Stainless steel corrugated pipe ground heat source heat exchange system and setting method thereof

A heat exchange system, stainless steel technology, applied in the field of construction tools, can solve the problems of unstable heat exchange, inconvenient setting, small heat conduction area, etc., to achieve the effect of reducing development cost, convenient installation, and ensuring heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

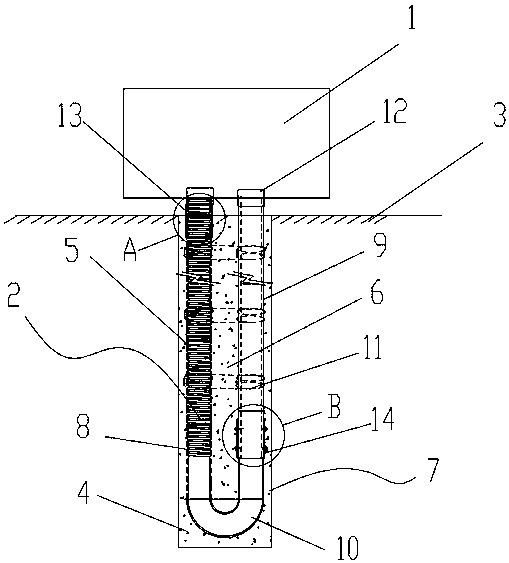

[0038] exist figure 1 , Figure 4 In the shown embodiment, a stainless steel bellows heat source heat exchange system includes:

[0039] Above-ground heat exchange device 1, an above-ground device for realizing heat energy exchange;

[0040] The underground heat exchange device 2 is a device connected to the above-ground heat exchange device 1 to realize underground heat conversion; the underground heat exchange device 2 includes a ground source hole 4 arranged under the foundation 3 and a heat exchange element 5 arranged inside the ground source hole 4 ;

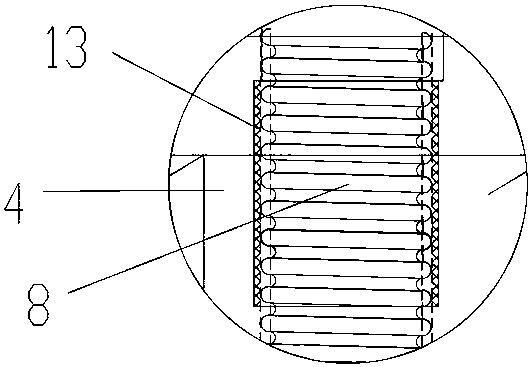

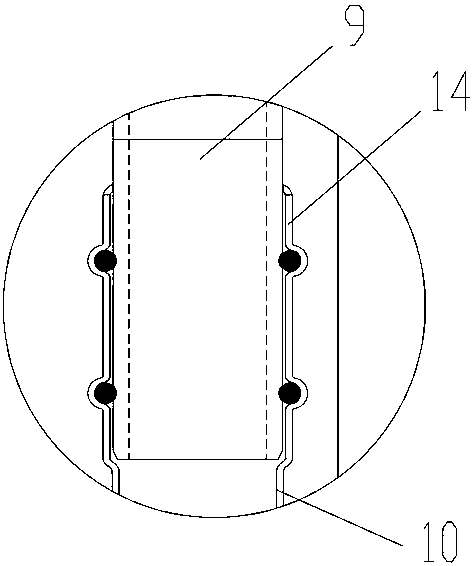

[0041] The heat exchange element 5 includes a solid filler 6 and at least one heat exchange system unit 7, and each heat exchange system unit 7 includes a stainless steel bellows section 8, a polyolefin material pipe section 9 and a stainless steel elbow section 10; the stainless steel bellows section 8 and polyolefin The material pipe section 9 is arranged parallel to the vertical direction of the ground source hole 4; ...

Embodiment 2

[0050] exist Figure 5 In the shown embodiment, a stainless steel bellows heat source heat exchange system includes:

[0051] Above-ground heat exchange device 1, an above-ground device for realizing heat energy exchange;

[0052] The underground heat exchange device 2 is a device connected to the above-ground heat exchange device 1 to realize underground heat conversion; the underground heat exchange device 2 includes a ground source hole 4 arranged under the foundation 3 and a heat exchange element 5 arranged inside the ground source hole 4 ;

[0053] The heat exchange element 5 includes a solid filler 6 and at least one heat exchange system unit 7, and each heat exchange system unit 7 includes a stainless steel bellows section 8, a polyolefin material pipe section 9 and a stainless steel elbow section 10; the stainless steel bellows section 8 and polyolefin The material pipe section 9 is arranged parallel to the vertical direction of the ground source hole 4; one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com