Slurry bed reactor and reaction system used for Fischer-Tropsch synthesis

A Fischer-Tropsch synthesis and reaction system technology, which is used in the preparation of liquid hydrocarbon mixtures, chemical instruments and methods, chemical/physical processes, etc. Improve the effect of gas-liquid-solid mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

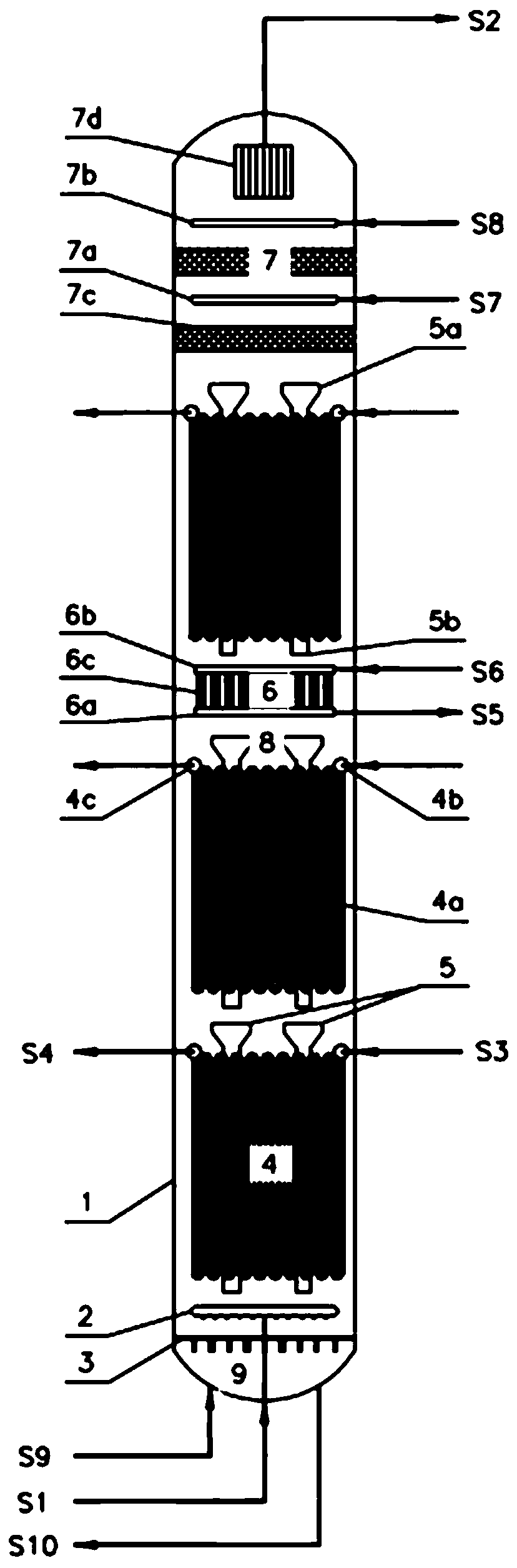

[0053] A slurry bed reactor for Fischer-Tropsch synthesis, its structure is as figure 1 As shown, it includes a reactor main body 1, a gas distributor 2 arranged at the bottom of the reactor main body 1, several groups of heat transfer devices 4 arranged in the reactor main body 1 and a downcomer 5 matched with the heat transfer device 4, two A liquid-solid separation device 6 is provided between the heat removal devices 4, and a gas-solid washing and separation device 7 is provided on the top of the reactor main body 1.

[0054] The reactor main body 1 is a vertical pressure vessel. A false bottom 3 is provided between the bottom head connected to the bottom of the reactor main body 1 and the gas distributor 2. The false bottom 3 is a circular partition and forms and reacts with the bottom head. The false bottom area 9 is isolated from each other, and the pressure charging pipe S9 and the balance pipe S10 are arranged between the false bottom area 9 and the outlet of the reac...

