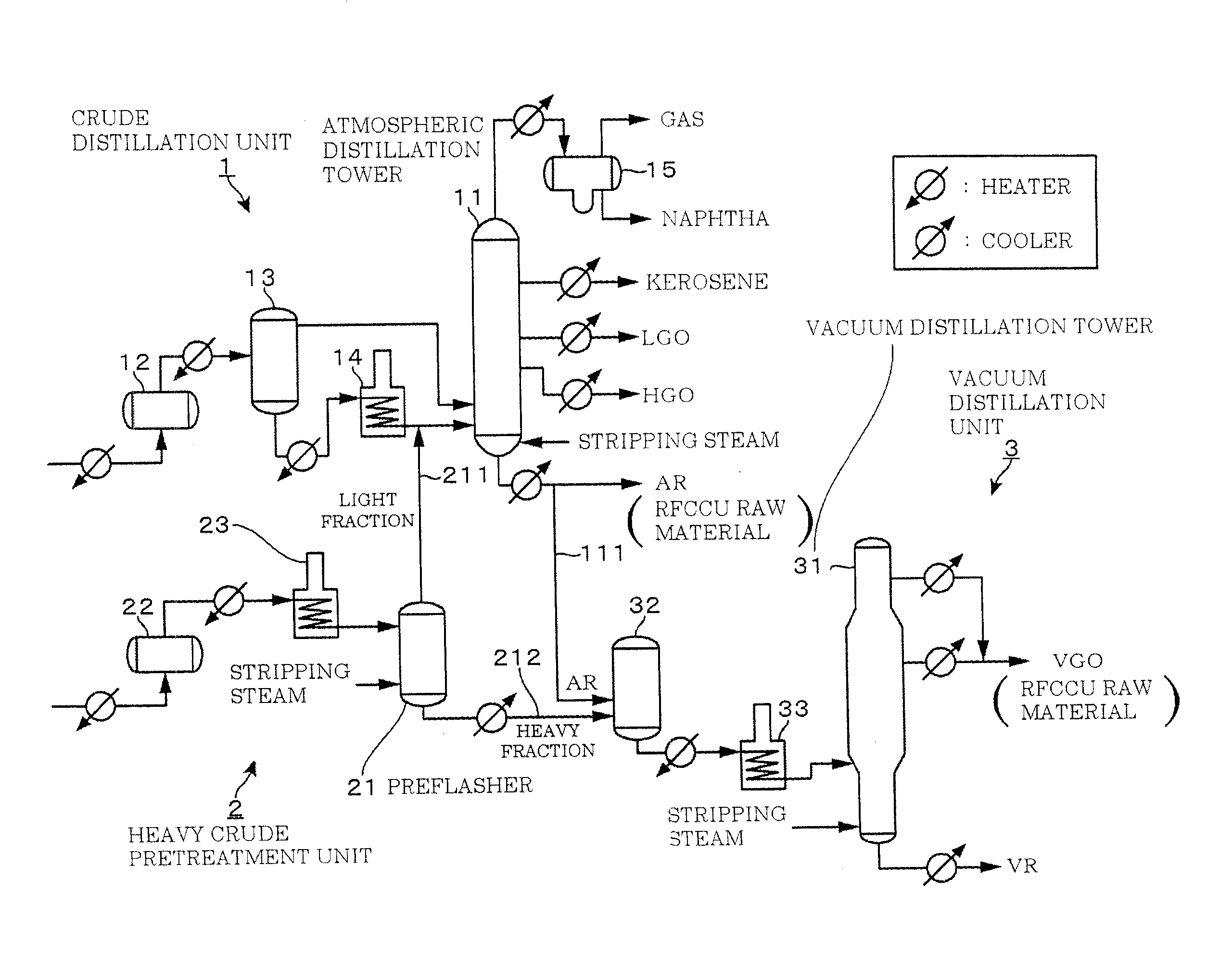

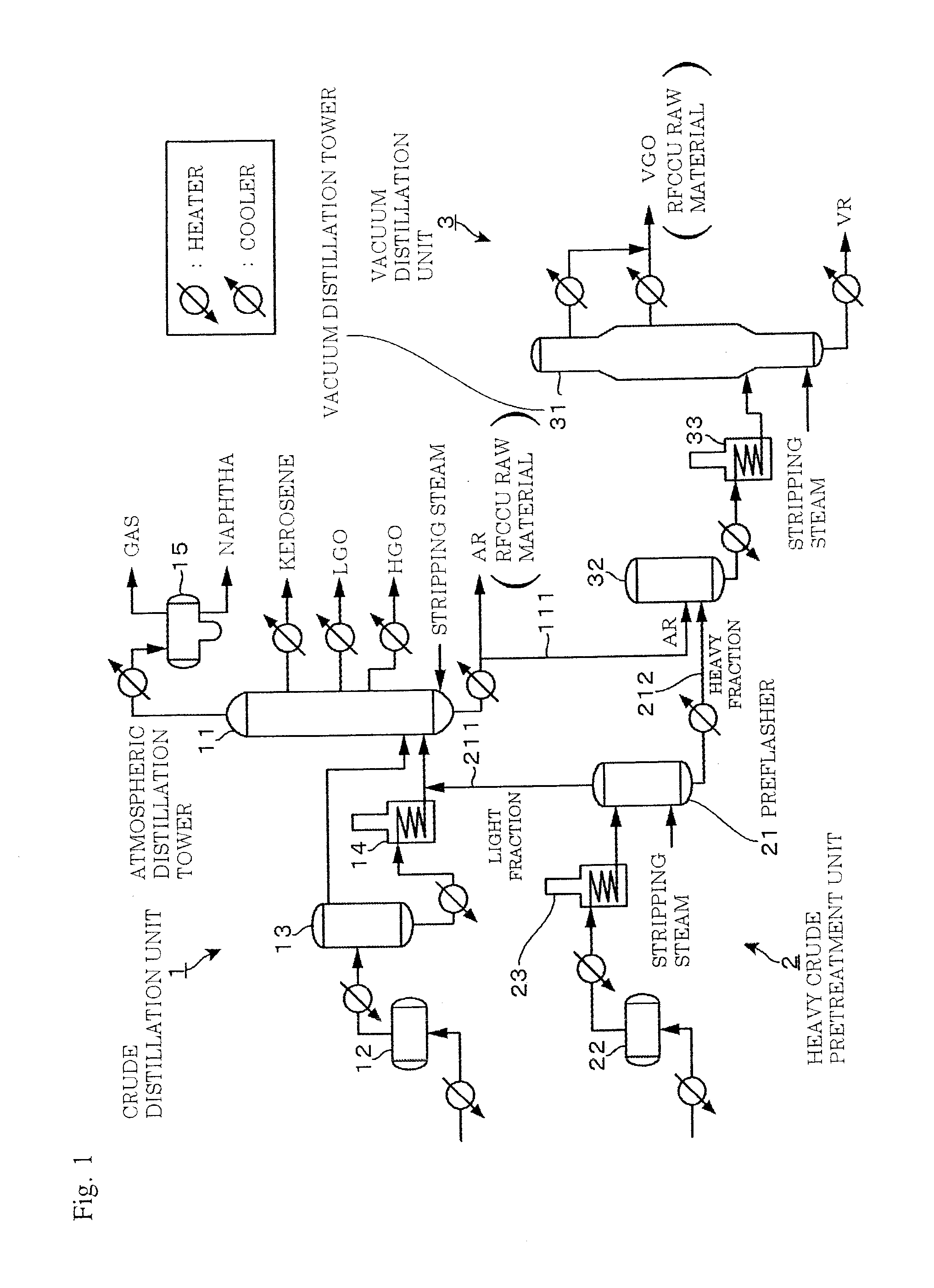

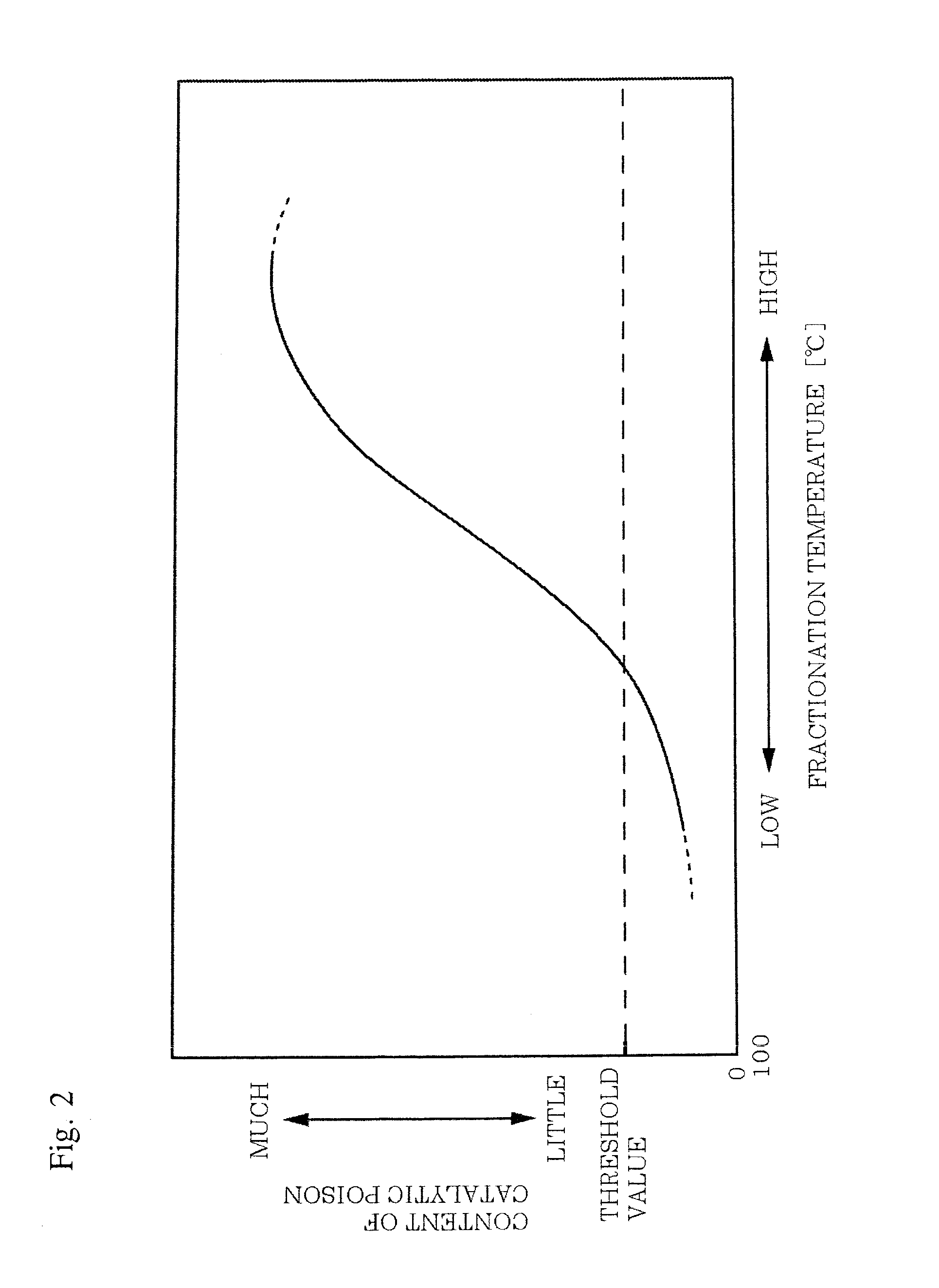

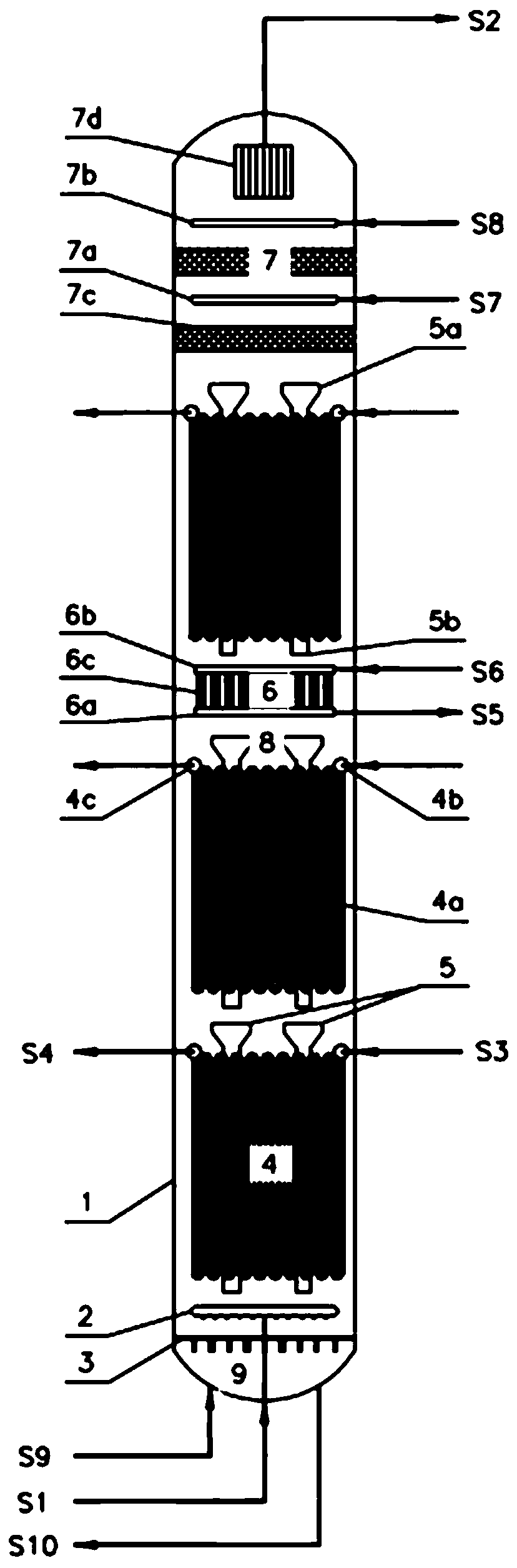

Method of operating crude treatment system

InactiveUS20150275100A1Catalyst content reductionReduce contentCatalytic crackingHydrocarbon oils refiningFractionating columnTower

Crude containing a comparatively large content of nickel, vanadium, or carbon residue is treated so as to supply a raw material to a downstream catalytic cracking process, A primary distillation tower fractionates first crude into a residue fraction partly used as raw oil of a catalytic cracking process and other fractions. A secondary distillation tower fractionates second crude containing a larger content of a catalytic poison with respect to catalysts used in the catalytic cracking process than the first crude into a light fraction included in a distillation temperature range of the other fractions and a heavy fraction as a rest thereof. A light fraction supply line supplies the light fraction to the primary distillation tower so as to be treated in the primary distillation tower.

Owner:JGC CORP

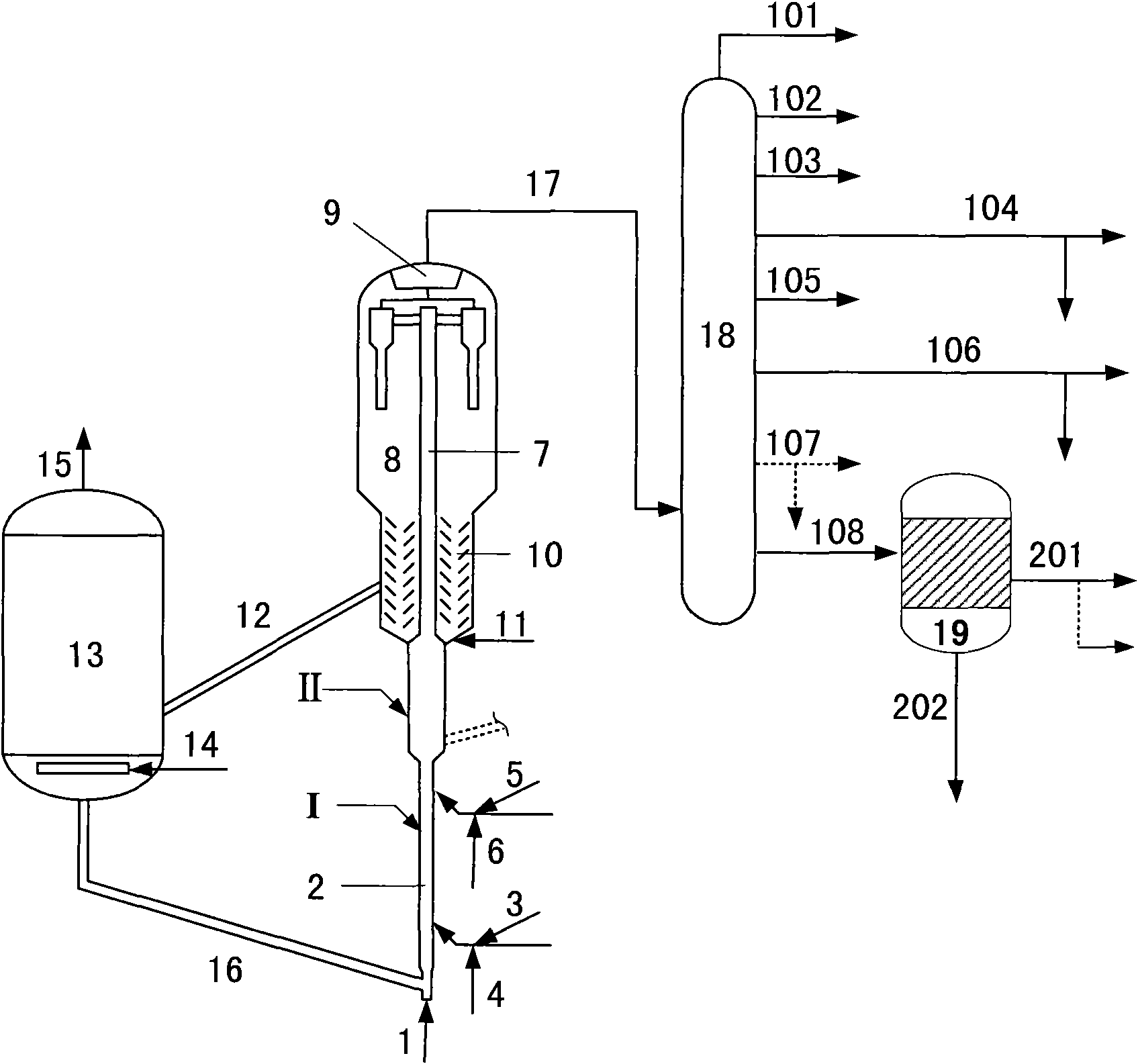

Catalytic conversion method for improving cetane number and yield of diesel

ActiveCN102041093AImprove performanceMaximize productionTreatment with hydrotreatment processesWaxReaction temperature

The invention discloses a catalytic conversion method for improving cetane number and yield of diesel. Raw oil is contacted with a catalyst containing large pore zeolite in a catalytic conversion reactor for reaction, and the reaction temperature, oil gas retention period, and the weight ratio of the catalyst to the raw oil sufficiently ensure that a reaction product containing catalytic wax oil which is 12 to 60 weight percent of the raw oil is obtained in the reaction, wherein the reaction temperature is 420 to 550DEG C, the oil gas retention period is 0.1 to 5 seconds and the weight ratio of the catalyst to the raw oil is 1-10; and the catalytic wax oil enters a hydrogenation unit, and the obtained hydrogenated catalytic wax oil returns to the catalytic conversion reactor. By the method, the diesel with high cetane number is produced maximally, the cracking catalyst with coarse particle size distribution can further improve the selectivity of dry gas and coke, and the catalyst breaking tendency and the catalyst consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

