Method for reducing catalyst loss in methanol to olefins regeneration system

A technology of methanol to olefins, regeneration system, applied in molecular sieve catalysts, chemical instruments and methods, catalyst regeneration/reactivation and other directions, can solve problems such as large catalyst running loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

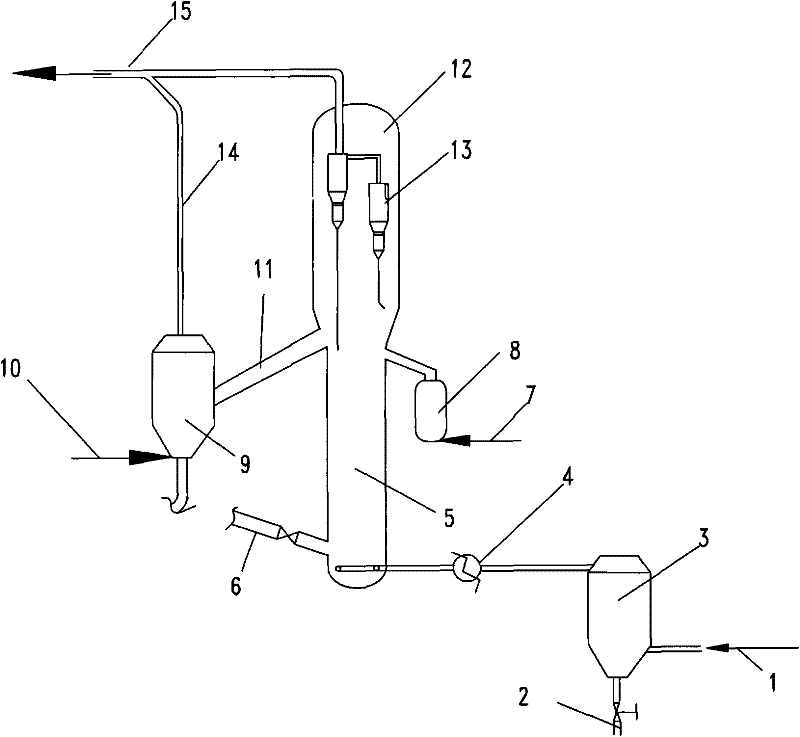

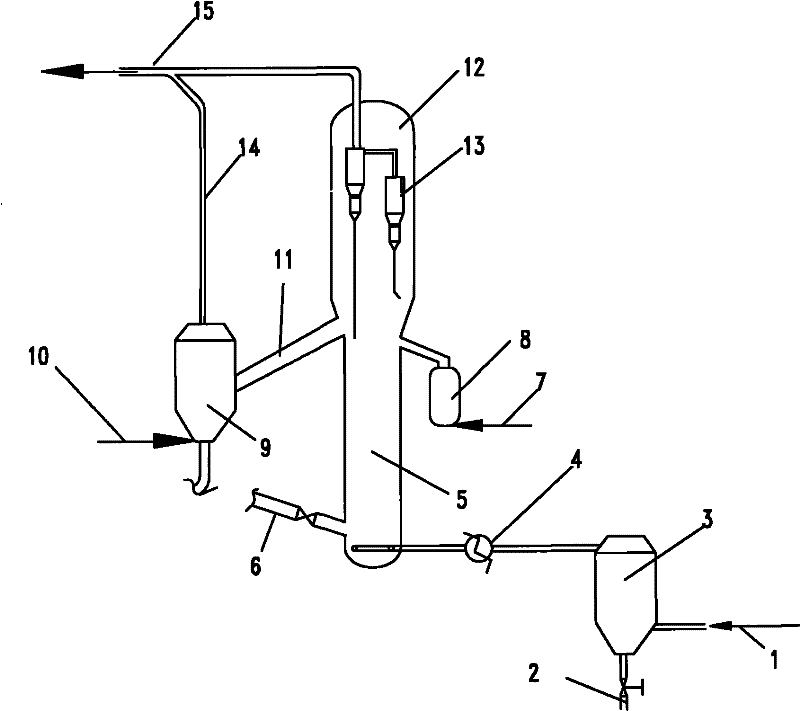

[0017] in such as figure 1 In the regeneration system shown, the catalyst is SAPO-34. After the regeneration air enters the dehydration area of the regeneration medium for dehydration, it enters the regeneration area of the regenerator after being heated to 155°C, and contacts with the carbon-deposited catalyst to generate flue gas and form a regeneration catalyst at the same time. After the flue gas is separated by the gas-solid cyclone separator, it enters the follow-up system through the flue gas pipeline, and the regenerated catalyst enters the degassing area, contacts with water vapor, removes the entrained flue gas and enters the reaction system, and the flue gas removed in the degassing area And the degassing medium enters the flue gas pipeline. The dehydration zone adopts silica gel drying method for dehydration. The carbon deposition mass fraction of the carbon deposition catalyst is 3.8%. A heat extraction zone is set outside the regenerator. The fluidized mediu...

Embodiment 2

[0019] According to the conditions and steps described in Example 1, the regeneration air enters the regeneration zone of the regenerator after being heated to 120° C., the mass fraction of the carbon deposition amount of the carbon deposition catalyst is 4.5%, the regeneration temperature is 685° C., and the regeneration pressure is 0.1 MPa. The linear velocity of the gas phase is 0.8 m / s, the partial pressure of water vapor in the regeneration zone of the regenerator is 19 kPa, and the catalyst content in the flue gas at the outlet of the gas-solid cyclone separator in the regenerator settling zone is 0.38 g / m 3 .

Embodiment 3

[0021] According to the conditions and steps described in Example 1, the regeneration air enters the regeneration area of the regenerator after being heated to 142°C. The regeneration temperature is 630°C, the regeneration pressure is 0.2 MPa, and the gas phase velocity is 0.4 m / s. The partial pressure of water vapor in the area is 8.7 kPa, the mass fraction of carbon deposition in the carbon deposition catalyst is 2.9%, the fluidized medium in the hot area is air, and the dehydration area adopts 13X molecular sieve drying method for dehydration, and the gas-solid cyclone in the regenerator settlement area Catalyst content in flue gas at separator outlet is 0.16 g / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com