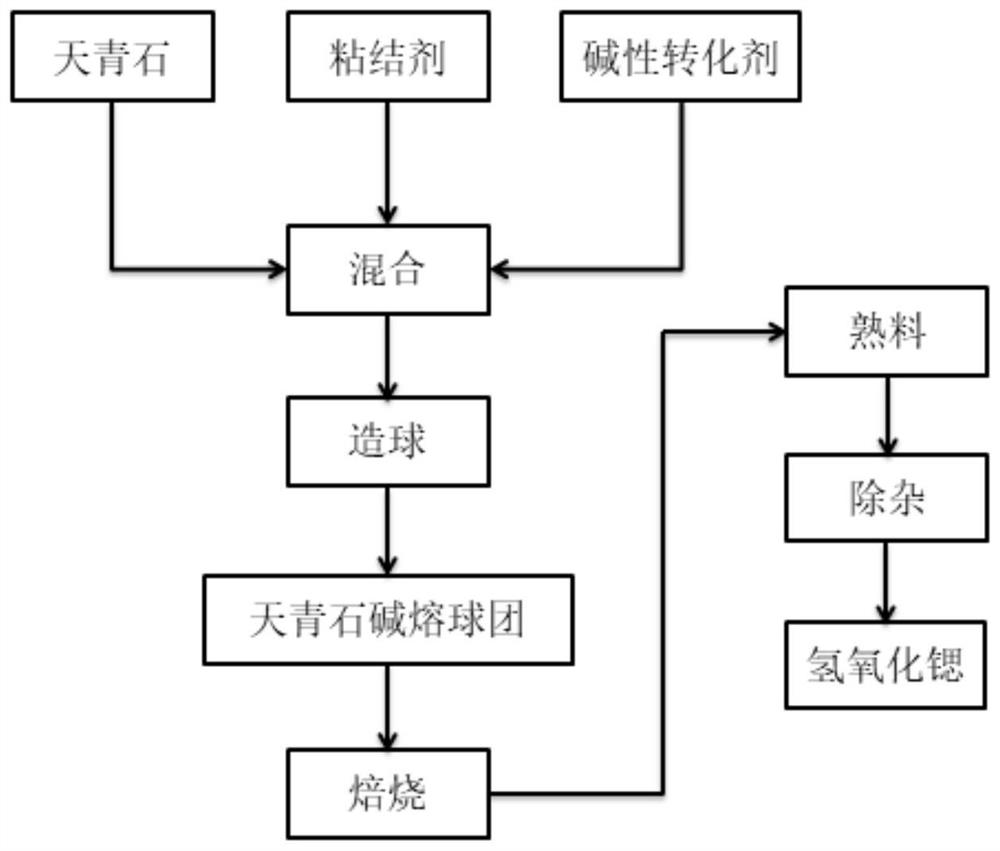

Method for preparing strontium hydroxide through celestite alkali fusion roasting

A technology of strontium hydroxide and celestite, which is applied in the direction of calcium/strontium/barium oxide/hydroxide, the improvement of process efficiency, etc., can solve the problems of high calcination temperature, cumbersome preparation method, large energy consumption, etc. The effect of shortening the process, reducing the diffusion resistance, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present embodiment provides a method for preparing strontium hydroxide by alkali fusion roasting of celestite, the method comprising the following steps:

[0037] (1) mix 65wt% celestite, 33wt% sodium hydroxide and 2wt% starch according to mass ratio to make pellets;

[0038] (2) calcining the pellets in step (1) at 400° C. for 120 min under air, and then performing leaching, filtration and recrystallization in sequence to obtain strontium hydroxide, and the flow rate of the air is 15 mL / min.

Embodiment 2

[0040] The present embodiment provides a method for preparing strontium hydroxide by alkali fusion roasting of celestite, the method comprising the following steps:

[0041] (1) mix 54wt% celestite, 41wt% potassium hydroxide and 5wt% cellulose according to mass ratio to make pellets;

[0042] (2) calcining the pellets described in step (1) at 300° C. for 60 min under nitrogen, and then sequentially performing leaching, filtration and recrystallization to obtain strontium hydroxide, and the flow rate of the nitrogen is 50 mL / min.

Embodiment 3

[0044] The present embodiment provides a method for preparing strontium hydroxide by alkali fusion roasting of celestite, the method comprising the following steps:

[0045] (1) mix 33wt% lapis lazuli, 64wt% lithium hydroxide and 3wt% water glass according to mass ratio to make pellets;

[0046] (2) calcining the pellets described in step (1) at 500° C. for 60 min under nitrogen, and then sequentially performing leaching, filtration and recrystallization to obtain strontium hydroxide, and the flow rate of the nitrogen is 500 mL / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com