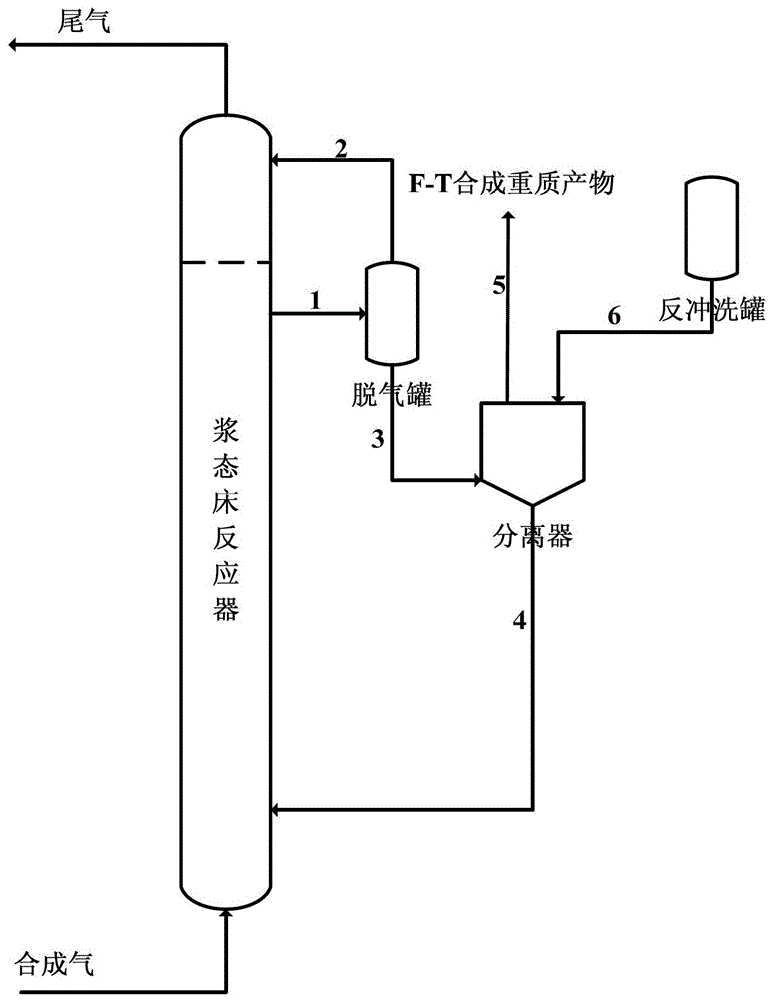

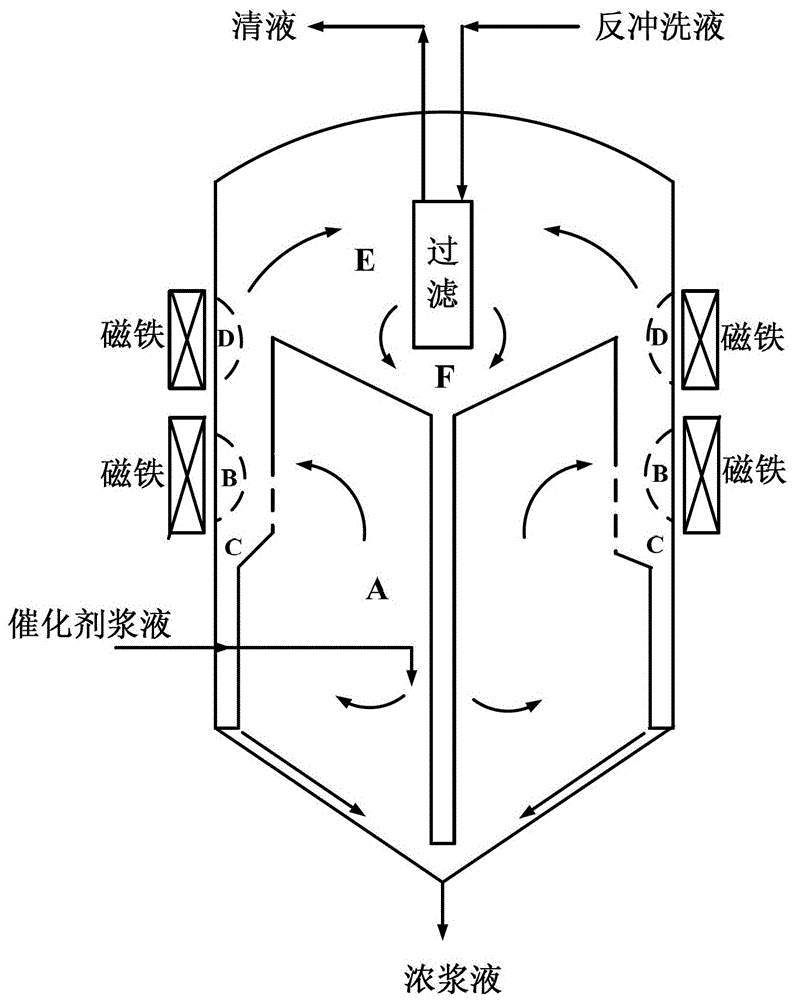

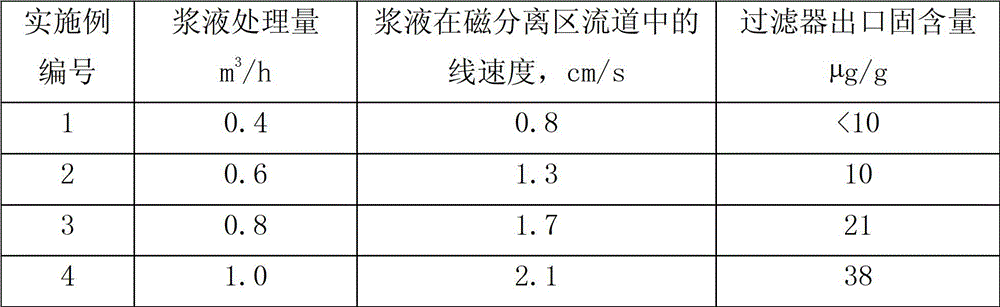

A kind of separation method of slurry bed Fischer-Tropsch synthesis heavy product and catalyst

ActiveCN103846160BEfficient separationImprove separation efficiencyMagnetic separationMagnetic separatorSlurry

A separation method for a slurry bed fischer-tropsch synthesis heavy product and a catalyst is characterized in that the fischer-tropsch synthesis heavy product from a slurry bed reactor and the magnetic fischer-tropsch synthesis catalyst, after degassing, enter the lower part of a separator, the catalyst and the fischer-tropsch synthesis heavy product are preliminarily separated by gravity settling to obtain concentrated slurry rich in the catalyst in the lower part of the separator, the concentrated slurry is cycled to the slurry bed reactor, and obtained diluted slurry enters into a magnetic separator zone on the upper part of the separator; in the magnetic separator zone, the catalyst is adsorbed by magnetic force in a magnetic field zone, when the amount of the catalyst adsorbed in the magnetic field zone reaches a set amount, the magnetic field is removed, the catalyst sinks by gravity to a flow guide pipe, flows to the bottom of the separator along the flow guide pipe, and is is cycled to the slurry bed reactor; after the magnetic separation, the catalyst is further separated from the fischer-tropsch synthesis heavy product containing less catalyst by a filter element, and is discharged out of the separator, and the filtered catalyst is cycled to the slurry bed reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing anhydrous perpropionic acid

ActiveCN108863883AAchieve serializationAchieve separationOrganic compound preparationChemical recyclingPhosphoric Acid EstersPerpropionic acid

The invention discloses a method for preparing anhydrous perpropionic acid free from a catalyst. 4-5 reactive distillation columns connected in series and a distillation rectification column are adopted, hydrogen peroxide, the catalyst, a light component and phosphate ester are fed, subjected to pre-mixing and fed into column bodies of the 4-5 continuous reactive distillation columns through pumpsin sequence, reactive distillation is conducted in the reactive distillation columns, column bottom liquid of the last reactive distillation column enters the distillation rectification column, the anhydrous perpropionic acid free from the catalyst is collected on the column top of the distillation rectification column, and the catalyst and phosphate ester contained in the column bottom are fed back to the first reactive distillation column for recycle. By means of the method for preparing the anhydrous perpropionic acid free from the catalyst, continuous anhydrous perpropionic acid preparation is achieved, moreover, the catalyst is recycled in a system, and synthesis of epsilon-caprolactone is not affected.

Owner:HUNAN JUREN CHEM NEW MATERIAL TECH CO LTD

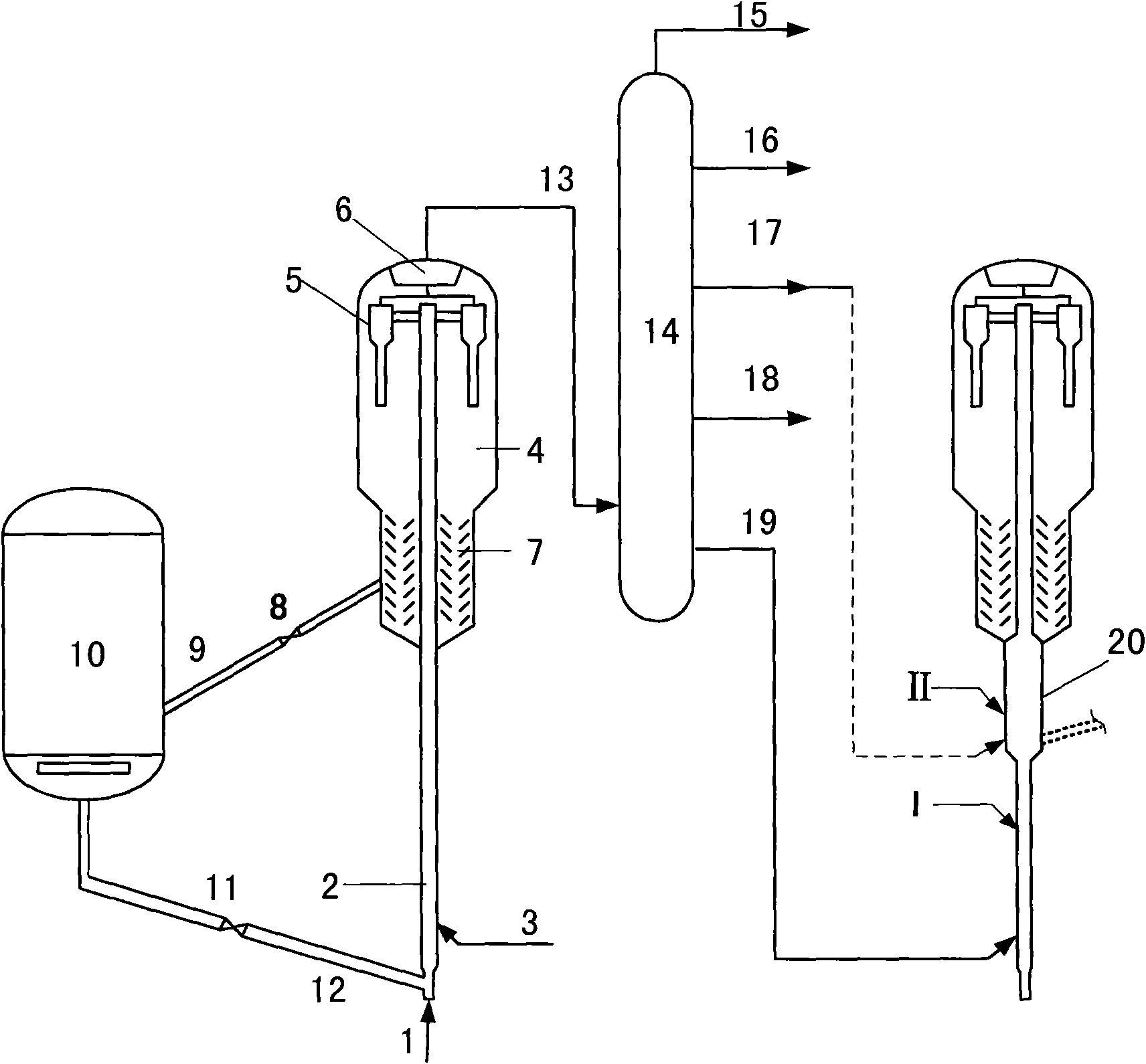

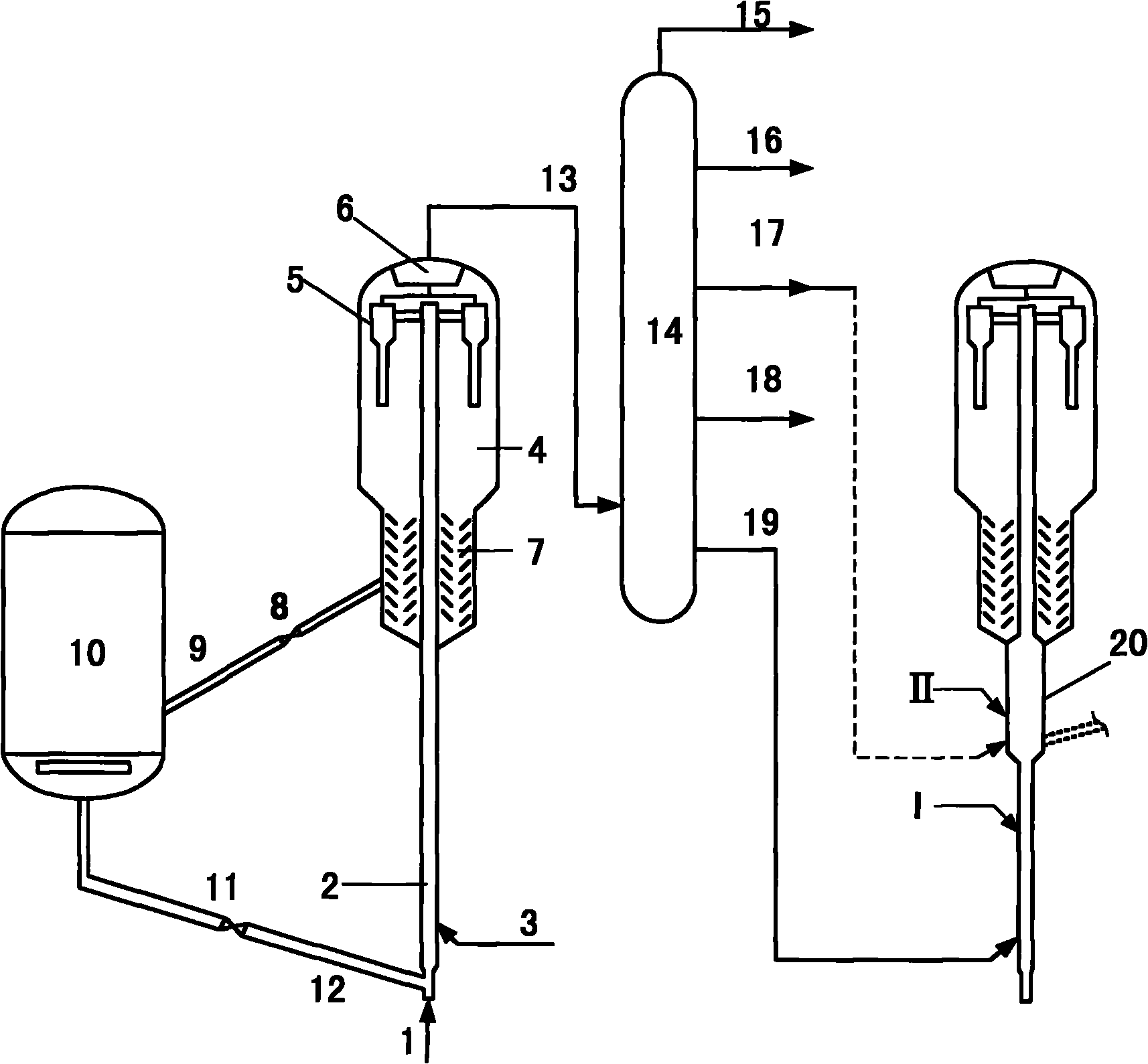

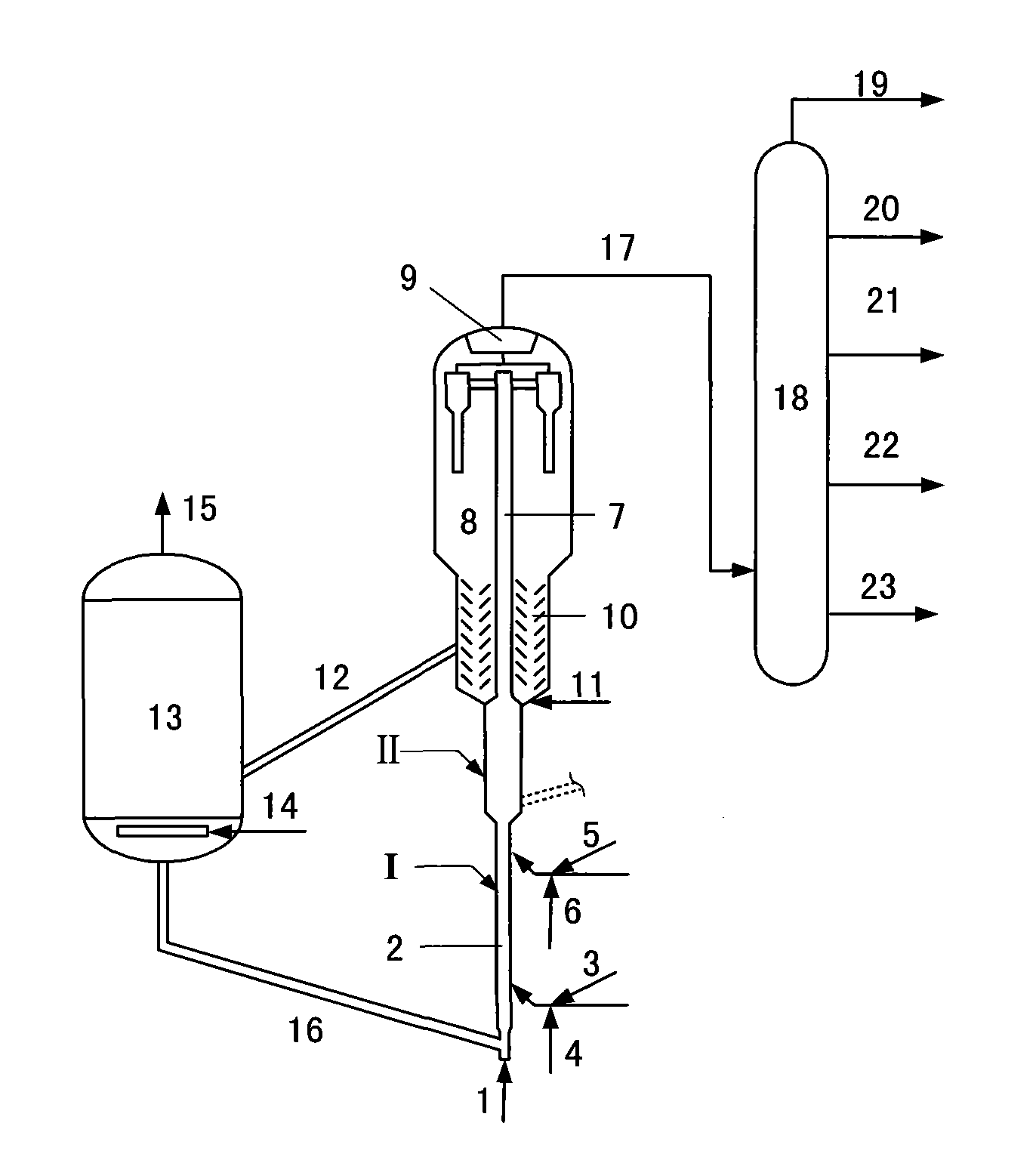

Catalytic conversion method for producing diesel and propylene in high yield

The invention discloses a catalytic conversion method for producing diesel and propylene in high yield. Raw oil is contacted with a catalyst in coarse particle size distribution in a reactor for reaction, the reaction temperature, weight hourly space velocity, and the weight ratio of the catalyst to the raw oil sufficiently ensures that a reaction product comprising catalytic wax oil which is 12 to 60 weight percent of the raw oil is obtained in the reaction, and the catalytic wax oil enters a hydrotreater for further treatment. The catalytic cracking, hydrotreating and a process of producing diesel in high yield are integrated, hydrocarbons such as alkane, alkyl side chain and the like in the raw material are selectively subjected to cracking and isomerization catalysis, aromatic hydrocarbon in the raw material is reduced to the greatest extent to enter diesel fraction, other components in the product are prevented from generating aromatic hydrocarbon through aromatization and other reaction so as not to remain the aromatic hydrocarbon in the diesel fraction, the raw material is converted into high cetane number diesel and propylene, the yield of dry gas and coke is greatly reduced, and the catalyst breaking trend and catalyst consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

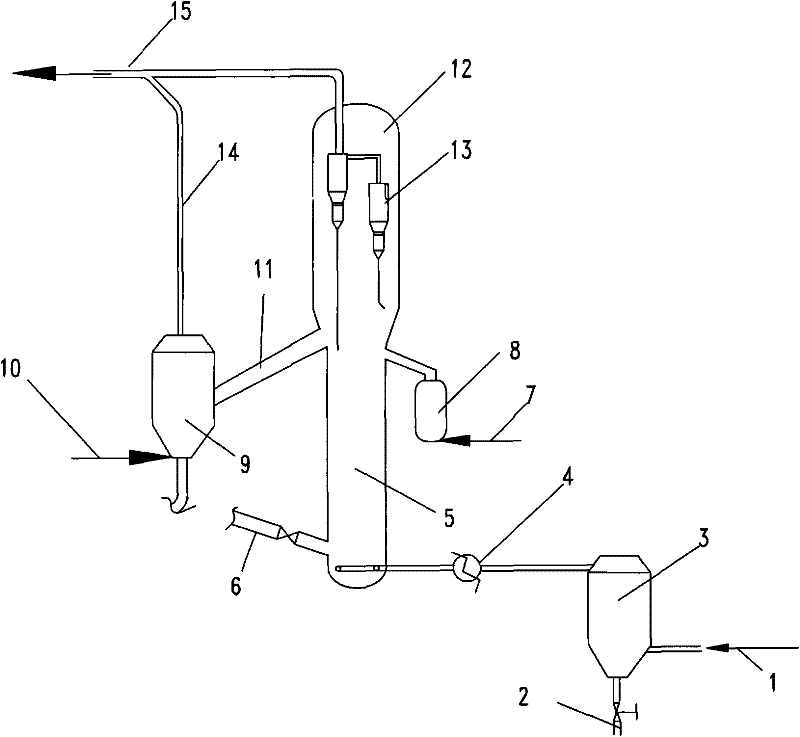

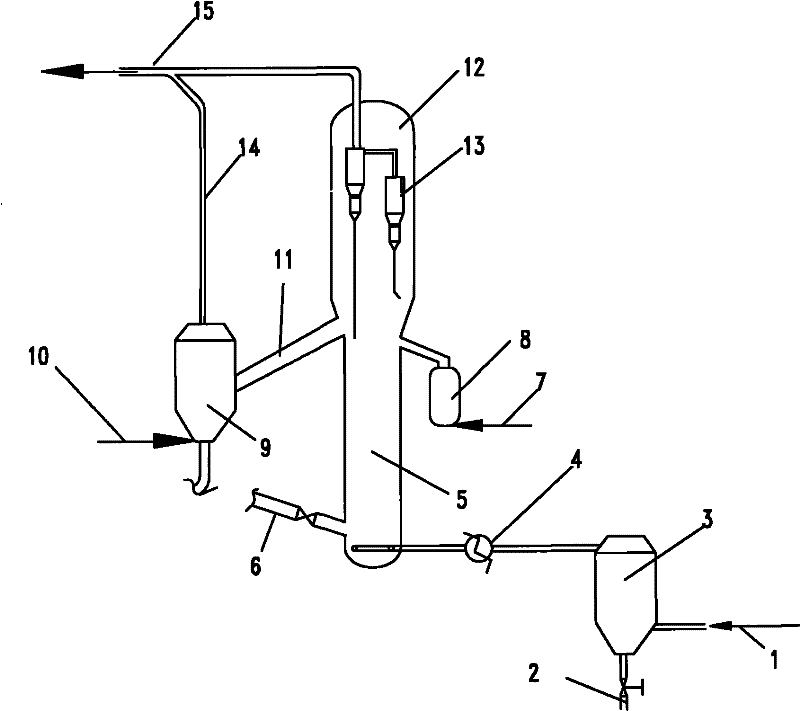

Method for reducing catalyst loss in methanol to olefins regeneration system

InactiveCN102294275ACatalyst content reductionMolecular sieve catalystsCatalyst regeneration/reactivationCycloneGas solid

