Patents

Literature

36results about How to "Guaranteed heat transfer area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

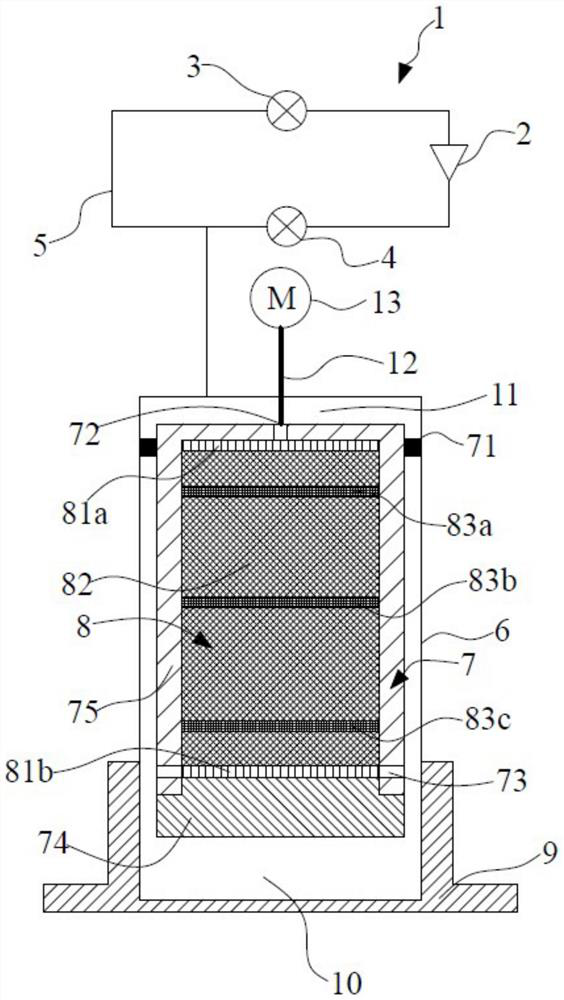

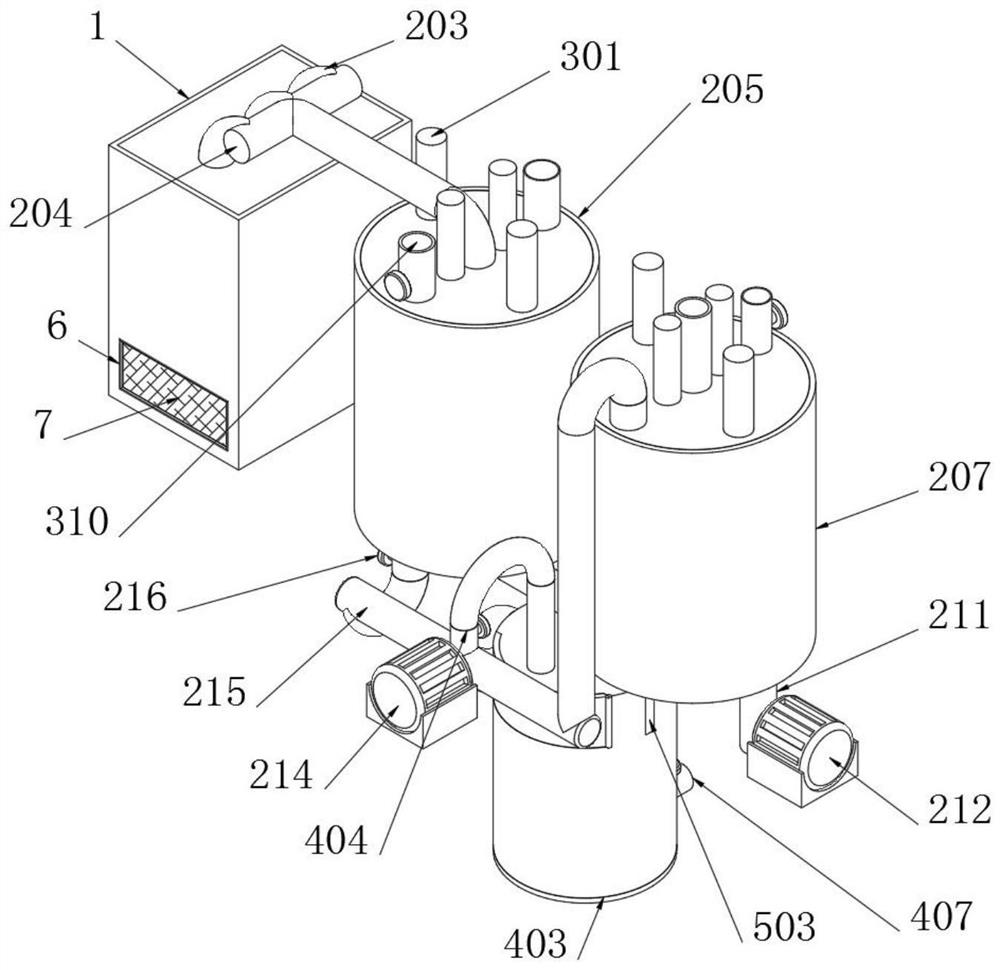

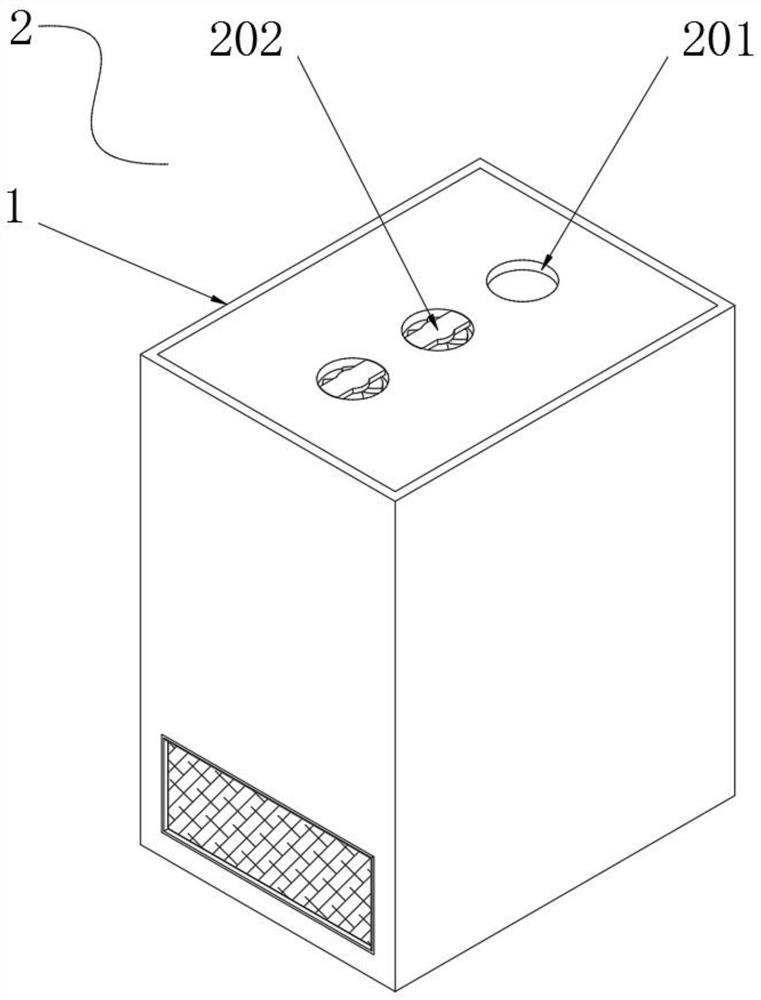

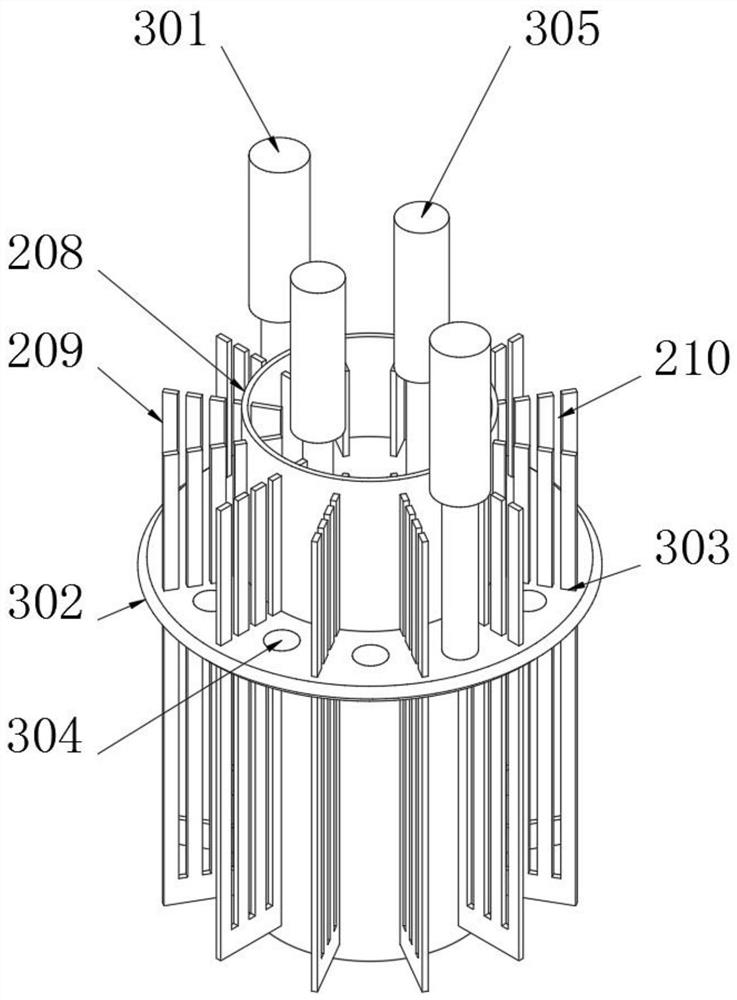

Direct type soil source heat pump system

InactiveCN101236030AGuaranteed heat transfer areaReduce heat transfer areaHeat pumpsCompression machines with reversible cycleVapor–liquid separatorProcess engineering

