A kind of coal direct liquefaction catalytic additive, preparation method and application thereof

A technology of direct coal liquefaction and additives, applied in the field of coal liquefaction, can solve the problems of catalytic reaction deviation from set reaction conditions, long time to reach the required temperature, uneven heating, etc., achieve simple and cheap preparation method, and reduce occurrence probability , Improve the effect of coal liquefaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

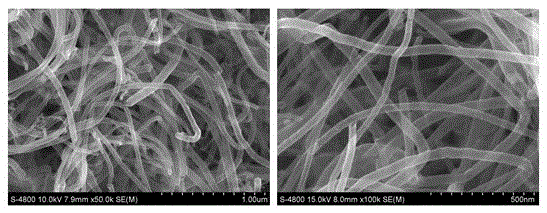

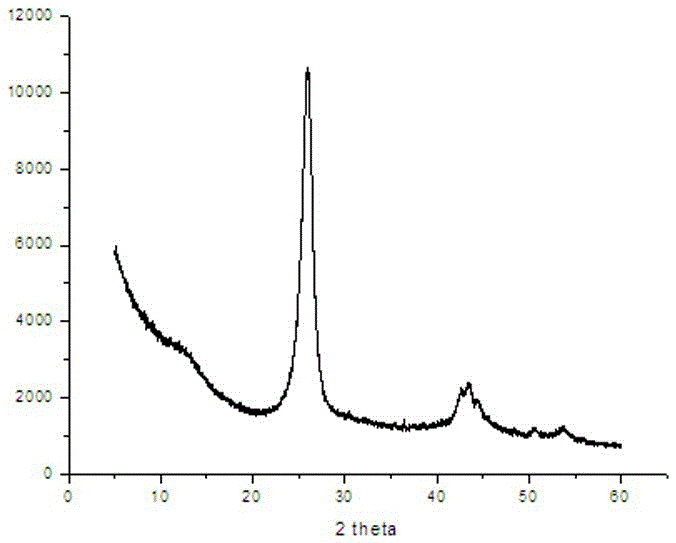

[0031] In this embodiment, first weigh 50gNi(NO 3 ) 2 ·6H 2 O was fully dissolved in 50g of distilled water, and then uniformly impregnated onto 50g of NaY molecular sieves. Then dry it at 105°C for 12 hours, grind it to below 150um, put it into a muffle furnace and bake it at 450°C for 5 hours, and cool naturally to obtain a Ni / NaY catalyst. Put the Ni / NaY catalyst sample into a quartz tube and adjust the nitrogen flow rate to 10 mL min -1 , the tube furnace was heated to 850°C by microwave, and diethylamine gas was introduced at the same time, and the temperature was kept at a constant temperature for 2 hours. After natural cooling, nickel nitrate was loaded on the obtained nitrogen-doped carbon nanotubes CNx by impregnation method, and the nickel nitrate solution was evenly impregnated. in doped carbon nanotubes CNx, then dried in an oven at 100 °C for 24 h, and then in N 2 The Ni / CNx composite catalytic additive was obtained after roasting at 450°C for 4h under protect...

Embodiment 2

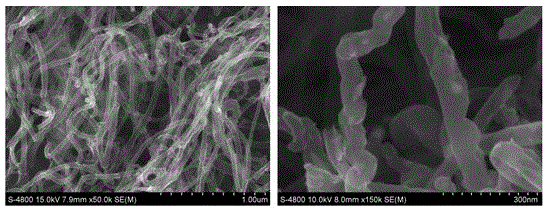

[0037] In this example, the tube furnace was heated to 1000° C. by microwave and kept at a constant temperature for 0.5 h. In addition, the method for preparing the Ni / CNx composite catalytic additive was consistent with Example 1.

[0038] In the hydrogenation reaction, the high-pressure reactor was heated by microwaves at a constant temperature of 400° C. and a hydrogen pressure of 15 MPa for 1 hour. Other than that, other conditions and methods were consistent with those of the hydrogenation reaction in Example 1. Through analysis, in the hydrogenation reaction of this example, the coal liquefaction conversion rate is 86.17%, the gas yield rate is 15.47%, the bitumen yield rate is 13.85%, and the liquefied oil yield rate is 48.46%.

Embodiment 3

[0040] In this embodiment, the organic amine is triethylamine gas. In addition, the method for preparing the Ni / CNx composite catalytic additive is consistent with that in Example 1.

[0041] The amount of Ni / CNx composite catalyst added in the hydrogenation reaction was 0.36g, and the high-pressure reactor was heated by microwave at 400°C and a hydrogen pressure of 15MPa for a constant temperature reaction for 1h. In addition, other conditions and methods were the same as those in the hydrogenation reaction in Example 1. keep consistent. Through analysis, in the hydrogenation reaction of this example, the coal liquefaction conversion rate is 87.28%, the gas yield rate is 13.72%, the bitumen yield rate is 11.12%, and the liquefied oil yield rate is 53.23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com