Catalyst separation device in furfuryl alcohol producing process and method thereof

A production process and separation device technology, applied in the direction of organic chemistry, can solve the problems of affecting furfuryl alcohol production, long time, waste of resources, etc., achieve the effects of reducing cost and energy consumption, improving product recovery rate, and avoiding blockage of pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

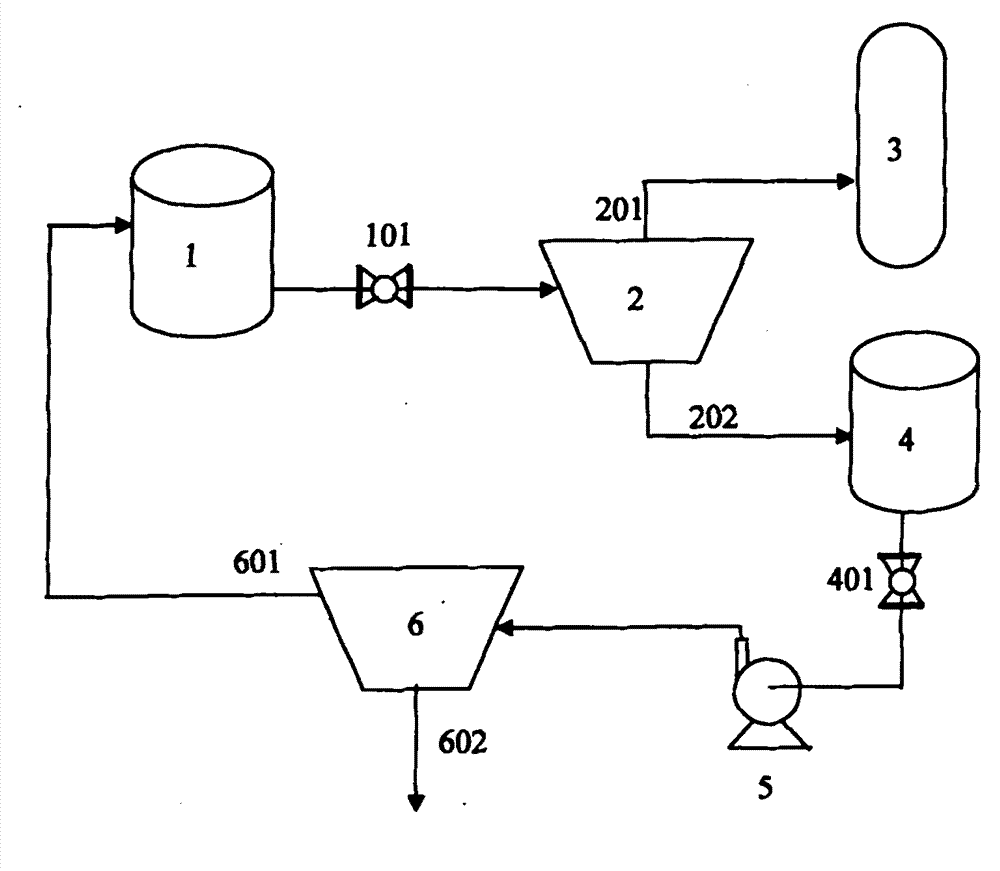

[0023] A catalyst separation device and method in a furfuryl alcohol production process, characterized in that it comprises the following devices and steps:

[0024] The furfuryl alcohol crude product contains the silicone catalyst of 1% (wt) in storage tank 1, and catalyst density is 2.6kg / m 3 , the average particle diameter is 4 μ m, in the production process, open the valve 101 that connects the furfuryl alcohol crude product storage tank 1 and the disc sedimentation centrifuge 2, the crude alcohol in the storage tank 1 enters the sedimentation centrifuge 2 continuously, and the centrifuge separation factor is 6100, After centrifugal separation, the catalyst removal rate can reach more than 95%. Clear liquid enters distillation tower 3 through outlet 201 and is refined, and the volume percent content of liquid in the gained liquid slag is 50%, adopts continuous slag discharge mode to be discharged into liquid slag recovery tank 4 through outlet 202; When the liquid stored i...

Embodiment 2

[0026] The furfuryl alcohol crude product contains the chromium ketone catalyst of 0.7% (wt) in storage tank 1, and catalyst density is 4.49kg / m 3 , with an average particle size of 3 μm. In the production process, open the valve 101 connecting the furfuryl alcohol crude product storage tank 1 and the disc sedimentation centrifuge 2, the crude alcohol in the storage tank 1 enters the sedimentation centrifuge 2 continuously, and the separation factor of the centrifuge is 8300. After centrifugation, the catalyst The removal rate can reach more than 95%. Clear liquid enters distillation tower 3 through outlet 201 and is refined, and the volume percent content of liquid in the gained liquid slag is 40%, adopts continuous slag discharge mode to be discharged into liquid slag recovery tank 4 through outlet 202; When the liquid stored in recovery tank 4 Slag up to 10m 3 When the volume of the recovery tank is 2 / 3, open the valve 401 between the recovery tank 4 and the slag pump 5, ...

Embodiment 3

[0028] The furfuryl alcohol crude product contains the chromium ketone catalyst of 2% (wt) in storage tank 1, and catalyst density is 4.49kg / m 3 , with an average particle size of 3 μm. In the production process, open the valve 101 connecting the furfuryl alcohol crude product storage tank 1 and the disc sedimentation centrifuge 2, the crude alcohol in the storage tank 1 enters the sedimentation centrifuge 2 continuously, and the separation factor of the centrifuge is 5500. After centrifugation, the catalyst The removal rate can reach more than 95%. Clear liquid enters distillation tower 3 through outlet 201 and is refined, and the volume percent content of liquid in the gained liquid slag is 50%, adopts continuous slag discharge mode to be discharged into liquid slag recovery tank 4 through outlet 202; When the liquid stored in recovery tank 4 Slag up to 10m 3 When the volume of the recovery tank is 2 / 3, open the valve 401 between the recovery tank 4 and the slag pump 5, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com