Embodiment 2

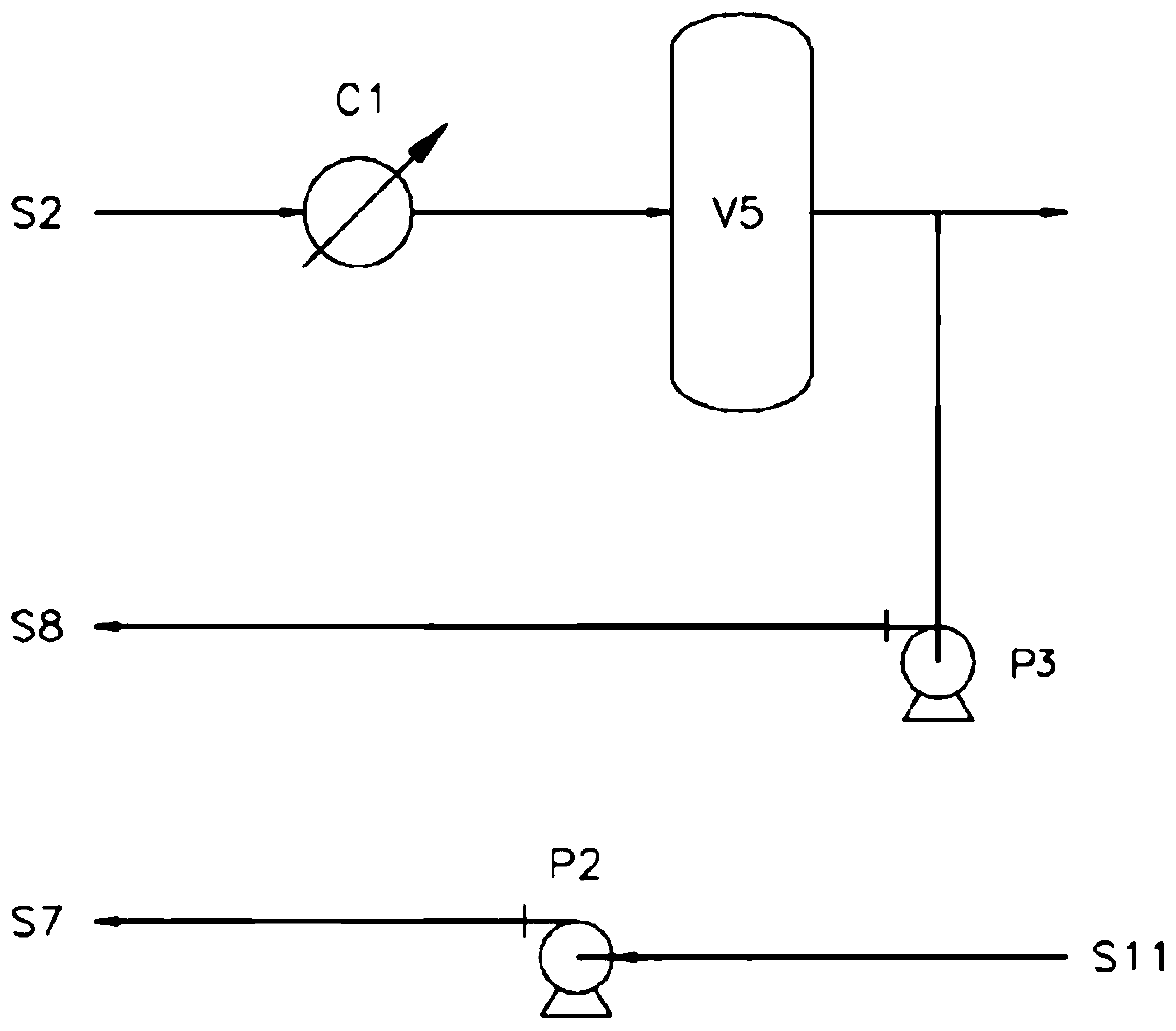

[0062] The slurry bed reaction system for Fischer-Tropsch synthesis is roughly the same as in Example 1, except that the flushing component in this embodiment is a gas flushing component, and the flushing wax collection tank and the flushing wax tank used are both high-pressure gas storage tank, and the flushing gas in the high-pressure gas storage tank is synthetic gas or inert gas.