The invention relates to a method for reducing catalyst running loss in a methanol-to-olefins regeneration system, which mainly solves the problem of relatively large catalyst running loss in a regenerator in the prior art. The present invention adopts a method for reducing catalyst running loss in a methanol-to-olefins regeneration system, comprising the following steps: (a) providing a methanol-to-olefins regeneration system, including a regenerator regeneration zone, a regenerator settling zone, a heat extraction zone, Degassing area, regeneration medium dehydration area, flue gas pipeline; (b) The regeneration medium enters the regeneration area of the regenerator after being dehydrated in the regeneration medium dehydration area, and contacts with the carbon deposition catalyst to generate flue gas and regeneration catalyst at the same time; (c) After the gas is separated by the gas-solid cyclone separator, it enters the follow-up system through the flue gas pipeline; (d) the regenerated catalyst enters the degassing area, removes the entrained flue gas and enters the reaction system, the flue gas removed in the degassing area and the degassing The technical proposal that the medium enters the flue gas pipe better solves the above problems and can be used in the industrial production of low-carbon olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

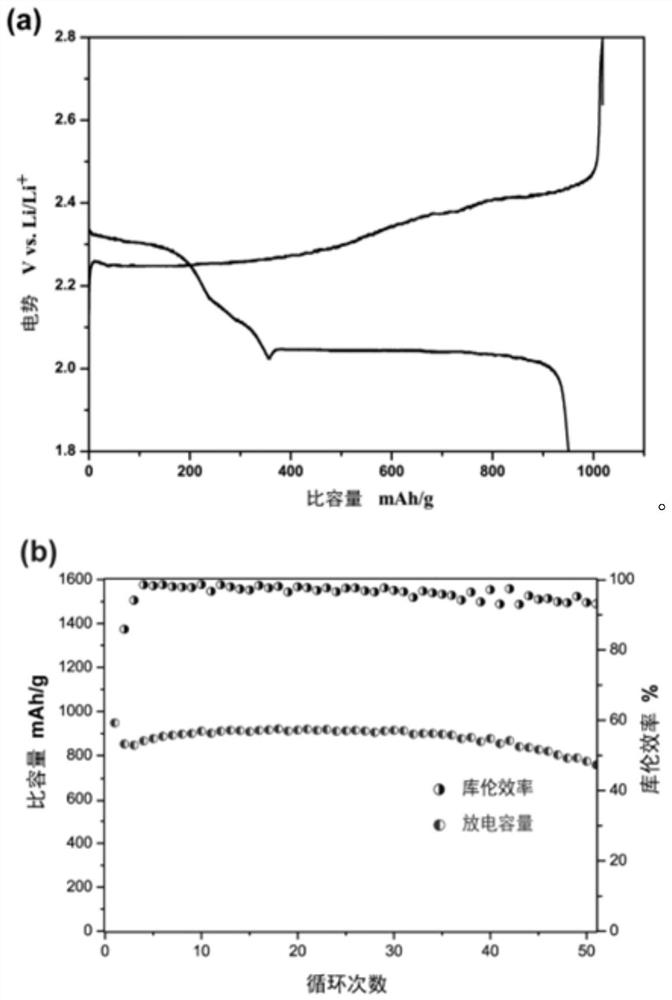

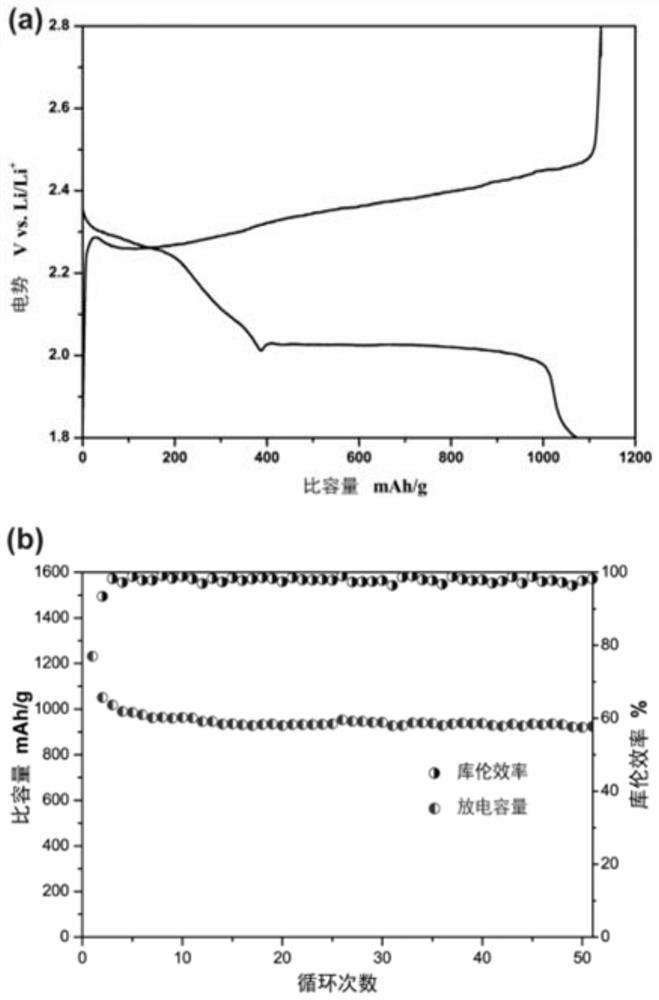

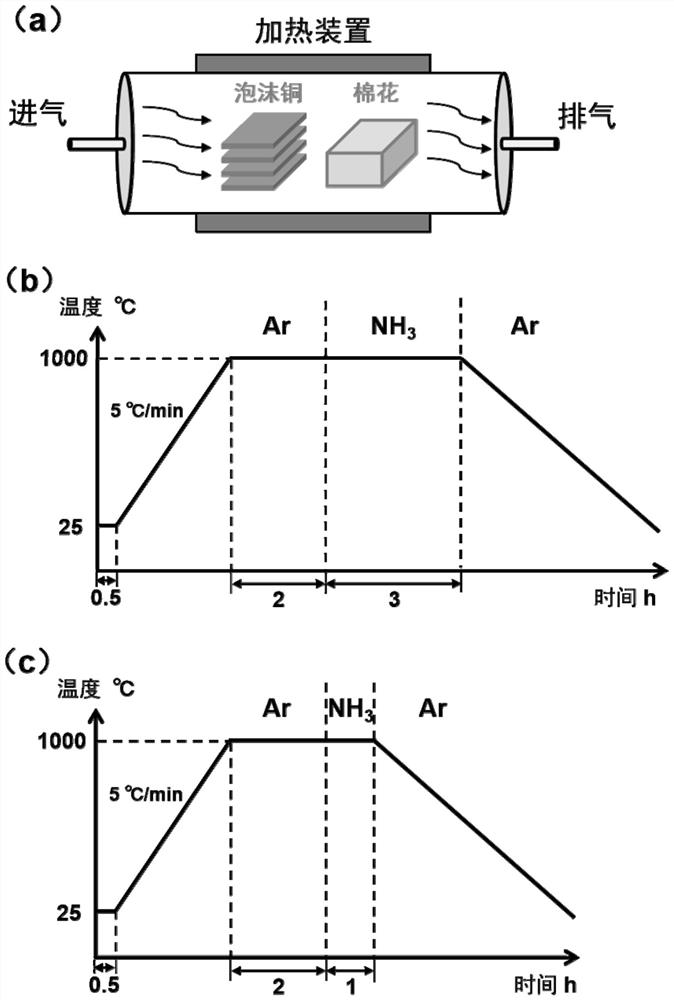

Preparation method of monatomic copper catalyst and application of monatomic copper catalyst in positive electrode of lithium-sulfur battery

ActiveCN111974430AIncrease sulfur loadSpeed up the conversion processCatalyst activation/preparationPositive electrodesPtru catalystCarbon fibers

The invention discloses a preparation method of a monatomic copper catalyst and an application of the monatomic copper catalyst in a positive electrode of a lithium-sulfur battery, and belongs to thetechnical field of battery materials. Copper atoms on foamy copper are captured and migrated to a carbon fiber matrix through high-temperature ammonia gas treatment, and nitrogen-doped carbon fiber foam material loaded with monatomic copper is prepared and serves as a carrier material of positive electrode sulfur in the lithium-sulfur battery. According to the monatomic copper catalyst prepared bythe preparation method, the lithium-sulfur battery has relatively high reaction kinetics, excellent capacity exertion and cycling stability under high sulfur loading capacity. The preparation methodis simple in process flow, and provides a wide prospect for the application of the monatomic catalyst in the lithium-sulfur battery.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for producing aliphatic polycarbonate

InactiveUS8779087B2Easy to produceCatalyst content reductionOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceMetal catalyst

The present invention provides an aliphatic polycarbonate production method which, using carbon dioxide and an epoxide, easily produces aliphatic polycarbonates having a low metal catalyst content.The invention relates to an aliphatic polycarbonate production method which includes a step of polymerization by reacting carbon dioxide with an epoxide in the presence of a metal catalyst; and a step of treating a polymer obtainable in the polymerization step with a surfactant. High-purity aliphatic polycarbonate having a low metal catalyst content can be easily provided by the aliphatic polycarbonate production method of the invention.

