Low-pressure economizer with finned tubes

A low-pressure economizer and finned tube technology, applied in feed water heaters, preheating, steam generation, etc., can solve the problems of finned tubes recovering waste heat deviated from the optimal state, reduced heating area, and dust accumulation, etc. To achieve the effect of improving service life, reducing low-temperature corrosion, and reducing dust accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

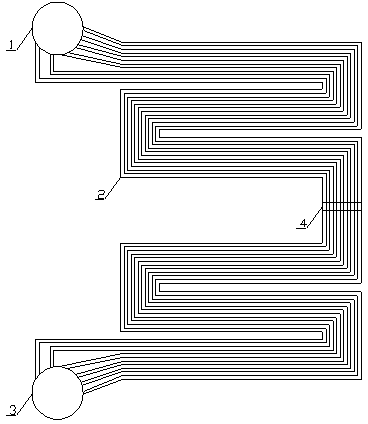

[0009] Depend on figure 1 It is known that a finned tube low-pressure economizer is composed of an inlet header 1, a finned tube row 2 and an outlet header 3. The finned tube row 2 is divided into two parts, the upper section and the lower section. The inlet header 1 and the finned tube The first six rows of the upper section of the row 2 are connected, the outlet header 3 is connected with the lower six rows of the finned tube row 2, and the upper section and the lower section of the finned tube row 2 are welded together as a whole through the installation weld 4. The upper section of the fin tube row 2 is 18 rows, the lower section is 18 rows, the height of the fins is 12mm, the thickness is 1.5mm, the spacing is 12mm, and the tube rings are 2 turns.

[0010] The first six rows of tubes in the upper section of the finned tube row 2 are made of ND steel and connected to the inlet header 1 to avoid low-temperature corrosion at the inlet and enhance the corrosion resistance of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com