Coal direct liquefaction catalyst and coal direct liquefaction method

A technology for direct liquefaction of coal and catalyst, which can be used in the preparation of liquid hydrocarbon mixtures, petroleum industry and other directions, and can solve problems such as reduced catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

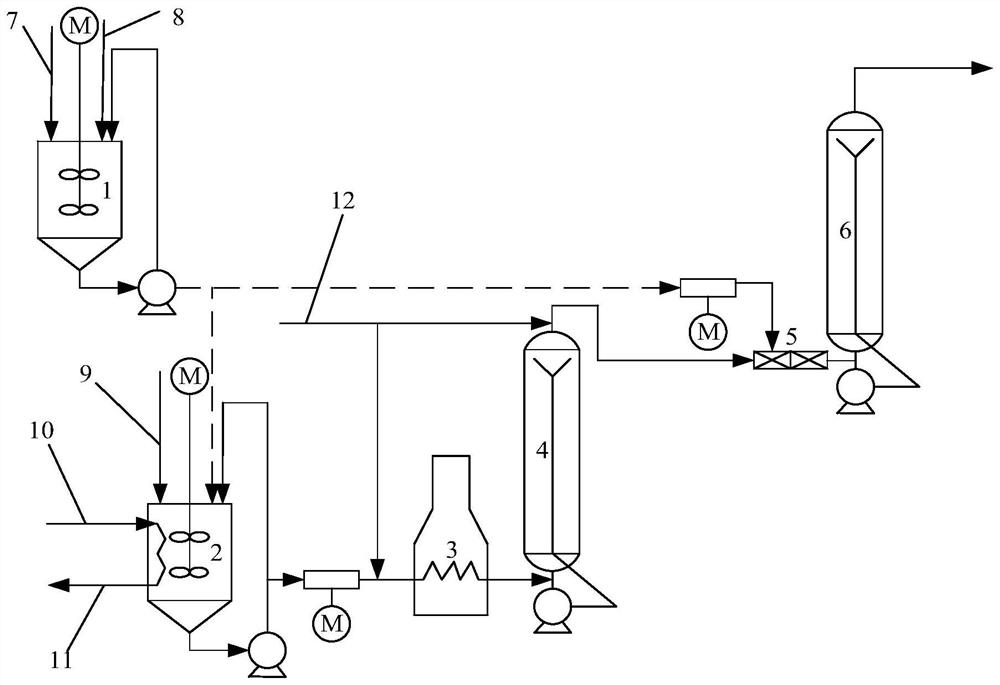

Method used

Image

Examples

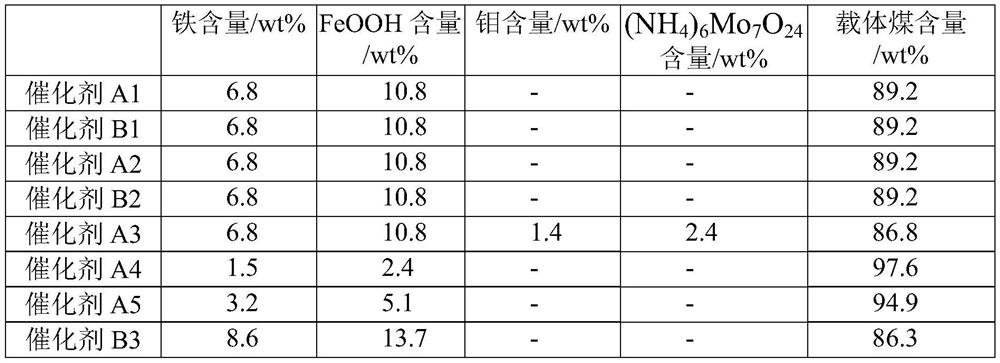

Embodiment 1

[0049] Preparation of coal direct liquefaction catalyst:

[0050] 5.7 parts by weight of FeSO 4 ·7H 2 O dissolved in 46.88 parts by weight of water to obtain FeSO 4 solution, in FeSO 4 Add 15.78 parts by weight of carrier coal (coal sample 2) to the solution and stir evenly to obtain FeSO 4 coal slurry; and

[0051] Dilute 1.27 parts by weight of concentrated ammonia water with 17.38 parts by weight of water to obtain aqueous ammonia solution;

[0052] Under stirring, the above ammonia solution was added to the above FeSO 4 In the coal slurry, adjust the pH to 7.8, continue to stir for 10s after the addition, and then put the above reaction product at 40°C, 3m 3 Oxidation was carried out for 100 min at an air flow rate of / h, and the oxidation product was centrifugally filtered and dried to obtain direct coal liquefaction catalyst A1, whose physical parameters are shown in Table 2.

[0053] Coal direct liquefaction reaction:

[0054] The direct coal liquefaction reacti...

Embodiment 2

[0070] According to the method of Example 1, the difference is: coal sample 3 is used as carrier coal to obtain direct coal liquefaction catalyst A2, and its physical parameters are as shown in Table 2;

[0071] Coal sample 1 is adopted as raw material coal, and the coal direct liquefaction reaction method is the same as embodiment 1;

[0072] The analysis method of coal direct liquefaction products is the same as that in Example 1, and the results are shown in Table 3.

Embodiment 3

[0078] According to the method of embodiment 1, the difference is that ammonium molybdate is added in the preparation process of the direct coal liquefaction catalyst, and the concrete steps are as follows:

[0079] 5.7 parts by weight of FeSO 4 ·7H 2 O and be dissolved in 46.88 parts by weight water to obtain mixed solution, add 15.78 parts by weight carrier coal (coal sample 2) in mixed solution, stir and make coal slurry;

[0080] Dilute 1.27 parts by weight of concentrated ammonia water with 17.38 parts by weight of water to obtain aqueous ammonia solution;

[0081] Under stirring, the above ammonia solution was added to the above FeSO 4 In the coal slurry, adjust the pH to 7.8, continue to stir for 10s after the addition, and then put the above reaction product at 40°C, 3m 3 Oxidation for 100min under the air flow rate per hour, the oxidation product was subjected to centrifugal filtration, impregnated in 2.5 parts by weight of 15% (NH 4 ) 6 Mo 7 o 24 Aqueous solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com