Owner:SUMITOMO SEIKA CHEM CO LTD

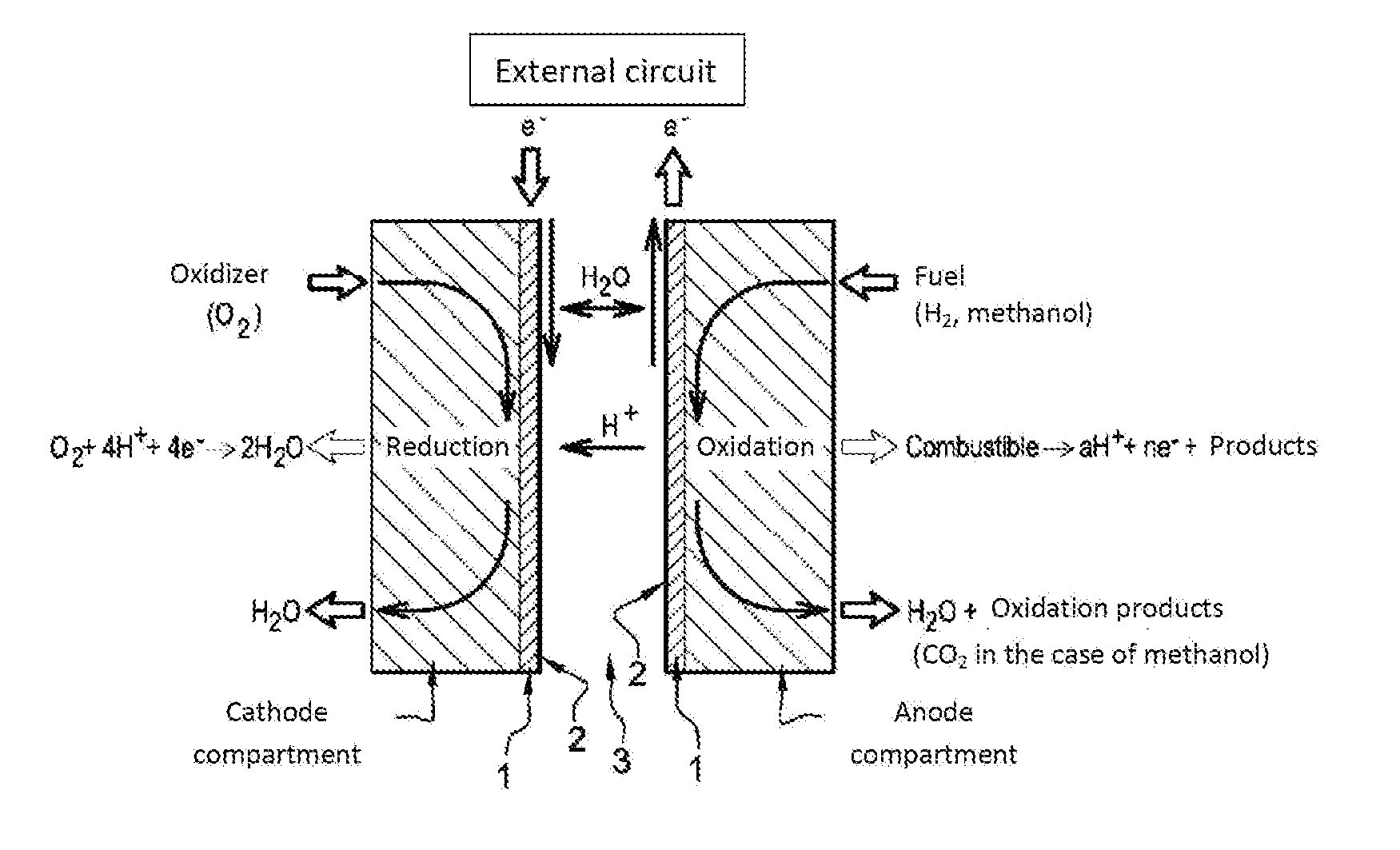

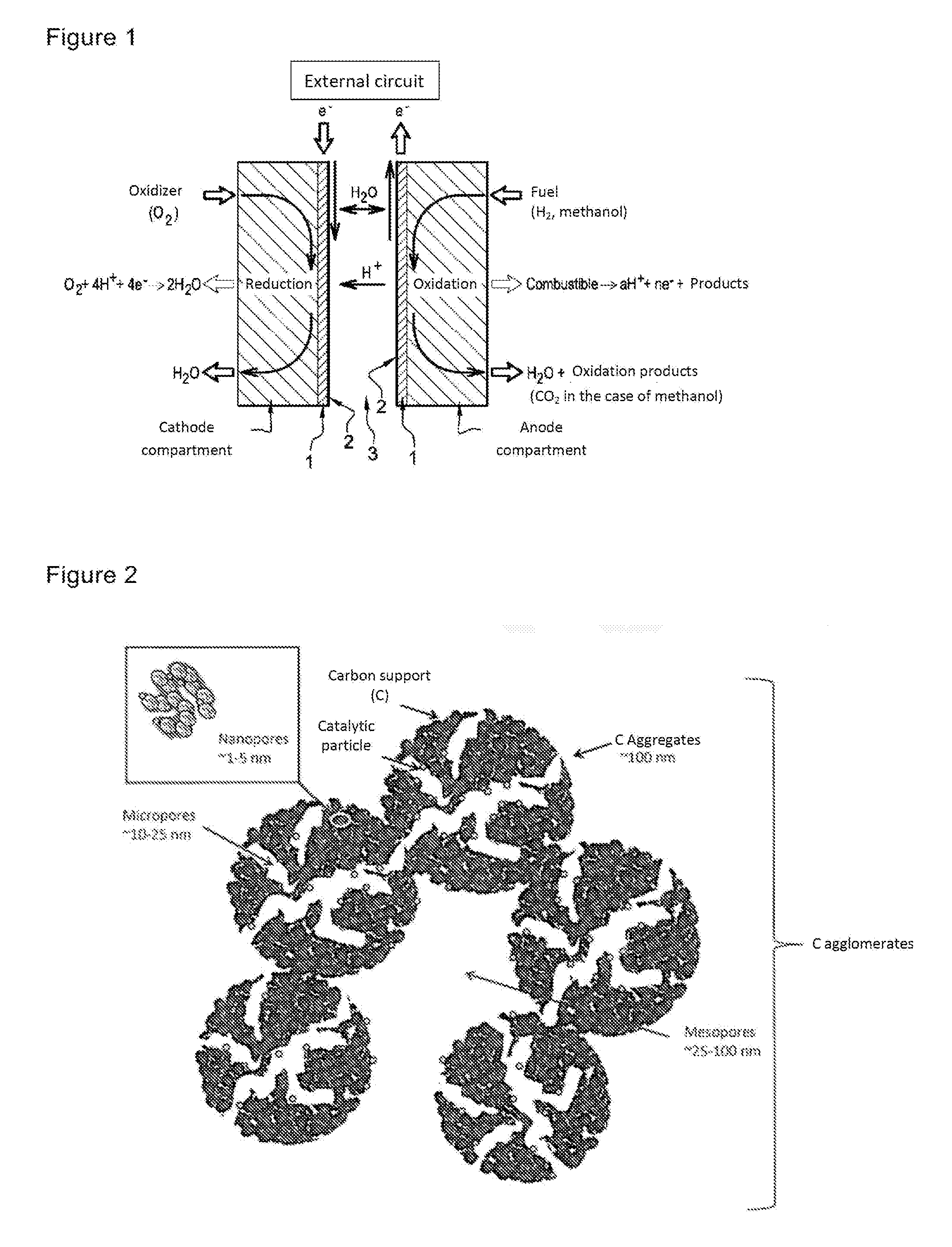

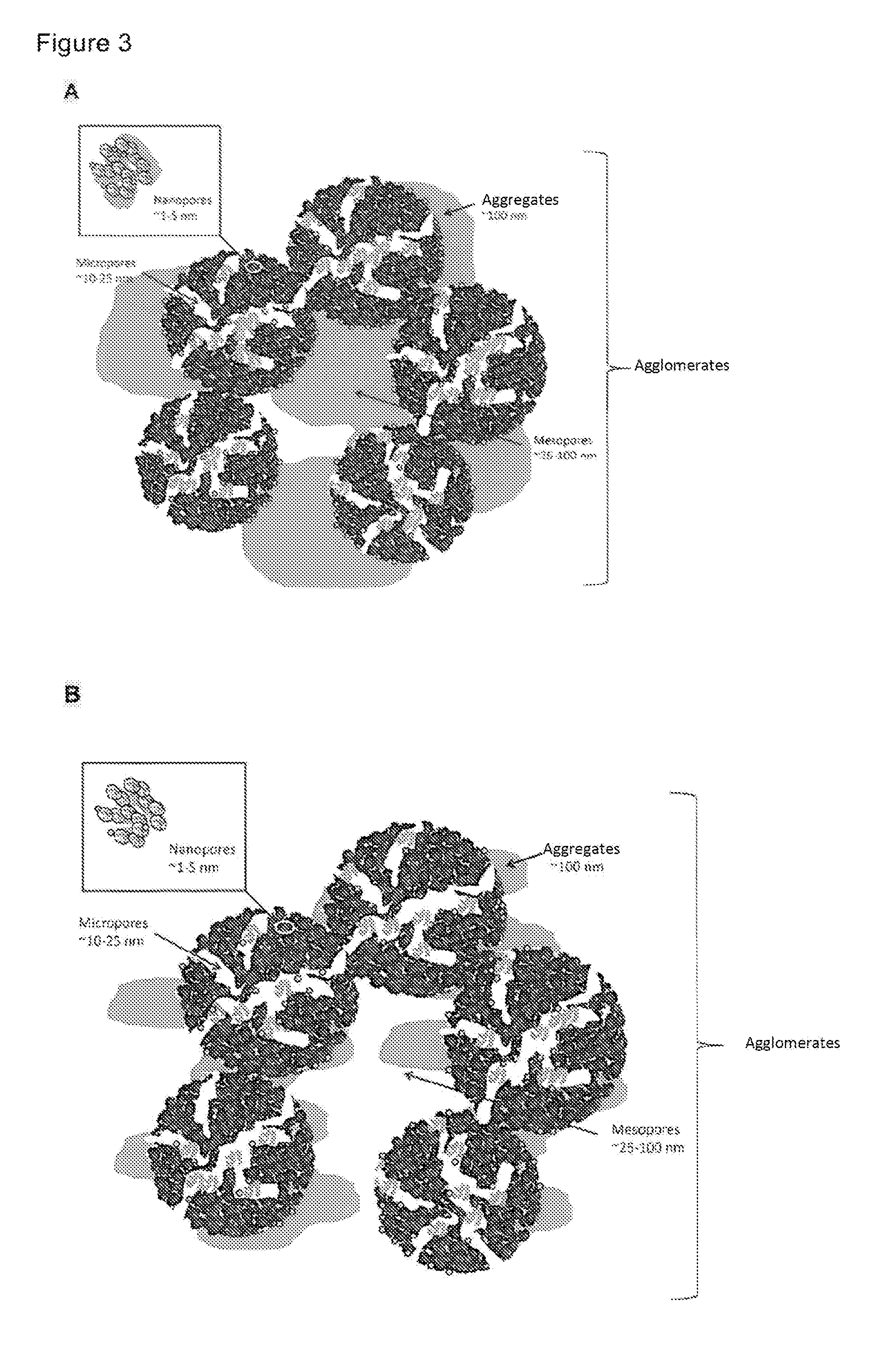

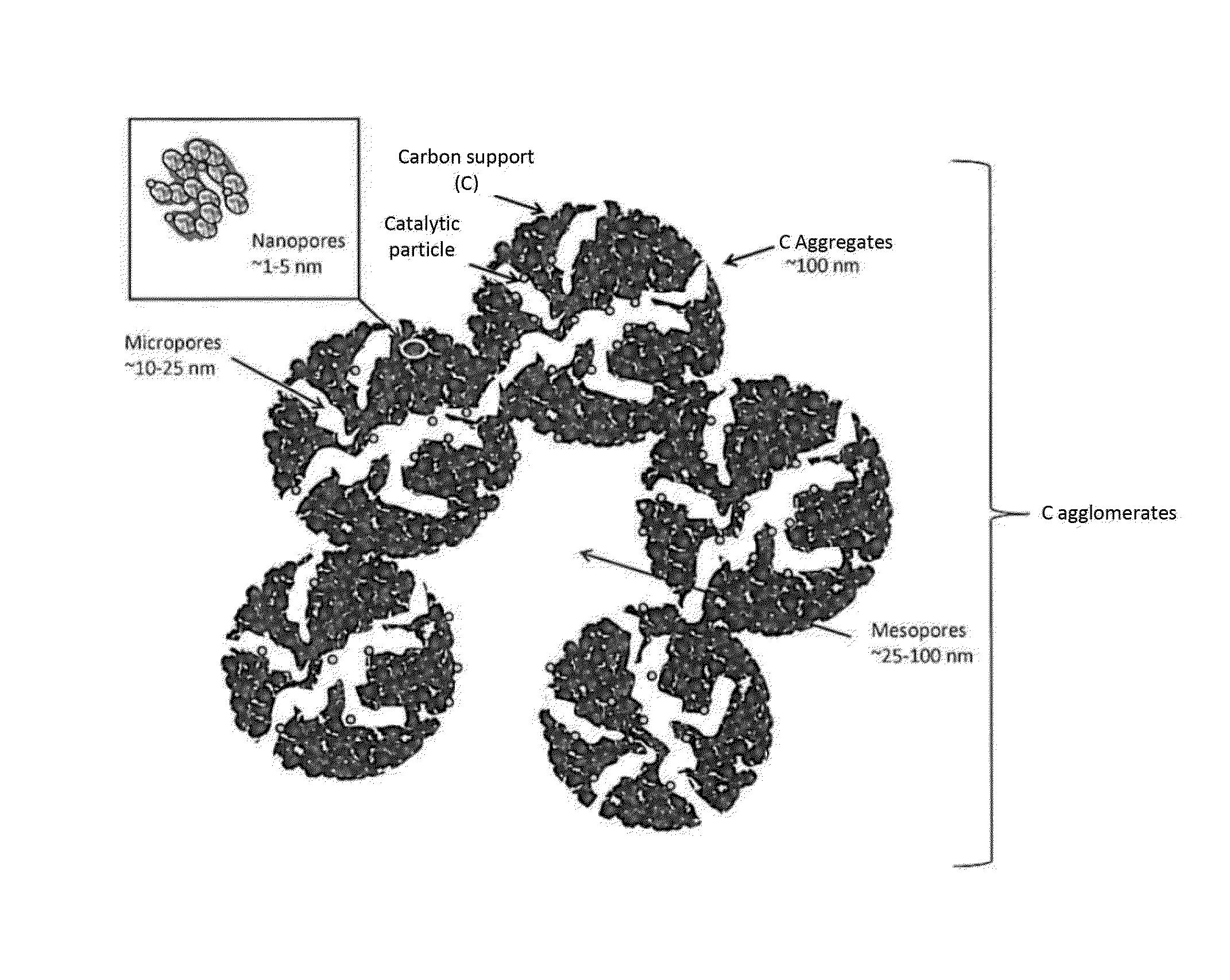

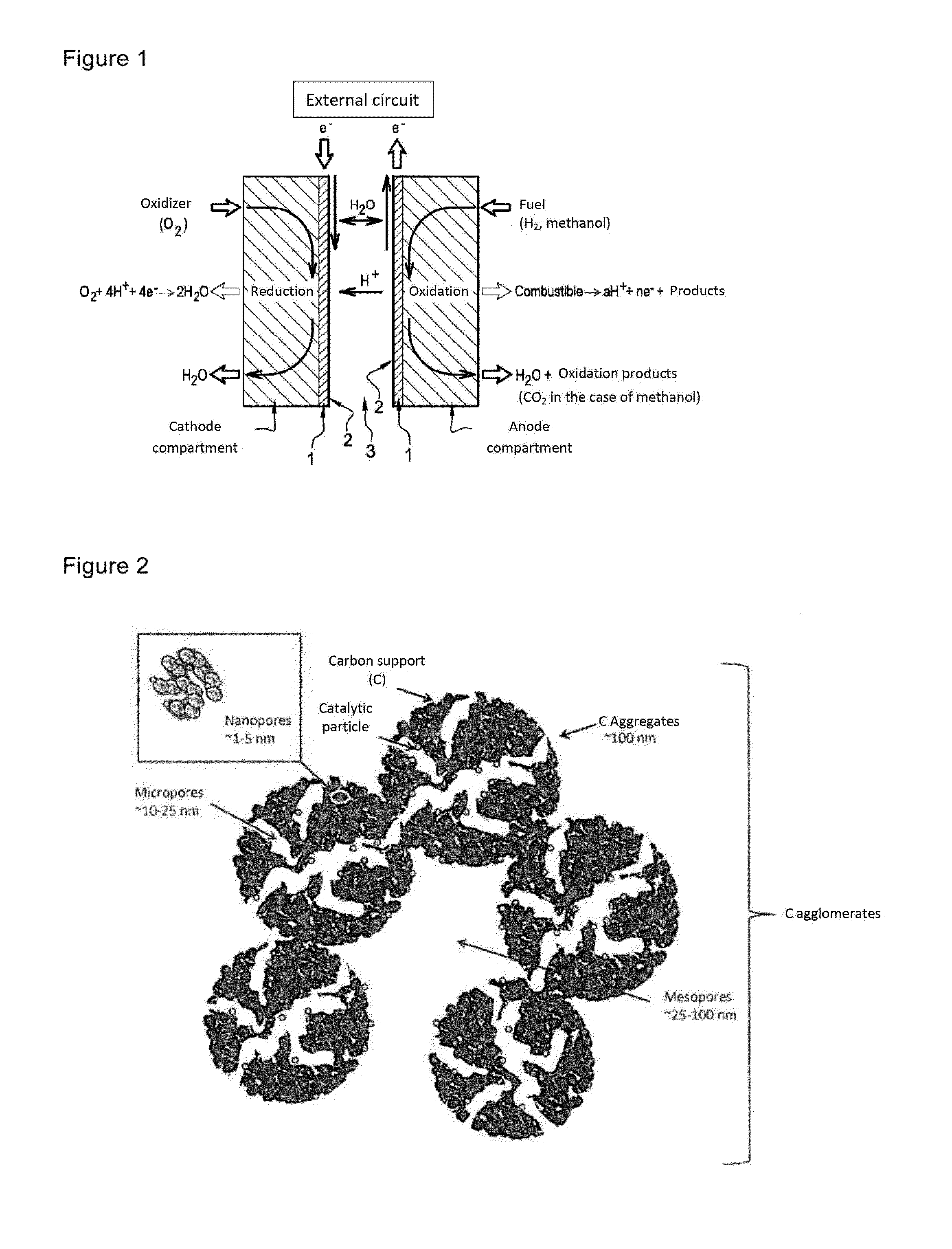

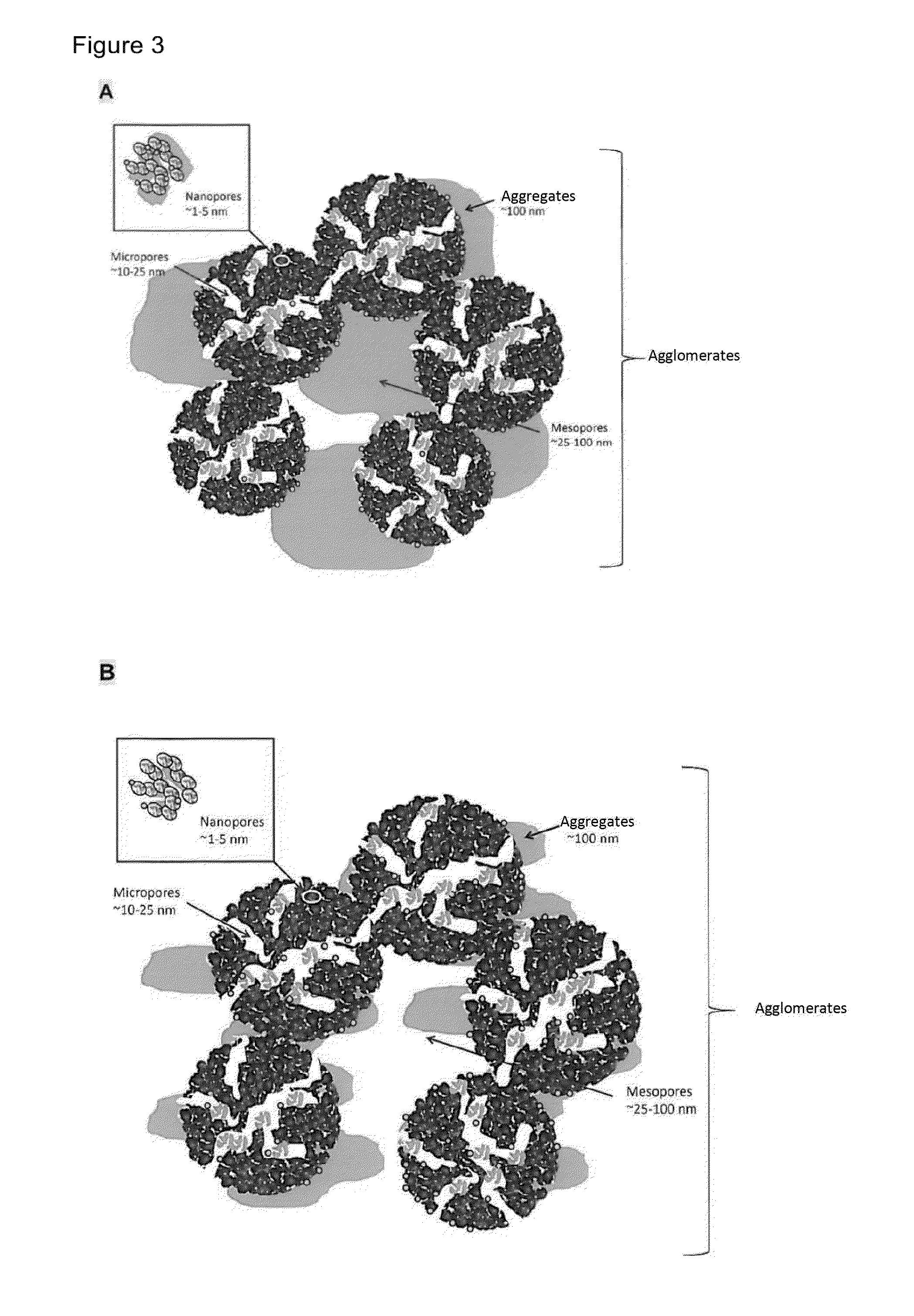

Proton-exchange membrane fuel cell electrode structuration

ActiveUS20130071771A1Improve hydrophobicityDecrease electrode porosityMaterial nanotechnologyCell electrodesElectrochemistryProton exchange membrane fuel cell

An electrode for an electrochemical system, such as a fuel cell, is formed by an active layer including: pores; at least one catalyst; at least one ionomer; and electrically-conductive particles. The catalyst content per pore ranges between 30 and 500 mg / cm3 with respect to the pore volume.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