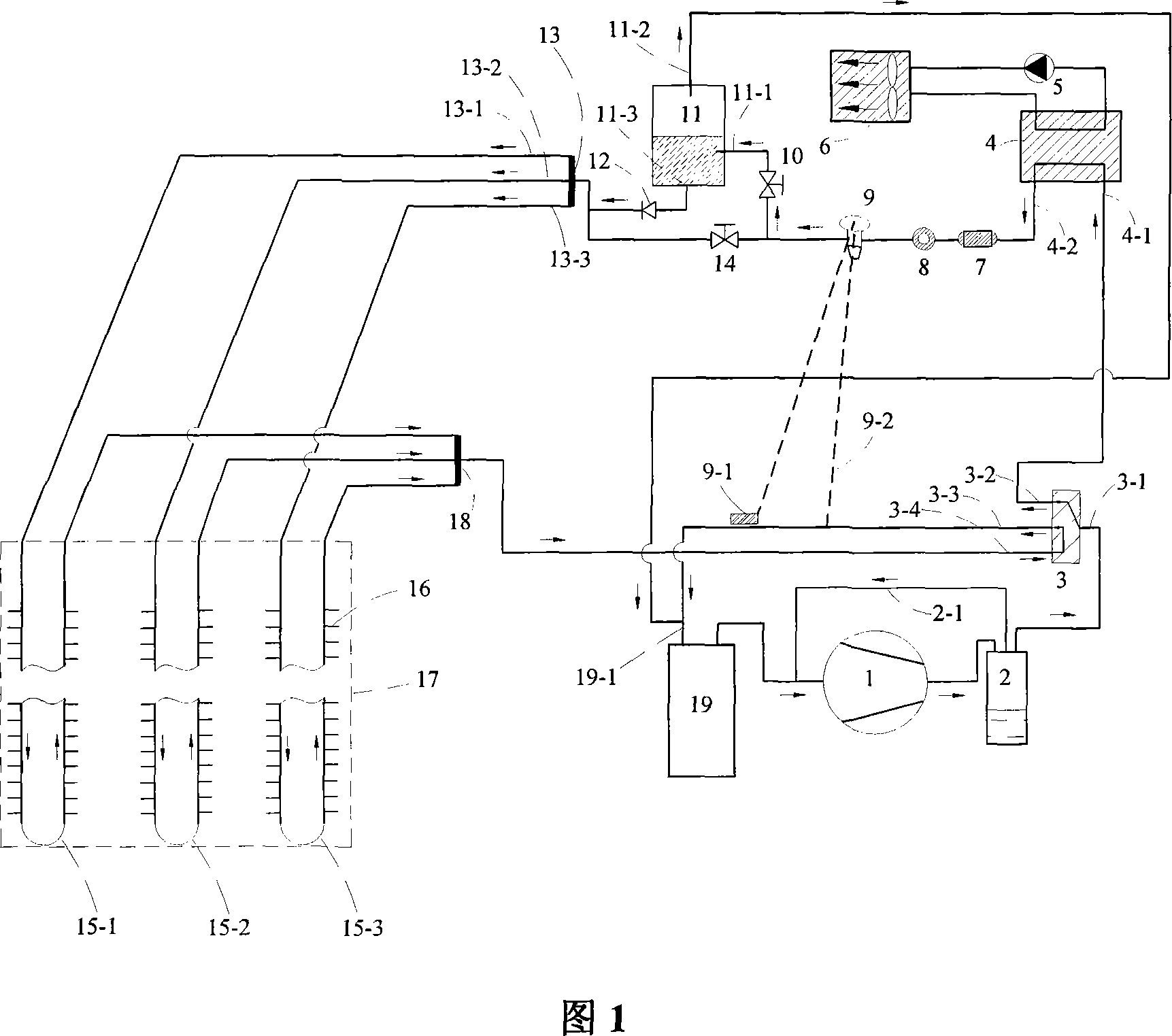

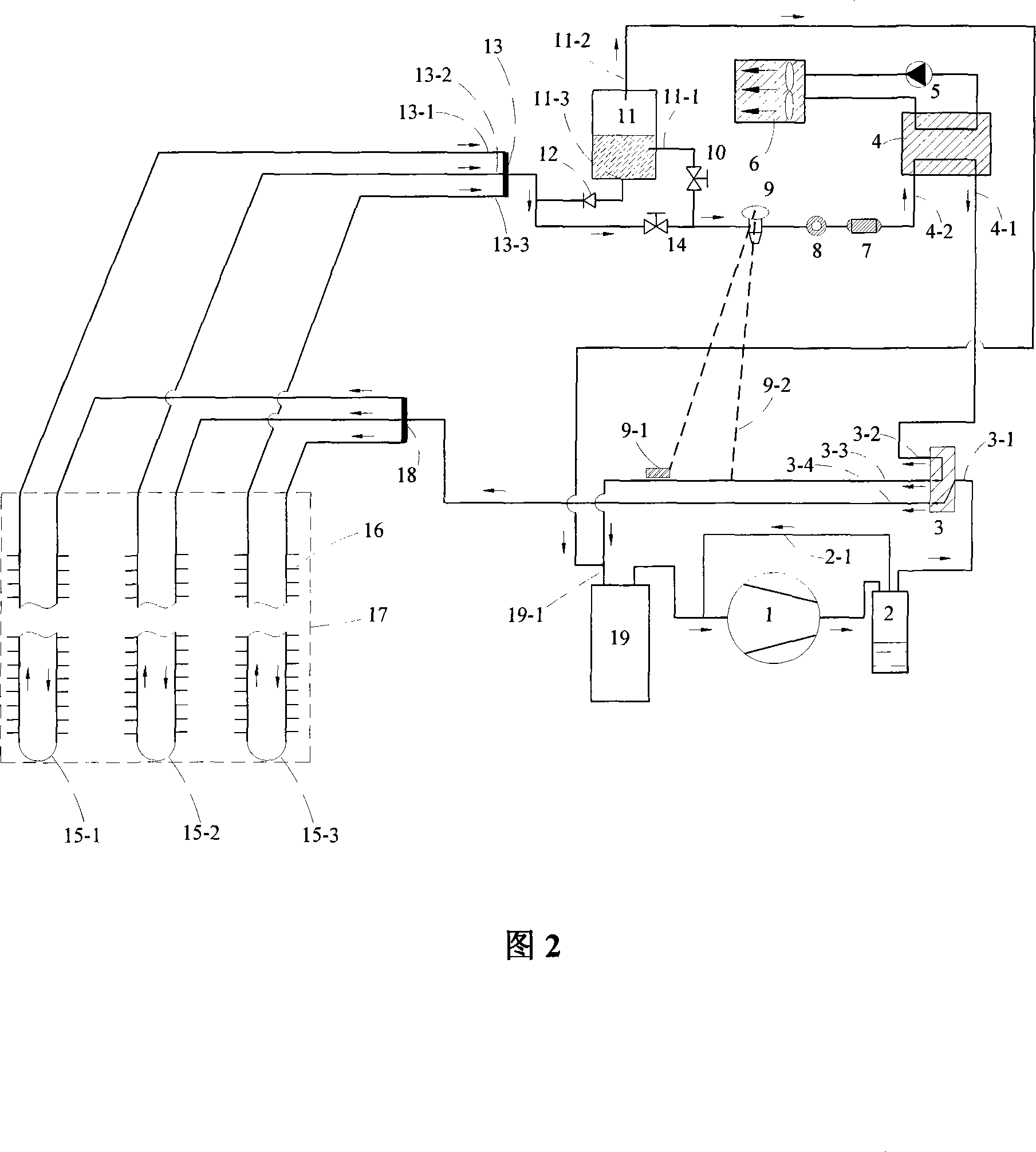

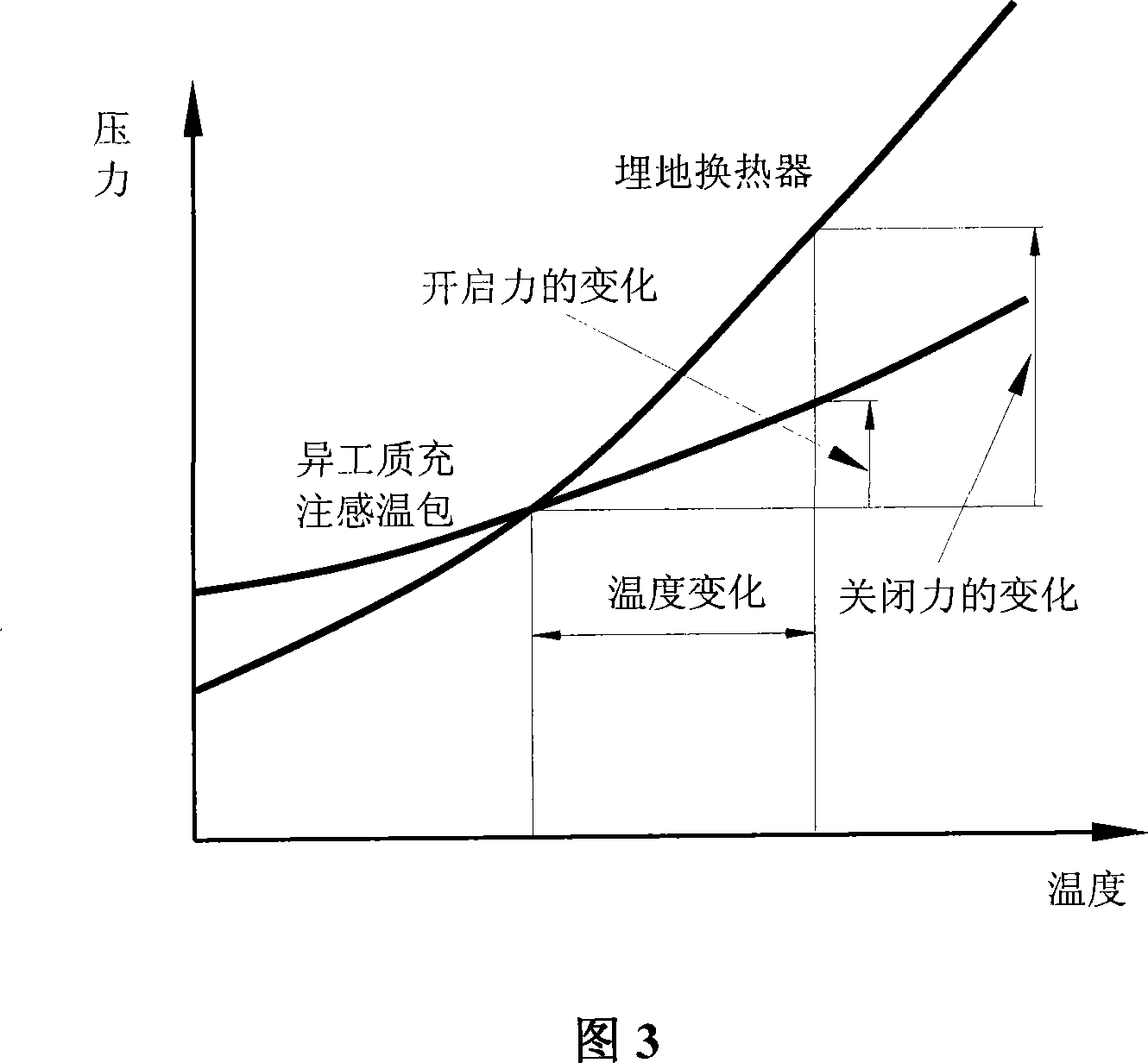

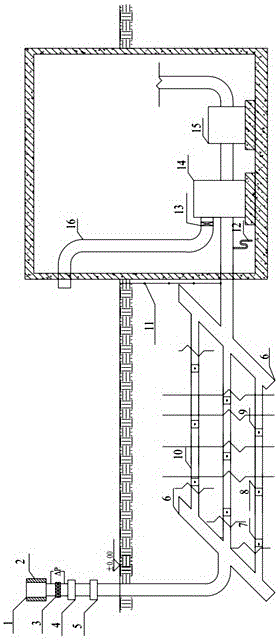

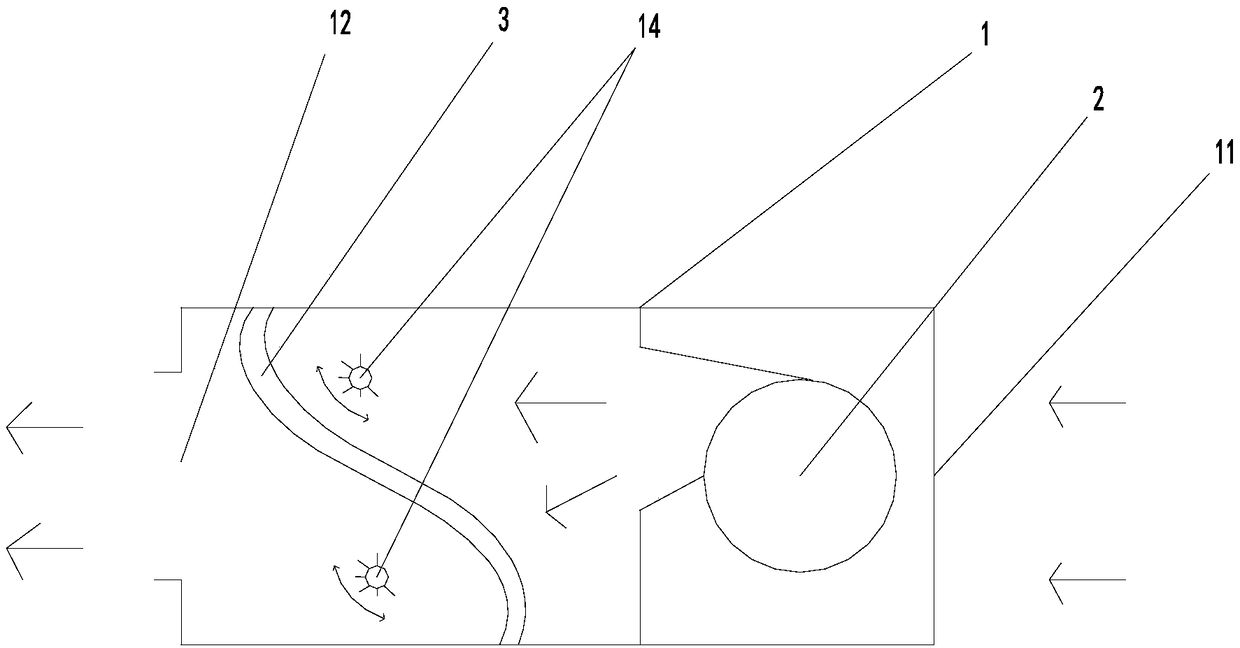

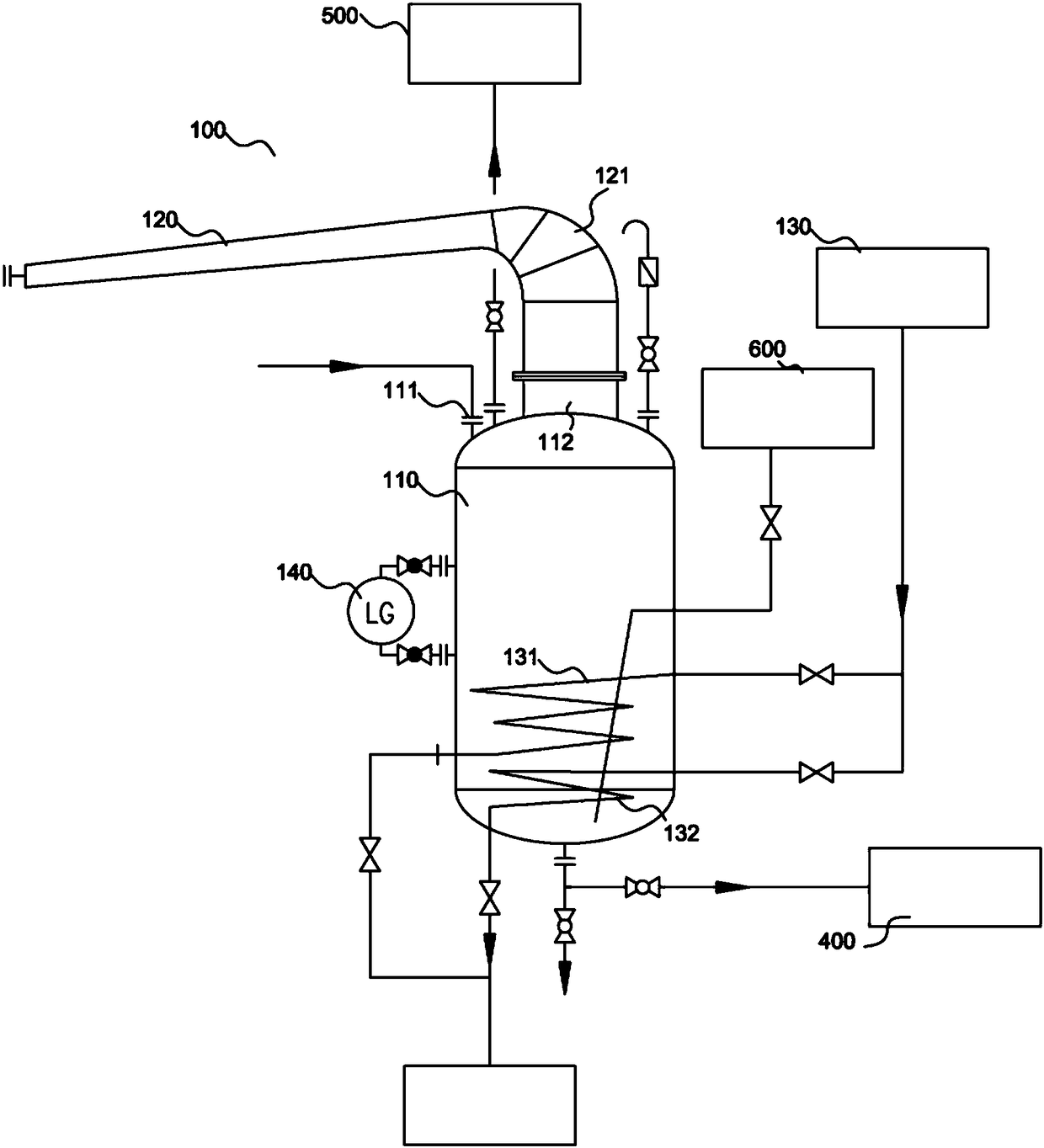

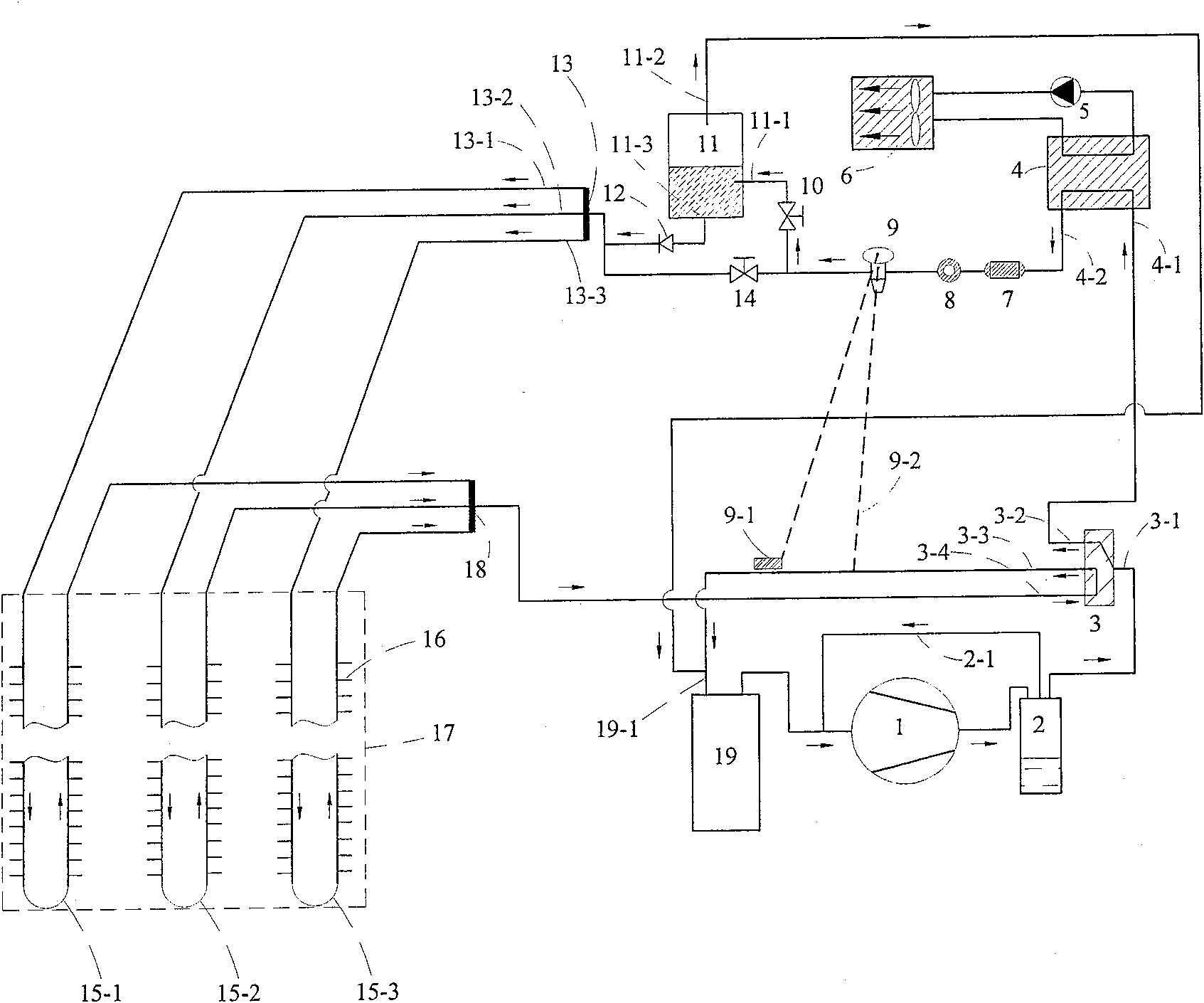

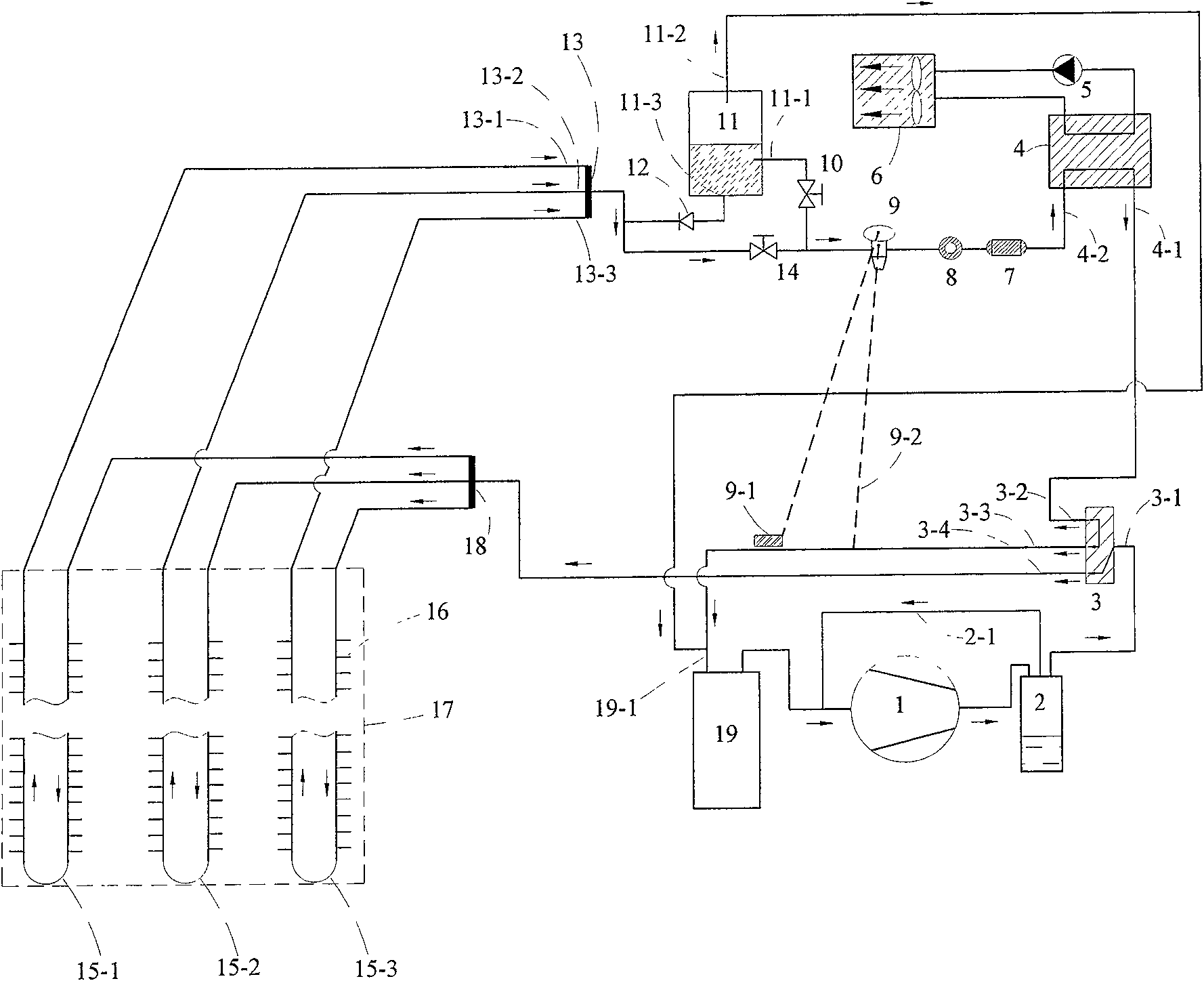

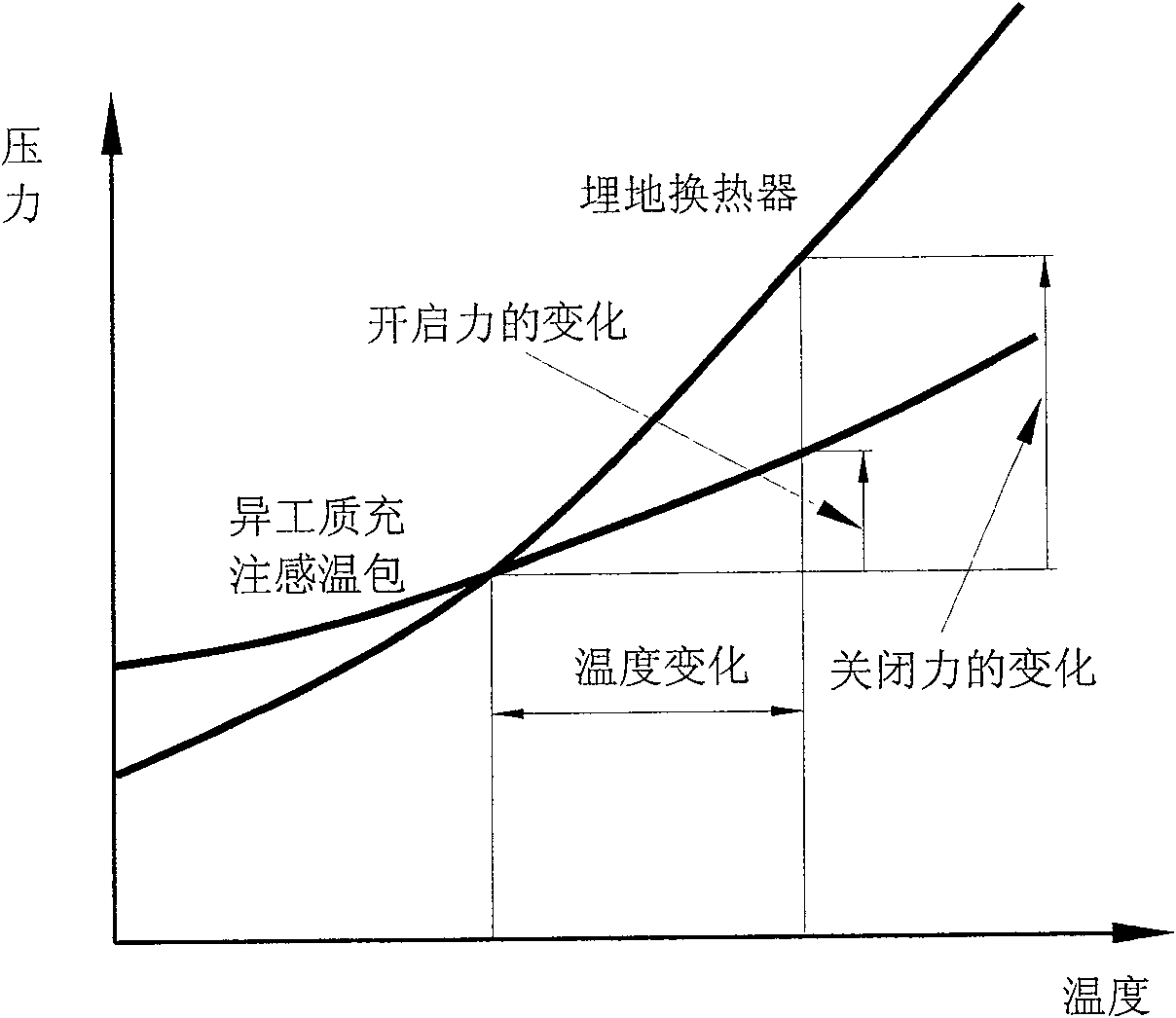

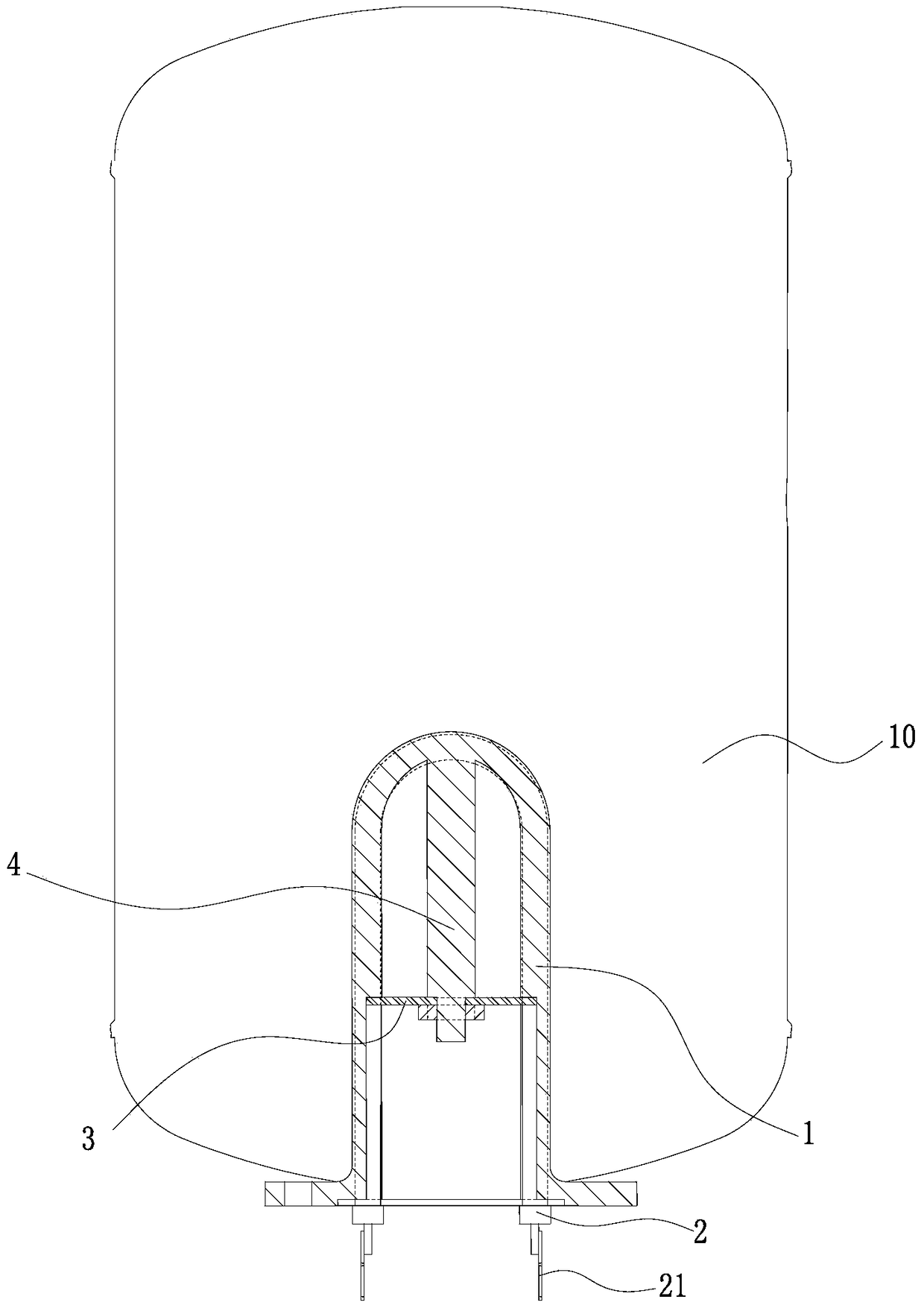

The invention relates to a direct type soil source heat pump system, which belongs to the technical field of refrigeration and heat pump. The system is composed of a compressor, a gas-liquid separator, an oil separator, a four-way change-over valve, a cooling agent / water heat exchanger, a bi-directional different working medium heat filling expansion valve, a device for drying and filtering, a level glass, a liquid separating device, an air collecting pipe, parallel branch of an outer fin copper pipe buried heat exchanger, an one-way valve, a solenoid-controlled valve and the like. The bi-directional different working medium heat filling expansion valve is used for throttle, liquid separating is accomplished to liquid cooling agent after gas-liquid separation when heat-production is in progress, and the buried heat exchanger employs compact outer ribbed structure and can operate heat-production and refrigeration. The direct type soil source heat pump system has the advantages of reliability, high efficient and environment protection.

