High-efficiency hydrogenation device and dinitrotoluene hydrogenating method

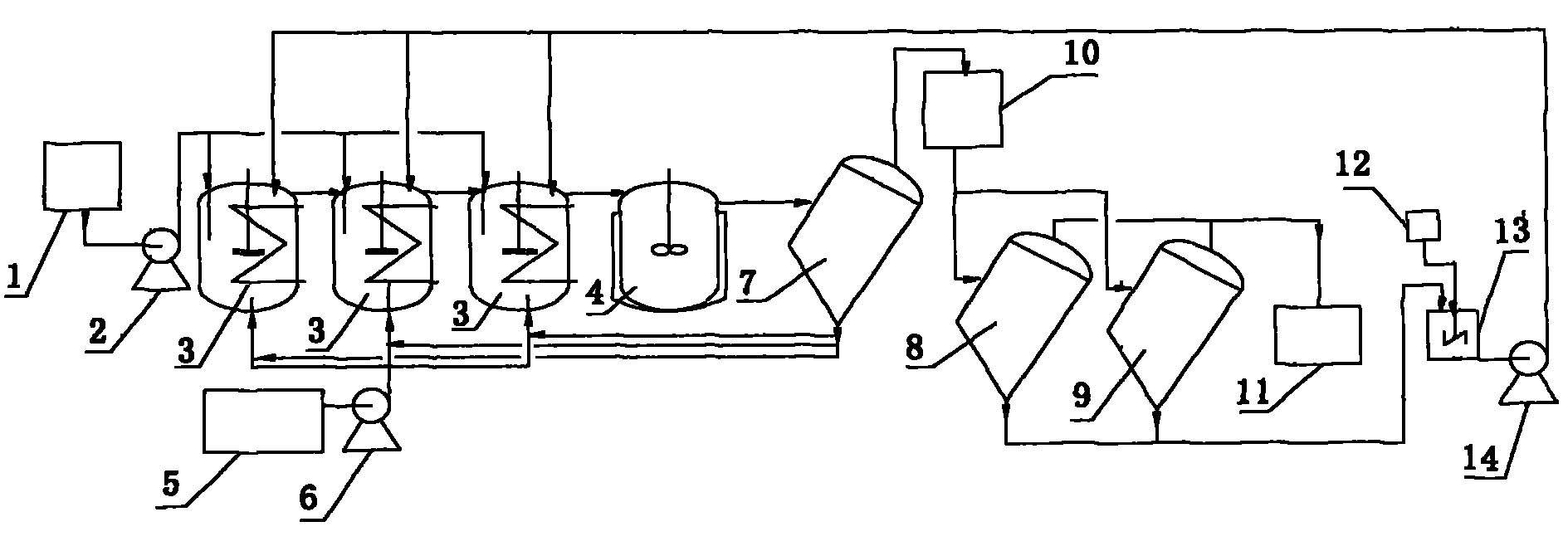

A technology for hydrogenation reaction and hydrogenation reactor, which is applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc., can solve the problems of excessively large stirring motor of the reactor, reducing the reaction volume, frequent mechanical failures, etc. , to achieve the effect of compact structure, reducing reaction volume and small thermal resistance of dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following examples serve to further illustrate the method of the present invention. The spirit and scope of the present invention disclosed above are not limited by these examples. Those skilled in the art will readily appreciate that known variations can be made using the conditions of the following methods.