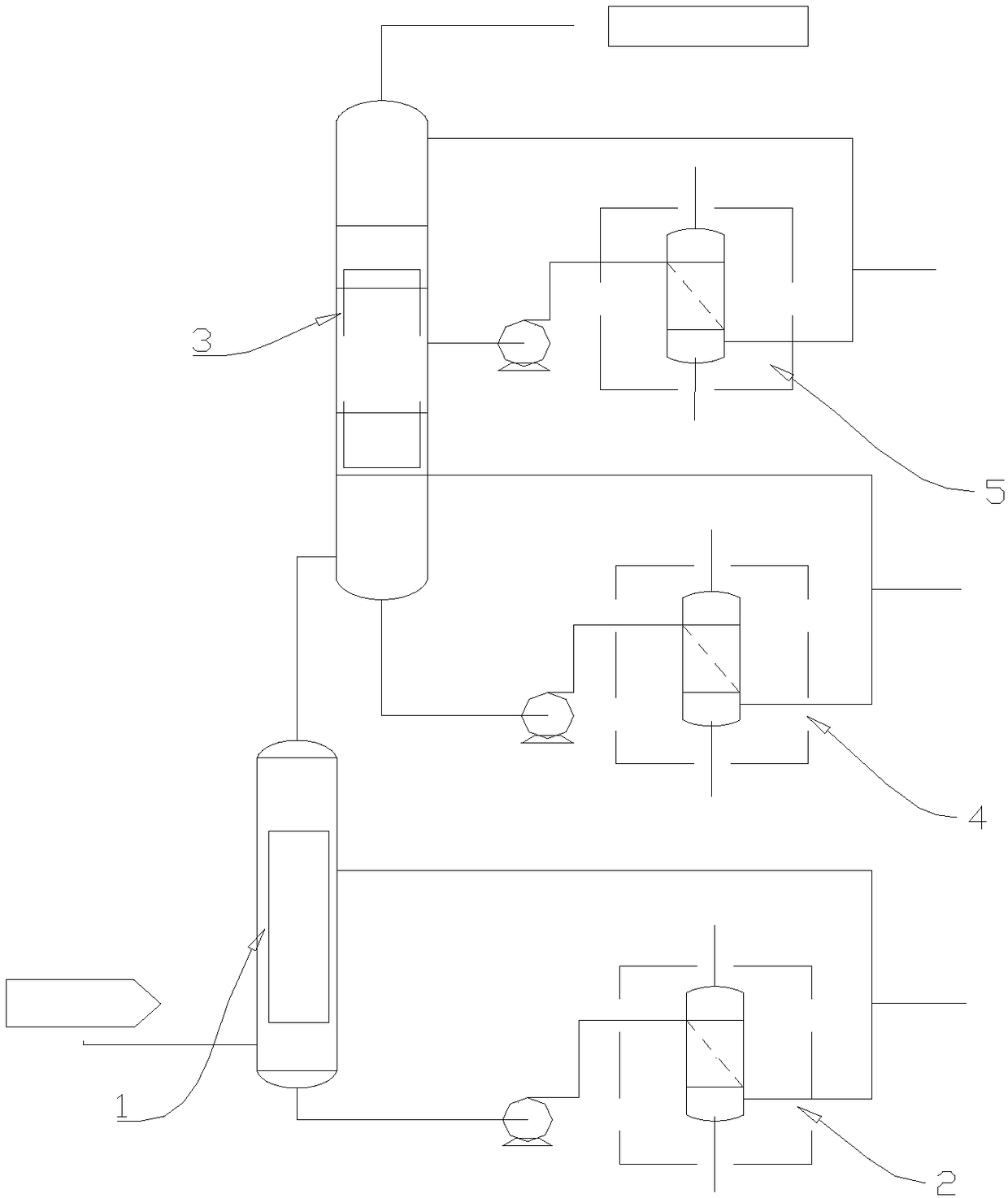

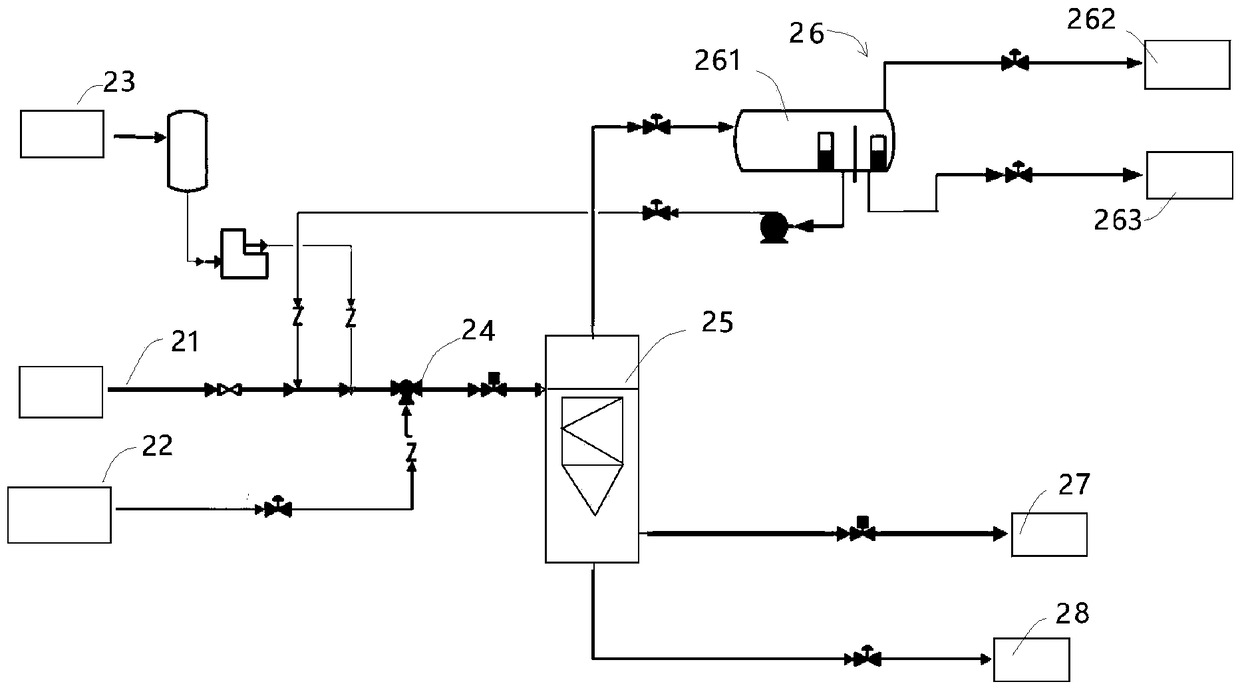

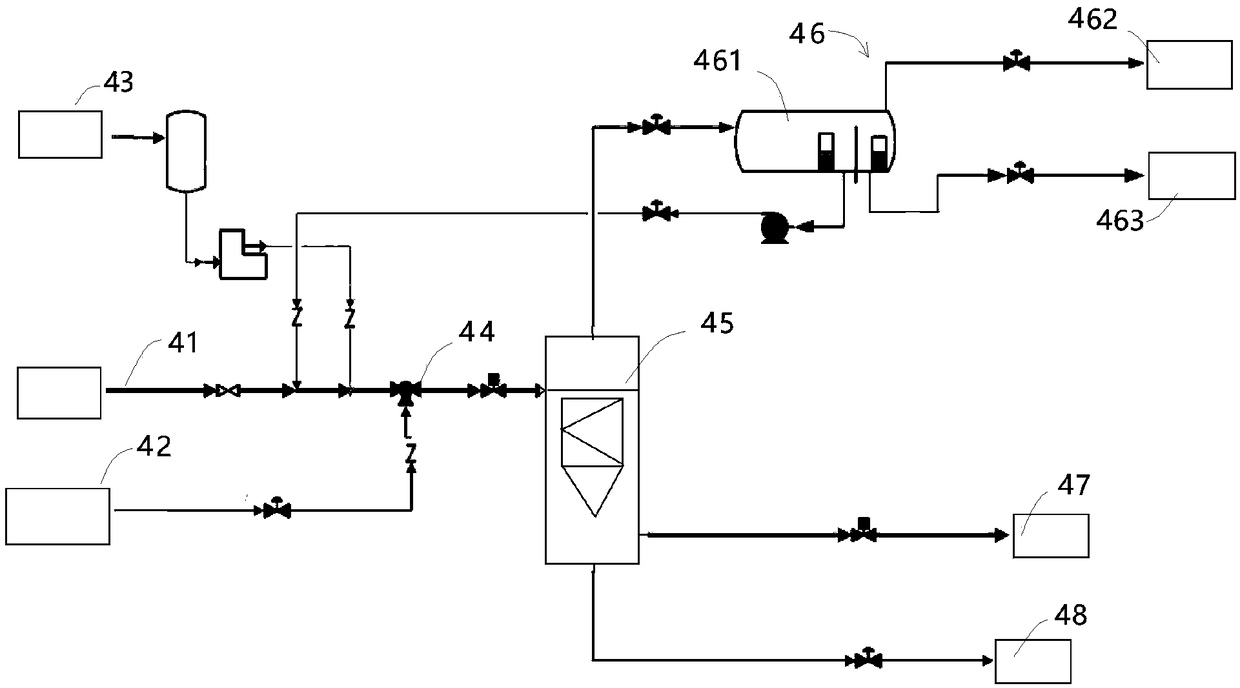

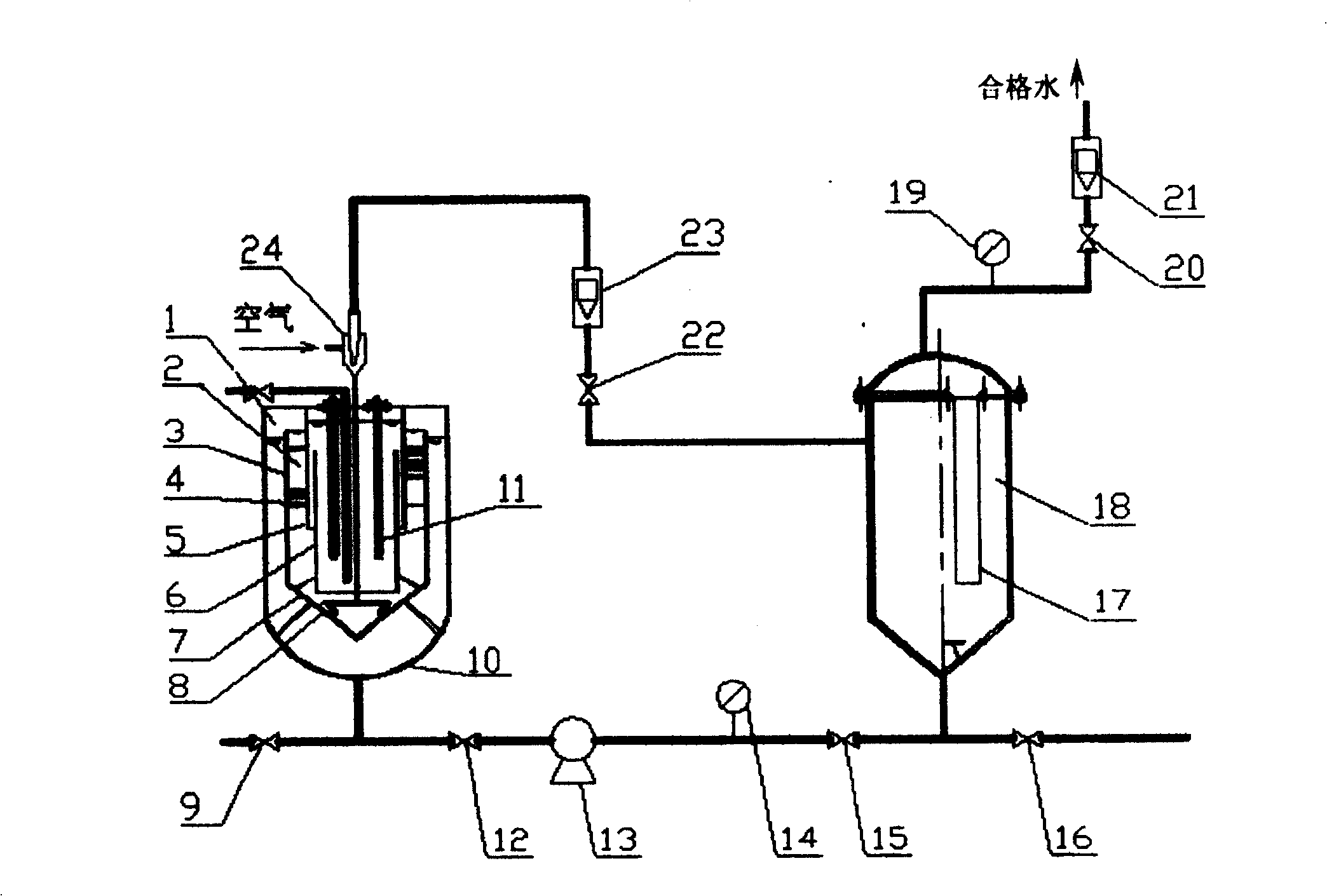

Treatment system for produced water of methanol alkene-production device

ActiveCN109205859AImprove washing effectReduce macromolecular oil and catalyst particlesWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningQuenchingProduced water

The invention discloses a treatment system for produced water of a methanol alkene-production device. Compared with the prior art, the treatment system comprises a first oil-water-solid treatment device, a second oil-water-solid treatment device and a third oil-water-solid treatment device, wherein the first oil-water-solid treatment device is connected with a quenching tower of the methanol alkene-production device and is used for separating oil and a catalyst in water pumped out from the bottom of the quenching tower and carrying out classified treatment and output; the second oil-water-solid treatment device is connected with the bottom of a water scrubbing tower of the methanol alkene-production device and is used for separating oil and a catalyst in water pumped out from the bottom ofthe water scrubbing tower and carrying out classified treatment and output; the third oil-water-solid treatment device is connected with the top of the water scrubbing tower of the methanol alkene-production device and is used for separating oil and a catalyst in tower top circulating water and carrying out classified treatment and output. According to the treatment system for the produced waterof the methanol alkene-production device, provided by the invention, the content of the oil and the catalyst in a water production system in the methanol alkene-production device can be greatly lowered, the problem of blockage during the operation of the device is systematically solved, meanwhile, the oil content and catalyst content of outside drainage of the device can be lowered, and the quality of the outside drainage is remarkably improved.

Owner:湖南泰山石环境科技有限公司 +1

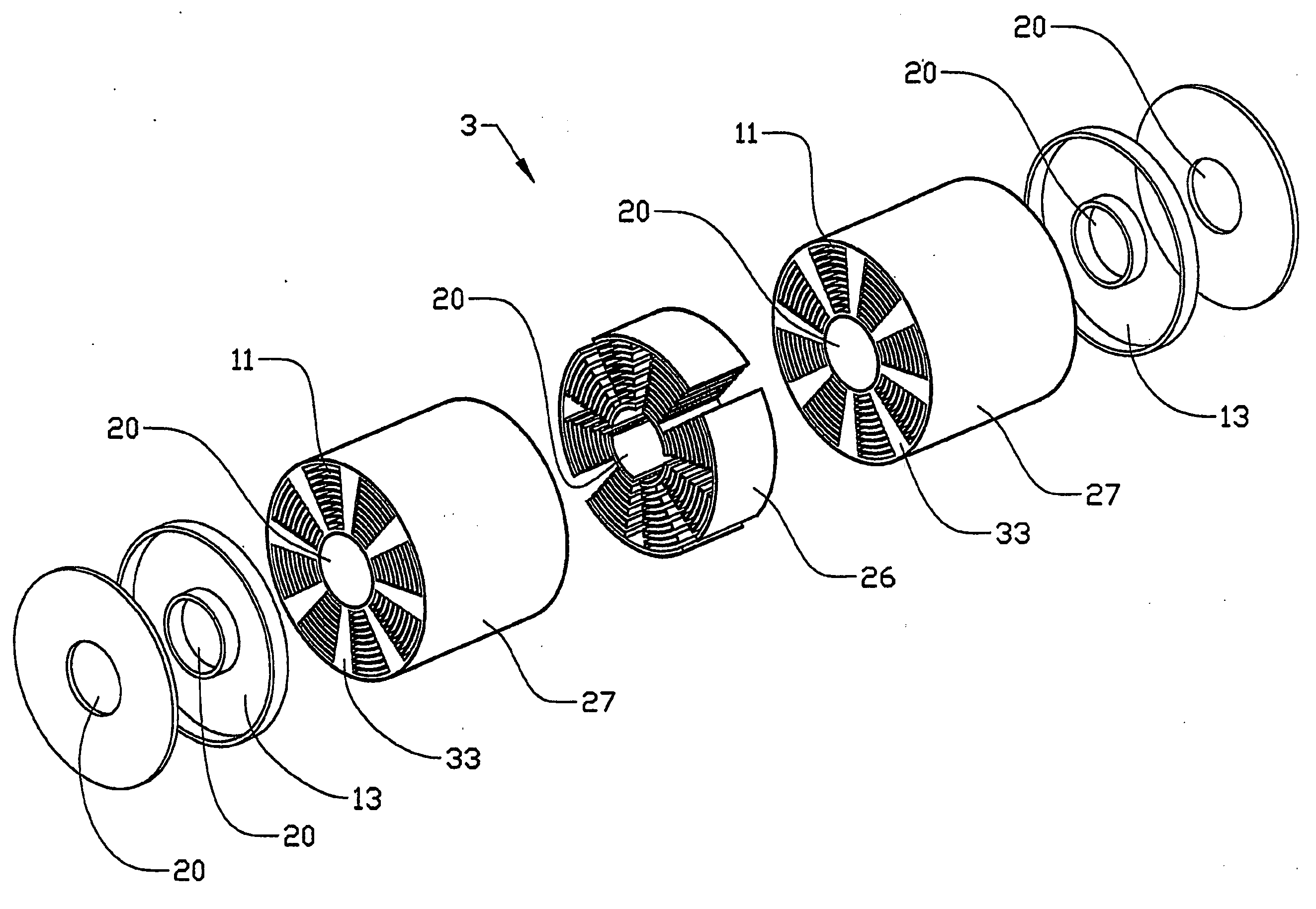

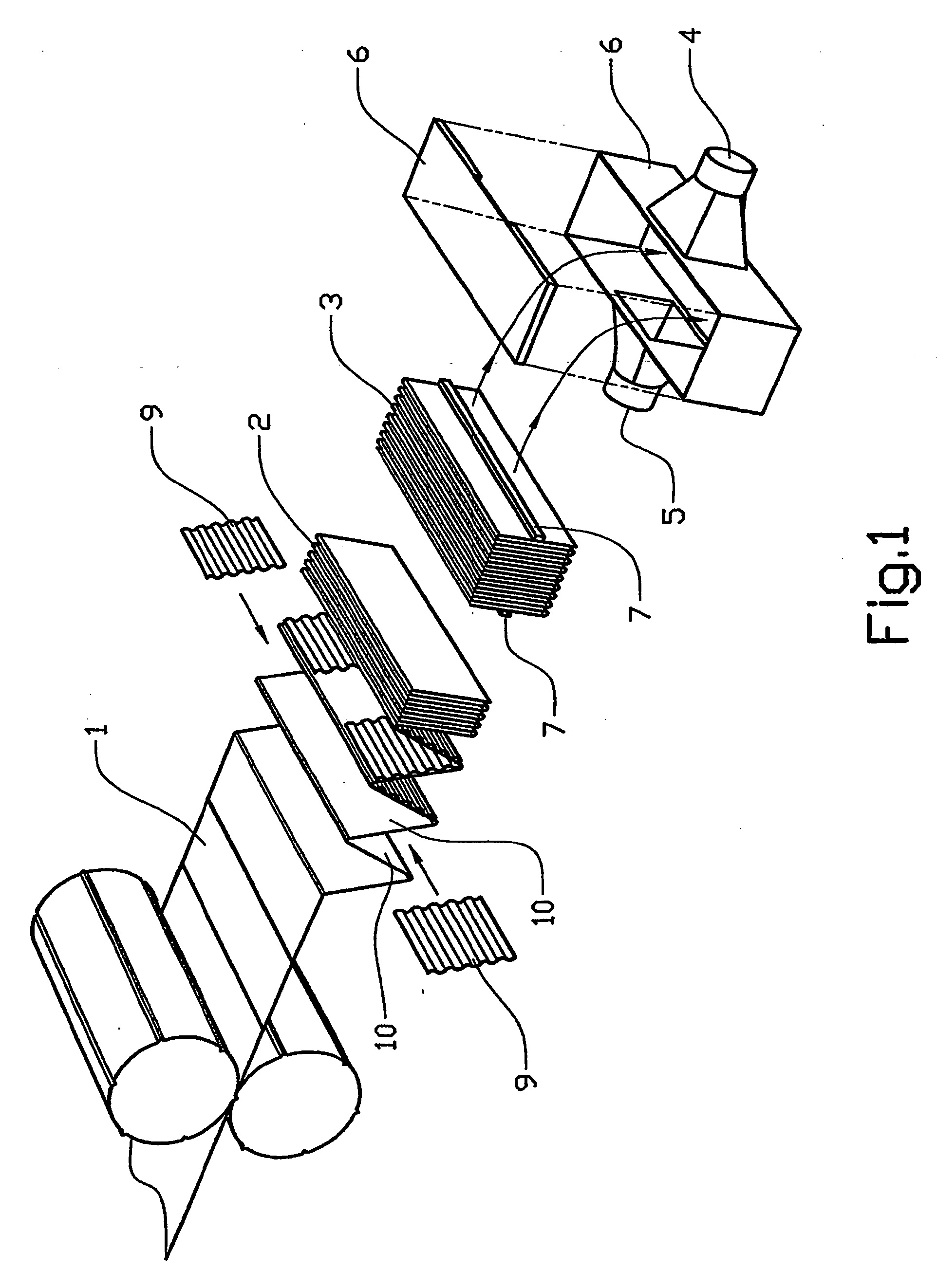

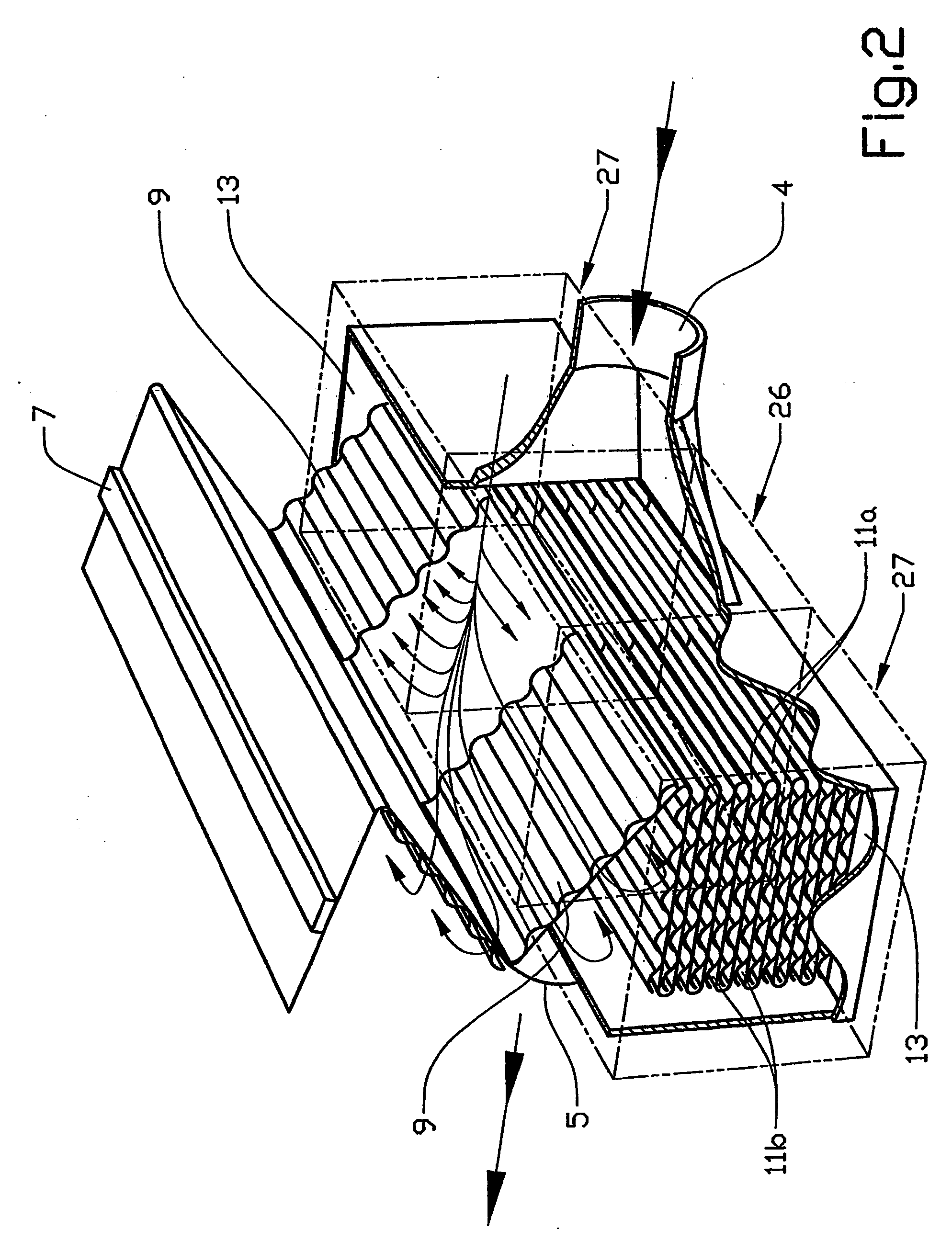

Device for treatment of a gas flow

InactiveUS20050079110A1Easy constructionImprove distributionPhysical/chemical process catalystsDispersed particle filtrationEngineeringAirflow