Owner:BEIJING UNIV OF TECH

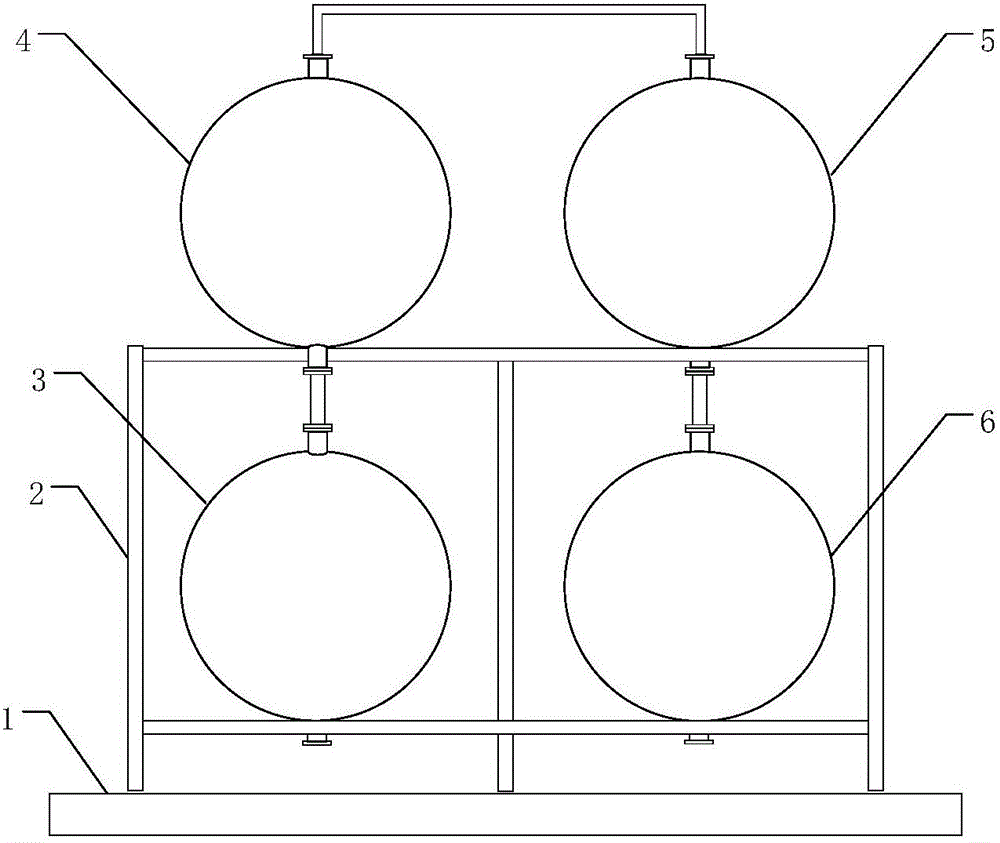

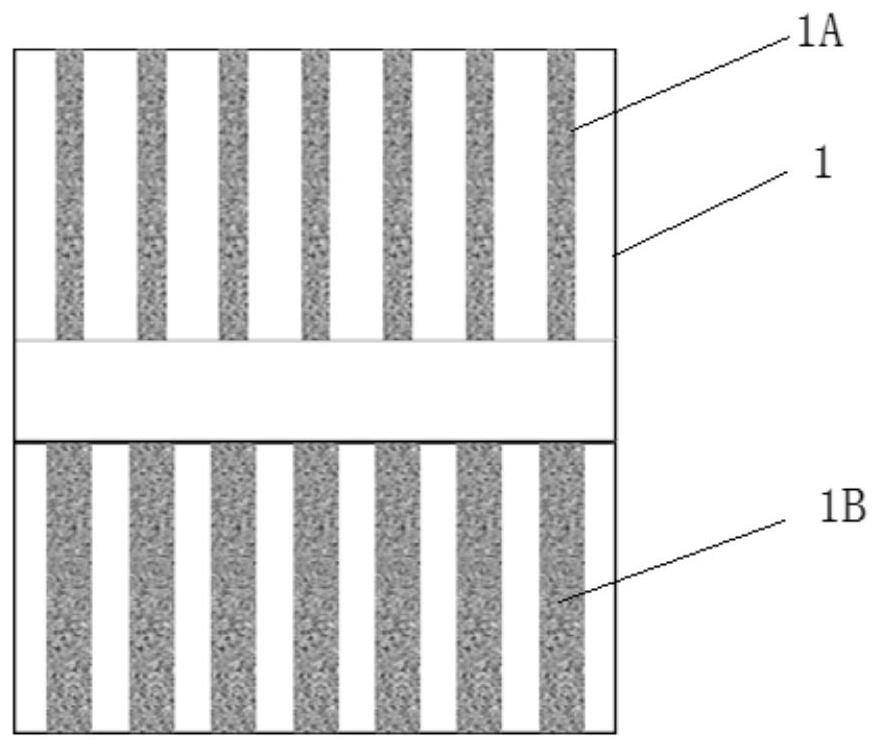

Anti-scaling multiple shell pass assembled heat exchanger

InactiveCN106705711AIncrease the lengthReduce the chance of foulingCorrosion preventionHeat exchanger casingsPlate heat exchangerShell and tube heat exchanger

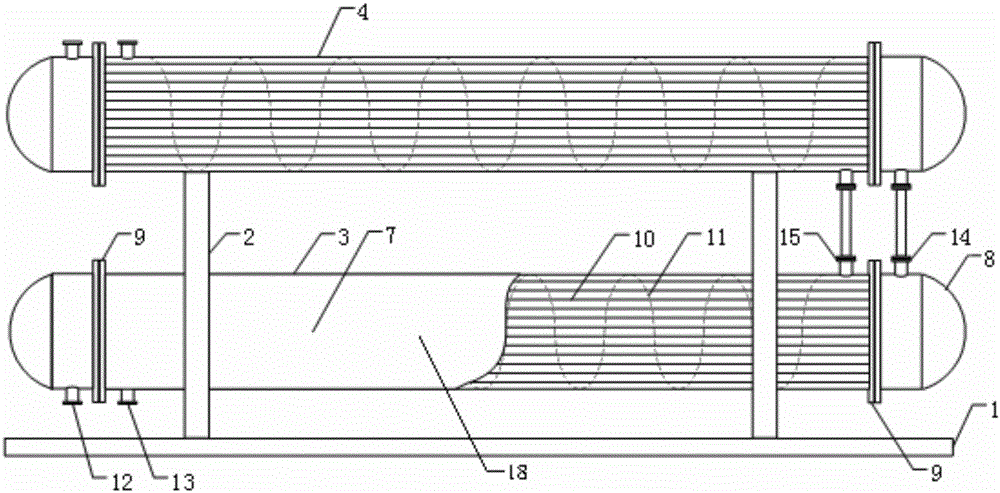

The invention relates to an anti-scaling multiple shell pass assembled heat exchanger. The anti-scaling multiple shell pas assembled heat exchanger comprises a base, a bracket and a plurality of heat exchange units, wherein the base is fixed on the ground, the bracket is mounted at the upper end of the base, the plurality of the heat exchange units are mounted on the bracket, each of the heat exchange units is an independent single tube pass and single shell pass shell-and-tube heat exchanger and the heat exchange units are connected in pairs; each of the heat exchange units comprises a housing, tube boxes, tube plates, a tube bundle, a spiral baffle plate, a tube pass inlet, a shell pass inlet, a tube pass outlet and a shell pass outlet; the tube boxes are arranged at two ends of the housing, the tube bundle and the spiral baffle plate are arranged in the housing, the tube bundle is composed of a plurality of heat transfer tubes, the tube plates are welded at two ends of the tube bundle, and the spiral baffle plate is continuously welded by fan-shaped surface plates to form a spiral surface structure and is mounted on the tube bundle. By lengthening the lengths of the tube passes of the heat exchangers, the sections of the tube passes are reduced and the fluid flow rate of the tube passes is improved, so that the scaling probability of the tube passes is greatly reduced.

Owner:张炳辰

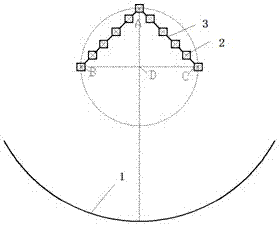

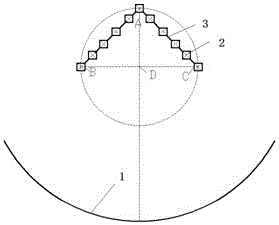

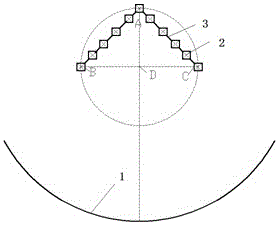

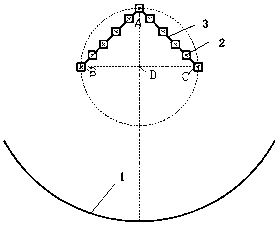

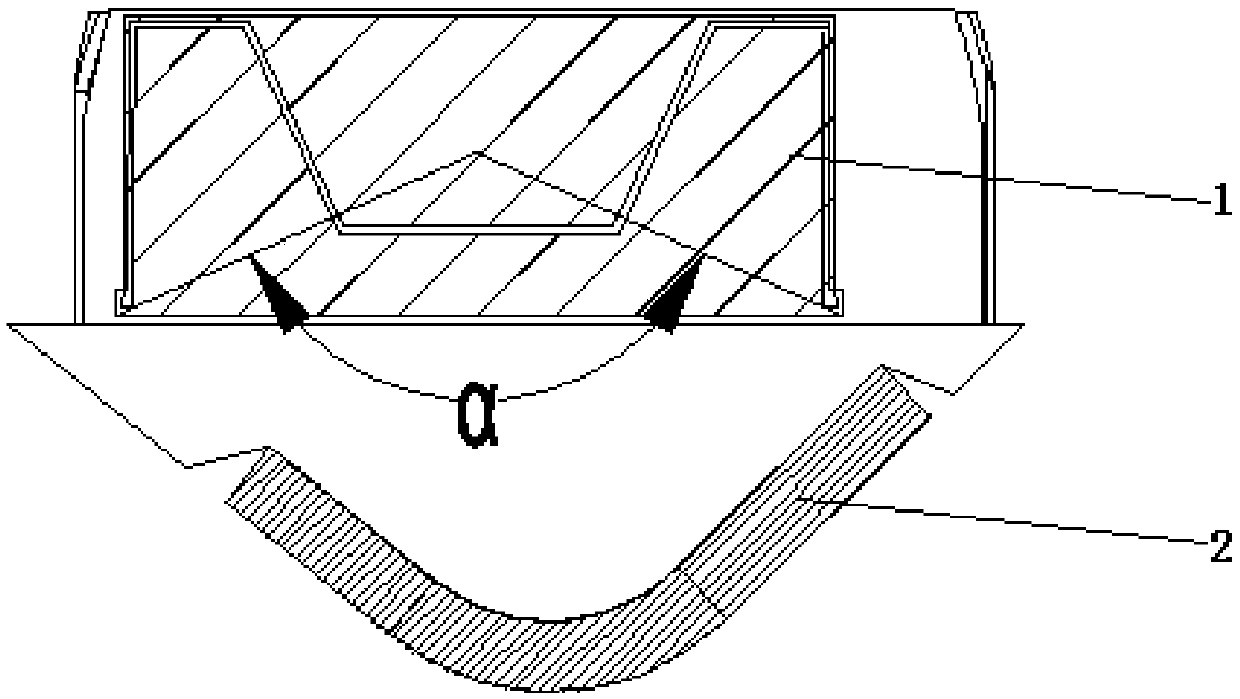

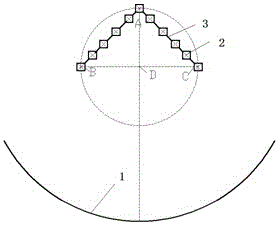

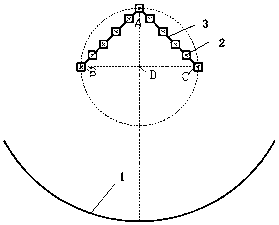

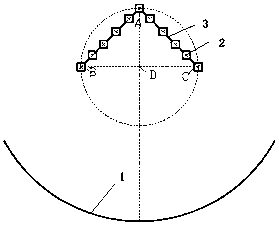

A solar heat collector with variable spacing of interconnecting holes

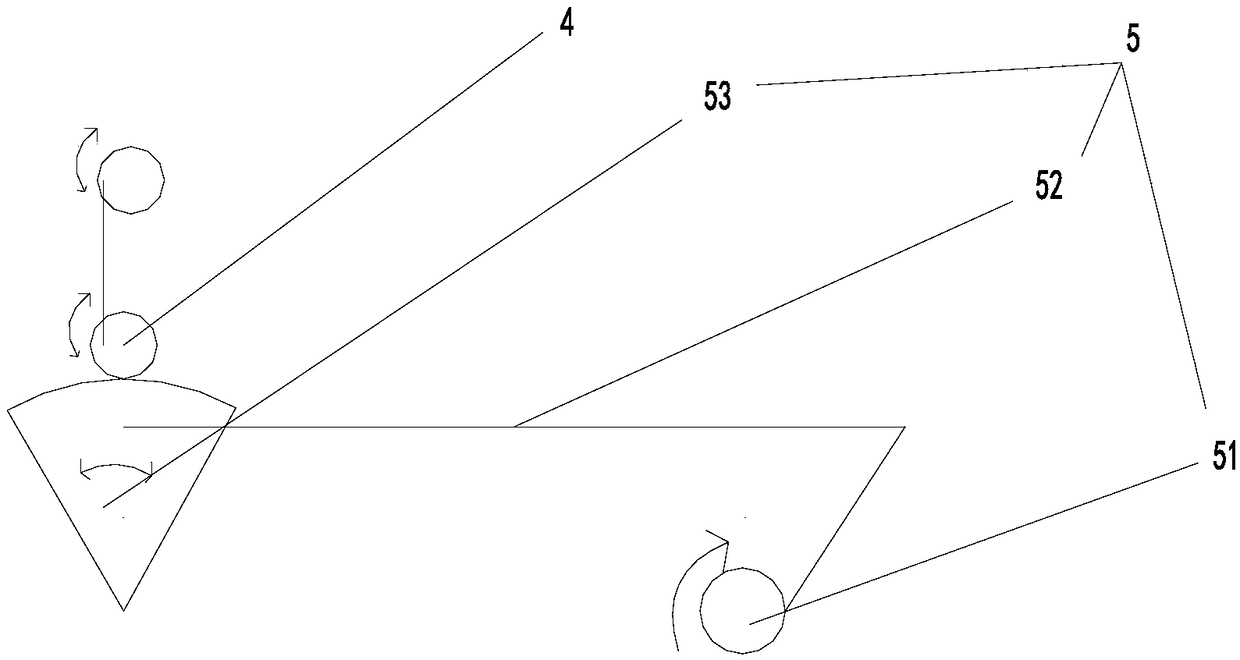

ActiveCN105758013BGuaranteed heat transfer areaExtended service lifeSolar heating energySolar heat devicesEngineeringSolar heat

The invention provides a solar heat collector. The solar heat collector comprises two tube plate structures, wherein a given angle is formed between the two tube plate structures, the direction of the angle is opposite to the bending direction of an arc linear structure of a reflector, a focal point of the reflector is disposed between the angles formed by the tube plate structures, inner fins are arranged inside a heat collection pipe, the inner fins are connected with a rectangular opposite angle, the interior of the heat collection pipe is divided by the inner fins into a plurality of small passages, communication holes are formed in the inner fins, and the spacing among the communication holes of different heat collection pipes is gradually reduced along the extension direction from the junction of the two tube plate structures to lowest positions on two sides. By adopting the solar heat collector, the basically identical pressure can be kept inside different heat collection pipes, so that the overall service life of the heat collection pipe is prolonged, the heat exchanging area of the inner fins of the heat collection pipes can be guaranteed, and the heat conduction can be improved.

Owner:常州高丰户外用品有限公司

Solar thermal collector with variable communicating hole area

ActiveCN105698406AGuaranteed heat transfer areaExtended service lifeSolar heating energyHeat transfer optimizationDiagonalEngineering

The invention provides a solar thermal collector which comprises two tube plate structures, wherein a certain included angle is formed between the two tube plate structures; the direction of the included angle is arranged opposite to the bending direction of an arch line structure of a reflector; the focus of the reflector is arranged in the included angle formed between the two tube plate structures; inner fins are arranged in each collector tube, are connected with corresponding diagonals of a rectangle and divide the interior of the corresponding collector tube into multiple small channels; communicating holes are formed in each inner fin; and the areas of the communicating holes of different collector tubes become larger and larger in the direction that a connecting point of the two tube plate structures extends towards the lowest positions on the two sides. The solar thermal collector can ensure the interiors of different collector tubes to keep basically same pressure so as to prolong the overall service life of the collector tubes, can also ensure the heat exchange areas of the inner fins of the collector tubes and strengthens heat transfer.

Owner:徐州中伦光伏材料有限公司

Fresh air pretreatment terrestrial heat exchange system

ActiveCN105737308AReduce indoor pollution sourcesEnsure efficient operationOther heat production devicesGeothermal energy generationVentilation tubeEngineering

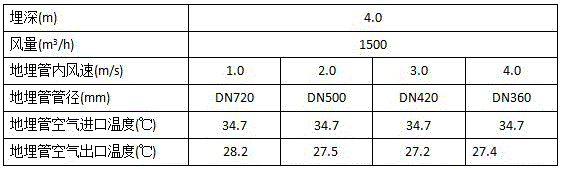

The invention relates to a fresh air pretreatment terrestrial heat exchange system. The fresh air pretreatment terrestrial heat exchange system comprises an outdoor fresh air taking part, a terrestrial heat exchange part and an indoor fresh air treatment part, wherein the outdoor fresh air taking part, the terrestrial heat exchange part and the indoor fresh air treatment part are communicated through ventilation pipelines. The fresh air pretreatment terrestrial heat exchange system is characterized in that the outdoor fresh air taking part is arranged on the ground, the outdoor fresh air taking part comprises a fresh air port, a coarse-efficiency filter device, a medium-efficiency filter device, an electrostatic dust collector and a solid dehumidification device which are arranged in sequence from top to bottom and are communicated; the terrestrial heat exchange part comprises buried pipes, temperature measuring points which are formed on the buried pipes, pneumatic cleaning device reserved openings and flow measuring points; the indoor fresh air treatment part comprises a fresh air unit, a drain pipe, a fresh air valve, a plenum chamber and a fresh air pipeline.

Owner:山东省建筑工程质量检验检测中心有限公司 +1

Air duct type air conditioner and air conditioning system

PendingCN108386913AReduce volumeImprove heat transfer efficiencyLighting and heating apparatusAir conditioning systemsPlate heat exchangerEngineering

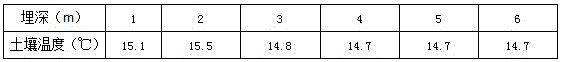

The invention provides an air duct type air conditioner and an air conditioning system. The air duct type air conditioner comprises a shell, a fan and a heat exchanger, and further comprises a wind wheel for adjusting the direction of airflow blowing towards the heat exchanger and / or adjusting the direction of airflow blowing an air outlet. The shell is provided with an air inlet and the air outlet. The fan and the heat exchanger are arranged inside the shell in sequence in the direction from the air inlet to the air outlet. The wind wheel is arranged inside the shell and can swing freely in the shell. According to the air duct type air conditioner and the air conditioning system provided by the invention, the airflow in the shell is guided through swinging of the wind wheel, output air ofthe fan can pass through the heat exchanger to the greatest extent, the quantity of heat exchange portions of the heat exchanger is increased accordingly, and the purpose of fully utilizing the heatexchange area of the heat exchanger is achieved; and the heat exchange efficiency of the air duct type air conditioner can be increased under the condition that the volume of the air duct type air conditioner is not changed, or the volume of the air duct type air conditioner is reduced as much as possible under the condition of ensuring certain heat exchange efficiency

Owner:GREE ELECTRIC APPLIANCES INC

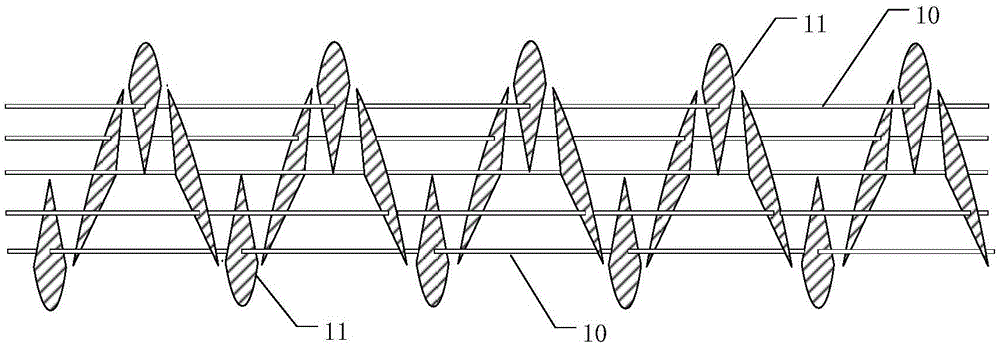

Heat exchange tube and air conditioner

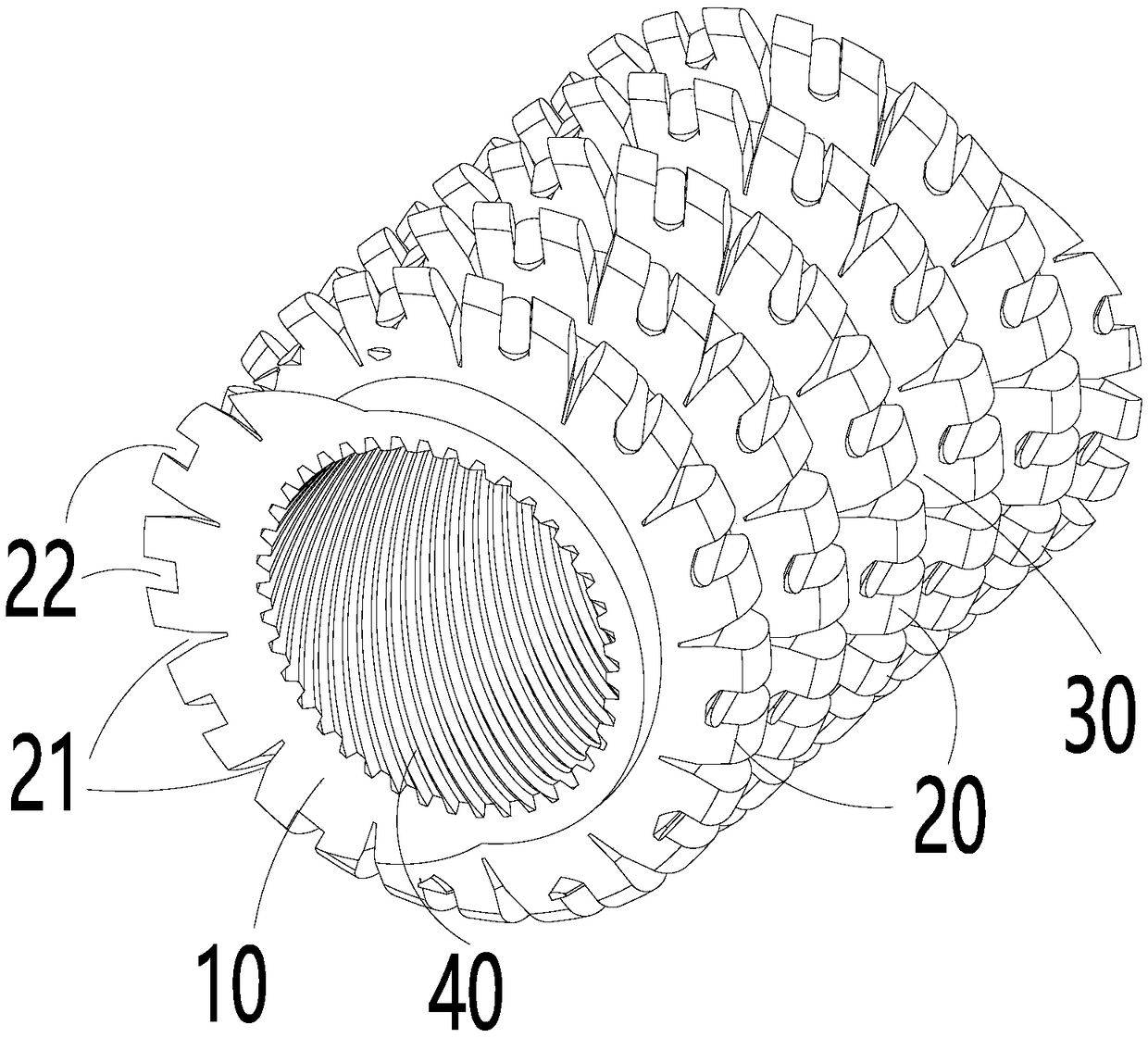

InactiveCN109099748AIncreased discharge channel areaImprove discharge effectEvaporators/condensersHeat exhanger finsHeat resistanceEngineering

The invention provides a heat exchange tube and an air conditioner. The heat exchange tube comprises a tube body and fins arranged on the outer surface of the tube body. Channels are formed between the adjacent fins. Communication grooves are formed in the fins to enable the adjacent channels to communicate, and the communication grooves are used for circulating refrigerants. By utilizing the technical scheme, the adjacent channels can communicate through the communication grooves formed in the fins, the area of discharging channels for condensed liquid refrigerants is increased, the refrigerant discharging capacity is enhanced, and the refrigerants can better circulate on the surface of the heat exchange tube. Therefore, the situation that the thickness of the liquid refrigerants on the surface of the heat exchange tube is increased too much, and consequently heat resistance is increased and heat exchange efficiency is lowered can be avoided.