Embodiment 3

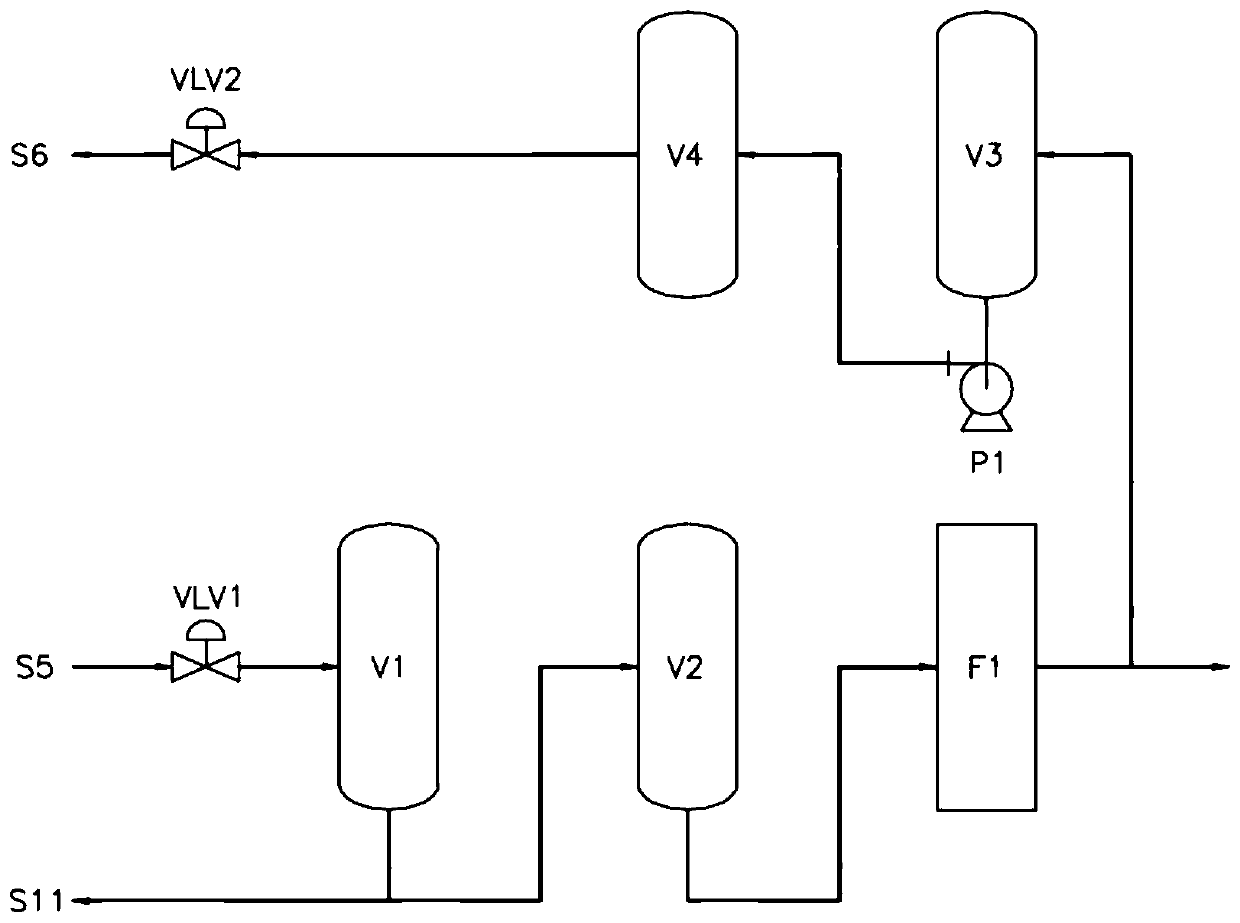

[0064] The technical solution in this embodiment includes figure 1 The slurry bed reactor shown, figure 2 filter-flush assembly shown and image 3 Wash components shown. The reactor has a tangential height of 45 m and an inner diameter of 0.52 m. Reaction zone 8 is filled with Fischer-Tropsch precipitated iron catalyst, and the gas volume of feed synthesis gas S1 is 320,000Nm 3 / h, where the ratio of hydrogen to carbon in the synthesis gas from the gas production unit is 2:1. The operating pressure of the reaction zone 8 is 2.3MPaG, and the operating temperature is 240°C. The output of Fischer-Tropsch wax is 4.8t / h, and the catalyst content in the mined Fischer-Tropsch wax S5 is 80ppm, and the catalyst content in the Fischer-Tropsch wax filtered out by filter F1 is <5ppm. The gas product condensate is 7.0t / h, and the catalyst content is <5ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com