Owner:VOLVO TECH +1

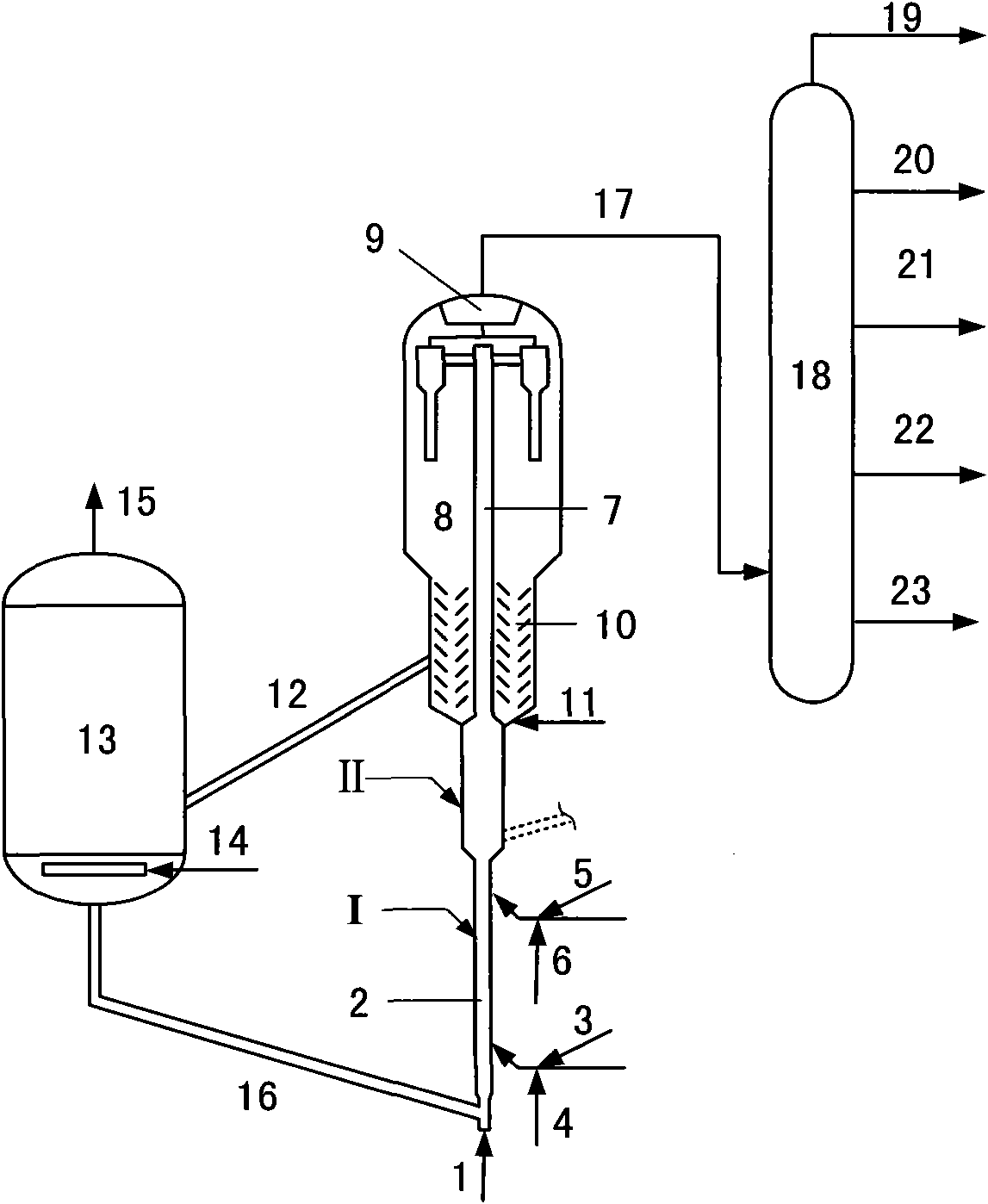

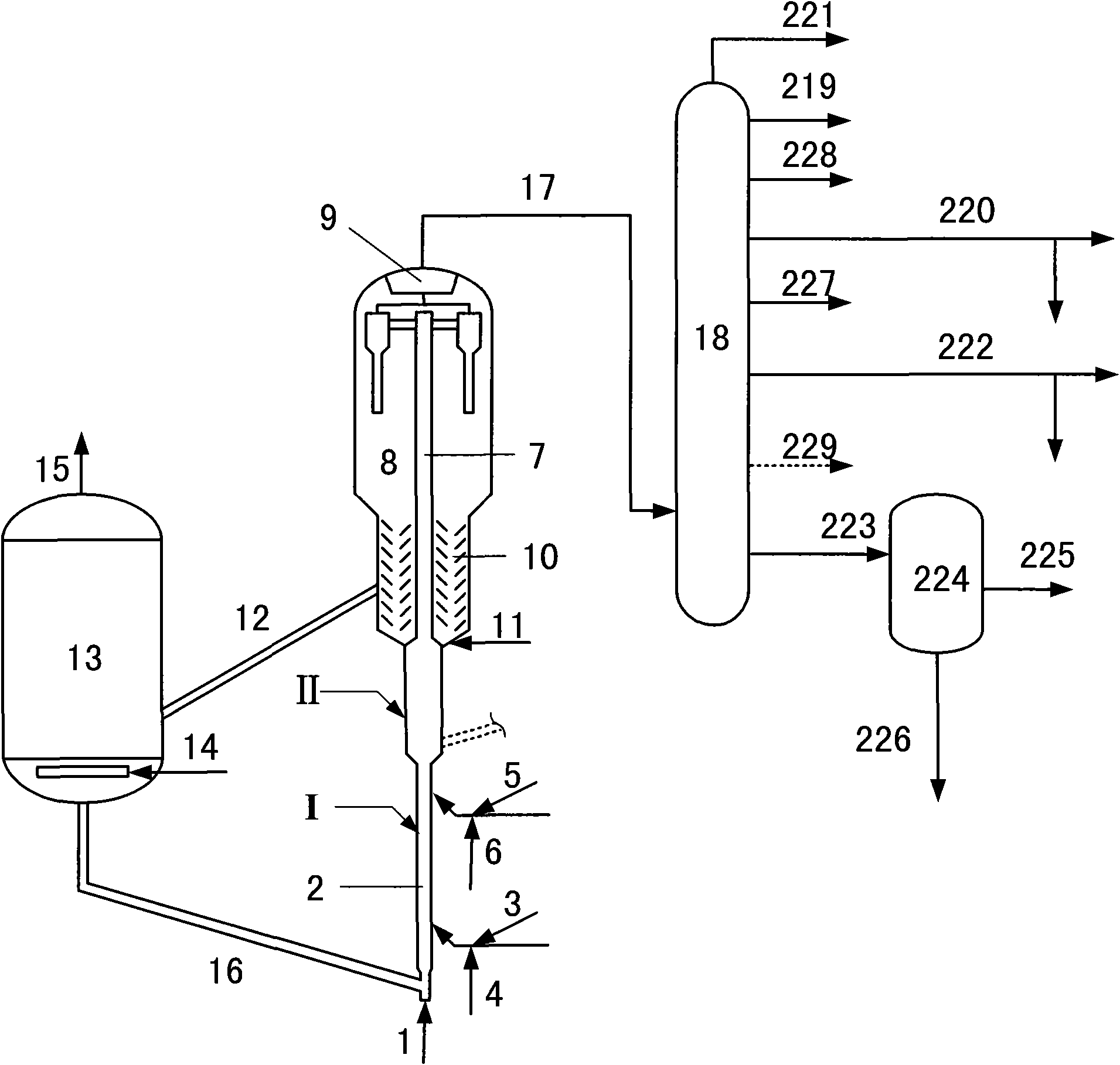

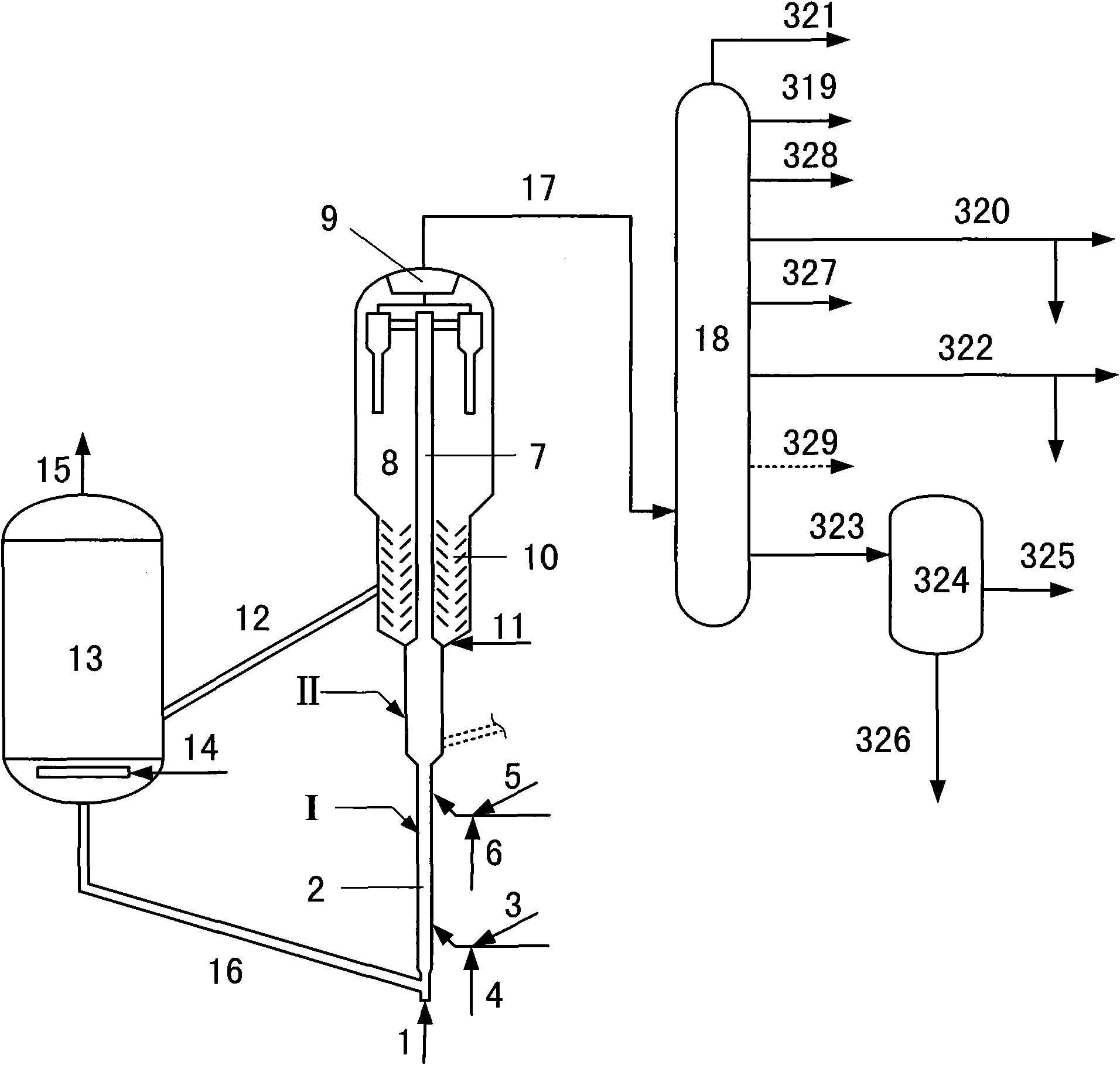

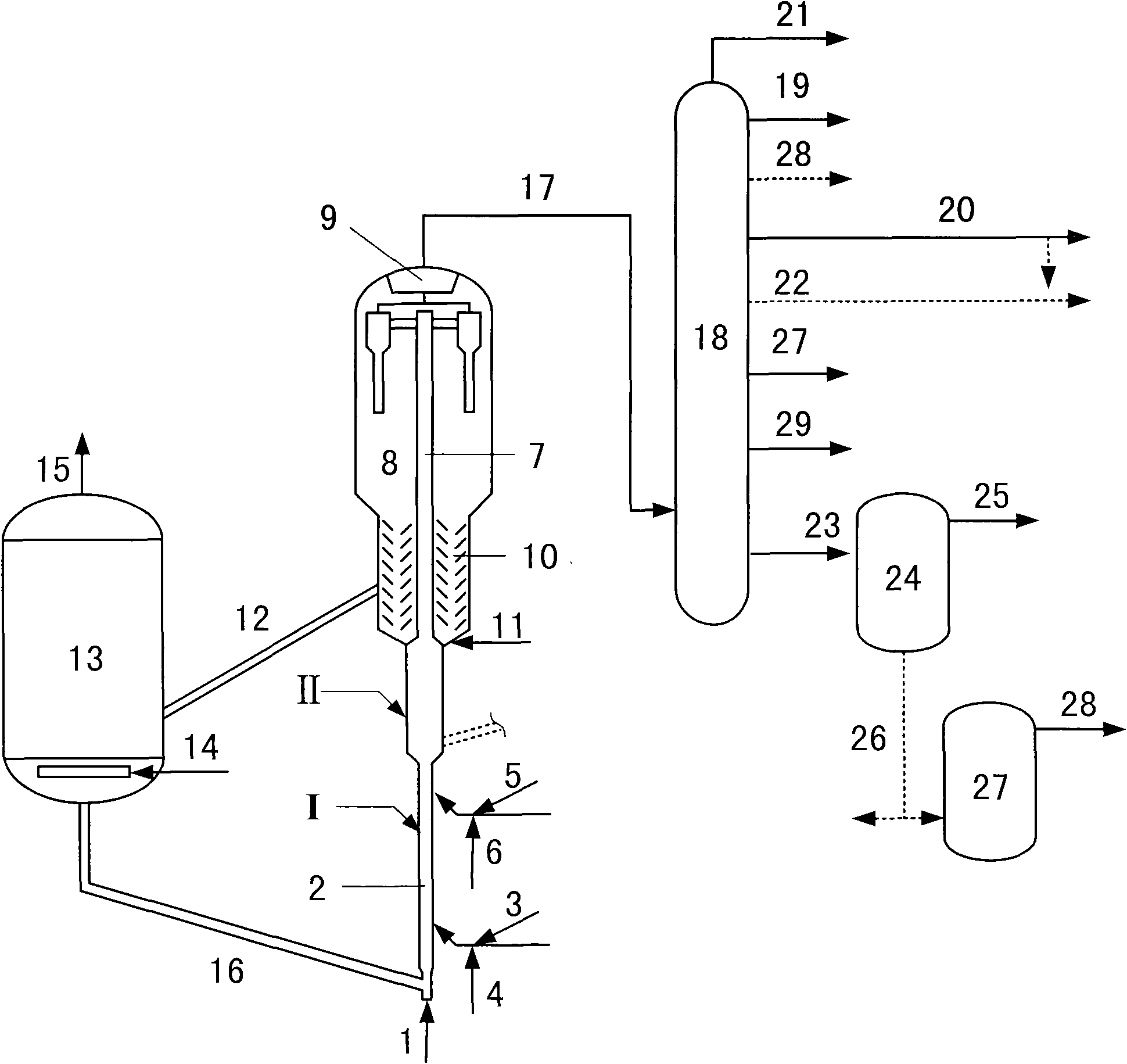

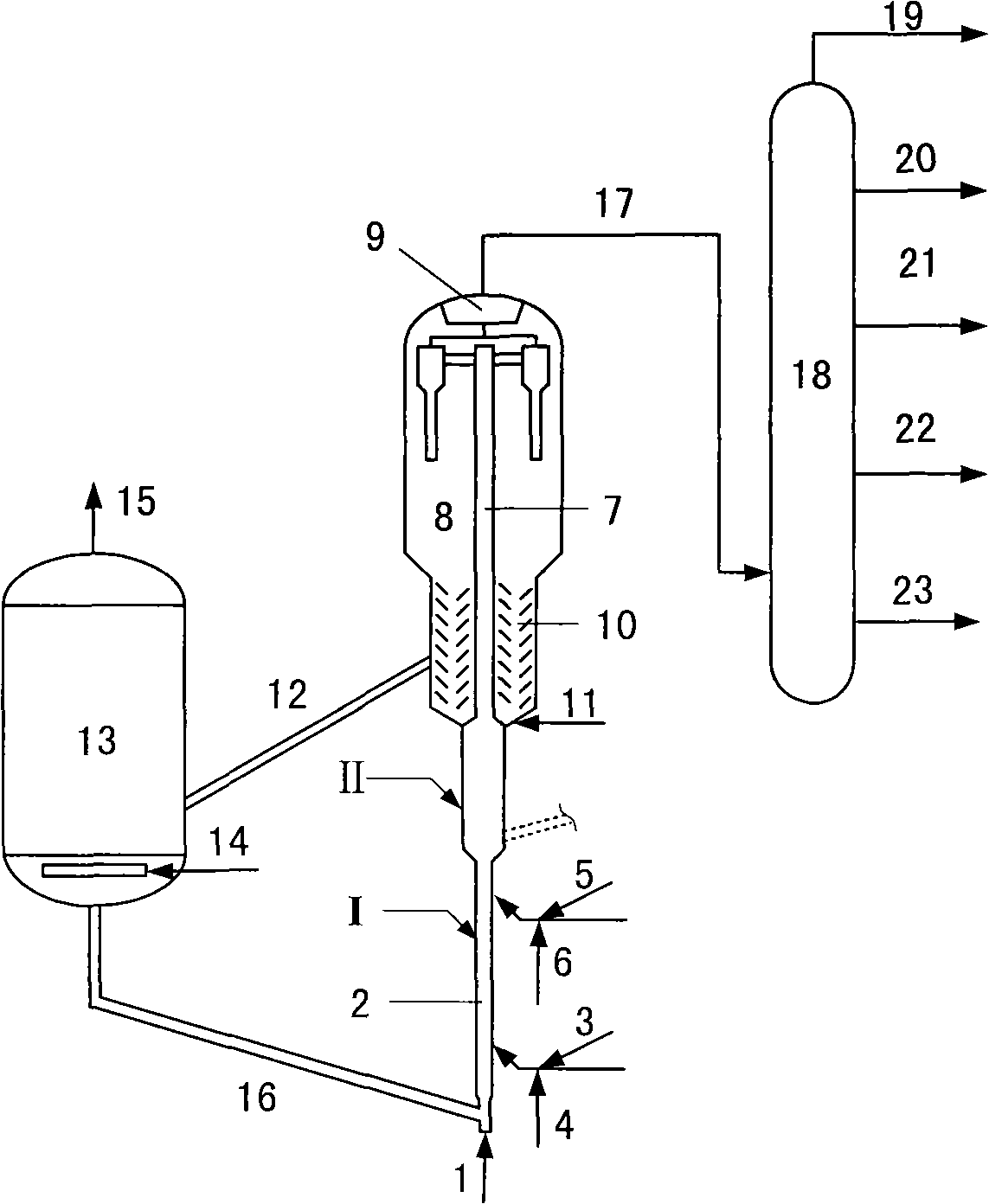

Slurry bed reactor and reaction system used for Fischer-Tropsch synthesis

PendingCN110180471AImprove gas-liquid-solid mixingEnsure safetyLiquid hydrocarbon mixture productionChemical/physical processesSlurryProcess engineering

The invention relates to a slurry bed reactor and a reaction system for Fischer-Tropsch synthesis. The reactor comprises: a reactor main body; a gas distributor arranged at the bottom part of the reactor main body; a plurality of groups of heat transfer devices arranged in the reactor main body, and downcomer pipes matching with the heat transfer devices, wherein a liquid-solid separation device is arranged between every two groups of heat transfer devices; and a gas-solid washing separation device arranged at the top part of the reactor. The reaction system comprises the reactor, and filtering-flushing assemblies and washing assemblies matching with the reactor. Compared with the prior art, the slurry bed reactor and the reaction system provided by the invention can realize industrial large-scale production of Fischer-Tropsch synthesis products, effectively increase the yield of a target product, and reduce the loss of a catalyst and the difficulty of separating the catalyst from a product.

Owner:YANKUANG ENERGY R&D CO LTD

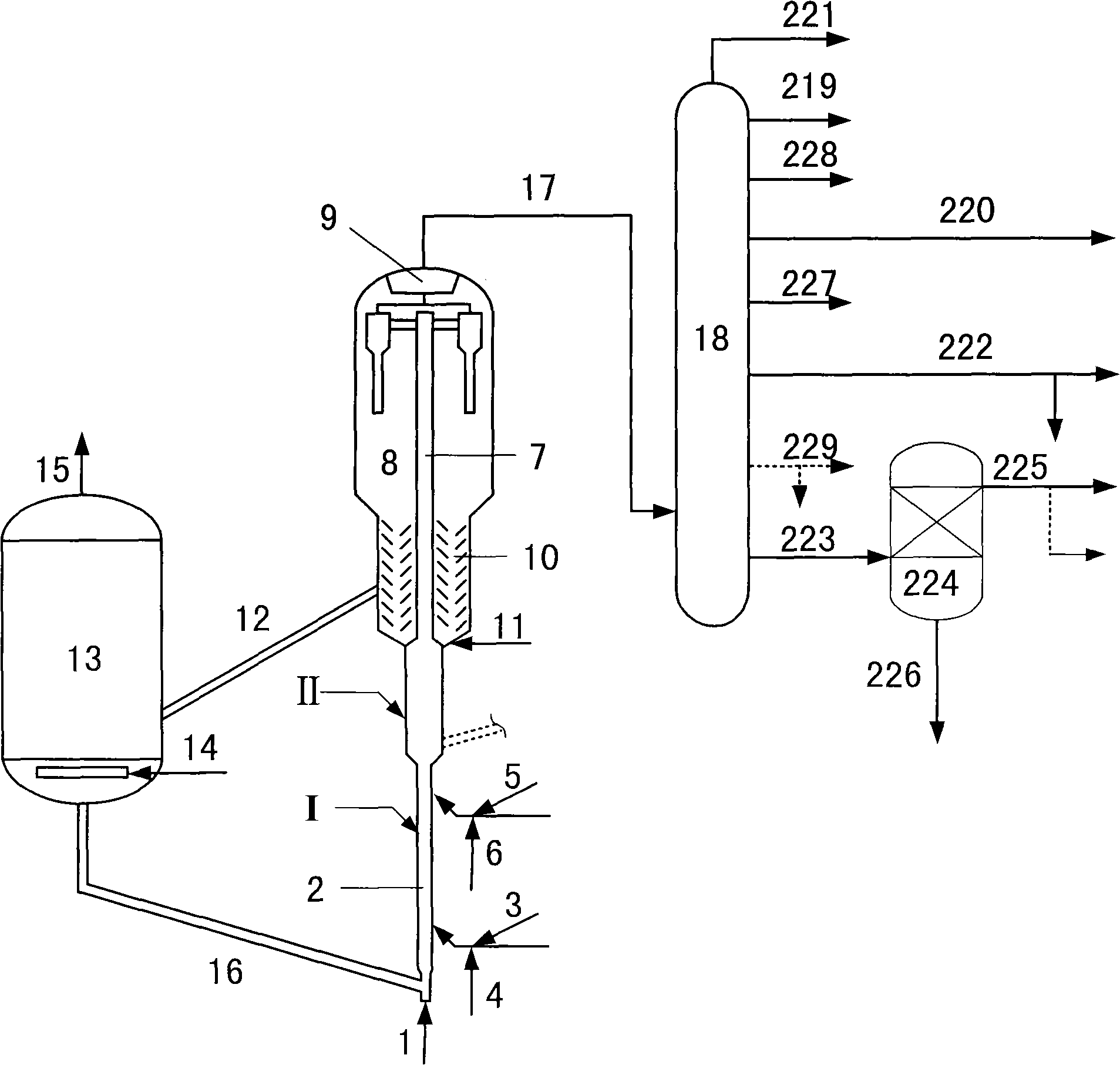

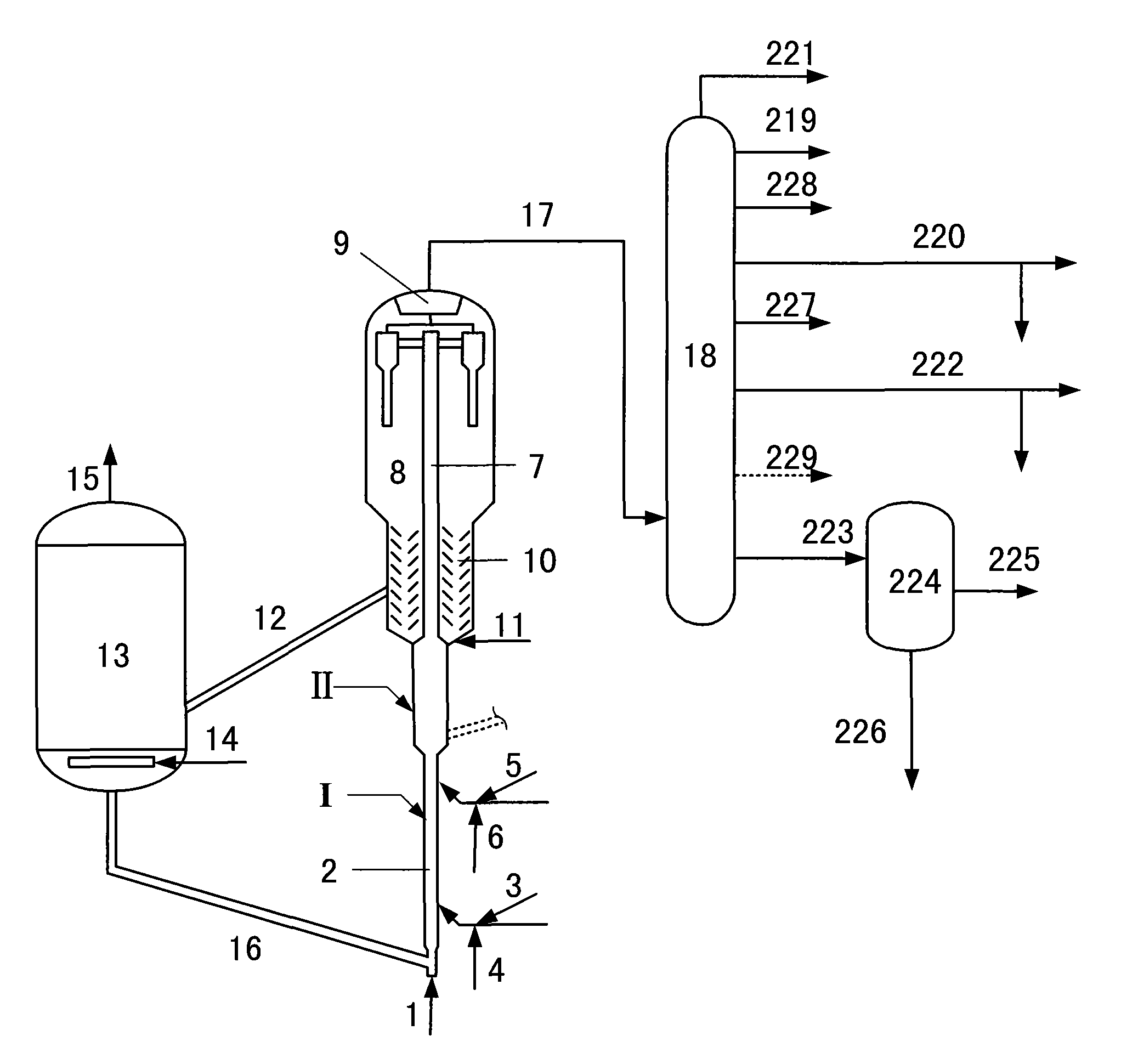

Catalytic conversion method for diesel oil and propylene with high yield

ActiveCN102051226AIncrease cetane numberHigh selectivityTreatment with hydrotreatment processesAlkaneReaction temperature