Owner:GREE ELECTRIC APPLIANCES INC

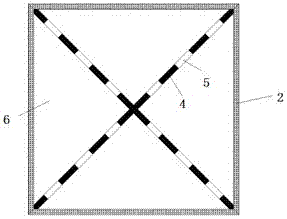

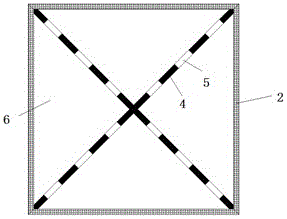

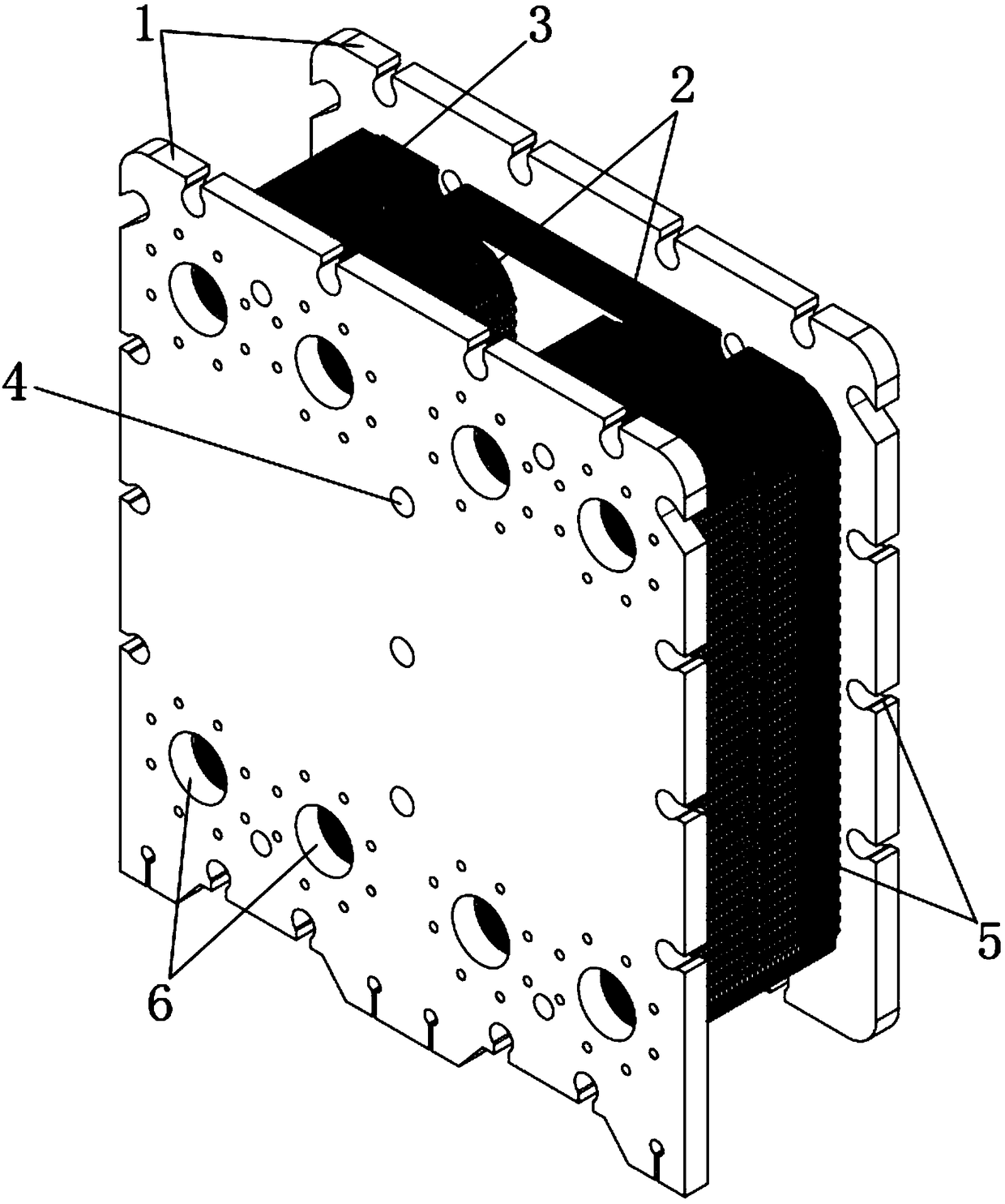

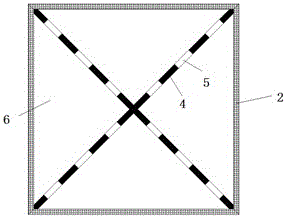

Plate-connected plate heat exchanger

PendingCN109186294AImprove connectivityExtended service lifeHeat exhanger sealing arrangementStationary plate conduit assembliesWater leakageEngineering

The invention relates to a plate-connected plate heat exchanger. The plate-connected plate heat exchangercomprises end pressing plates and heat exchange plate bundles, and the heat exchange plate bundlesare disposed between the end pressing plates.The plate-connected plate heat exchanger further comprises communication plate bundles. The heat exchange plate bundles are arranged at intervals between the end pressing plates. The plurality of sets of heat exchange plate bundles are connected to each other in a series, parallel or parallel serial manner by the communication plate bundles, and theheat exchange plate bundles and the communication plate bundles are clamped and fixed by the end pressing plates.According to the plate-connected plate heat exchanger, the problem that the large heatexchange plate is easy to be deformed and water leakage occurs can be overcome, the maintenance workload and cost reduction are facilitated, the service life of the heat exchanger is prolonged, heat exchange efficiency is high, and combination is flexible. A matching custom function is realized according to the requirements, installation environment and other needs, the structure is compact, the space is small, and the transportation is more convenient.

Owner:SHANGHAI PANDA MACHINEGRP CO LTD

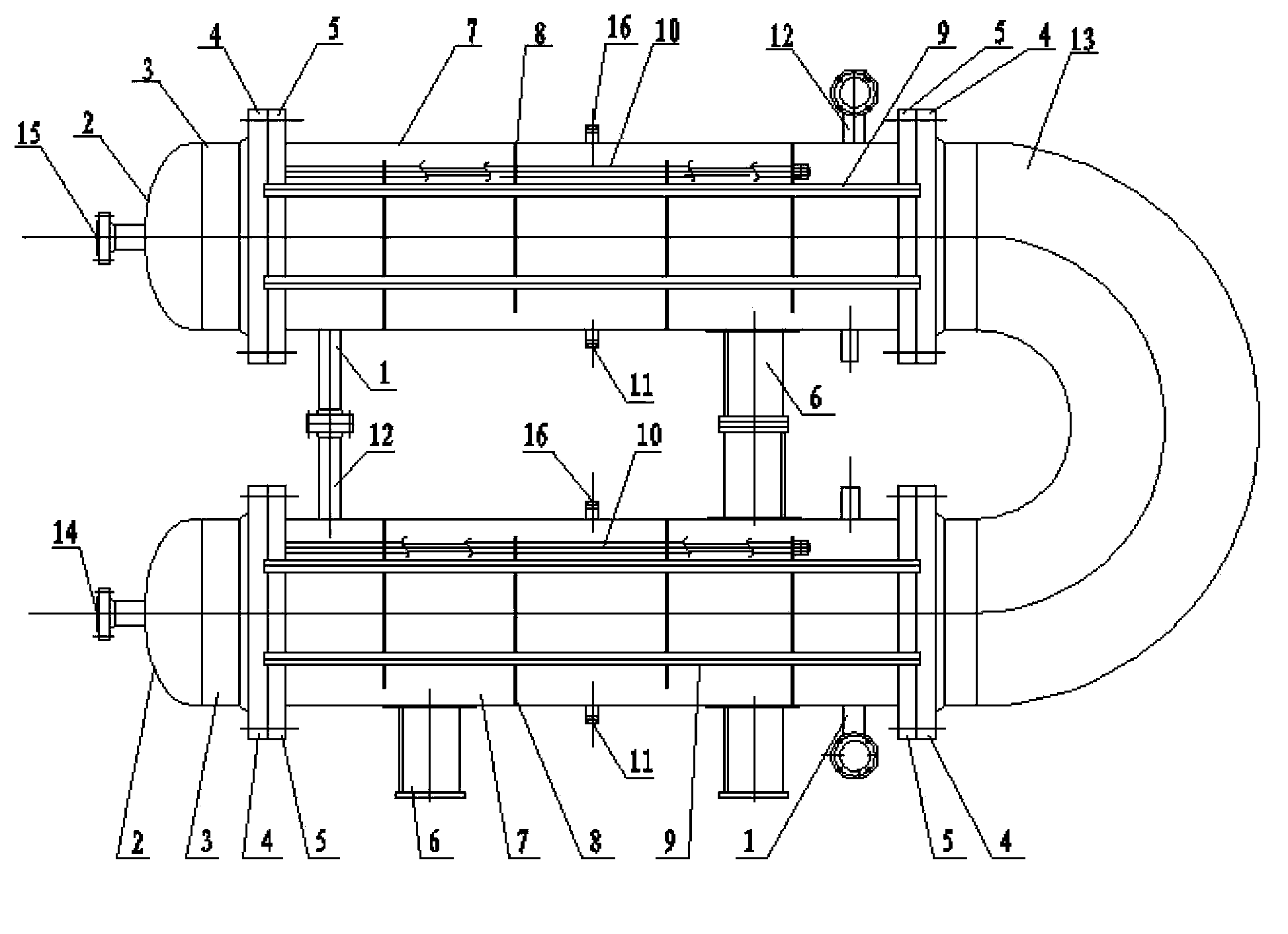

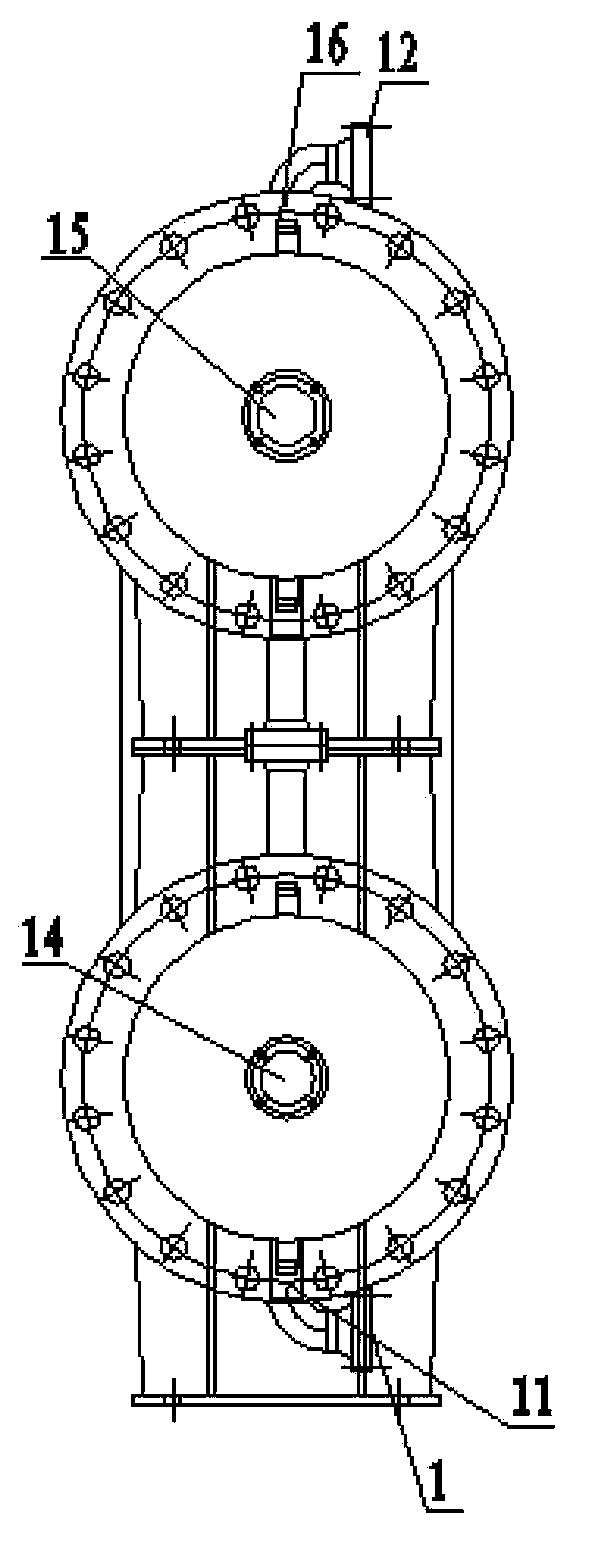

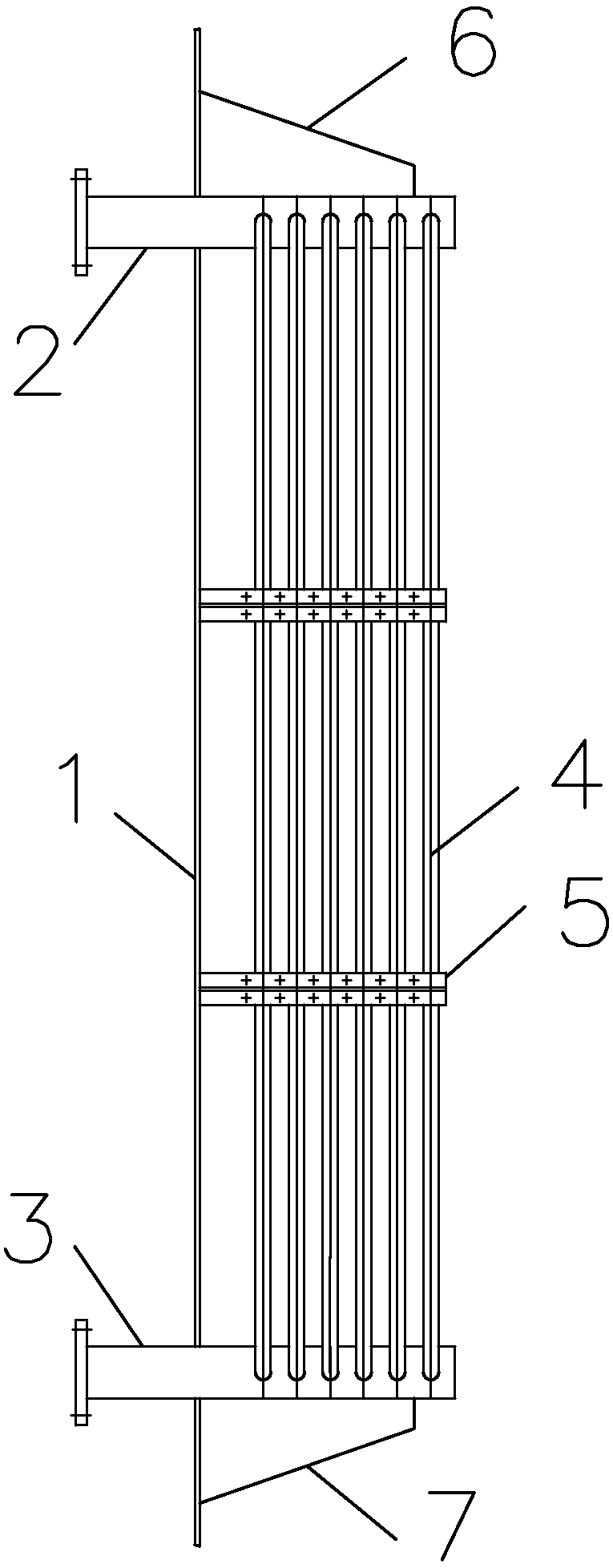

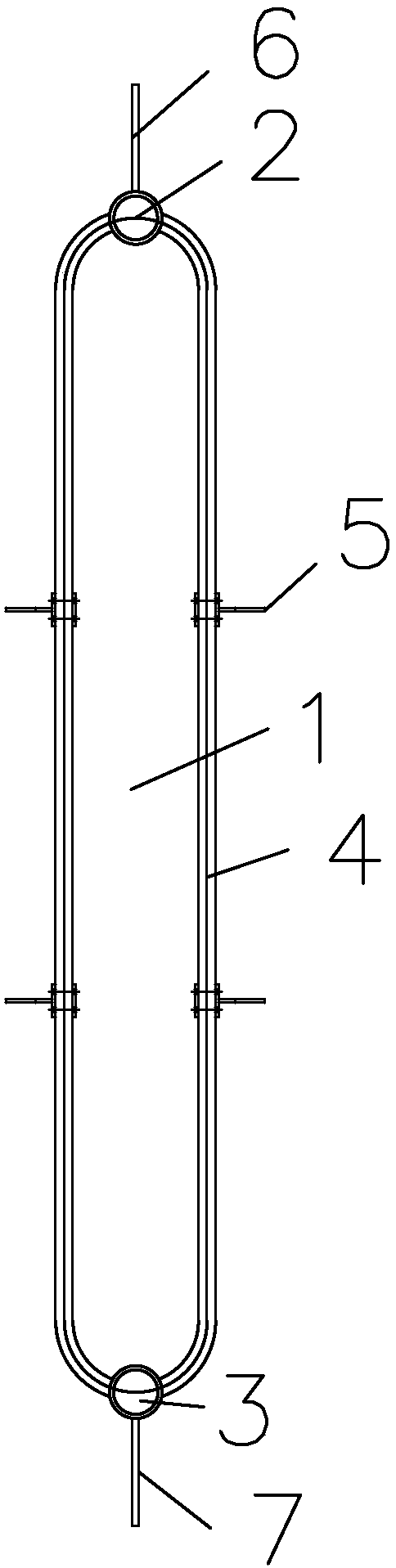

U-shaped-pipe-bundle warm-water-circulating large-flow natural gas recuperator

InactiveCN104110979AImprove heat transfer performanceReduce heat transfer areaStationary tubular conduit assembliesWarm waterEngineering

The invention provides a U-shaped-pipe-bundle warm-water-circulating large-flow natural gas recuperator which comprises a first heat exchanger and a second heat exchanger. The first heat exchanger and the second heat exchanger are placed in an overlapped manner, one ends of the first heat exchanger and the second heat exchanger are connected through an elbow, a circulating water inlet, a circulating water outlet, and a non-condensable gas emptying port and an emptying port are arranged on each of the first heat exchanger and the second heat exchanger; the circulating water outlet of the first heat exchanger is connected with the circulating water inlet of the second heat exchanger; a liquefied natural gas inlet is arranged at the other end of the first heat exchanger, and a gaseous natural gas outlet is arranged at the other end of the second heat exchanger. The U-shaped-pipe-bundle warm-water-circulating large-flow natural gas recuperator has the advantages that the recuperator is free of influence of heat-induced expansion and cold-induced contraction of media large in temperature difference, and is resistant to low temperature and corrosion; hot and cold media form reverse flow, and hot fluid is forced to circulate; a baffle plate is arranged, so that heat transfer effect is improved, heat exchange area is reduced; an overlapped structure is adopted, so that heat exchange area can be guaranteed, heat exchange requirements can be met, occupied area can be saved, space can be utilized effectively, and the like.

Owner:天津奥利环保设备有限公司

Solar heat collector with high corrosion resistance

ActiveCN105737404AImprove corrosion resistanceExtended service lifeSolar heating energySolar heat devicesSolar thermal collectorSolar heat

The invention provides a solar heat collector which comprises two tube plate structures. A certain included angle is formed between the two tube plate structures. The direction of the included angle is opposite to the bending direction of an arc structure of a reflector. The focal point of the reflector is located within the included angle formed by the tube plate structures. Inner fins are arranged in heat collecting tubes and connected with opposite corners of a rectangle. The interiors of the heat collecting tubes are divided into a plurality of small channels through the inner fins. Communicating holes are formed in the inner fins. The outer surfaces of the heat colleting tubes and the outer surfaces of heat collecting plates are coated with anti-corrosion layers. The surface of the heat collector is coated with a corrosion-resisting material, so that the corrosion resistance of the heat collecting tubes is increased, and the service life is prolonged.

