De-heavy kettle recycling system and method for camphor production

A recycling system and deweighting technology, applied in chemical instruments and methods, separation/purification of carbonyl compounds, chemical/physical/physical-chemical processes, etc., can solve the problems of no recycling, large consumption of raw materials, etc. Pipes, improve product yield, and ensure the effect of heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

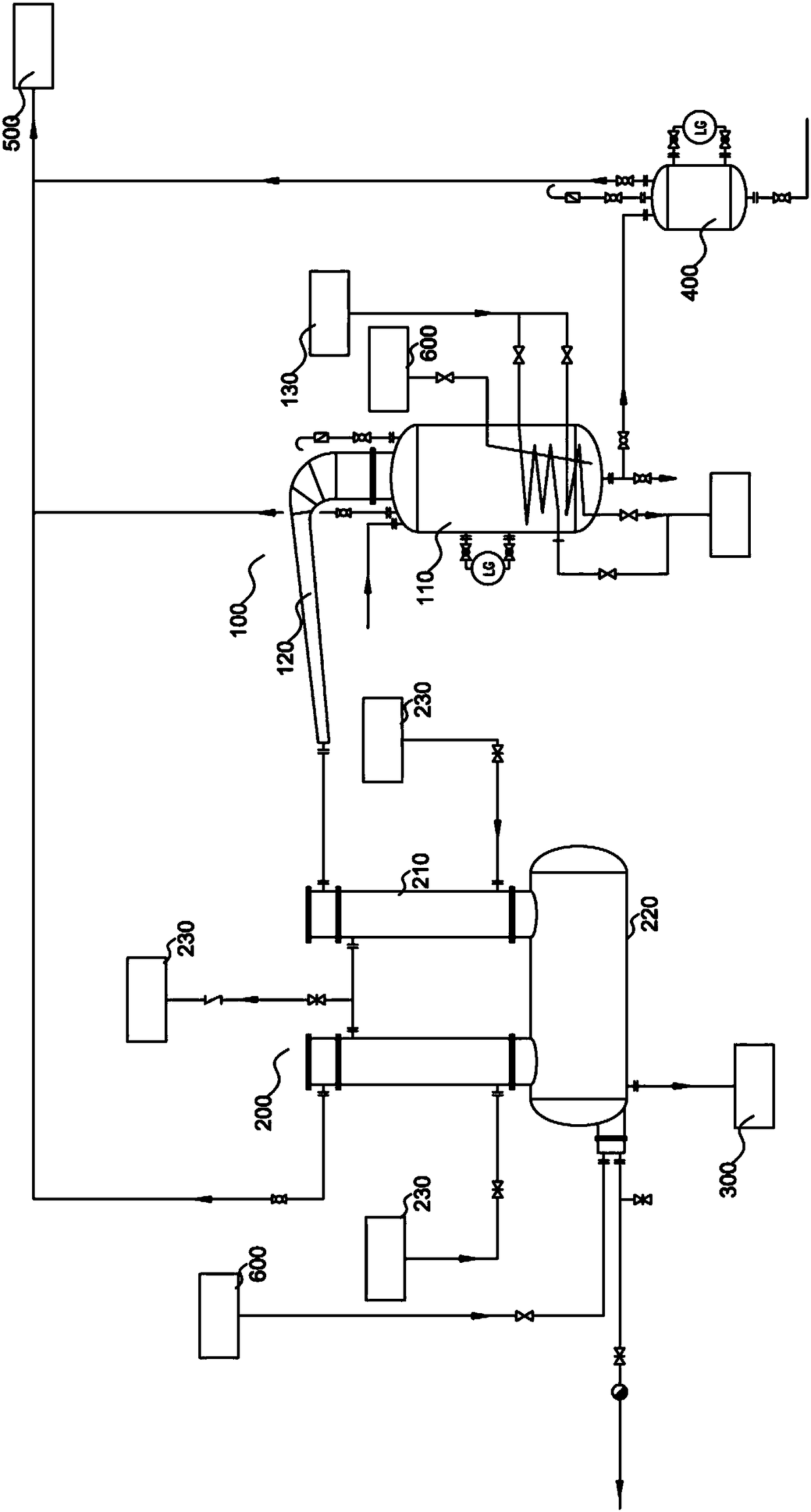

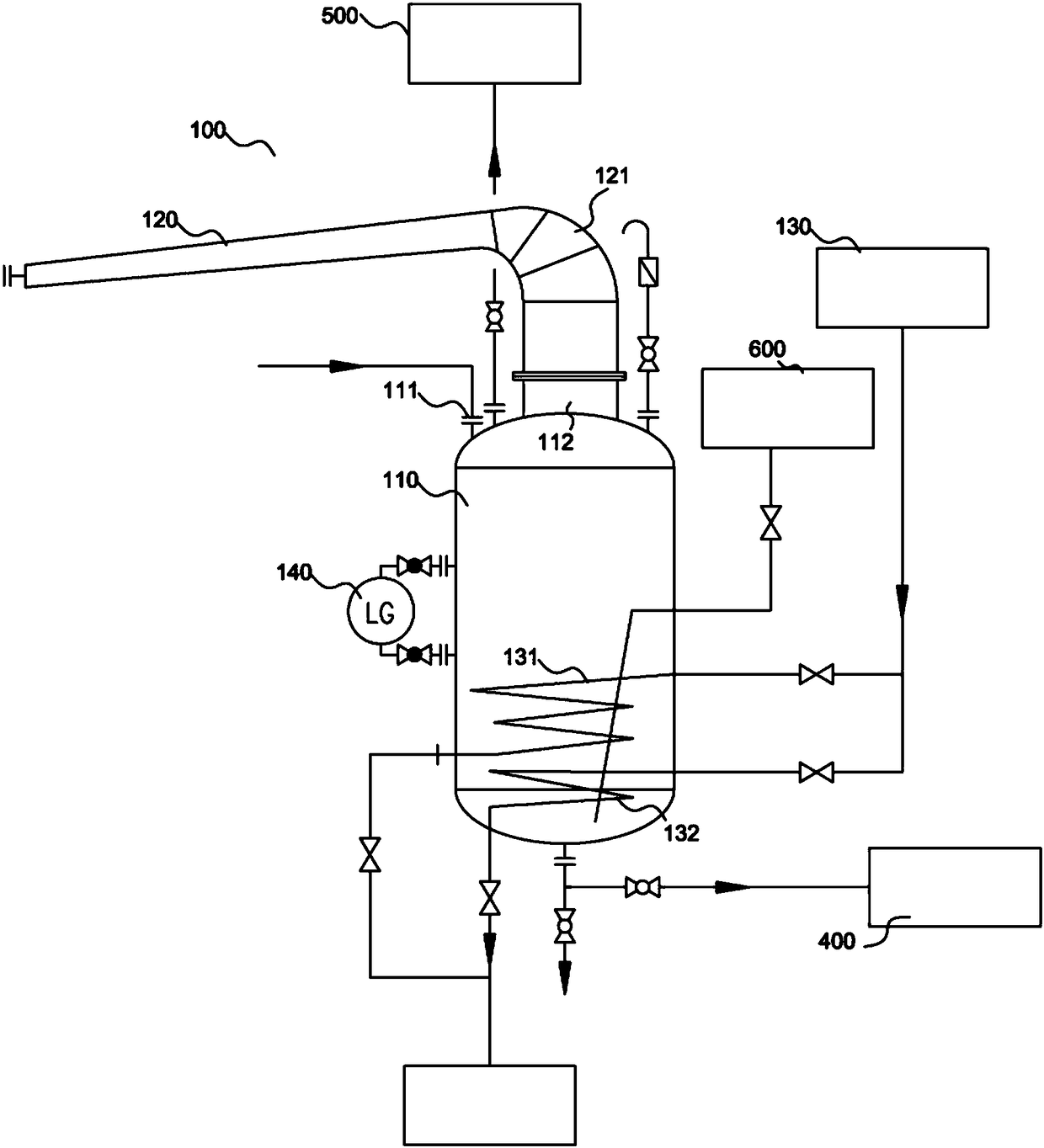

[0023] Such as figure 1 , 2 Shown, a kind of weight-removing kettle recovery system for camphor production of the present invention mainly comprises: weight-removing kettle 100, naphtha receiving device 200, crystallization box 300, surplus oil tank 400, negative pressure vacuum device 500 and steam device 600. The deheavy still 100 is used to deheavily distill the residual oil and output it to the naphtha receiving device 200 , and recover the heavy oil after the deheavy distillation is connected to the bottom of the residual oil tank 400 . The lower end of the naphtha receiving device 200 is connected to the crystallization tank 300, the naphtha receiving device 200 is used for temperature-controlled storage of the distillate from the weight removal kettle 100, and the crystallization tank 300 is used to process the distillate stored in the naphtha receiving device 200 Crystallization to obtain camphor. During the whole recovery process, the negative pressure vacuum devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com