The invention discloses a catalytic conversion method for diesel oil and propylene with high yield. Raw material oil is contacted with a catalyst with coarse particle size distribution in a reactor to react; reaction temperature, weight hourly space velocity and weight ratio of the catalyst to the raw material oil are sufficient so that a reaction product containing catalytic wax oil which is 12 to 60 weight percent of the raw material oil; and the catalytic wax oil is fed into a hydro-cracking device for further treatment. Catalytic cracking, hydro-cracking and high-yield diesel oil processes are organically combined, hydrocarbons such as alkane, alkyl side chain and the like in the catalytic raw materials are selectively cracked and isomerized, meanwhile, aromatic hydrocarbons in the raw materials are furthest reduced to enter the diesel oil fraction, and aromatic hydrocarbons generated by reaction of other components in the product such as aromatization and the like are prevented from being left in the diesel oil fraction; and when the raw materials are transformed into the diesel oil with high cetane number and the propylene, the yields of dry gas and coke are greatly reduced, and catalyst crushing tendency and catalyst consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Proton-exchange membrane fuel cell electrode structuration

ActiveUS8900773B2Catalyst content reductionImprove propertiesMaterial nanotechnologyCell electrodesElectrochemistryProton exchange membrane fuel cell

An electrode for an electrochemical system, such as a fuel cell, is formed by an active layer including: pores; at least one catalyst; at least one ionomer; and electrically-conductive particles. The catalyst content per pore ranges between 30 and 500 mg / cm3 with respect to the pore volume.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

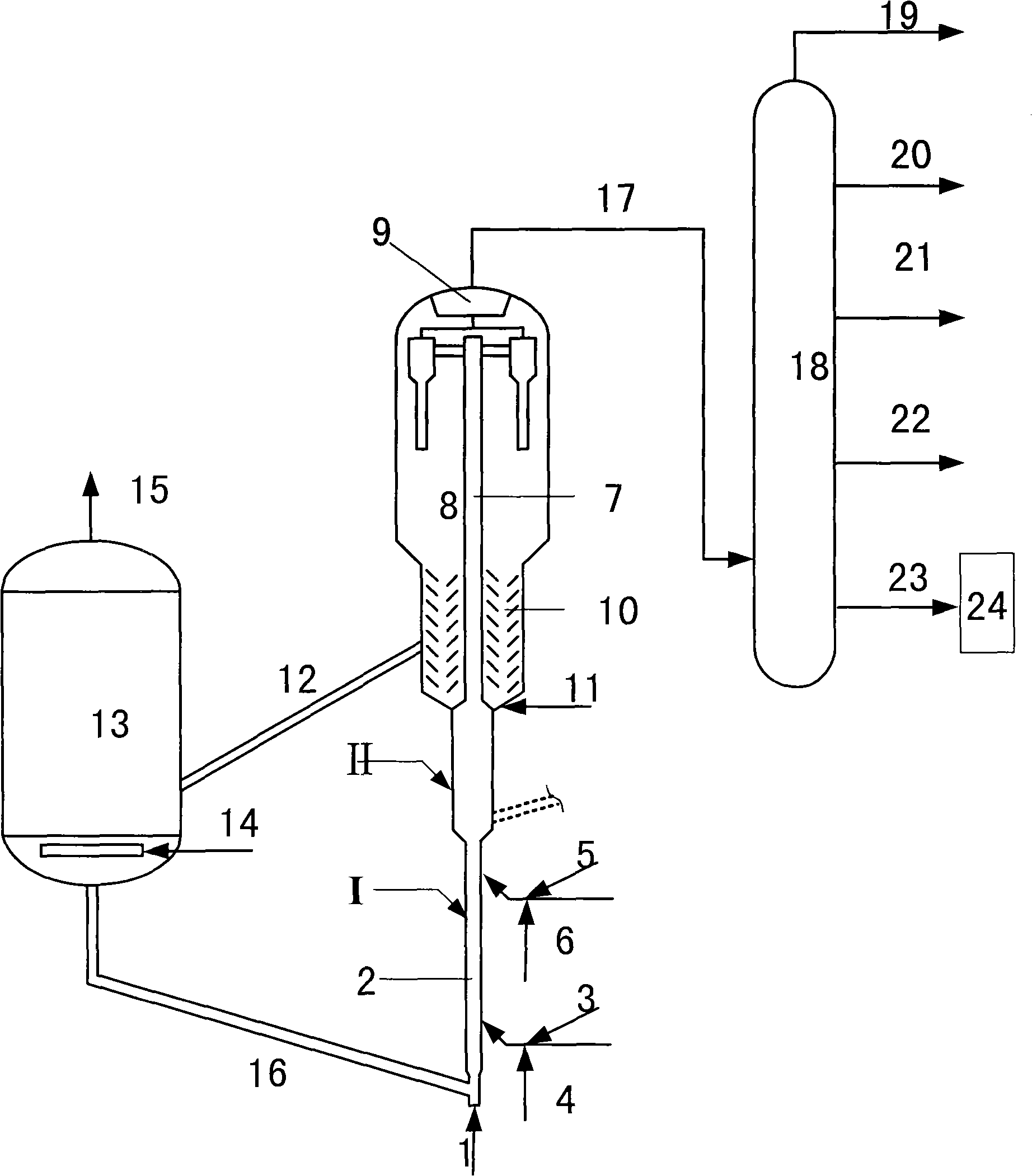

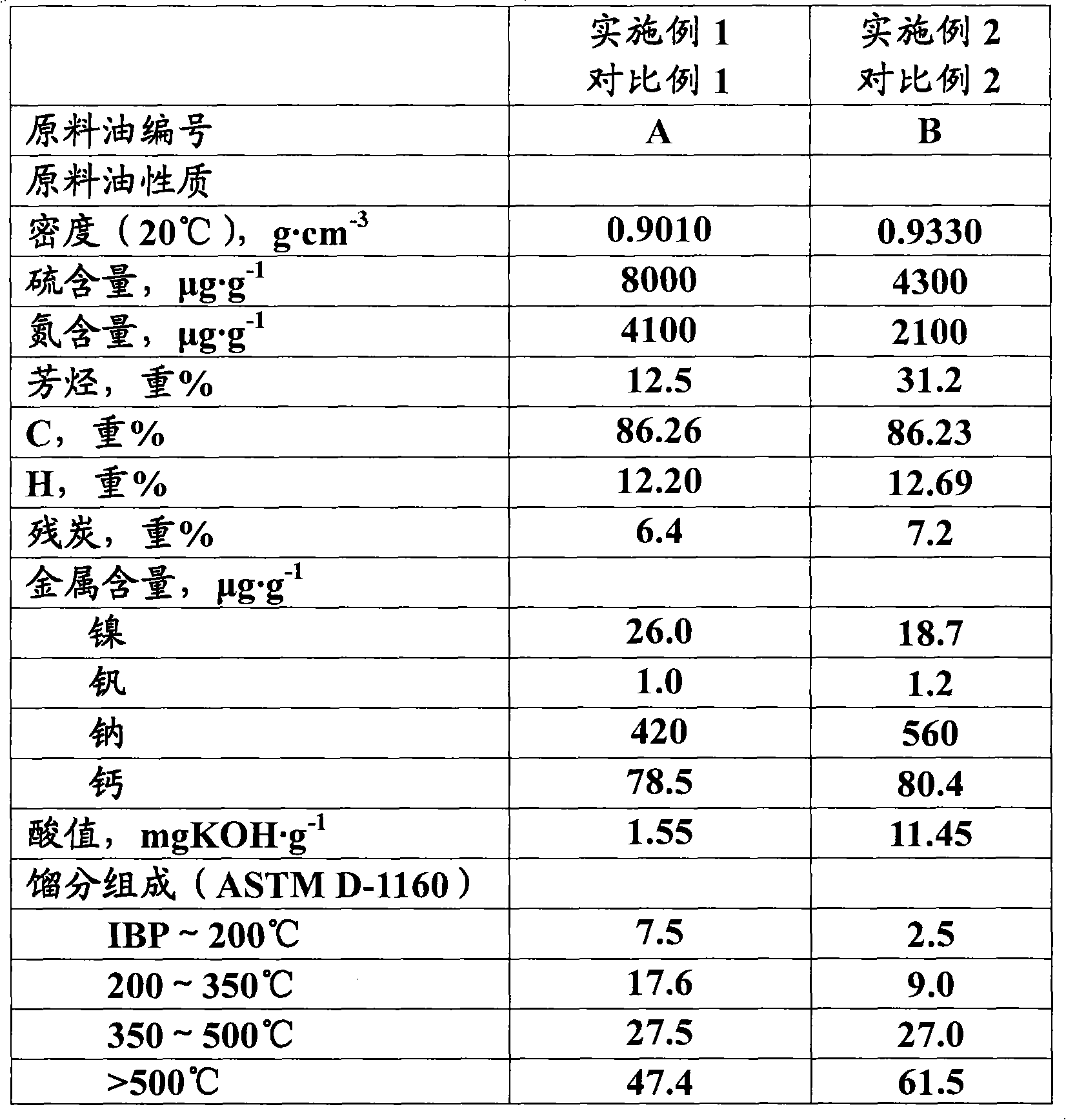

Catalyst conversion method for producing high-octane gasoline by using crude oil

ActiveCN102108308ALess investmentReduce corrosion costsCatalytic crackingTreatment with plural serial stages onlyWaxPetroleum

The invention provides a catalytic conversion method for producing high-octane gasoline by using crude oil, which comprises: contacting pretreated crude oil serving as raw material oil with a catalyst which contains macroporous zeolite and is distributed according to a coarse particle size in a catalytic conversion reactor to perform a reaction according to reaction temperature, oil gas dwell time and catalyst to raw material oil weight ratio, which are proper enough to enable the reaction to obtain a reaction product containing catalytic wax oil which accounts for 15 to 60 percent of the weight of the raw material oil, wherein the weight hourly space velocity is 25 to 100h<-1>, the reaction temperature is 450 to 600 DEG C, and he weight ratio of the catalyst to the raw material oil is 1 to 30. In the method, while low-quality crude oil is converted into high-octane gasoline, the dry gas and coke yields are reduced considerably, the high-efficient utilization of oil resources is realized, and the higher particle uniformity of the catalyst makes the local temperature distribution in a regeneration process more uniform and the breakage orientation of the catalyst lowered correspondingly.

Owner:CHINA PETROLEUM & CHEM CORP +1

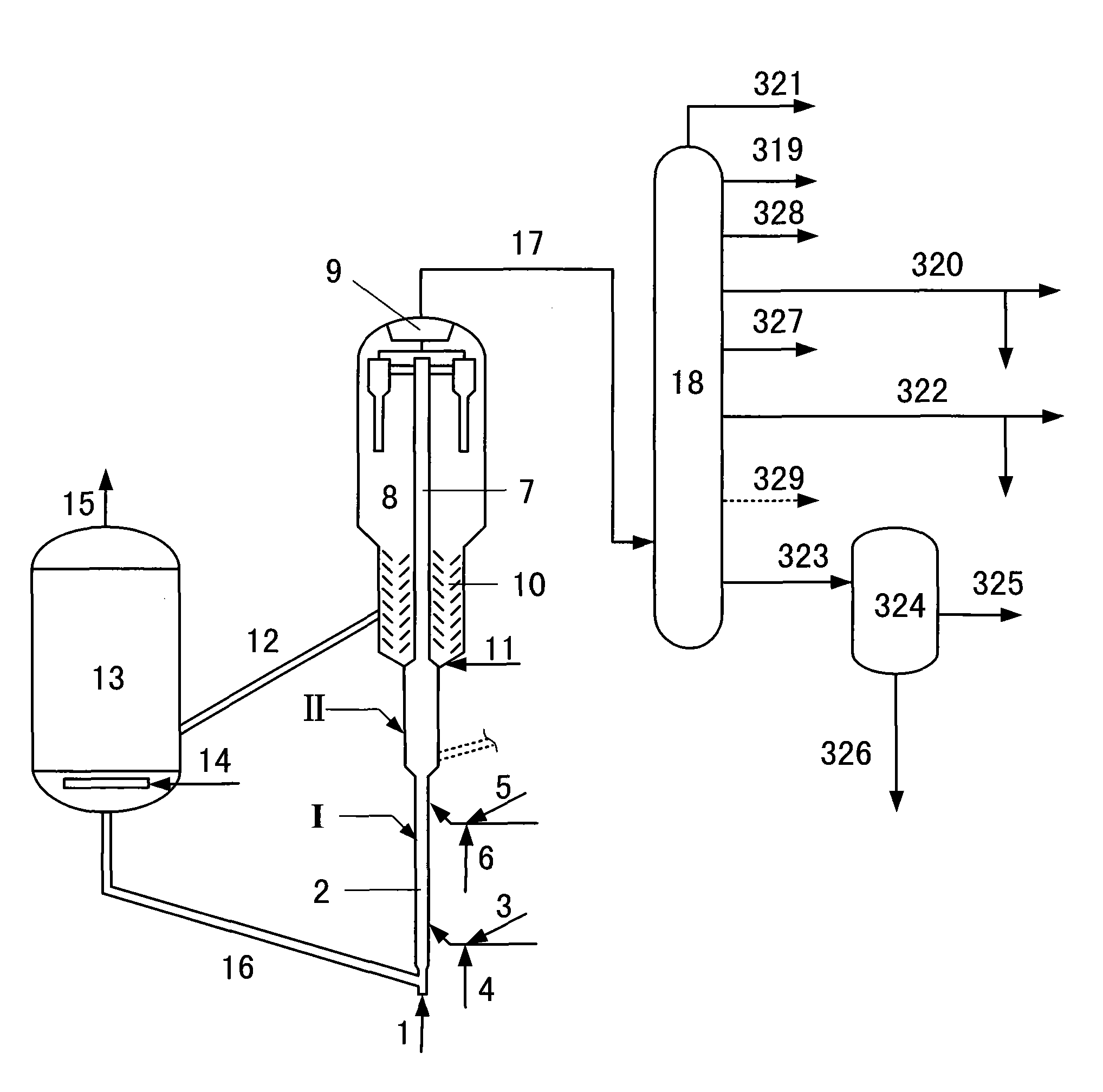

Catalytic conversion method for producing high-quality light fuels from crude oil

ActiveCN102079996ALess investmentReduce corrosion costsTreatment with hydrotreatment processesReaction temperaturePetroleum

The invention discloses a catalytic conversion method for producing high-quality light fuels from crude oil. The crude oil contacts and reacts with a catalyst which is rich in mesoporous zeolite and in coarse particle size distribution. The catalytic conversion method is characterized in that a reaction product containing catalytic wax oil which accounts for 12-60 wt% of the weight of raw material is obtained by the reaction temperature, weight hourly space velocity and the weight ratio of raw oil to catalyst, wherein the reaction temperature is 420-600 DEG C, the weight hourly space velocity is 25-100 hours<-1>, the weight ratio of catalyst to raw oil is 1 to 30, and the wax is catalyzed before hydrocracks. In the invention, crude oil catalytic converter and hydrocracking methods are provided, which, in particular, reduces dry gas and coke yield significantly while converting the poor quality of crude oil into high octane gasoline and high-cetane diesel fuel so as to achieve efficient use of oil resources, and reduce the broken tendency of the catalyst and the catalyst consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for producing high-cetane number light diesel oil and low-olefin gasoline

ActiveCN102079992AReduce production processGood choiceCatalytic crackingTreatment with plural serial stages onlyWaxIsomerization

The invention relates to a catalytic conversion method for producing high-cetane number light diesel oil and low-olefin gasoline, which comprises the following steps of: making raw oil contact mitigated converting catalyst with rough grain diameter distribution in a mitigated converting reactor for reacting, wherein the reaction temperature, oil and gas retaining time and the weight ratio of the mitigated converting catalyst to the raw oil are enough to obtain a reaction product containing catalytic wax oil which accounts for 12-60 percent by weight of raw oil, and the reaction product also comprises high-cetane number diesel oil and gasoline; carrying out cracking reaction on the catalytic wax oil in a harsh converting reactor; carrying out hydrogen transfer reaction and isomerization reaction on the generated oil and gas in a certain reaction environment; and separating to obtain a reaction product containing low-olefin gasoline. The method can directly produce high-cetane number light diesel oil and low-olefin gasoline simultaneously by catalytic cracking and reduce the catalyst breakage tendency and catalyst consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

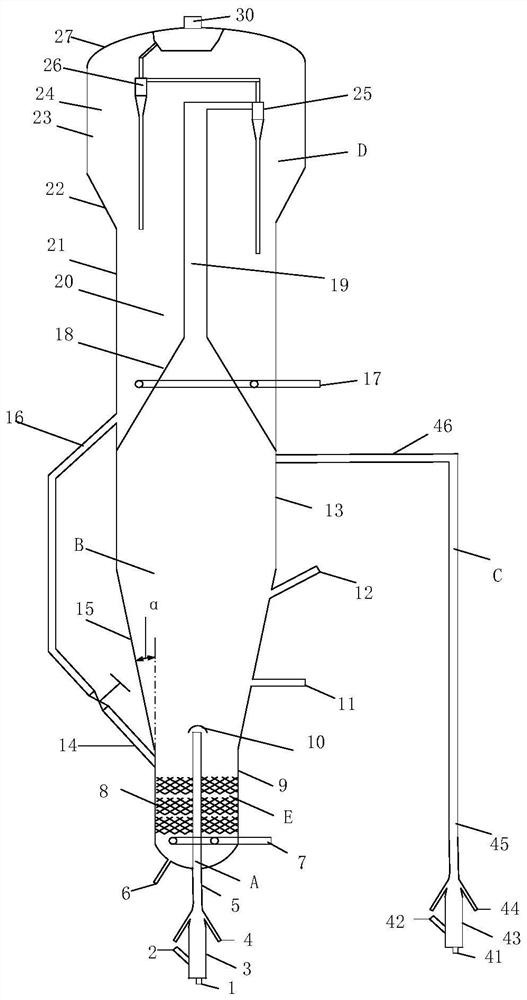

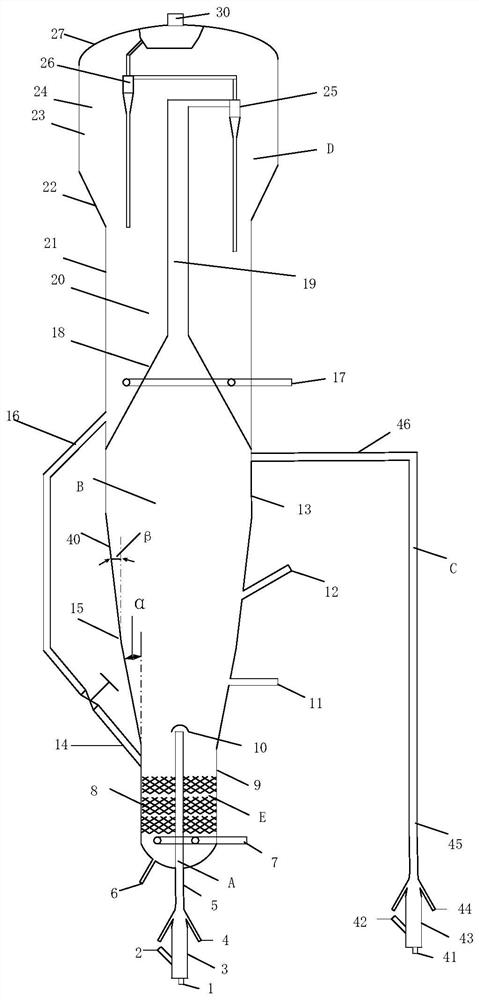

Catalytic conversion reactor for heavy oil and method for preparing propylene through catalytic cracking of heavy oil

ActiveCN113926396AReduce the impact of density reductionReduce dosageCatalytic crackingChemical/physical processesPtru catalystReaction zone