Owner:长沙威航新能源技术有限公司

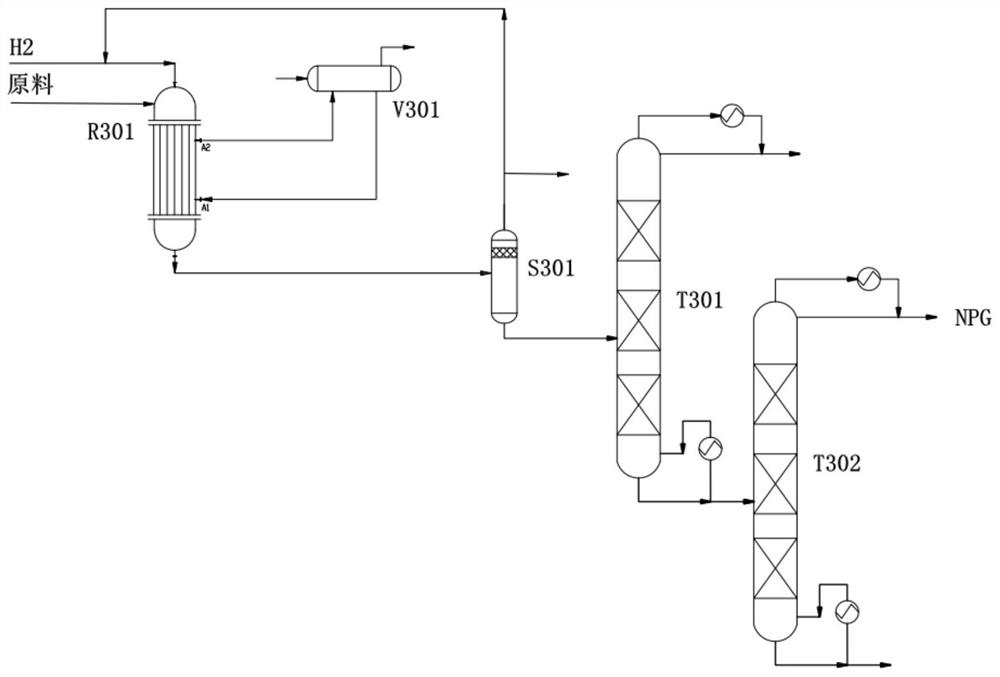

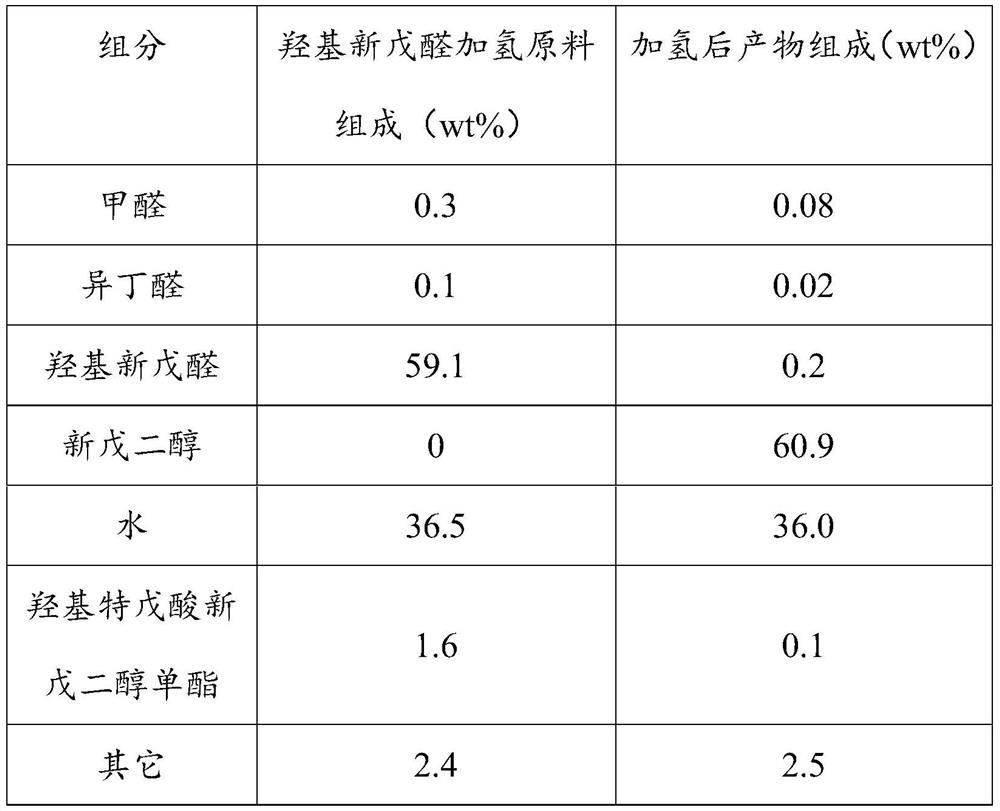

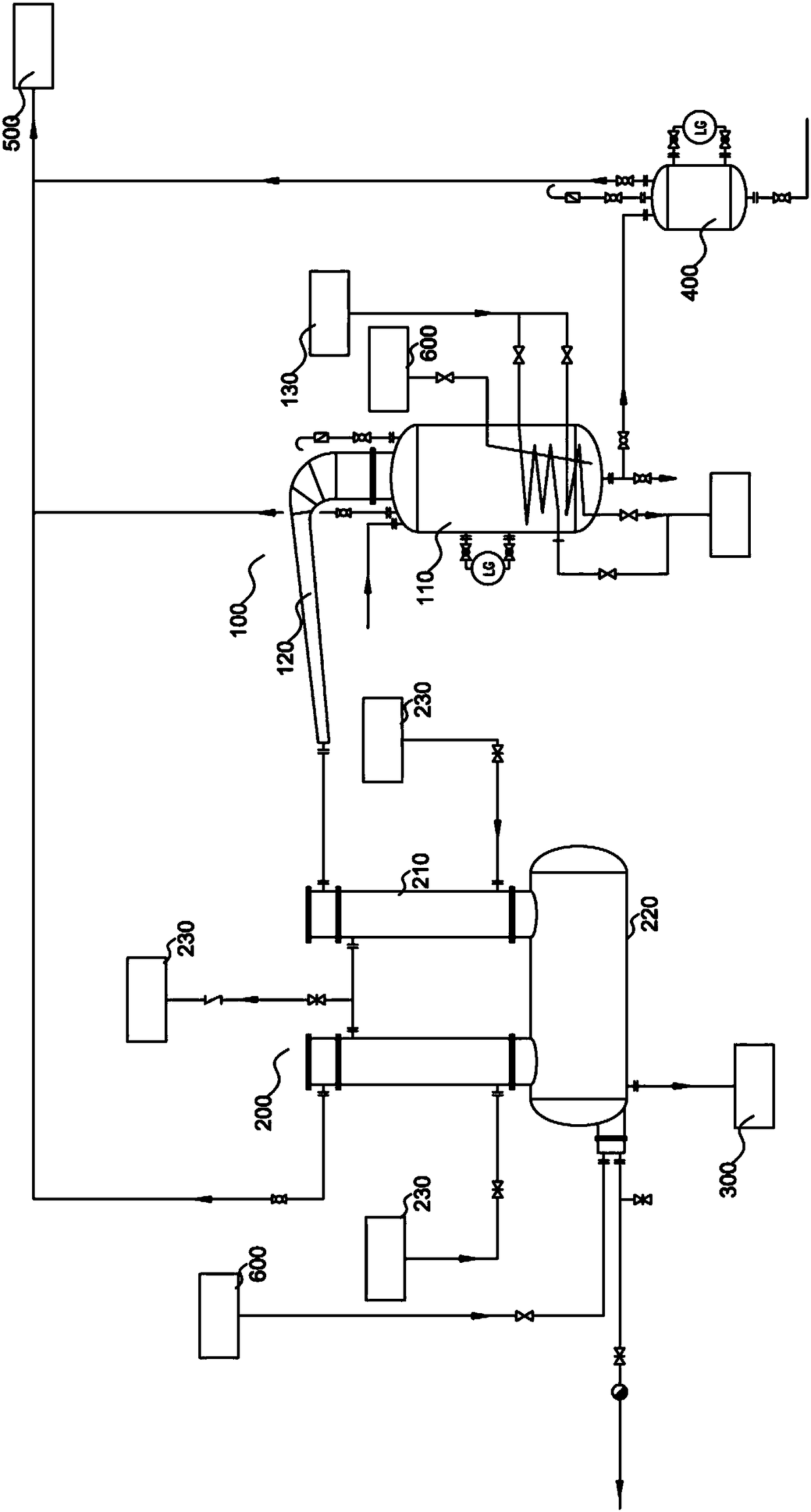

Process for producing neopentyl glycol by continuous catalytic hydrogenation

ActiveCN112537998AReduce lossesReduce energy consumptionOrganic compound preparationHydroxy compound preparationPtru catalystOrganic solvent

The invention discloses a process for producing neopentyl glycol by continuous catalytic hydrogenation, which solves the problems of complex operation, long flow and high investment and cost in the traditional neopentyl glycol production process, and adopts the technical scheme that a hydroxypivalaldehyde hydrogenation raw material and hydrogen are directly fed into a heat transfer hydrogenation reactor filled with a hydrogenation catalyst for reaction; a reaction product is led out from the bottom of the reactor and sent into a hydrogenation outlet separator for gas-liquid separation, one part of the separated gas returns to an inlet of the heat transfer hydrogenation reactor for cyclic utilization, and the other part of the separated gas is exhausted as purge gas; the separated liquid istreated through a light component removal tower and a heavy component removal tower to obtain a refined neopentyl glycol product; and the hydrogen-aldehyde molar ratio of the hydrogen to the hydroxypivalaldehyde hydrogenation raw material is (1.1-3): 1. The method has the advantages of simple process, short flow, mild reaction conditions, no need of additional addition of an organic solvent or separation and refining, energy saving, consumption reduction, low production cost and investment cost, and high yield.

Owner:上海翼湍科技有限责任公司 +1

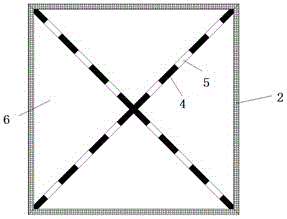

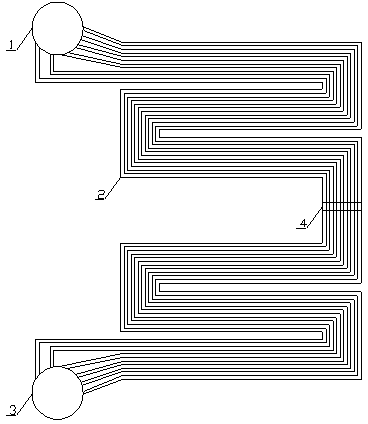

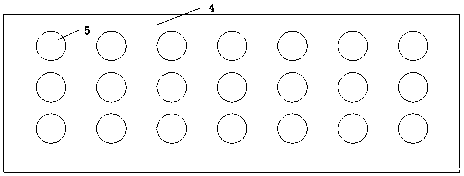

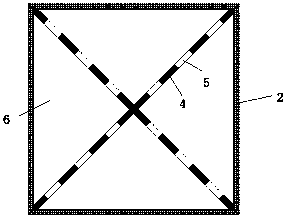

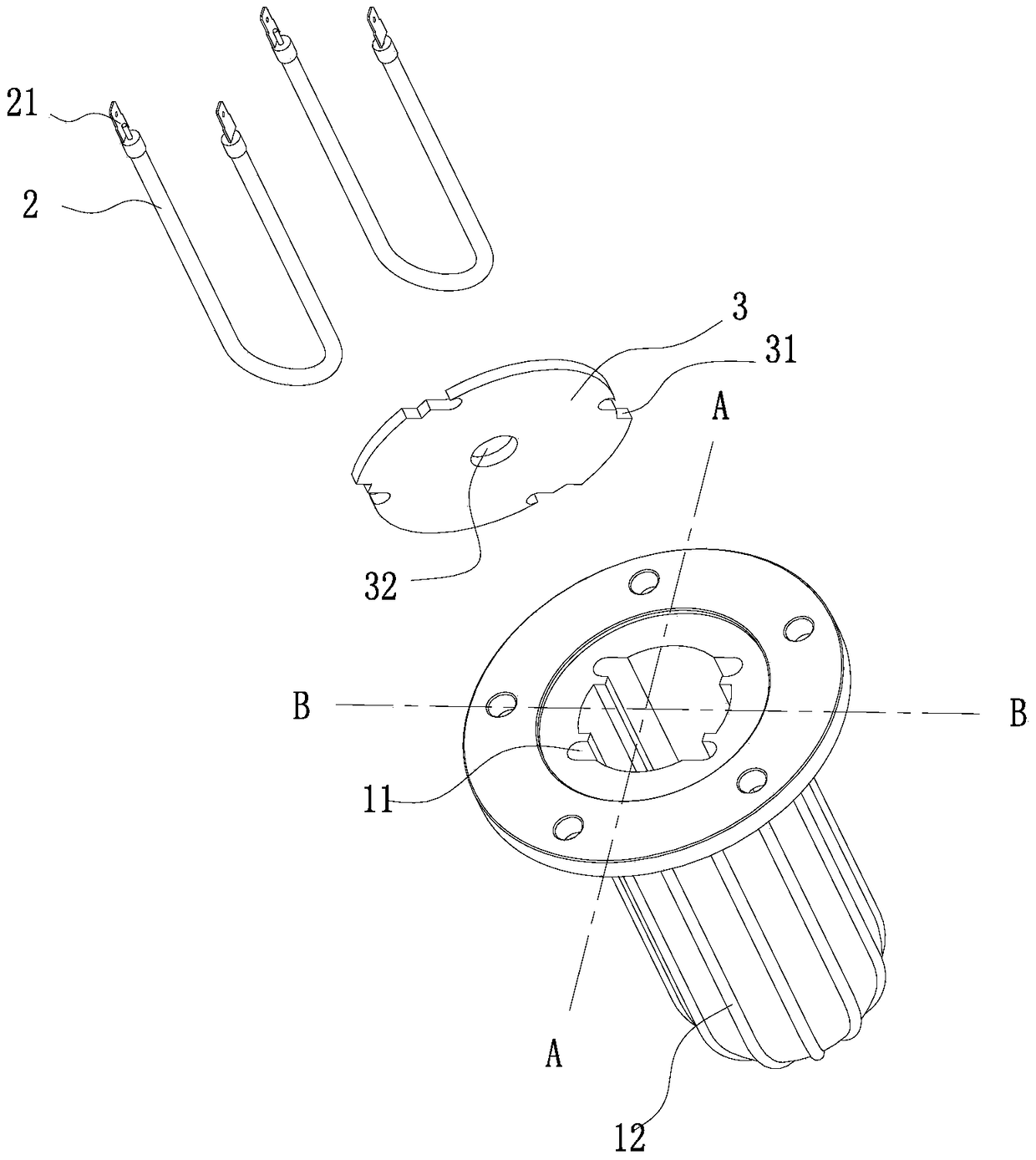

Low-pressure economizer with finned tubes

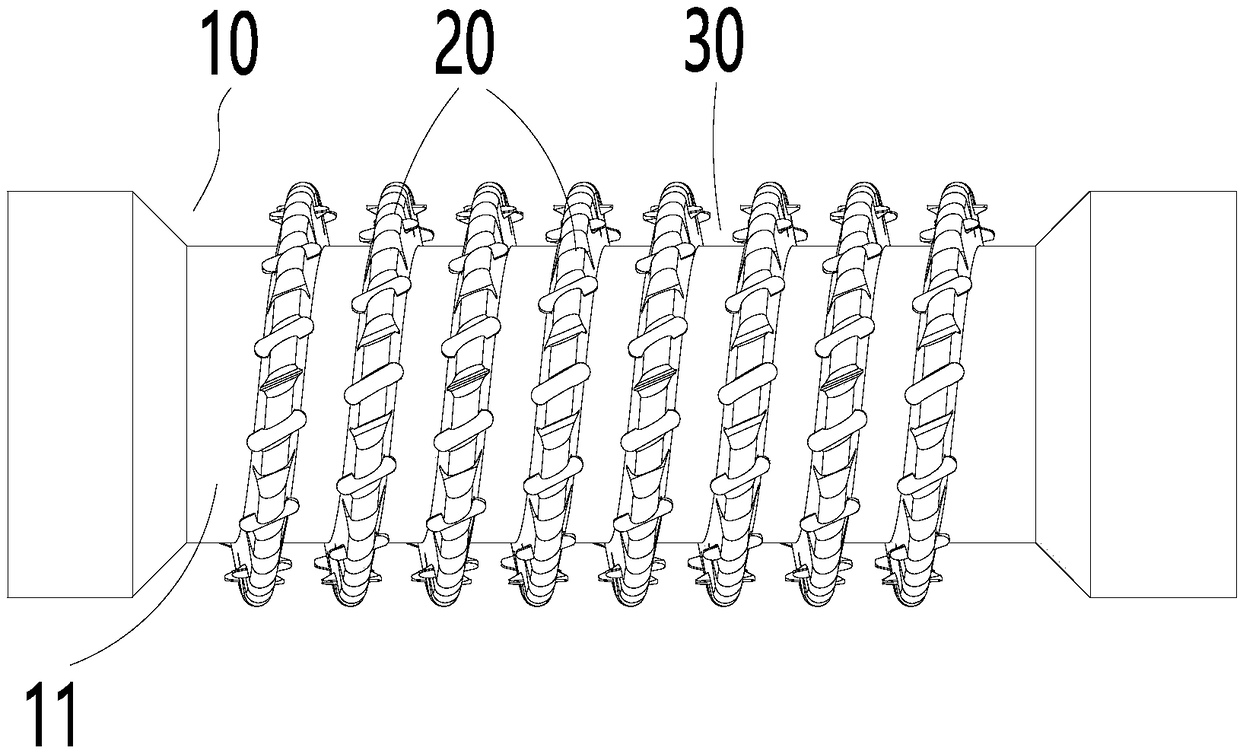

InactiveCN103697455AExtended service lifeReduce low temperature corrosionFeed-water heatersEngineeringEconomizer

A low-pressure economizer with finned tubes consists of an inlet header (1), finned tube rows (2) and an outlet header (3). The finned tube rows (2) are divided into the upper section and the lower section, the inlet header (1) is connected with the front six finned tube rows of the upper section, and the outlet header (3) is connected with the rear six rows of the finned tube rows (2). The low-pressure economizer is characterized in that the upper section of the finned tube rows (2) and the lower section thereof are welded integrally by an installation weld junction (4). The front six finned tube rows are made of ND steel, so that low-temperature corrosion is decreased, and the service life of the low-pressure economizer is prolonged. Due to the finned tubes of the new specification, heat exchange area is guaranteed while ash accumulation is reduced, and the low-pressure economizer stays at the best state for exhaust heat recovery.

Owner:JIANGSU ZHENGTONG HONGTAI INC

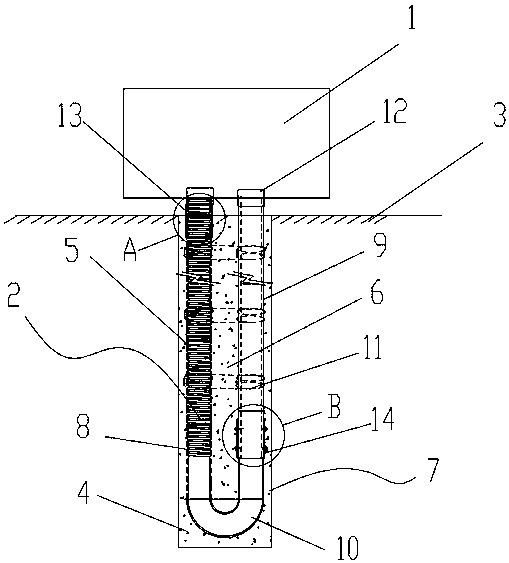

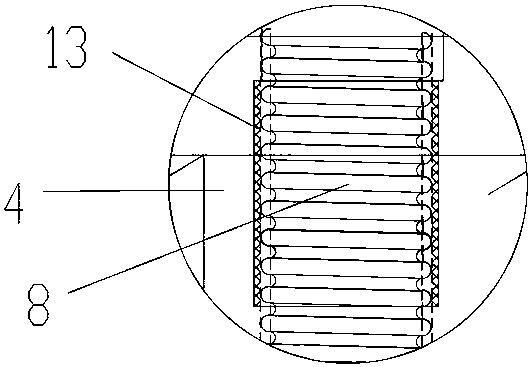

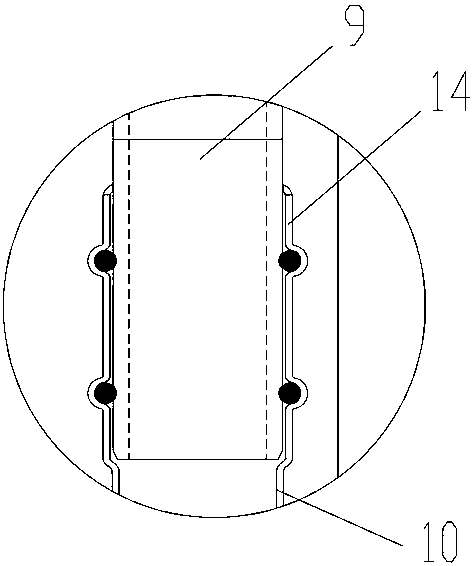

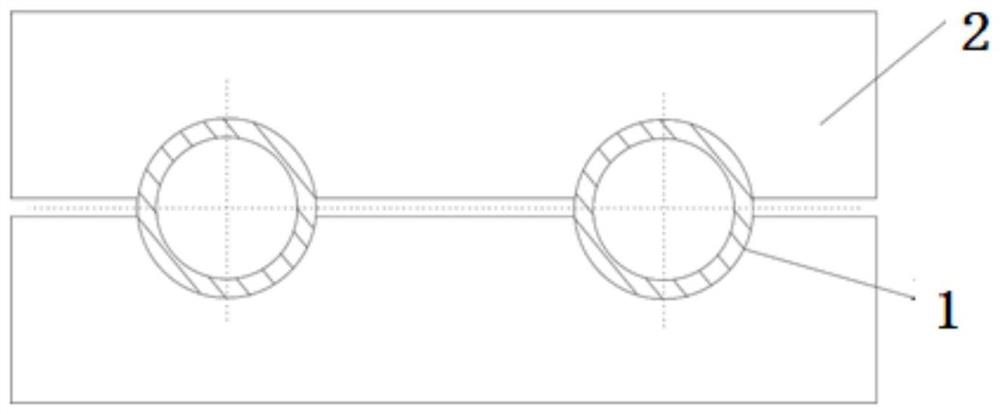

Stainless steel corrugated pipe ground heat source heat exchange system and setting method thereof

InactiveCN108088102AEasy to operateEasy to installHeat pumpsGeothermal energy generationPolyolefinButt joint

The invention discloses a stainless steel corrugated pipe ground heat source heat exchange system and a setting method thereof. The system comprises an overground heat exchange device and an underground heat exchange device, wherein the underground heat exchange device comprises a ground source hole arranged under a ground foundation and a heat exchange piece arranged in the ground source hole; the heat exchange part comprises a stable filling part and at least one heat exchange system unit, each heat exchange system unit comprises a stainless steel corrugated pipe section, a polyolefin material pipe section and a stainless steel bent pipe section; the stainless steel corrugated pipe section and the polyolefin material pipe section are arranged in parallel in the vertical direction of theground source hole; one end of the stainless steel bent pipe section is connected to the lower end of the stainless steel corrugated pipe section in a butt joint mode, and the other end is connected to the lower end of the polyolefin material tube section in a butt joint mode, and communicates with the stainless steel bent pipe section and the polyolefin material pipe section; and the stable filling piece is filled in the ground source hole, so that the sealing stability of the heat exchange system unit is achieved. According to the stainless steel corrugated pipe ground heat source heat exchange system, the heat exchange area is greatly increased, and heat exchange amount is greatly improved.