[0047] preferred embodiment

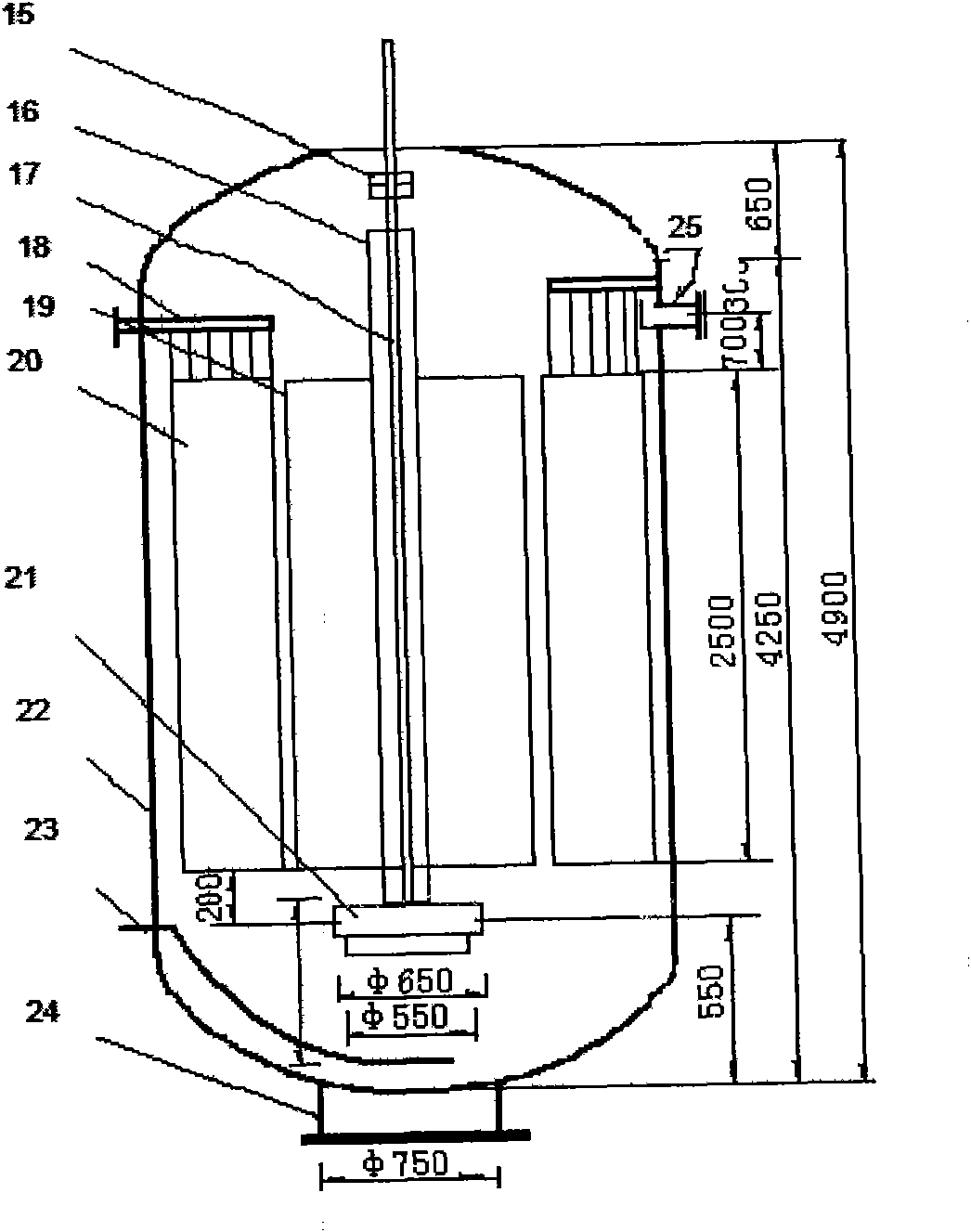

[0048] Hydrogenation reactor:

[0049]①Body: Due to high-pressure equipment, an elliptical head is selected, with a diameter of φ2400mm, a barrel height of 3700mm, a head height of 600mm, a total equipment height of 4900mm, a straight edge height of 50mm, and a head volume of 2.05m 3 , with a height of 4.20mm and a total volume of 18.32m 3 , the effective volume is 14.879m 3 . Shaft sleeve 220mm×4mm, shaft φ110mm / φ60mm, cooling water main inlet pipe φ210mm×5mm, 4 pieces. The lower manhole is φ750mm, and the discharge pipe is φ230mm×40mm.

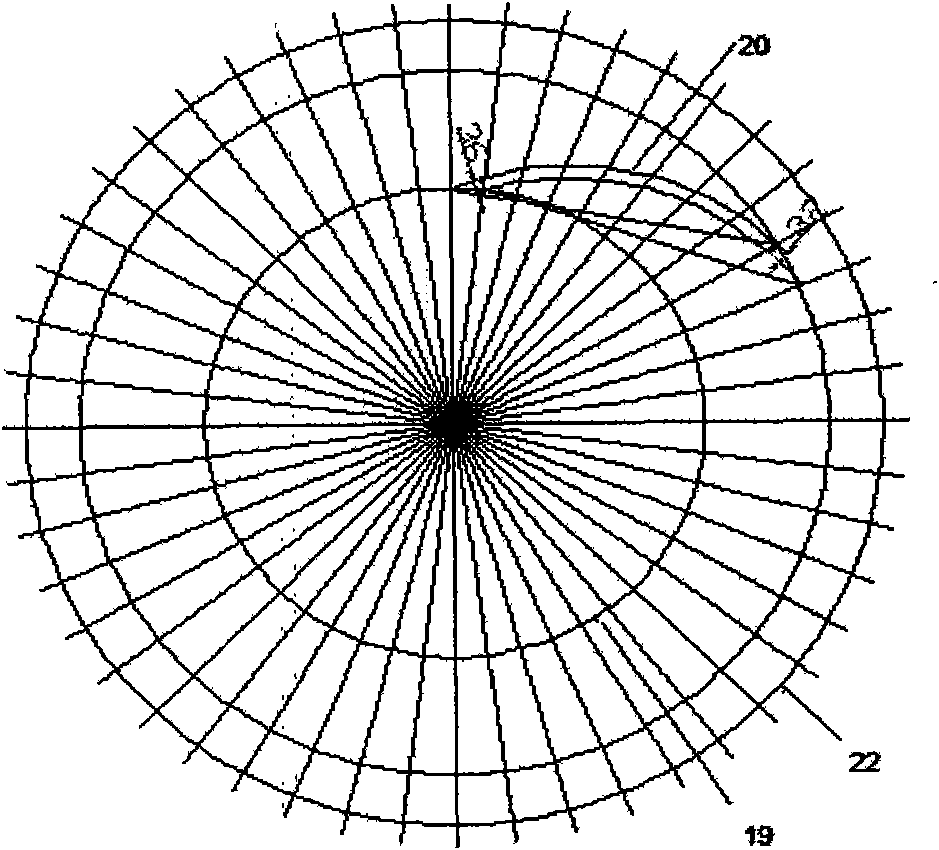

[0050] ②Plate cooler: curved plate, width 940mm, height 2500mm, thickness 14mm, arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com