The invention discloses a catalytic conversion reactor for heavy oil and a method for preparing propylene through catalytic cracking of heavy oil. The reactor comprises reaction zones, a gas-solid separation zone and a steam stripping zone, wherein a first reaction zone is located below a second reaction zone and is opened at the bottom of the second reaction zone, a third reaction zone is arranged in parallel with the first reaction zone and the second reaction zone, an opening of the third reaction zone is located in the second reaction zone, the steam stripping zone is positioned below the second reaction zone, the top of the steam stripping zone communicates with the second reaction zone, the top of the second reaction zone is opened in the gas-solid separation zone, the lower part of the gas-solid separation zone is a catalyst collecting zone, the bottom of the gas-solid separation zone communicates with the steam stripping zone through a catalyst collecting pipe, and the inner diameters of the second reaction zone and the gas-solid separation zone are greater than the inner diameter of the first reaction zone. The reactor is used for preparing propylene by catalytic cracking of heavy oil. The reactor, a device and the method for catalytic conversion of heavy oil in the invention have the advantages of low coke and dry gas yield of catalytic cracking, high propylene yield and low energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for preparing propylene and high-octane value gasoline

ActiveCN101935266BHigh yieldImprove octaneCatalytic crackingBulk chemical productionReaction temperaturePetroleum

The invention discloses a catalytic conversion method for preparing propylene and high-octane value gasoline. Crude oil contacts a catalyst rich in mesoporous zeolite and with coarse particle size distribution for reaction; and reaction temperature, weight hourly space velocity and the weight ratio of the catalyst to the crude oil are sufficiently proper for preparing a reaction product comprising 12 to 60 percent of catalytic wax oil based on the weight of the crude oil in the reaction, wherein the weight hourly space velocity is 25 to 100 h<-1>; the reaction temperature is 450 to 600 DEG C;and the weight ratio of the catalyst to the crude oil is 1 to 30. The invention provides the catalytic conversion method based on the prior art, which particularly has the advantages of greatly reducing dry gas yield and coke yield at the same time of converting the heavy crude oil into the high-octane value gasoline and the propylene so as to realize the high-efficiency utilization of oil resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

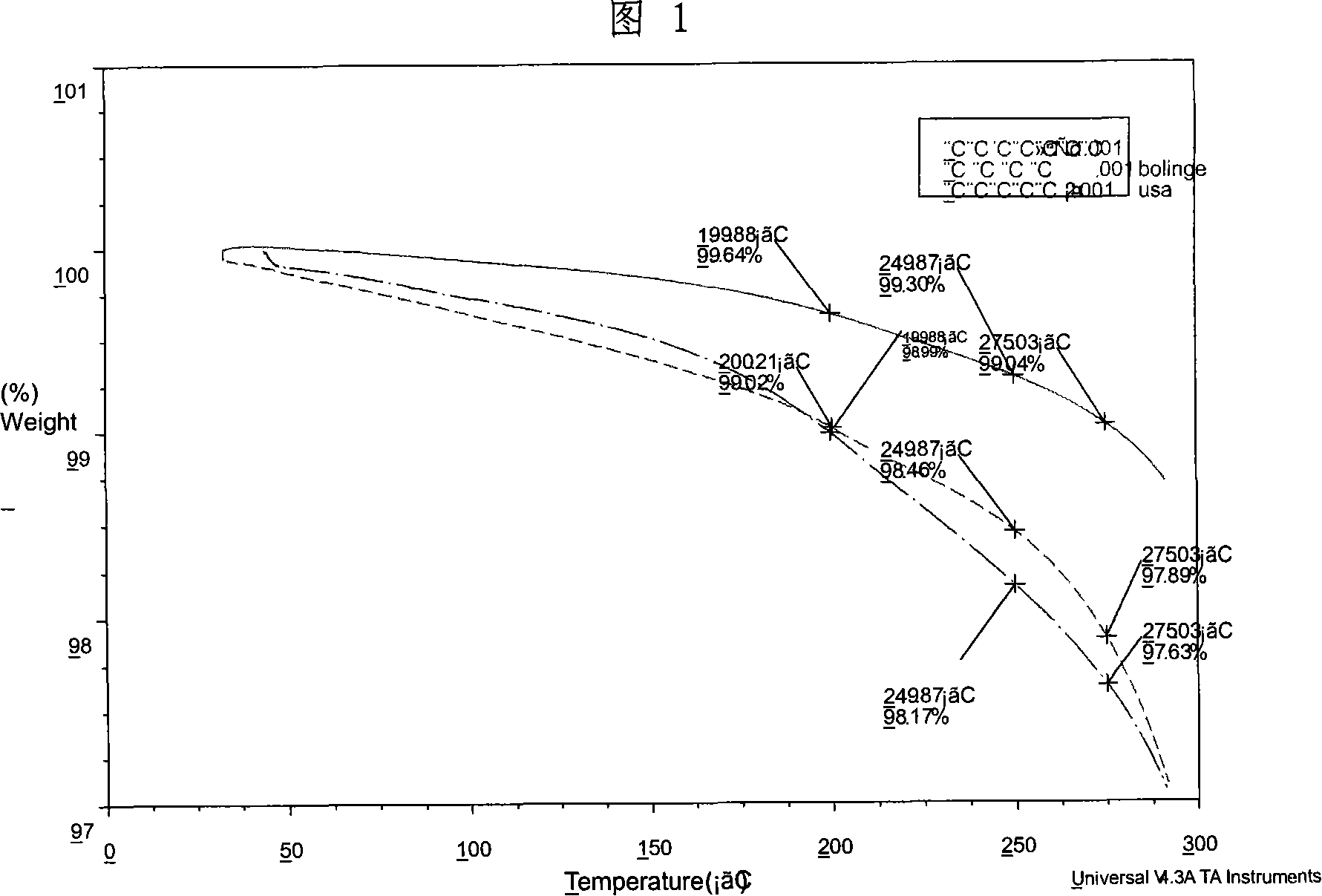

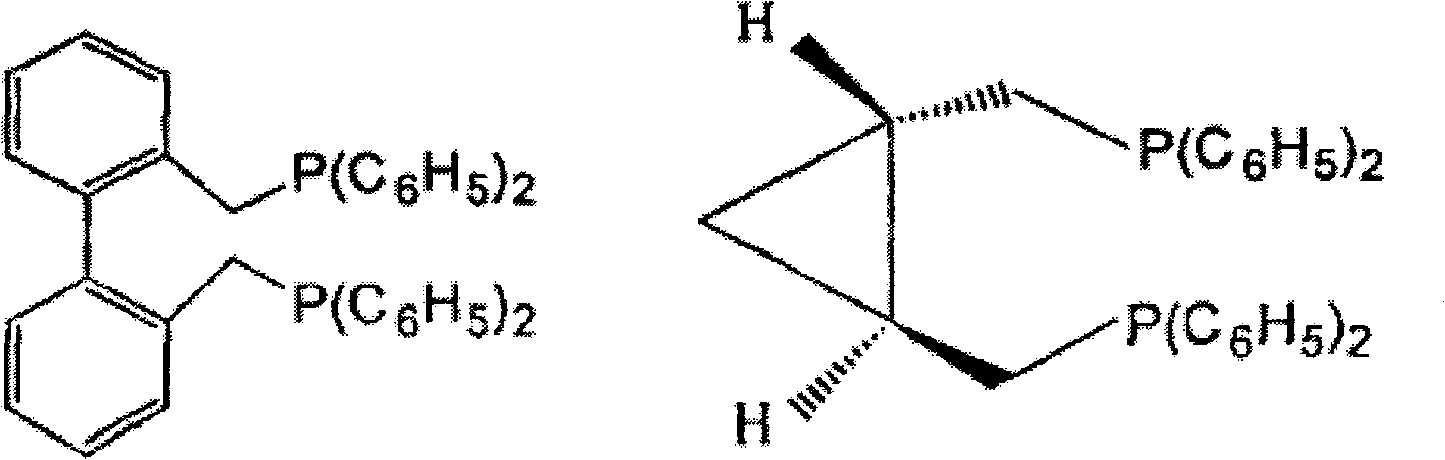

Method for preparing poly (lactic-co-glycolic acid)

The invention provides a preparation method of a lactic and glycolic acid. The method comprises a catalyst containing three compounds of a catalytic induction system. The catalyst catalyzes and induces ring cleavage copolymerization between diglycolide and lactide to synthesize lactic and glycolic acid. The monomer to catalyst (mol ratio) is at 20,000 to 500,000 and the reaction temperature is 100 to 220 DEG C for 1 to 200 hours with inert gas protection or in vacuum. The invention has the advantages of high transformation ration, low catalyst contents of products, high molecular weight, narrow molecular weight disposition, good heat stability, small degradation of high temperature molten, good uniformity of materials, and is provided with excellent biological degradability and biologicalcompatibleness. The lactic and glycolic acid prepared by the invention can be widely used for surgical operation suture, internal fixation of fracture, tissue repair, plastic surgery, anti-organic conglutination, medical slow release, organic engineering, etc.

Owner:HUIZHOU HUAYANG MEDICAL EQUIP

Catalyst separation device in furfuryl alcohol producing process and method thereof

InactiveCN101265244BRaise the catalyst contentCatalyst content reductionOrganic chemistryDistillationProcess engineering

Owner:TIANJIN UNIV

Catalytic conversion method for producing high-cetane number light diesel oil and low-olefin gasoline

ActiveCN102079992BReduce production processGood choiceCatalytic crackingTreatment with plural serial stages onlyWaxIsomerization

The invention relates to a catalytic conversion method for producing high-cetane number light diesel oil and low-olefin gasoline, which comprises the following steps of: making raw oil contact mitigated converting catalyst with rough grain diameter distribution in a mitigated converting reactor for reacting, wherein the reaction temperature, oil and gas retaining time and the weight ratio of the mitigated converting catalyst to the raw oil are enough to obtain a reaction product containing catalytic wax oil which accounts for 12-60 percent by weight of raw oil, and the reaction product also comprises high-cetane number diesel oil and gasoline; carrying out cracking reaction on the catalytic wax oil in a harsh converting reactor; carrying out hydrogen transfer reaction and isomerization reaction on the generated oil and gas in a certain reaction environment; and separating to obtain a reaction product containing low-olefin gasoline. The method can directly produce high-cetane number light diesel oil and low-olefin gasoline simultaneously by catalytic cracking and reduce the catalyst breakage tendency and catalyst consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

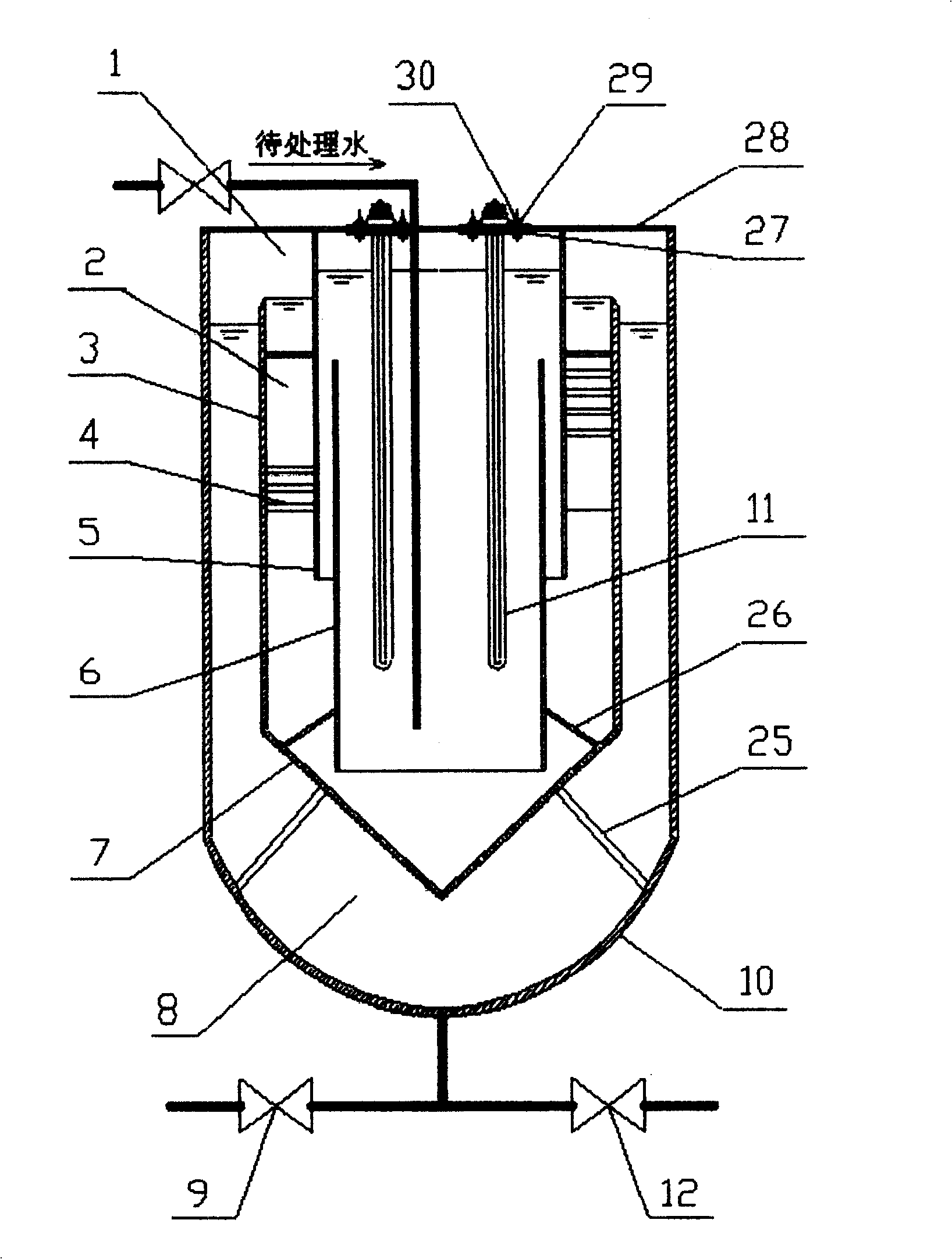

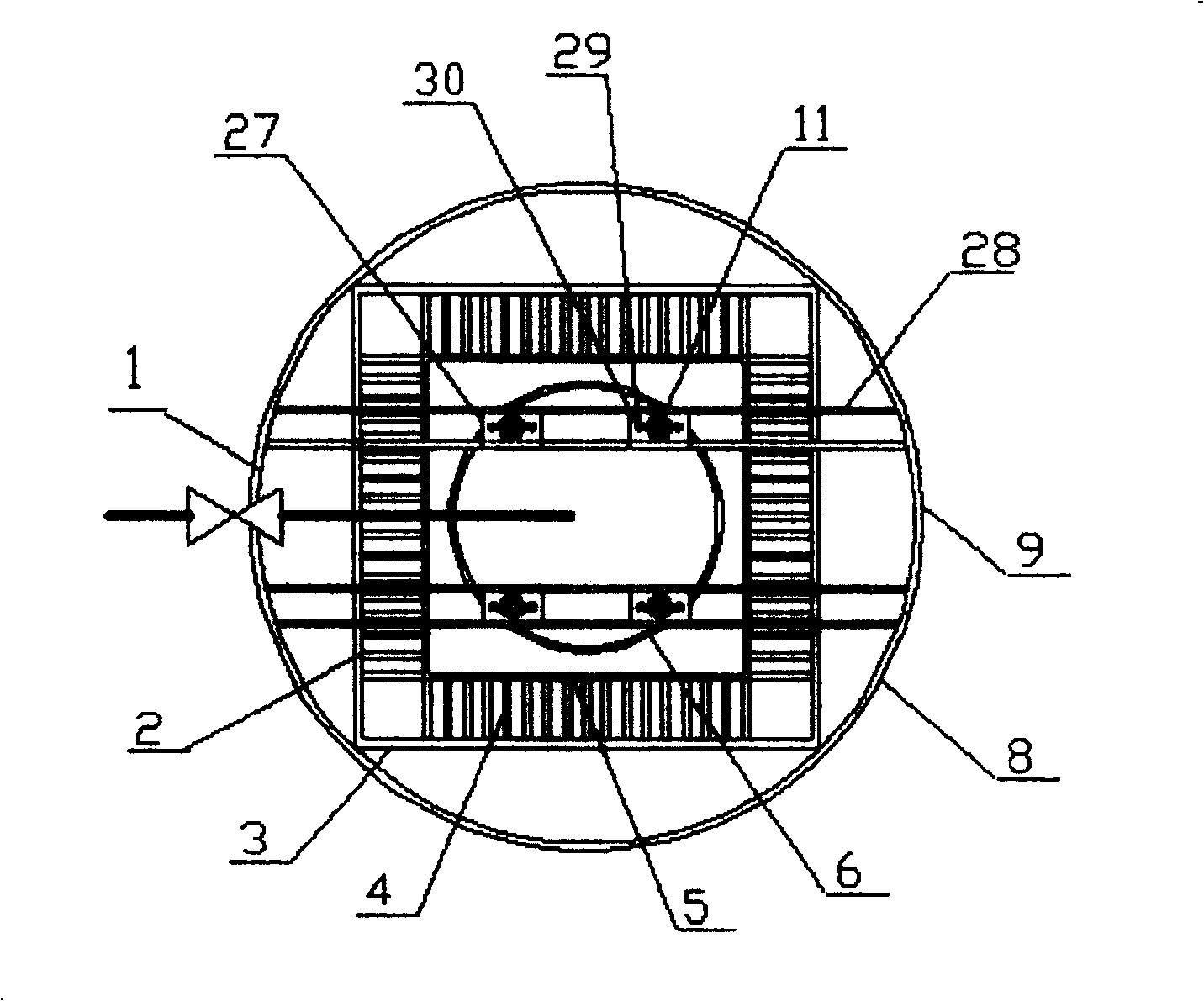

Energy-saving highly-efficient photocatalysis and film filter water treatment system

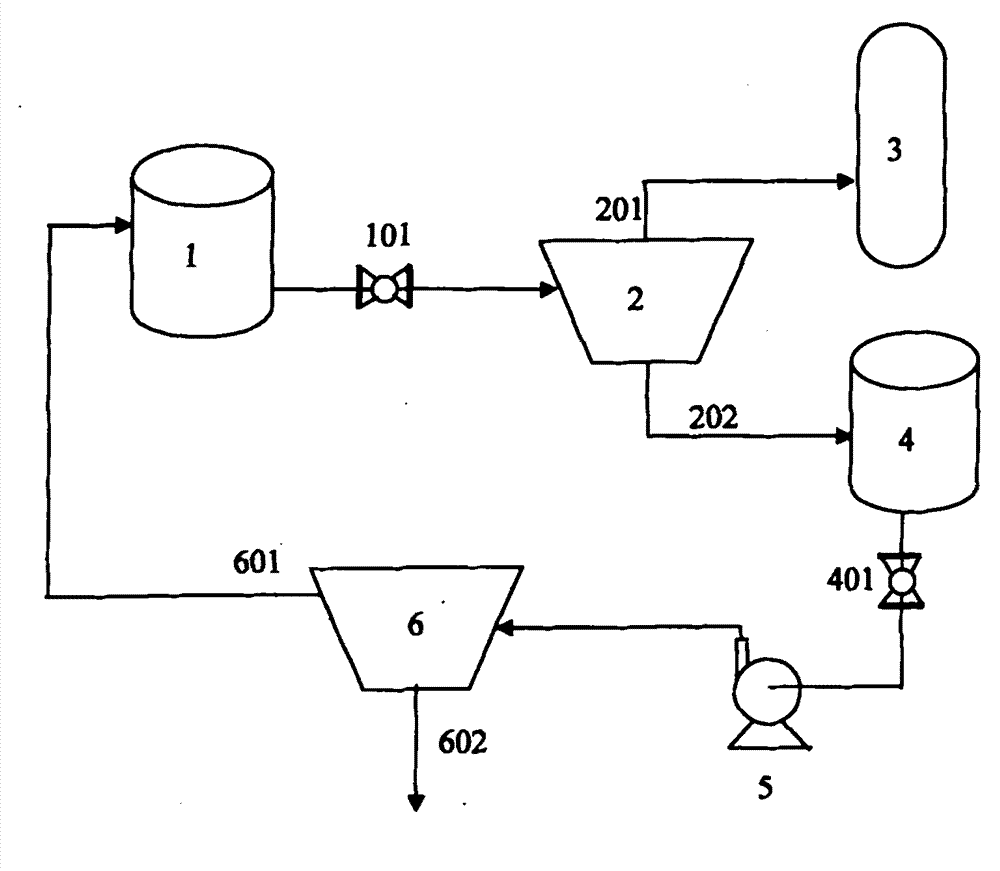

InactiveCN100445213CIncrease contactFully supplementedWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisWater treatment systemWater quality

The invention discloses a water disposing device, which comprises the following parts: photocatalytic water processor (1) with pipe connecting valve sequently, jet pump (13), film separator (18) and ejector (24), wherein the photocatalytic water processor (1) consists of reactor (2) and water collector (8); the cylinder-shaped baffle (6) separates reactor (2) into reacting area and separating area; the case support (25) and baffle support (26) are fixed among spherical closure head (10) of water collector, hopper-shaped closure head (7) of reactor and cylinder-shaped baffle (6); the baffle (5) is set between cylinder-shaped baffle (6) and square case (3); the tipping plate settler (4) is set between baffle (5) and square case (3); the steel rack (28) with ultraviolet lamp (11) is assembled on the top of water collector (8); the outlet pipe of ejector (24) possesses triplet to correlate the flow with inlet pipe on the side.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com