Owner:GREENTOWN DECORATION ENG GRP CO LTD

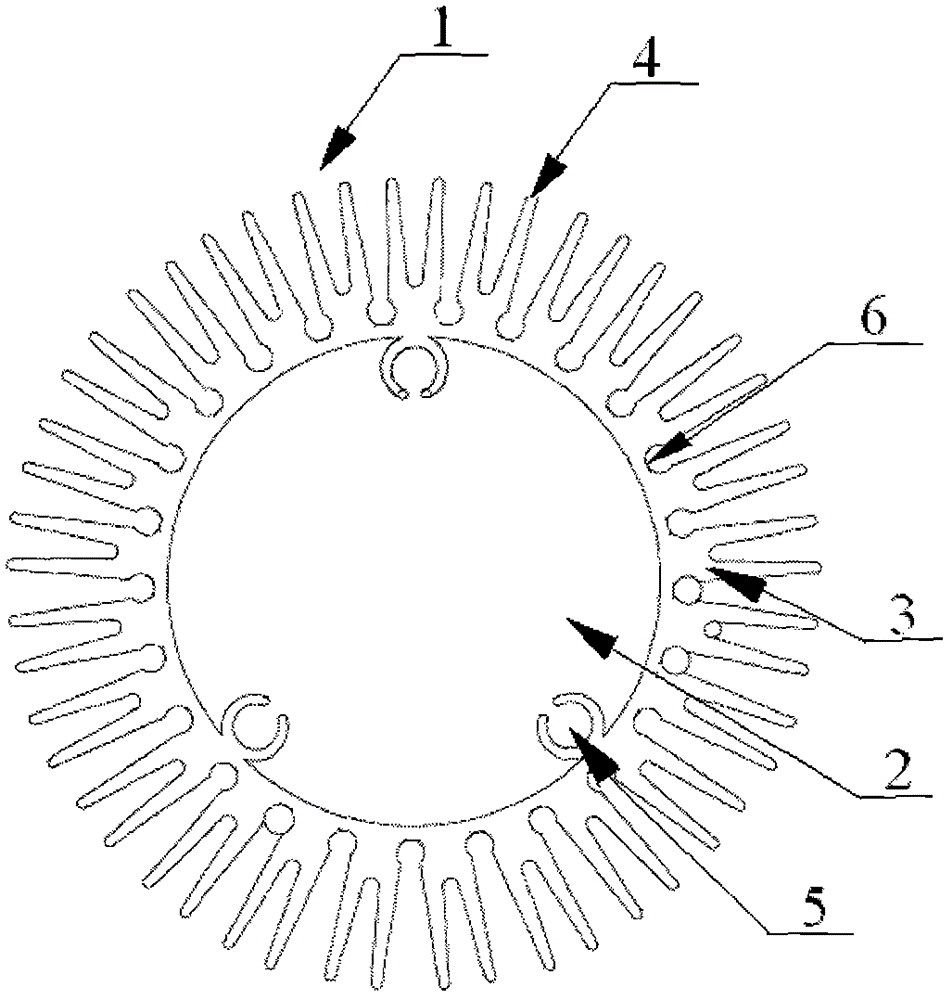

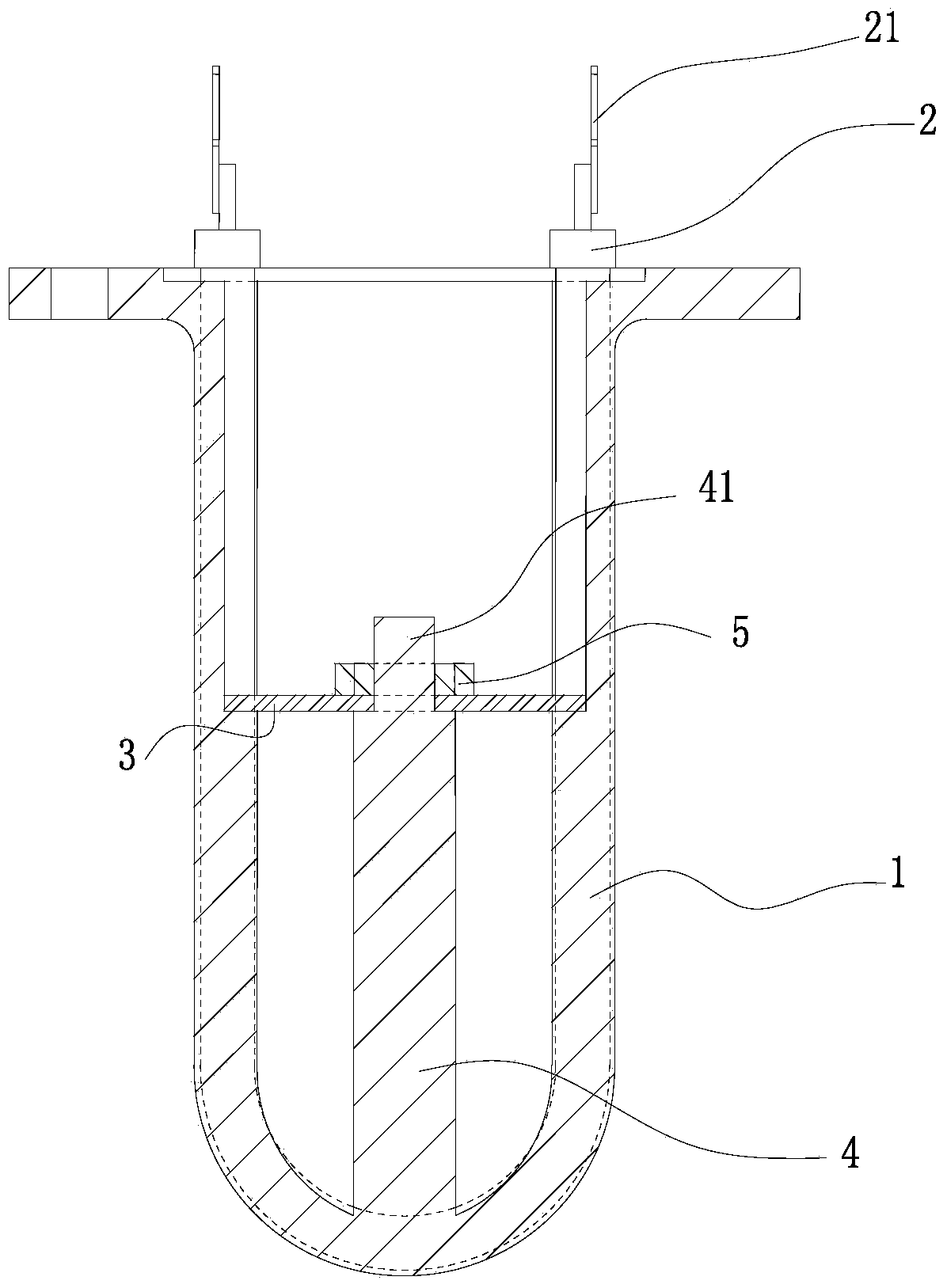

Refrigeration adsorber and its manufacturing method

InactiveCN1641296ACompact structureGuaranteed heat transfer areaClimate change adaptationEnergy efficient heating/coolingSorbentEngineering

The invention is a type of refrigerating absorber and its manufacturing method. It comprises inner and outer two round tubes suiting with each other. There is fixed with up and down cover boards, entrance and exit of carrier at each end of the outer round tube while passage of the carrier and passage of cryogen in the inner round tube. There is fixed pipe for cryogen in or out on the up cover board and up end cap while mouth for absorbent to be loaded. The absorbent is filled between the passage of cryogen and the passage of carrier. The manufacturing process is welding elements adopting the method of argon-arc welding with stainless steel. The invention makes advantages of jacket-style heat exchanger and heat exchanger with arranging pipes so it not only has high efficiency of diathermancy and mass transfer, fine pressure endure, but also has compact structure because of which it can reduce volume of the absorber to a large degree and increase charge of the absorbent.

