Energy-saving highly-efficient photocatalysis and film filter water treatment system

A water treatment device and photocatalytic technology, applied in the direction of light water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as high operating costs, accelerated membrane fouling, and affecting the degradation efficiency of organic matter , to achieve the effect of prolonging the backwash cycle, stable system operation and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

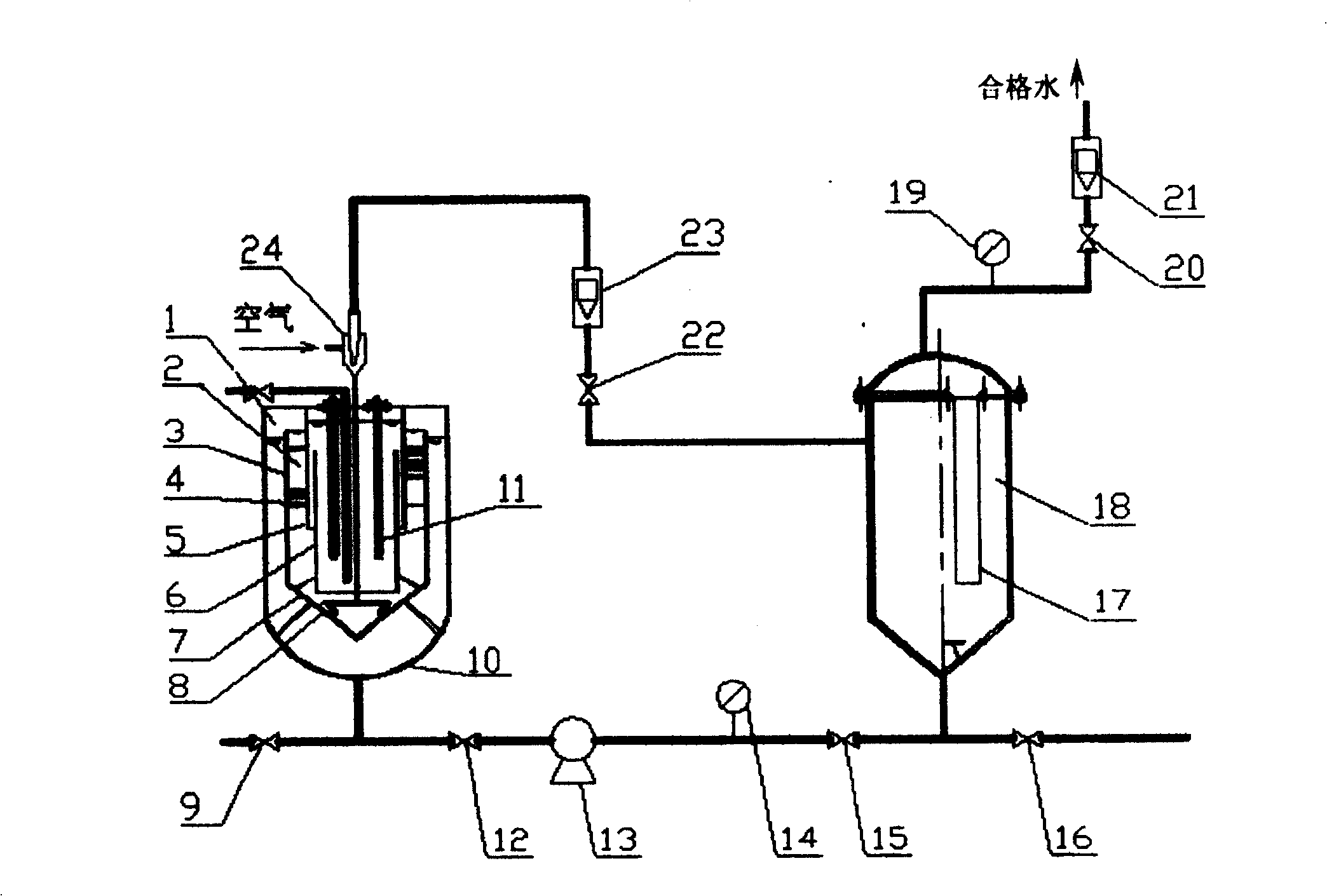

