Method for two-stage catalytic direct liquefaction of coal and application thereof

A direct and catalytic technology, applied in the preparation of liquid hydrocarbon mixtures, bulk chemical production, petroleum industry, etc., can solve the problems of insufficient coal conversion rate and oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

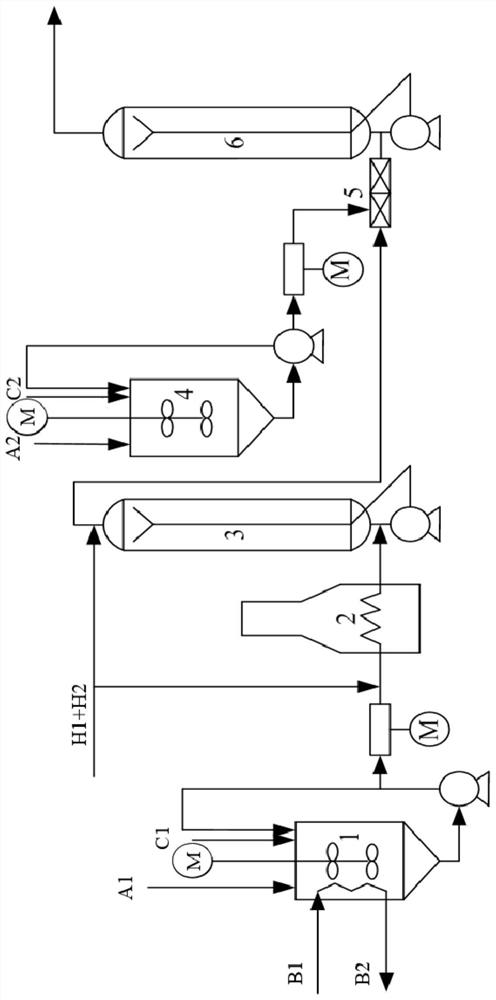

[0111] 1) Stir the first catalyst C1, sulfur powder, coal powder and hydrogen-donating solvent A1 in the coal slurry preparation tank 1, and mix uniformly to prepare a coal slurry, wherein the concentration of the coal slurry is 45% by weight, calculated as iron element , the amount of the first catalyst used is 0.8% by weight of the coal powder, and the molar ratio of the first catalyst in terms of iron element to the sulfur powder in terms of sulfur element is 1:1.5. After mixing evenly, it is preheated to 395°C by the coal slurry preheater 2, and then sent to the first-stage reactor bubbling bed reactor 3 for a stage of liquefaction reaction. 19MPa;

[0112] 2) Homogenously mix the second catalyst C2 with the hydrogen-donating solvent A2 in the catalyst oil slurry homogenization tank 4, and then mix it with the first-stage liquefaction reaction product obtained in step 1) under the action of the static mixer 5, and then introduce the mixture into The second-stage reactor b...

Embodiment 2

[0114] 1) Stir the first catalyst C1, sulfur powder, coal powder and hydrogen-donating solvent A1 in the coal slurry preparation tank 1, and mix uniformly to prepare a coal slurry, wherein the concentration of the coal slurry is 40% by weight, calculated as iron element , the amount of the first catalyst is 0.5% by weight of the coal powder, and the molar ratio of the first catalyst in terms of iron element to the sulfur powder in terms of sulfur element is 1:2.5. After mixing evenly, it is preheated to 385°C by the coal slurry preheater 2, and then sent to the first-stage reactor bubbling bed reactor 3 for a first-stage liquefaction reaction. The temperature of the first-stage liquefaction reaction is 440°C, the time is 30 minutes, and the hydrogen pressure is 20MPa;

[0115] 2) Homogenously mix the second catalyst C2 with the hydrogen-donating solvent A2 in the catalyst oil slurry homogenization tank 4, and then mix it with the first-stage liquefaction reaction product obtai...

Embodiment 3

[0117] 1) Stir the first catalyst C1, sulfur powder, coal powder and hydrogen-donating solvent A1 in the coal slurry preparation tank 1, and mix uniformly to prepare a coal slurry, wherein the concentration of the coal slurry is 50% by weight, calculated as iron element , the amount of the first catalyst is 1.2% by weight of the coal powder, and the molar ratio of the first catalyst in terms of iron element to the sulfur powder in terms of sulfur element is 1:2. After mixing evenly, it is preheated to 399°C by the coal slurry preheater 2, and then sent to the first-stage reactor bubbling bed reactor 3 for a stage of liquefaction reaction. 19MPa;

[0118] 2) Homogenously mix the second catalyst C2 with the hydrogen-donating solvent A2 in the catalyst oil slurry homogenization tank 4, and then mix it with the first-stage liquefaction reaction product obtained in step 1) under the action of the static mixer 5, and then introduce the mixture into Two-stage reactor The two-stage l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com