Owner:SOUTH CHINA UNIV OF TECH

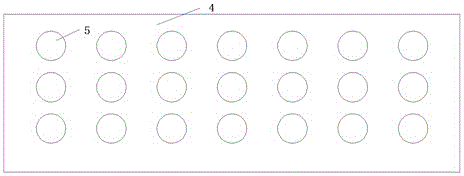

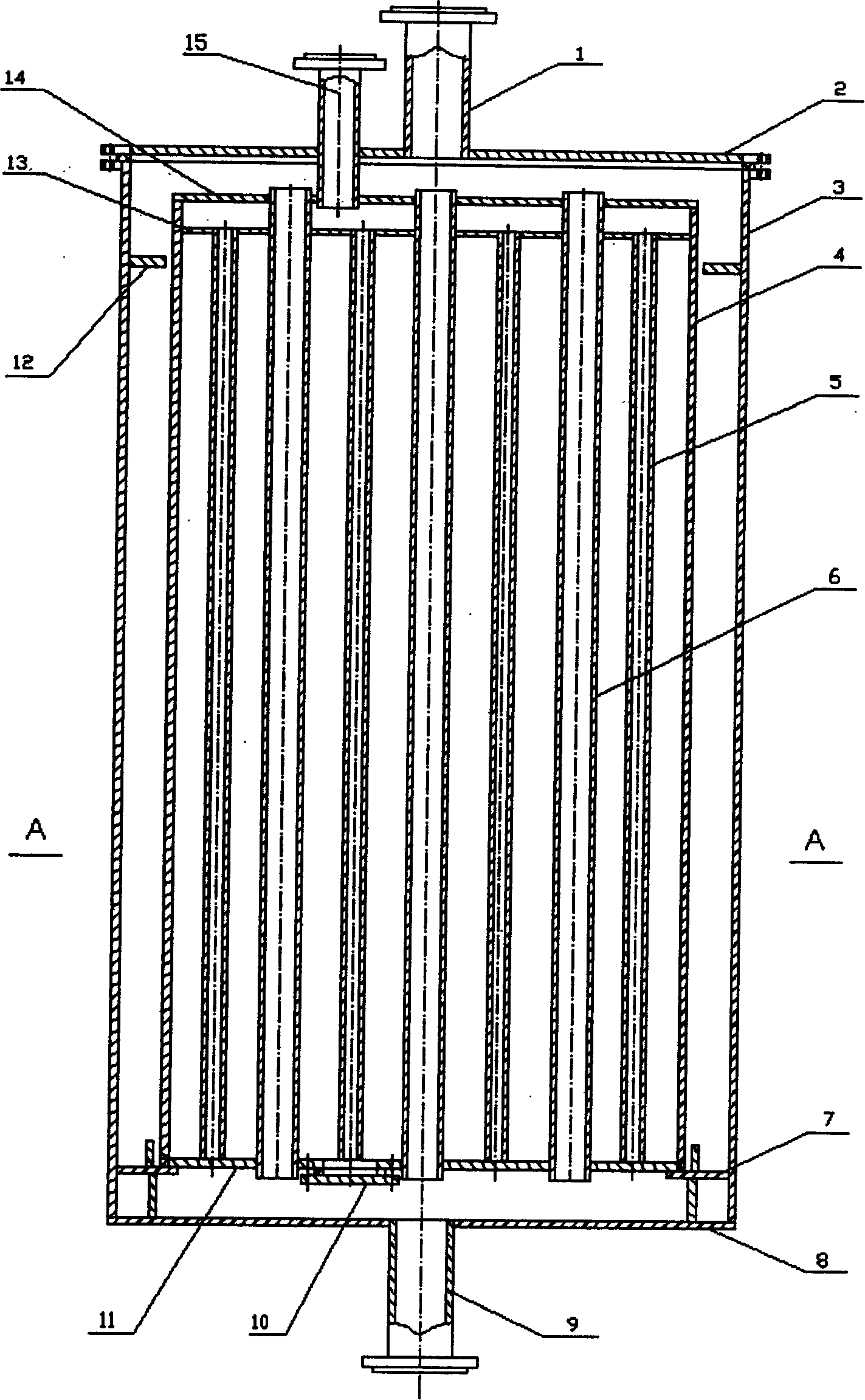

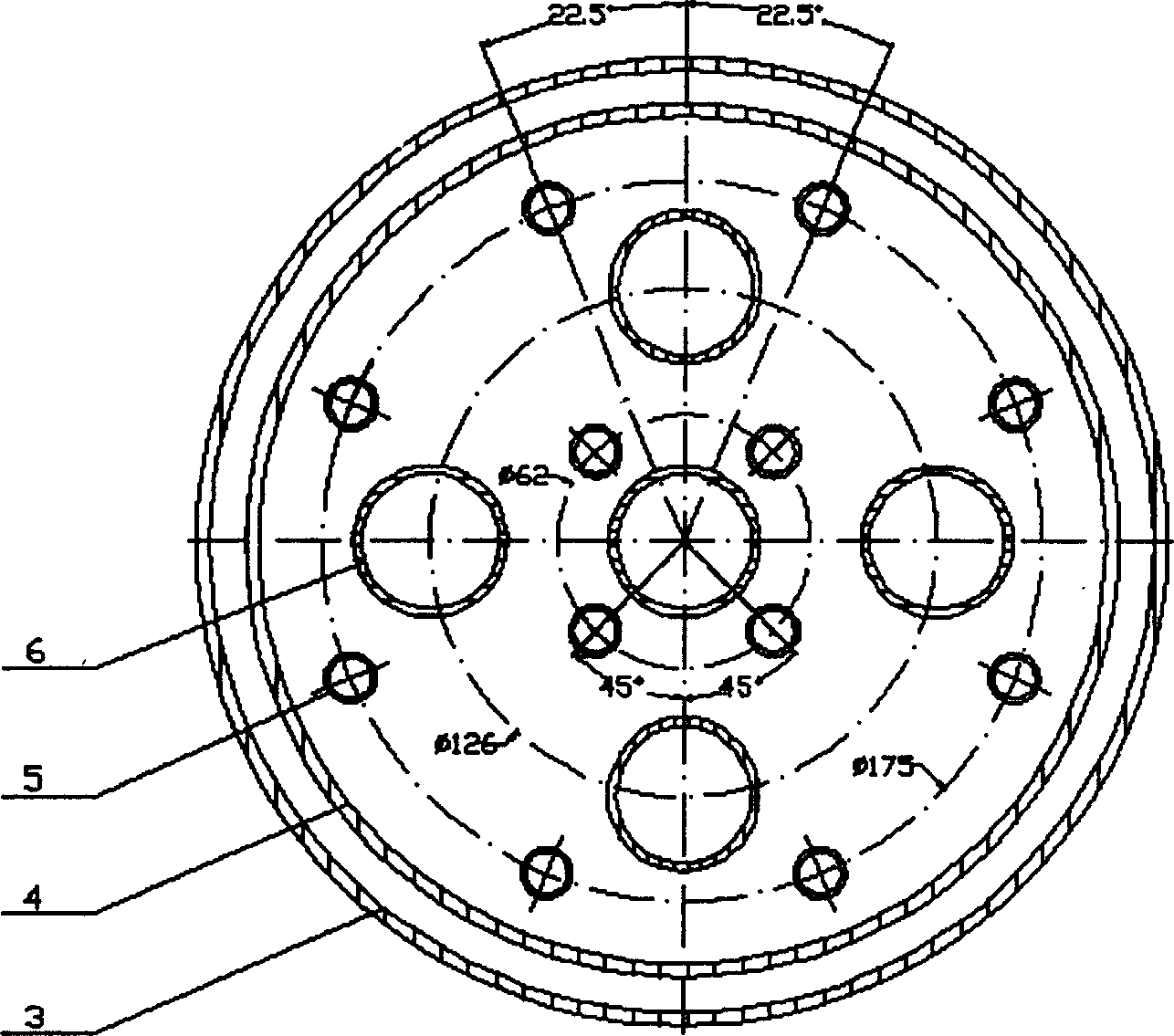

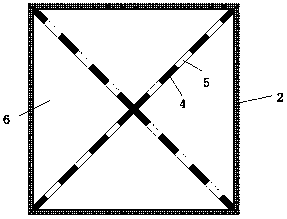

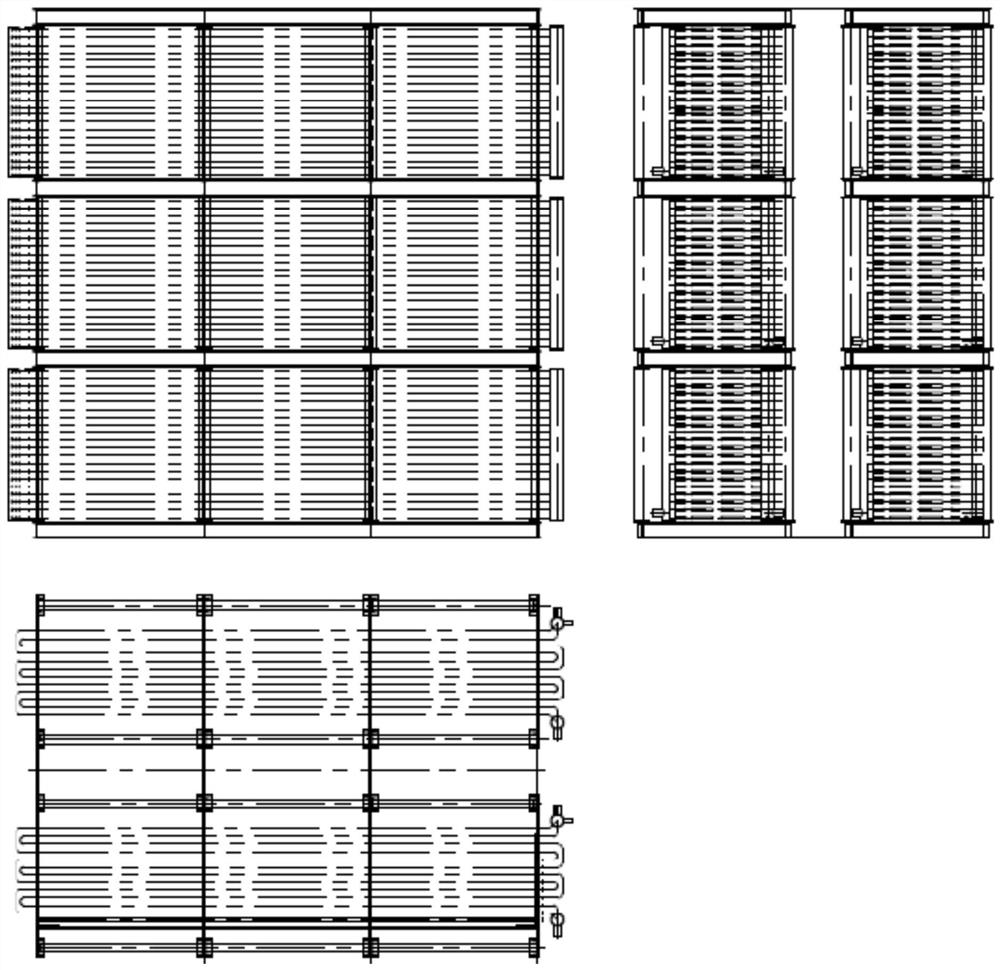

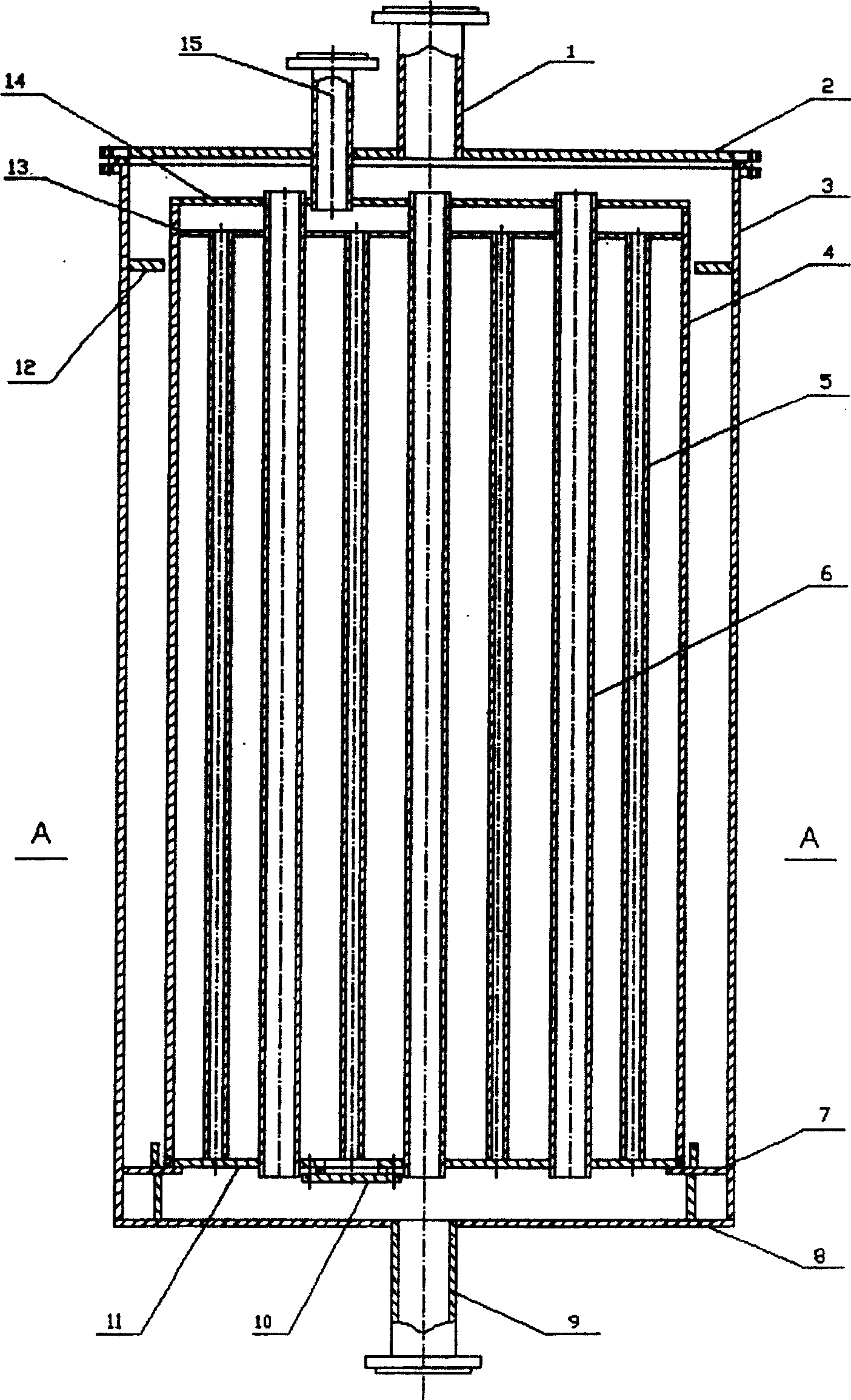

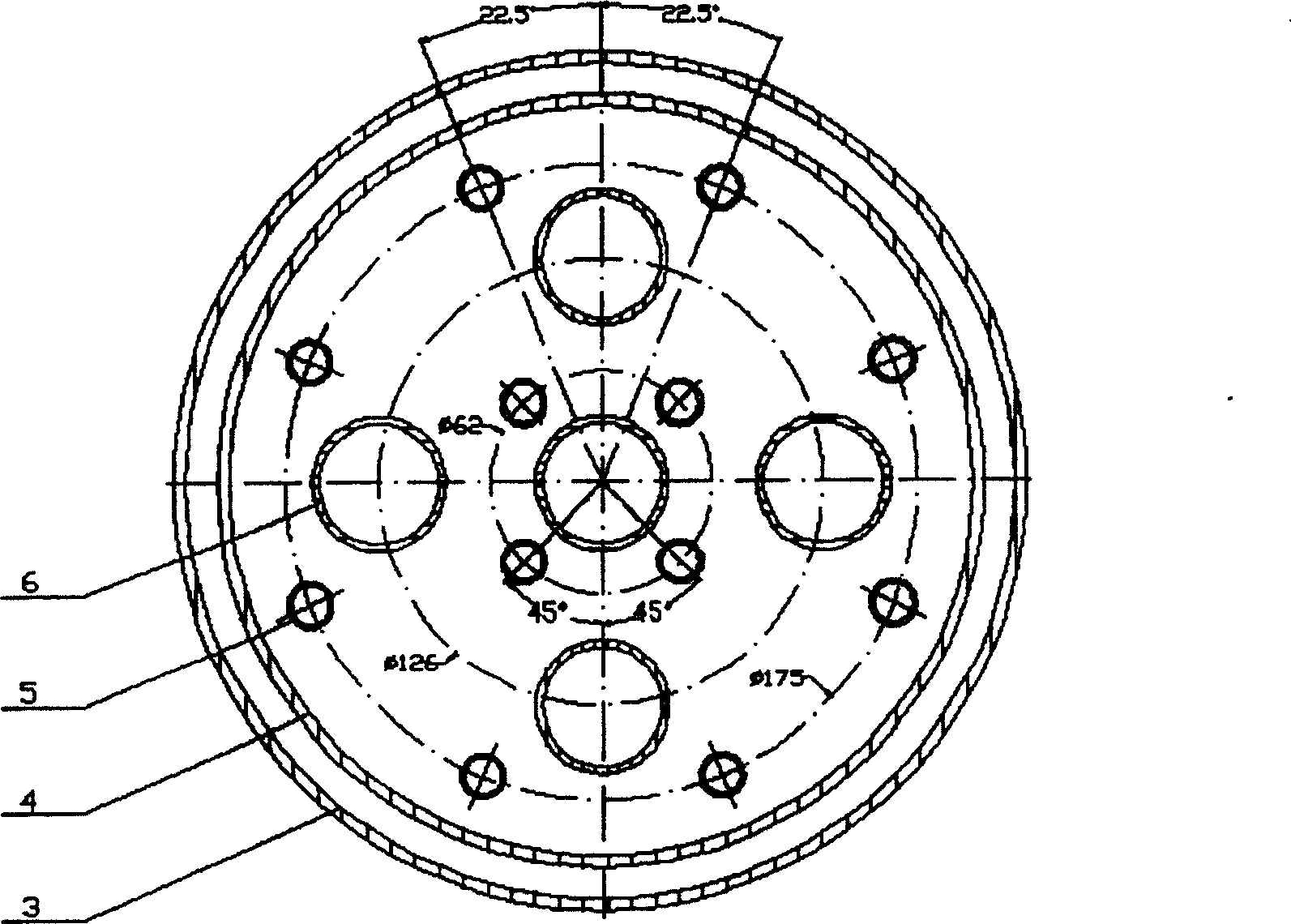

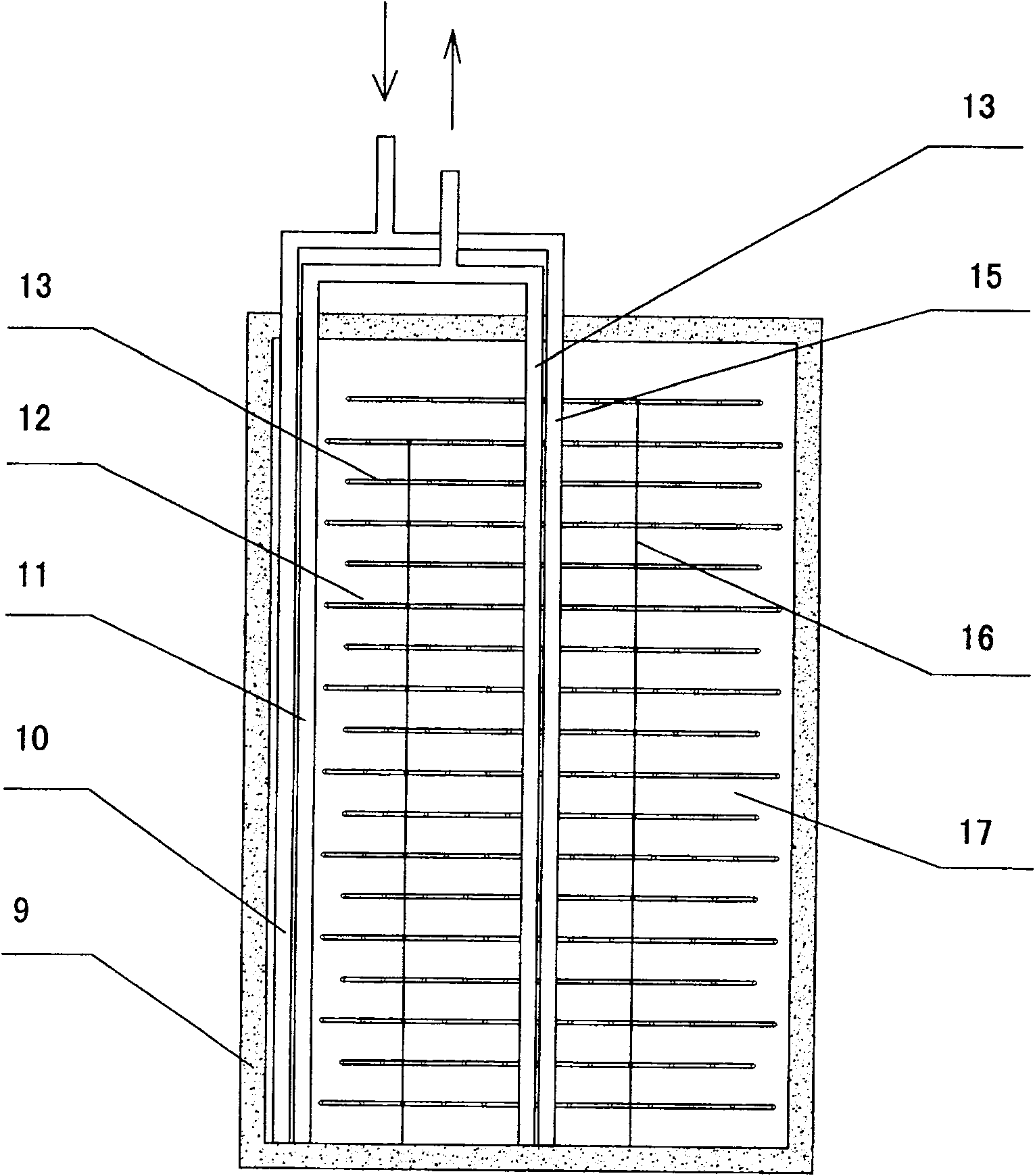

Large fermentation tank heat exchange device

InactiveCN105950444AGuaranteed heat transfer areaReduce resistanceBioreactor/fermenter combinationsBiological substance pretreatmentsWater flowEngineering

The invention discloses a large fermentation tank heat exchange device which comprises an upper converging pipe and a lower converging pipe, and a plurality of parallel row tubes are arranged between the upper converging pipe and the lower converging pipe; the upper ends of the row tubes are communicated with the upper converging pipe, and the lower ends of the row tubes are communicated with the lower converging pipe. According to the large fermentation tank heat exchange device, the upper part and the lower part of the device are equipped with the converging pipes respectively, and the plurality of small vertical row tubes which are connected in parallel are arranged between the upper converging pipe and the lower converging pipe, so that the heat exchange area of the fermentation tank is guaranteed; water enters the device from the lower converging pipe, flows through the vertical row tubes which are connected in parallel simultaneously and enters the upper converging pipe, so that the water inlet and outlet path is short, the water flow resistance is mall, the water can exchange heat in the fermentation tank rapidly, and the heat exchange efficiency is high.

Owner:JIANGSU SHANGKUN BIOLOGICAL EQUIP

A kind of solar heat collector with changing flow rate of heat collecting tube

ActiveCN105758009BHomogeneous mixingAvoid lostSolar heating energyHeat transfer optimizationEngineeringStreamflow

The invention provides a solar thermal collector. The solar thermal collector comprises two tube plate structures, wherein a certain included angle is formed between the two tube plate structures; the direction of the included angle is opposite to the bending direction of an arc structure of a reflecting mirror; the focus of the reflecting mirror is in the included angle formed by the tube plate structures; inner fins are arranged inside collector tubes, are connected with opposite angles of rectangles and divide the interiors of the collector tubes into a plurality of small channels; communication pores are formed in the inner fins; the flows of fluids in different collector tubes are larger and larger in the extension directions from the collection point of the two tube plate structures to the lowest positions at the two sides. The solar thermal collector has the advantages that the uniform mixedness of fluids is maintained, thus avoiding loss of heat during fluid mixing; the temperatures of the collector tubes are ensured to basically keep the same, thus prolonging the overall service lives of the collector tubes.

Owner:青岛酒店管理职业技术学院

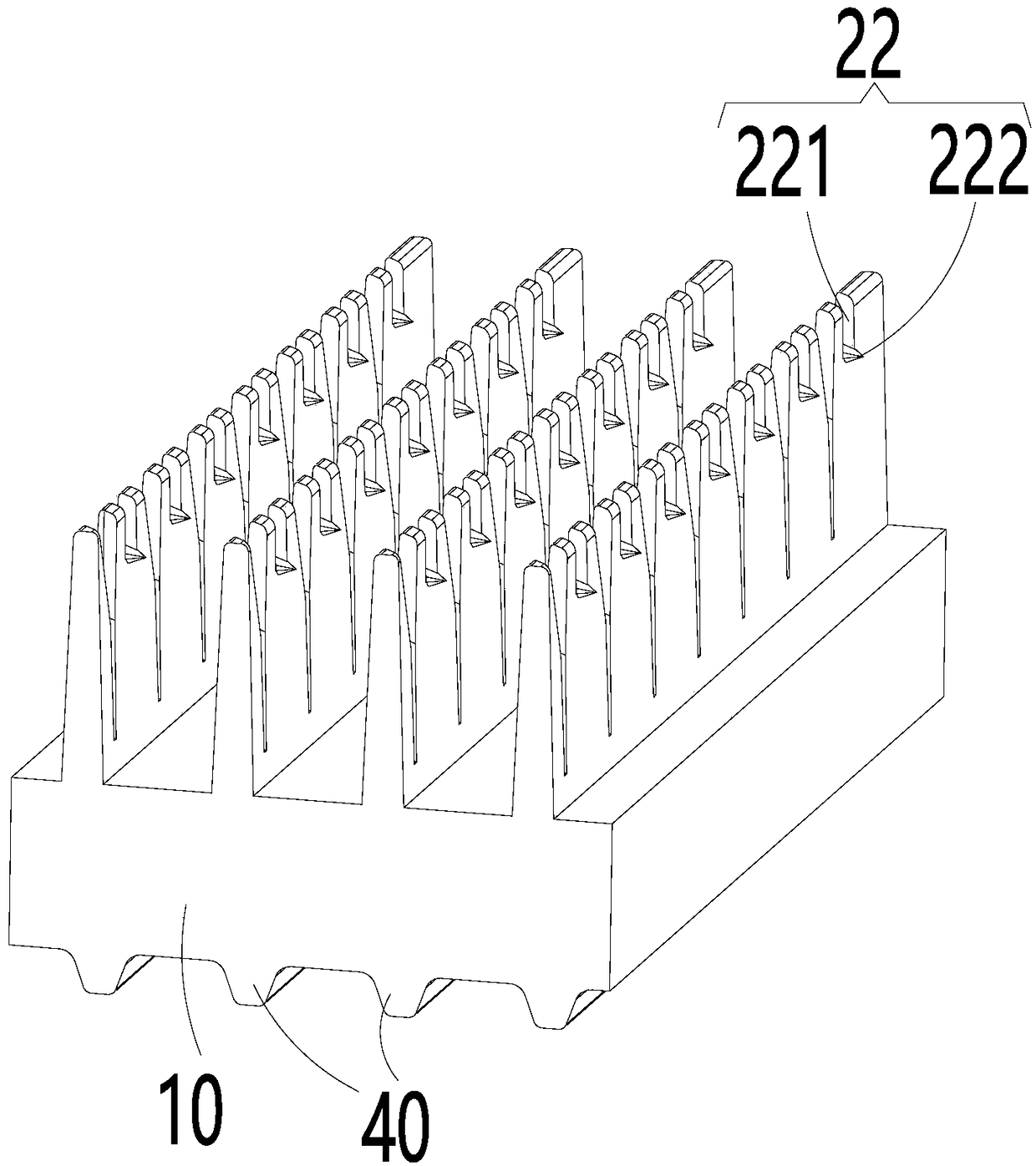

Second-grade heat radiation insertion piece casing

InactiveCN105896800AGuaranteed heat transfer areaGuaranteed stabilitySupports/enclosures/casingsEngineeringEnergy loss

The present invention discloses a second-grade heat radiation insertion piece casing. The casing is provided with a cavity, a plurality of first insertion pieces along the axial direction of the casing is arranged at the outer surface of the casing, second insertion pieces are arranged at the end portion of the first insertion pieces, and a motor installation structure is arranged at the inner surface of the casing. The first pieces and the second pieces are arranged to ensure the heat exchange area of the surface of the casing. Compared with the technical scheme of individually increasing the length of the second insertion pieces, the effective heat exchange area is obviously increased; and a buckle groove arranged in the cavity is able to ensure the work stability of the stator rotor and avoid the mutual motion generated by the stator rotor and the casing so as to reduce the energy loss.

Owner:陆建明

De-heavy kettle recycling system and method for camphor production

PendingCN108164406AHeating up fastAvoid cloggingChemical/physical/physico-chemical processesCarbonyl compound separation/purificationPetroleum engineeringCamphor

The invention provides a de-heavy kettle recycling system and method for camphor production. The de-heavy kettle recycling system comprises a de-heavy kettle, the de-heavy kettle is used for conducting de-heavy and distilling on excessive oil and outputting the excessive oil to a camphor oil receiving device, and the lower end of the camphor oil receiving device is connected with a crystallizationbox; the de-heavy kettle recycling system is further provided with a negative pressure vacuum device to provide negative pressure for the de-heavy kettle and the camphor oil receiving device separately. According to the method, the de-heavy kettle is utilized to recycle camphor in the excessive oil. By means of the de-heavy kettle recycling system, the problem in the prior art that a lot of camphor in the excessive oil fails to be fully recycled is solved, the recycling rate of the camphor is increased, and the consumption of production raw materials is reduced.

Owner:WUZHOU HUANGPU CHEM PHARM CO LTD

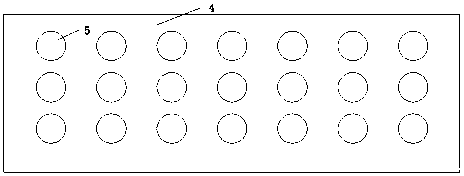

Trapping device for tetrachloroisophthalonitrile synthesis gas, and use method and application of trapping device

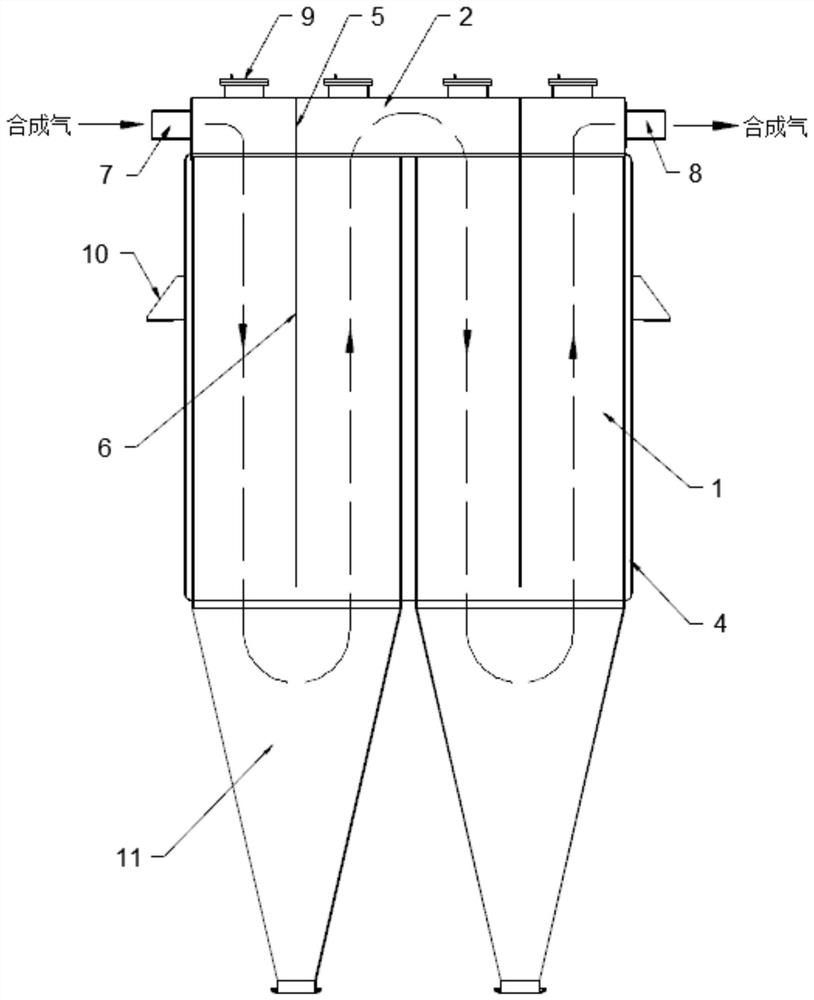

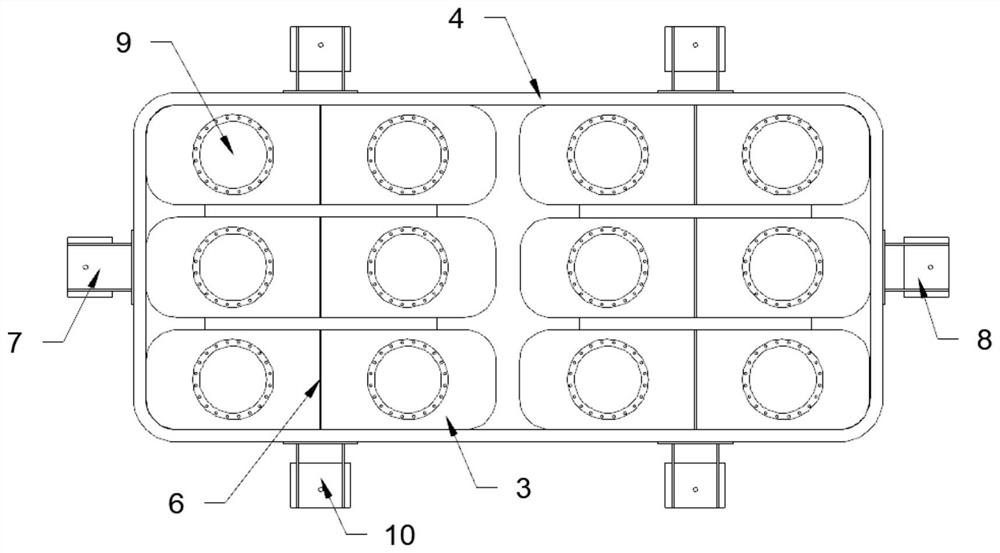

PendingCN111714919ASufficient heat exchangeImprove capture efficiencyVapor condensationCarboxylic acid nitrile purification/separationTrappingMaterials science

The invention provides a trapping device for tetrachloroisophthalonitrile synthesis gas, and a use method and application of the trapping device. The trapping device comprises a trapping device body and a top sealing head arranged above the trapping device body, wherein the trapping device body comprises at least two sets of trapping assemblies which are arranged at intervals and are independent of each other in the length direction of the trapping device body; each set of trapping assembly comprises at least one trapping shell arranged side by side in the width direction of the trapping device body, a longitudinal baffling baffle is arranged in each trapping shell, the baffling baffles are parallel to the width direction of the trapping device body, and the baffling baffles divide the interior of each trapping shell into an outward trapping chamber and a return trapping chamber with communicating bottoms; a jacket is arranged on the outer side of the trapping device body; the trappingshells are arranged in the jacket at intervals in a matrix mode, and a cooling medium is introduced into the jacket; and the top sealing head is used for communicating the tops of the two adjacent trapping assemblies, longitudinal partition plates opposite to the baffling baffles are arranged in the sealing head, and a gas inlet and a gas outlet are formed in the two sides of the short edge of the top sealing head respectively.

Owner:JIANGSU XINHE AGROCHEM

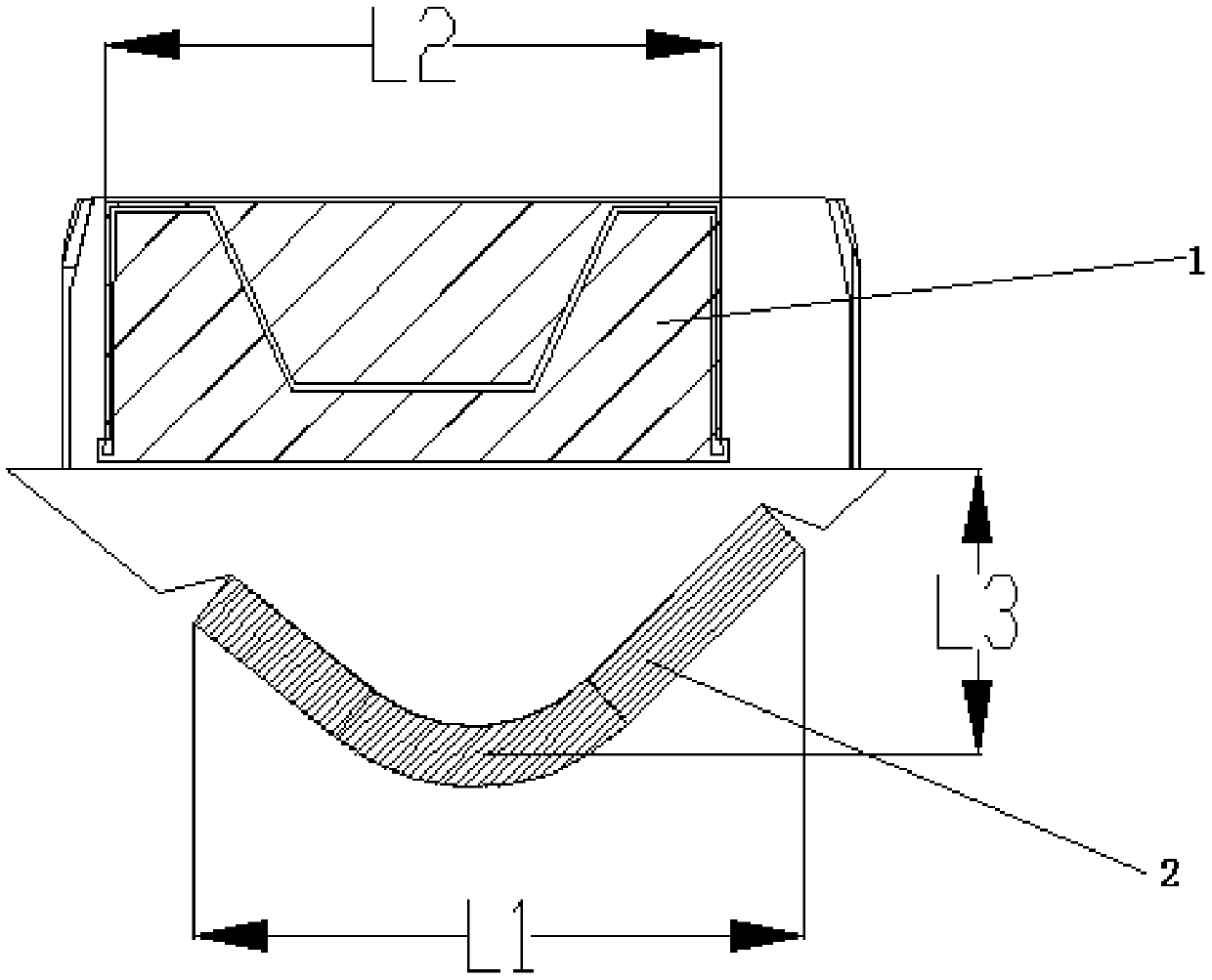

Heat exchange fan assembly and air conditioner

ActiveCN111197816AImprove heat transfer effectGuaranteed heat transfer areaLighting and heating apparatusSpace heating and ventilation detailsEngineeringMechanical engineering

The invention provides a heat exchange fan assembly and a heat exchanger. The heat exchange fan assembly comprises a centrifugal fan and the heat exchanger; the centrifugal fan comprises centrifugal fan blades, and the diameter of the centrifugal fan blades is L2; the heat exchanger is arranged on the air inlet side of the centrifugal fan, the width of the heat exchanger is L1, and the width of the heat exchanger refers to the distance of two end points, close to the centrifugal fan blade, of the heat exchanger in the horizontal direction; and L2 is greater than or equal to L1. The heat exchanger is completely located in the flow field driven by the centrifugal fan blades, so that the heat exchanger fully exchanges heat with air, and the heat exchange fan assembly has good heat exchange performance.