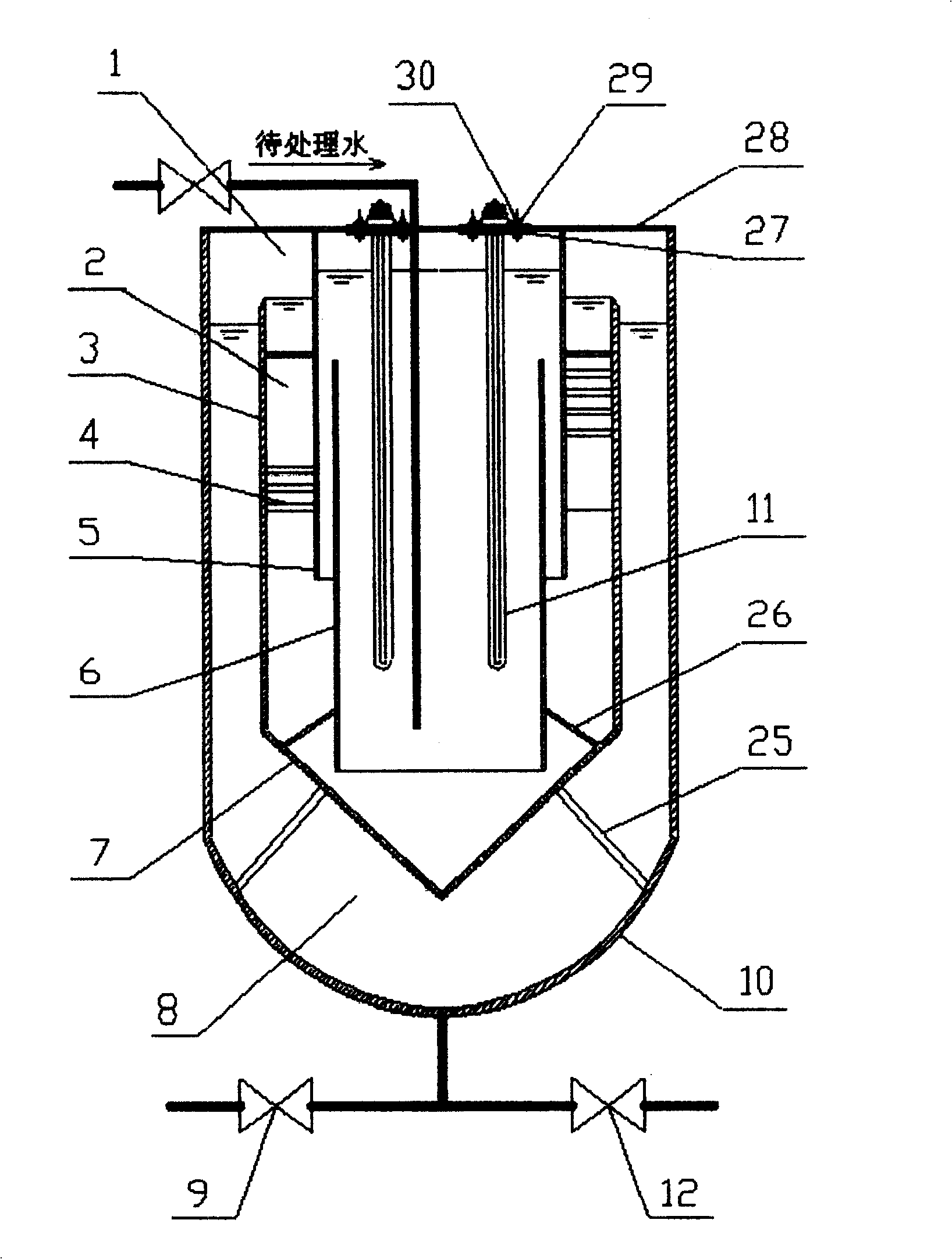

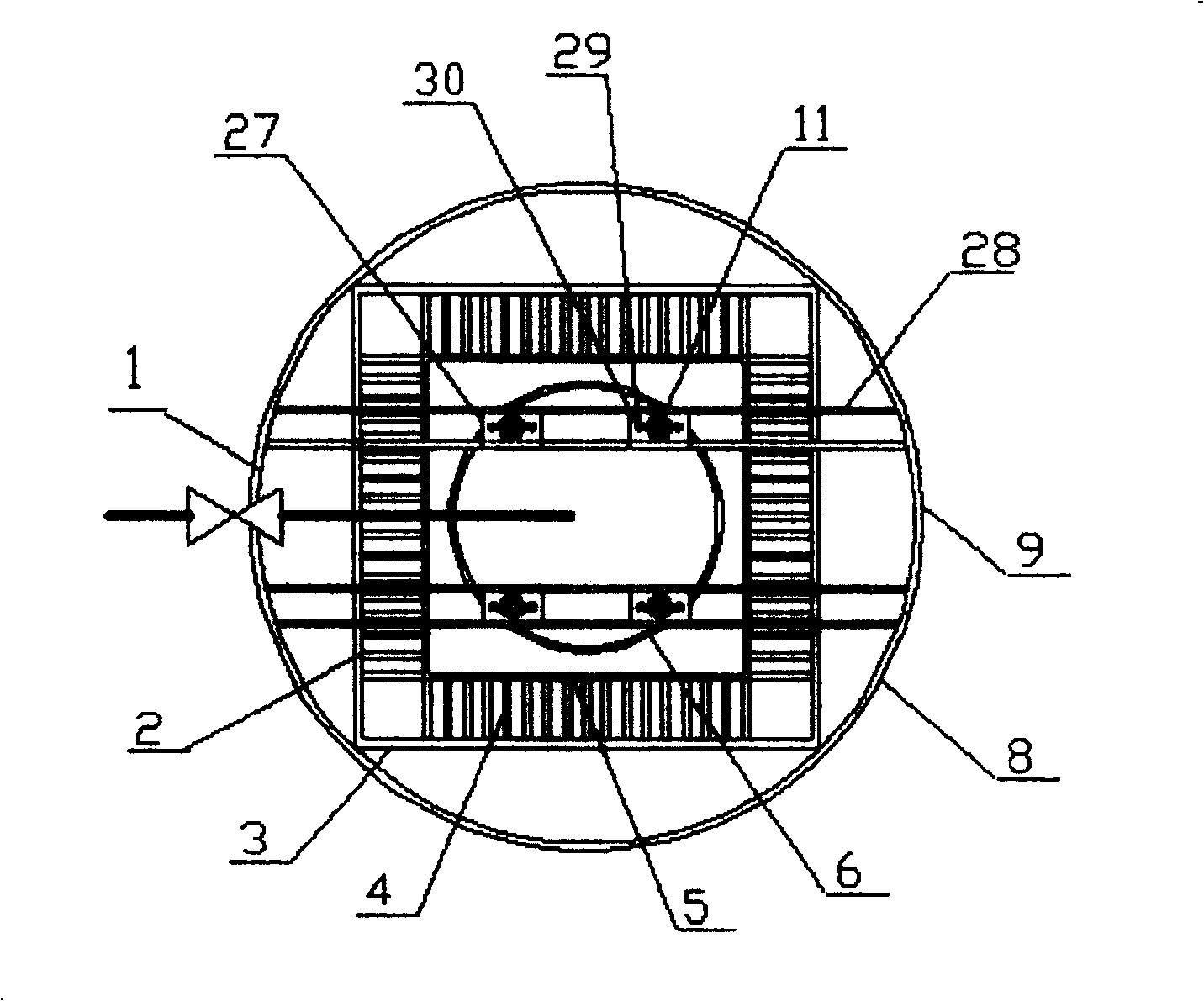

[0017] see figure 1 , 2 and 3.

[0018] The present invention includes a photocatalytic water processor 1 , a fluidizer 24 and a membrane separator 18 . A jet pump 13 is connected between the photocatalytic water processor 1 and the membrane separator 18 through a pipeline, and a water inlet control valve 15 is installed between the jet pump 13 and the membrane separator 18, and a pre-membrane pressure gauge is installed in front of the water inlet control valve 15 14; The top of the membrane separator 18 is also connected to the treated qualified water outlet valve 20, the pressure gauge 19 behind the membrane is installed before the qualified water outlet valve 20, and the qualified water flow meter 21 is installed afterwards; the upper part of the membrane separator 18 is controlled by the backflow water The valve 22 is connected to the water inlet of the ejector 24, and the return water flow meter 23 is provided behind the return water control valve 22; The tee, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com