Preparation method of monatomic copper catalyst and application of monatomic copper catalyst in positive electrode of lithium-sulfur battery

A copper catalyst and atomic technology, which is applied in the preparation of single-atom copper catalysts and the application field in the cathode of lithium-sulfur batteries, can solve the problems of low utilization rate of catalysts, and achieve cheap source of raw materials, high sulfur loading, high capacity and cycle. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

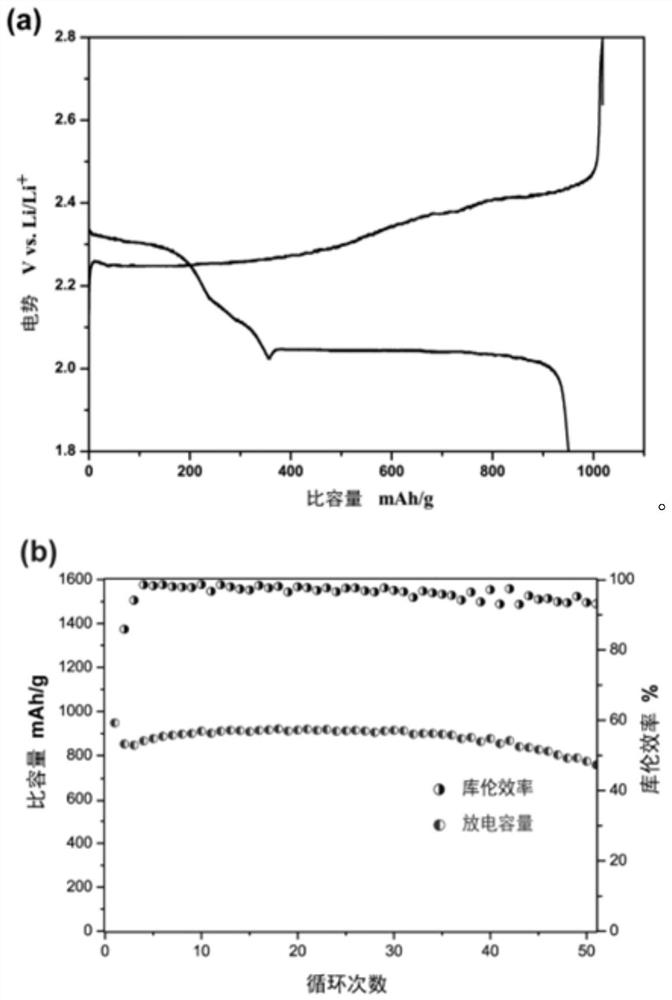

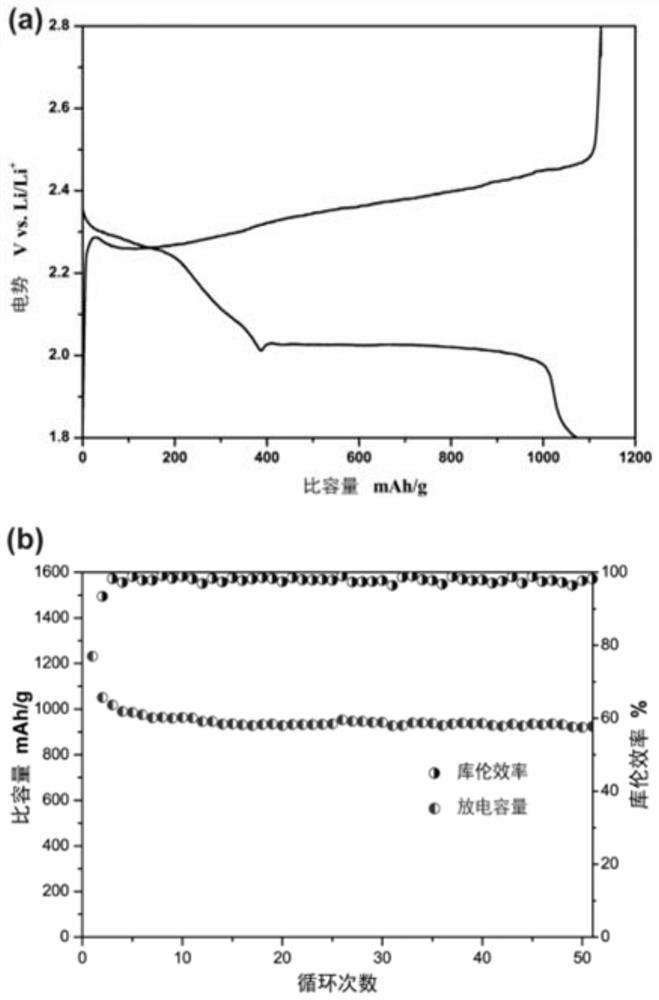

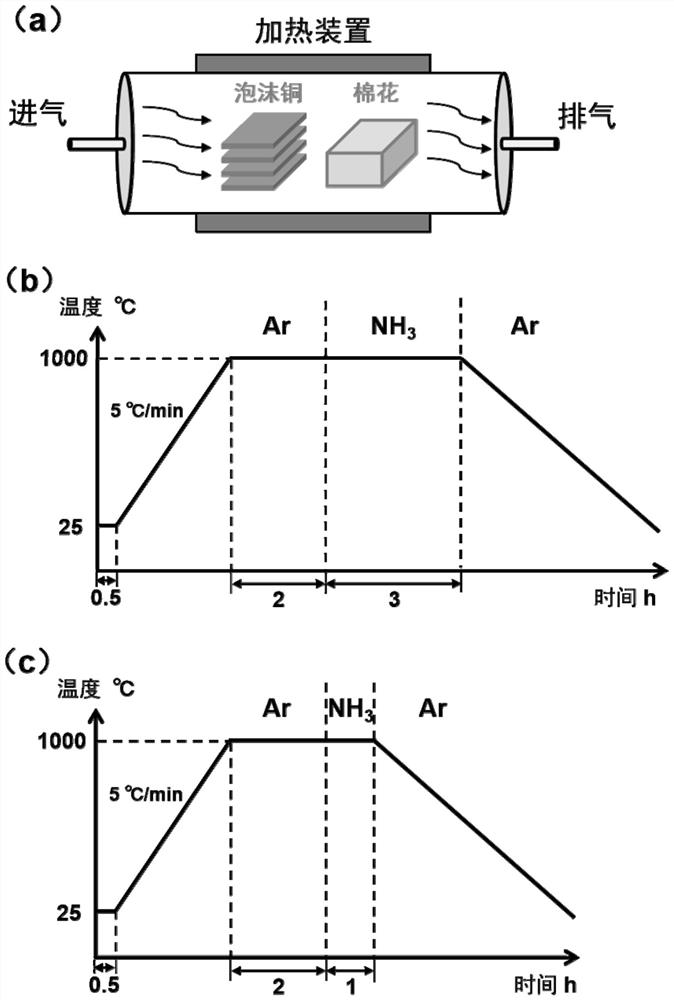

[0045] Example 1 is the preparation of SA-Cu / NCNF and its application in lithium-sulfur battery cathode. The natural cotton is washed successively with 10% dilute hydrochloric acid, distilled water and ethanol, and the washed cotton is dried in an oven at 60°C for 24 hours. Such as image 3 As shown in (a), the dried cotton and copper foam are put into the tube furnace together. Such as image 3 As shown in (c), under argon atmosphere, keep warm at 25°C for 30 minutes, raise the temperature to 1000°C at a rate of 5°C / min, keep warm for 2 hours, switch to ammonia atmosphere, keep warm for 1 hour, and then heat it under argon atmosphere. The furnace was cooled to room temperature, and the SA-Cu / NCNF foam was obtained. Such as Figure 6 As shown, no obvious particles were observed locally in the carbon fiber, but the X-ray energy scattering spectrum showed uniformly dispersed copper signals, and copper was uniformly dispersed in the nitrogen-doped carbon fiber matrix in the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com