Coal direct liquefaction method and coal direct liquefaction device

A technology of direct coal liquefaction and coal liquefaction, applied in the field of coal chemical industry, can solve the problems of poor oil yield, high gas yield, and low liquefaction conversion rate, so as to improve oil yield, increase hydrogen partial pressure, and reduce residence time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

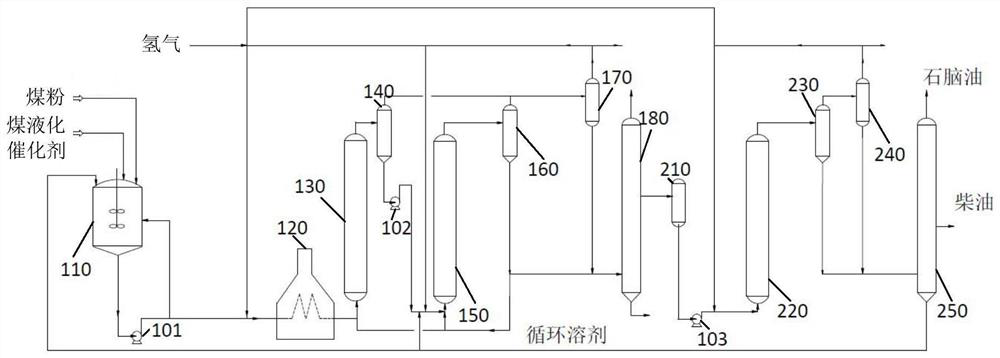

[0047] In the preparation method provided by the present invention, the liquefaction reaction can adopt the reactor commonly used by those skilled in the art. In a preferred embodiment, the first liquefaction reactor 130 and the second liquefaction reactor 150 are independently selected from a forced circulation suspended bed reactor, a bubbling bed reactor, a slurry bed reactor or a reactor with a draft tube The loop reactor, more preferably a forced circulation suspended bed reactor, can ensure the liquid flow rate in the coal liquefaction reactor, reduce the deposition of solids, and realize the long-term stable operation of the device.

[0048] According to the above teaching of the present invention, those skilled in the art can select a specific operating system for directly liquefying coal to prepare liquid fuel. The specific operation process can be as follows:

[0049] The coal is crushed and turned into coal powder, which is dried and mixed with circulating solvent ...

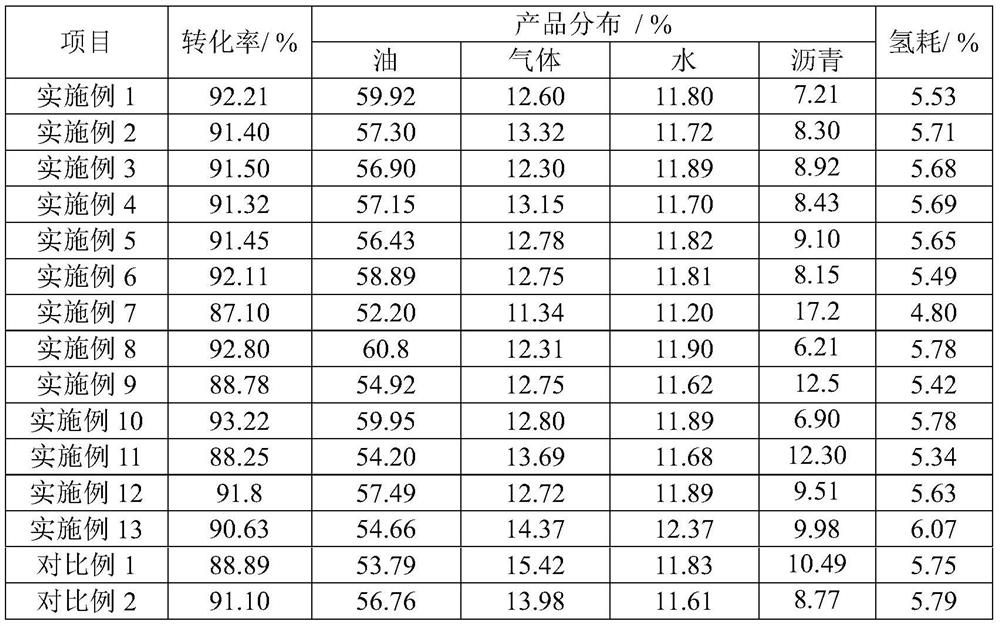

Embodiment 1

[0054] The coal direct liquefaction method provided in this example adopts the coal direct liquefaction continuous test device to carry out the coal liquefaction test. The device adopts two suspended bed reactors with forced circulation, and an intermediate separator is arranged between the reactors. After separation, the liquid and solid phase materials are partly recycled back to the inlet of the first liquefaction reactor. Using Shendong coal as the test raw material coal, the raw material coal, catalyst, and coal liquefaction circulating solvent were mixed in a coal slurry tank to obtain a coal slurry. The basic properties of the raw material coal are shown in Table 1. The above-mentioned direct coal liquefaction method includes the following steps:

[0055] First, the above-mentioned coal slurry and hydrogen enter the first liquefaction reactor (forced circulation suspended bed reactor), and the first liquefied product at the outlet of the first liquefaction reactor enters...

Embodiment 2

[0058] The difference between the direct coal liquefaction method provided in this example and Example 1 is:

[0059] The feed ratio of part of the second liquid phase product to the first raw material is 0.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com