Owner:GREE ELECTRIC APPLIANCES INC

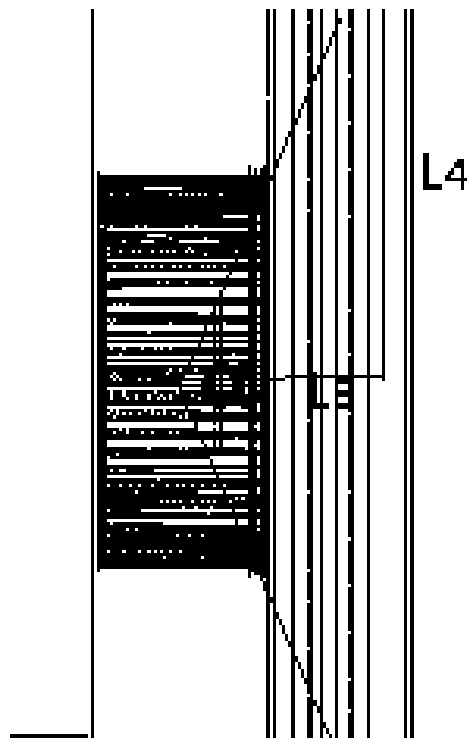

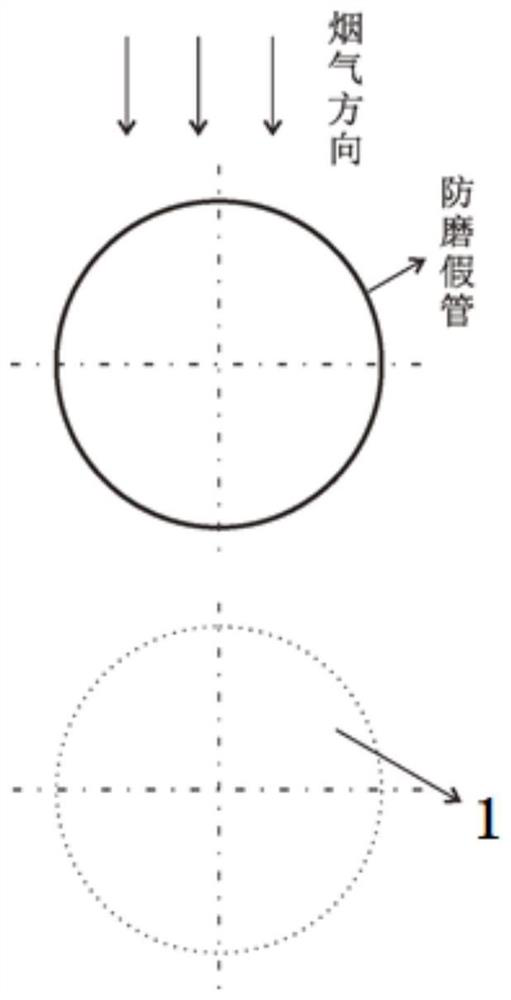

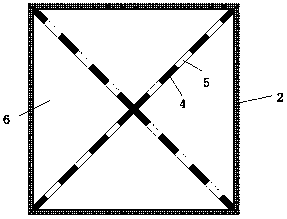

Finned tube heating surface tube structure and coal economizer

PendingCN112985155AReduce wearSolve the problem of leakage caused by non-wearCorrosion preventionTubular elementsThermodynamicsEngineering

The invention discloses a finned tube heating surface tube structure and a coal economizer. The finned tube heating surface tube structure comprises a heating tube, fins and anti-abrasion plates, wherein the fins and the anti-abrasion plates are connected with the heating tube; a plurality of fins are arranged in parallel in the radial direction of the heating tube; the anti-abrasion plates penetrate through the fins and are arranged in the axial direction of the heating tube; and a plurality of anti-abrasion plates are arranged along the circumference of the heating tube and distributed in a radial shape. The anti-abrasion plates are arranged on the portion, right facing the windward side, of the heating tube, so that the problem that leakage is caused due to the fact that a finned tube on the heating surface of an existing low-temperature coal economizer is not resistant to abrasion is thoroughly solved; the anti-abrasion plates and the fins are combined on the heating tube, so that the effects of preventing leakage of the heating tube and guaranteeing the heat transfer area of the heating tube are achieved; and the anti-abrasion plates are directly welded to the heating tube, and smoke heat absorbed by the anti-abrasion plates is directly transferred to the heating surface tube, so that the area of the heating tube is increased, the temperature of media in the tube is increased, the anti-abrasion effect is achieved, the heat utilization rate is increased, and the finned tube heating surface tube structure has high use value and popularization value.

Owner:大唐秦岭发电有限公司

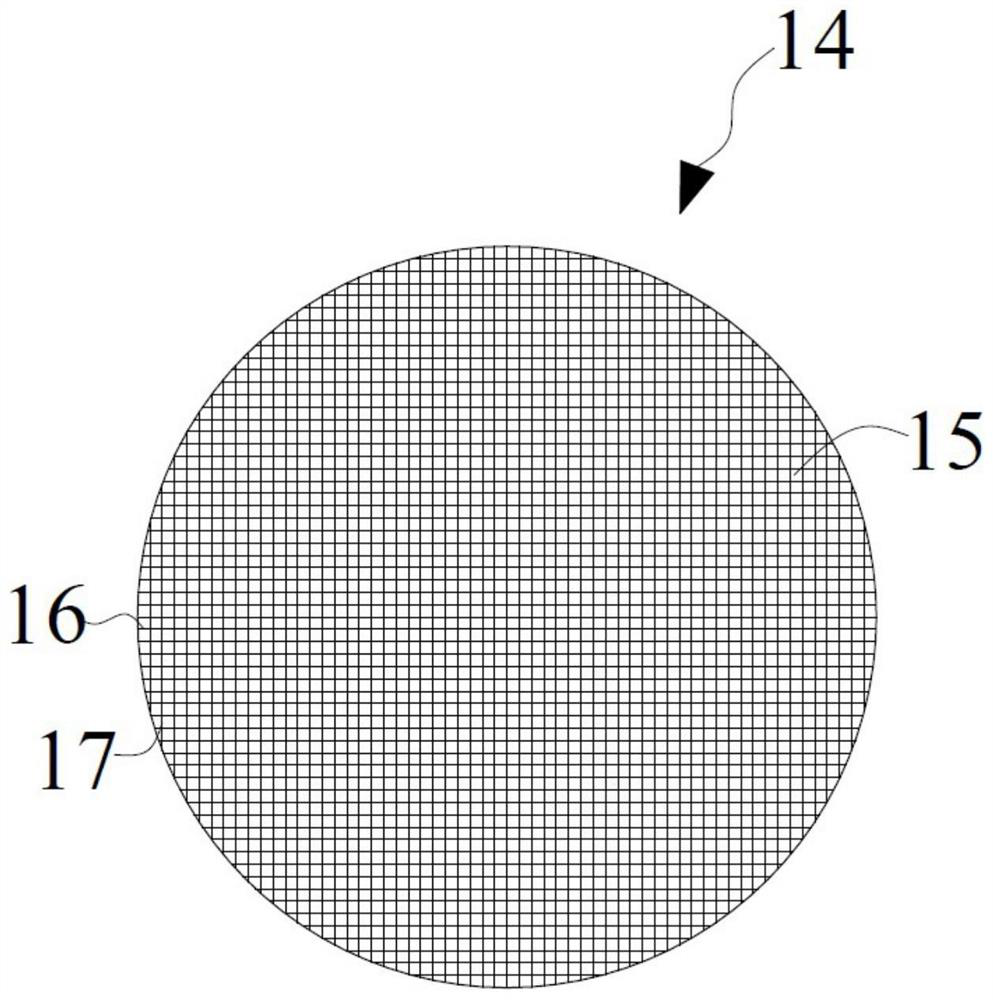

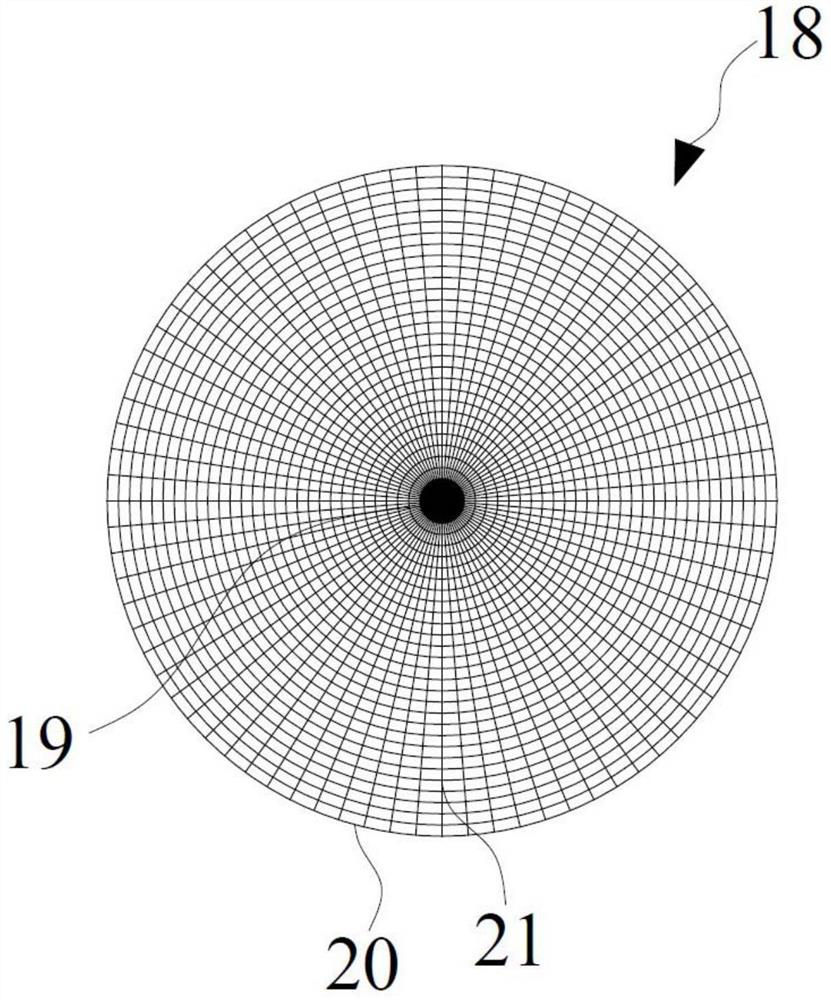

Regenerator and cold accumulation type low-temperature refrigerator adopting same

PendingCN114111083AReduce cooling lossImprove cooling efficiencyCompression machinesRefrigeration componentsThermodynamicsEngineering

The invention discloses a regenerator and a cold accumulation type low-temperature refrigerator adopting the regenerator, and belongs to the technical field of low-temperature refrigerators. The silk screens of the two different structures are composed of laminated substrate silk screens with uniform void ratios and laminated interval silk screens with different void ratios in the radial direction. The regenerator has the variable porosity in the radial direction, the flow resistance of working medium gas in the regenerator can be adjusted, the refrigerating capacity loss of the refrigerator caused by uneven radial temperature distribution is reduced, and the refrigerating efficiency of the refrigerator is improved. Meanwhile, due to the fact that the material of the laminated interval silk screen is the same as that of the laminated substrate silk screen serving as the main cold storage material, the heat exchange area and the heat exchange efficiency can be guaranteed, the problems that the heat exchange efficiency is reduced and the refrigeration performance is degraded due to the insertion part can be solved, and the performance of the refrigerator is further improved.

Owner:SHENZHEN POWER SUPPLY BUREAU

Refrigeration adsorber and its manufacturing method

InactiveCN100498133CCompact structureGuaranteed heat transfer areaClimate change adaptationEnergy efficient heating/coolingSorbentEngineering

Owner:SOUTH CHINA UNIV OF TECH

A kind of solar heat collector with changing hole area

ActiveCN105698406BGuaranteed heat transfer areaExtended service lifeSolar heating energySolar heat devicesDiagonalEngineering

Owner:徐州中伦光伏材料有限公司

A kind of solar heat collector with regularly changing size of heat collecting tube

ActiveCN105758016BHomogeneous mixingAvoid lostSolar heating energySolar heat collectors with working fluidsEngineeringSolar thermal collector

Owner:太仓戴萌兔服饰有限公司

A high heat transfer solar collector

ActiveCN105758015BRaise the ratioImprove high temperature resistanceSolar heating energySolar heat collectors with working fluidsEngineeringCopper

The invention provides a solar thermal collector which comprises two tube plate structures, wherein a certain included angle is formed between the two tube plate structures; the direction of the included angle is opposite to a bending direction of an arch-shaped structure of a reflecting mirror; the focus of the reflecting mirror is positioned between the included angle formed by the tube plate structures; thermal collection tubes are internally provided inner fins; the inner fins are connected with rectangular inner corners; the thermal collection tubes are internally divided into a plurality of small channels by the inner fins; communication holes are formed in the inner fins; the thermal collection tubes and the thermal collection plates are made of a copper aluminum alloy. As a novel copper aluminum alloy is researched and developed and applied to the thermal collection tubes, the function of thermal collection can be improved, and meanwhile the high-temperature resistance of the thermal collector can be greatly improved.

Owner:河北三环太阳能有限公司

A high-efficiency waste heat recovery system for steelmaking and continuous casting

ActiveCN112013704BScientific and reasonable structureEasy to useCorrosion preventionIncreasing energy efficiencyThermodynamicsProcess engineering

The invention discloses a high-efficiency waste heat recovery system for steelmaking and continuous casting. A heat recovery component is installed on one side of the crystallizer base body, and several exhaust holes are equidistantly opened on the top of the crystallizer base body, and the inner side of the exhaust hole is embedded and installed. There is an exhaust fan, the bottom of the first recovery tank and the second recovery tank are welded with a deceleration tube, one end of the deceleration tube is installed with a heat conduction plate, the bottom of the second recovery tank is installed with the first water inlet pipe, and the top of the second recovery tank is installed with the first The outlet pipe accelerates the discharge of the hot steam inside the crystallizer through the exhaust fan, and discharges the hot steam into the recovery tank, and slows down its flow speed through the deceleration tube in the recovery tank, thus ensuring the heat dissipation time of the hot steam in the tank. And through the heat conduction plate to increase the heat conduction area, through two recovery tanks and continuously circulating cold water, the effect of recovering the heat energy contained in the hot steam is ensured, thereby ensuring the utilization rate of heat energy and reducing the waste of resources.

Owner:SHENYANG JIANZHU UNIVERSITY

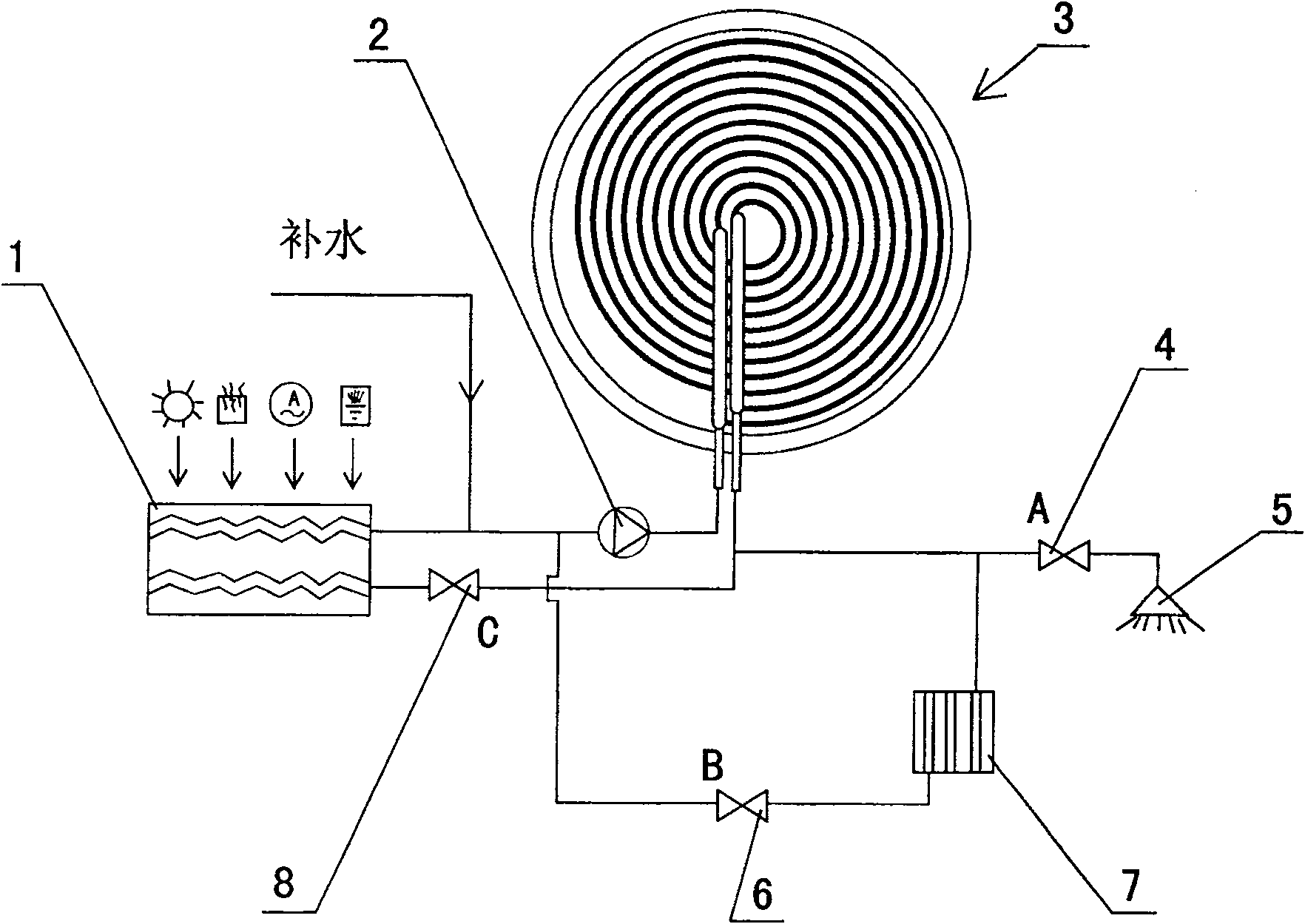

Phase change heat storage heat supply device

InactiveCN100547337CSmall heat transfer temperature differenceReduce volumeHeat storage plantsEnergy storageExternal energyWater cycling

The phase change heat storing and supplying apparatus includes external energy source heater, water circulating pump, phase change heat storing device, valve A, valve B, valve C, heat sink, and shower connected together. By means of the direct phase change heat storing and releasing mode and stereo double involute heat accumulator, the present invention has homogeneous distribution of heat exchange pipe inside the heat accumulator, raised heat absorbing and releasing efficiency of the heat accumulating agent, reduce water flow pipe resistance and heat transfer temperature difference, increased heat accumulating capacity per unit volume, reduced apparatus size, full utilization of solar energy, waste heat and low price electric power, and stable hot water supply.

Owner:皇明太阳能(上海)有限公司

Direct type soil source heat pump system

InactiveCN100587364CGuaranteed heat transfer areaReduce heat transfer areaHeat pumpsCompression machines with reversible cycleVapor–liquid separatorProcess engineering

The invention relates to a direct type soil source heat pump system, which belongs to the technical field of refrigeration and heat pump. The system is composed of a compressor, a gas-liquid separator, an oil separator, a four-way change-over valve, a cooling agent / water heat exchanger, a bi-directional different working medium heat filling expansion valve, a device for drying and filtering, a level glass, a liquid separating device, an air collecting pipe, parallel branch of an outer fin copper pipe buried heat exchanger, an one-way valve, a solenoid-controlled valve and the like. The bi-directional different working medium heat filling expansion valve is used for throttle, liquid separating is accomplished to liquid cooling agent after gas-liquid separation when heat-production is in progress, and the buried heat exchanger employs compact outer ribbed structure and can operate heat-production and refrigeration. The direct type soil source heat pump system has the advantages of reliability, high efficient and environment protection.

Owner:BEIJING UNIV OF TECH

vertical electric water heater

ActiveCN105026851BUniform temperatureMaximize energy storage effectHeating fuelImmersion heating arrangementsEngineeringTemperature difference

Disclosed is a vertical electric water heater, which mainly consists of a liner and a heating device arranged in the liner. The heating device comprises a heat generation cover of which one end is provided with an opening, and at least one electric heating pipe sleeved in an inner chamber of the heat generation cover and closely fitted with the inner wall of the heat generation cover, with the heat generation cover being located on a vertical centre line of the liner. Further, the vertical centre line of the liner coincides with the centre line of the heat generation cover, and the electric heating pipes are uniformly distributed around the centre line of the heat generation cover. The heating device is located on the vertical centre line of the liner, so that an isothermal body which uses the heating device as a centre can be formed, thereby enabling the temperature differences among various mass points in water to be substantially reduced, so that the temperature uniformity of water in the liner is good; moreover, the arranged heat generation cover enables heat exchange area between the electric heating pipe and water to be increased, so that the temperature uniformity of water in the liner is further guaranteed, and the deposit formed in unit area on the heat exchange surface is reduced; in addition, the electric heating pipe is simple and convenient to replace and disassemble because of being sleeved in the heat generation cover.

Owner:GUANGDONG VANWARD ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com