Direct type soil source heat pump system

A soil source heat pump, a direct technology, applied in the field of refrigeration and heat pumps, can solve the problems of excessive refrigerant charge, complex system structure, increased cost, etc., to achieve the effect of reducing charge, reducing internal volume, and improving COP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

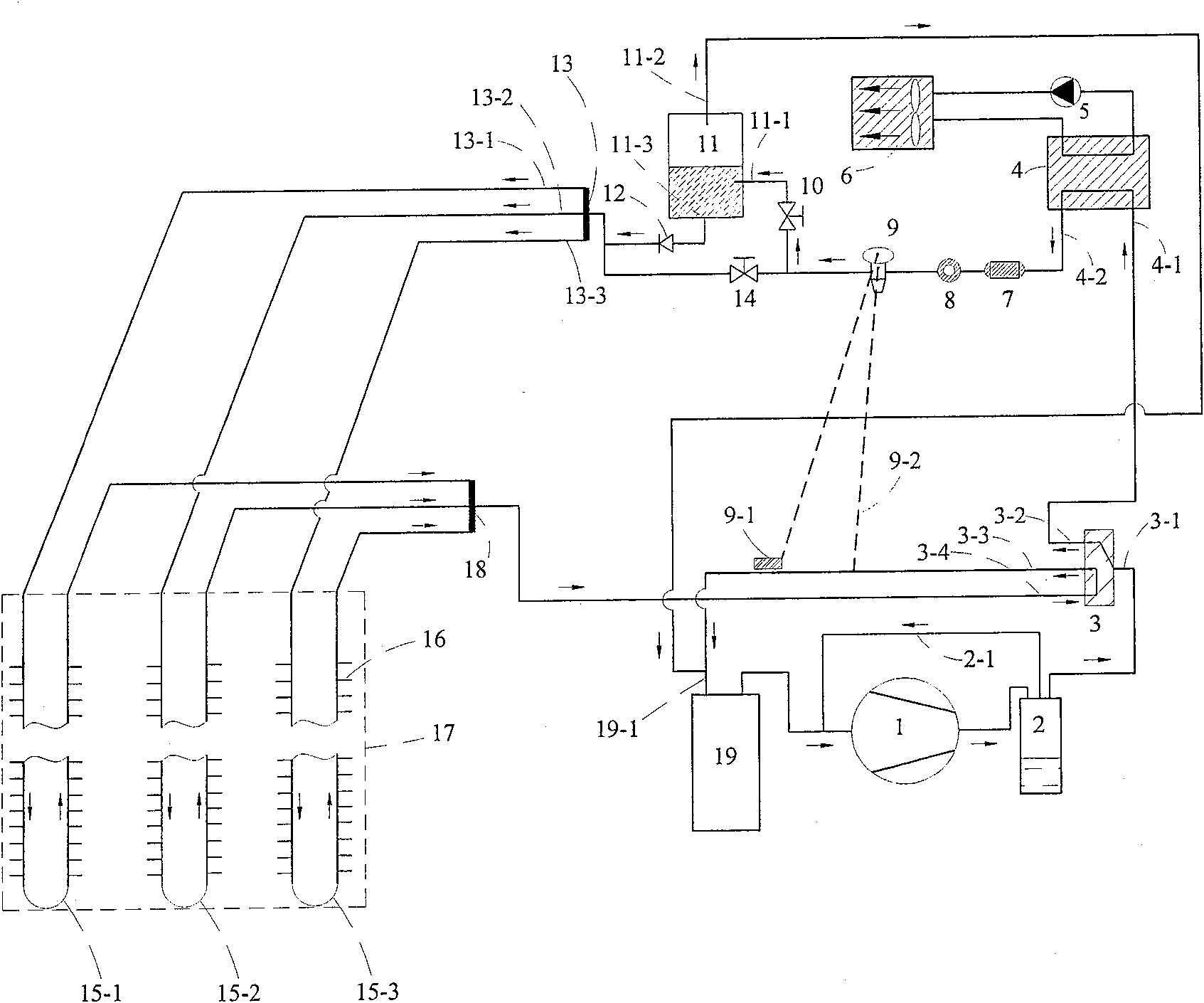

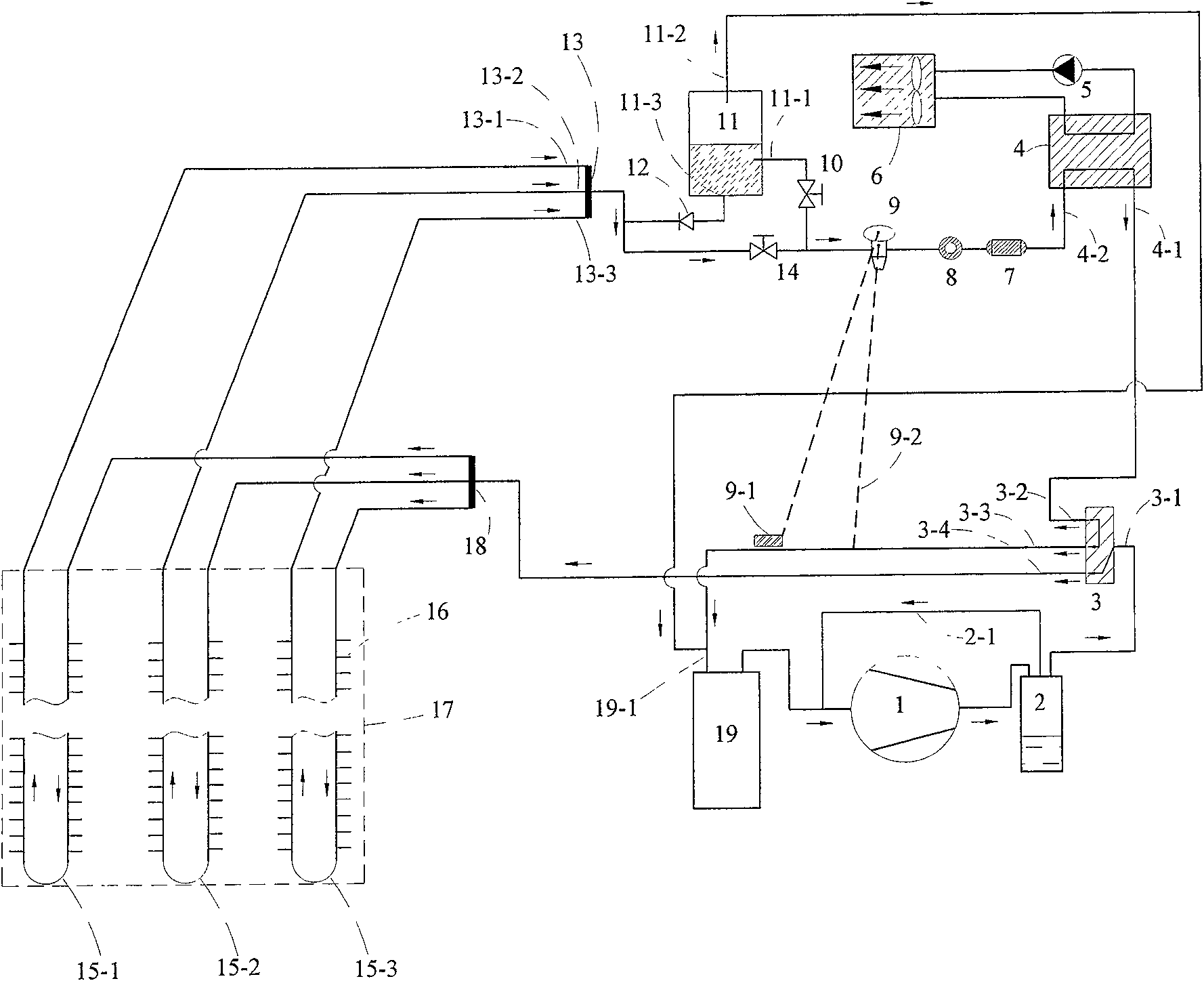

[0023] The following combination figure 1 and figure 2 The heating mode and cooling mode of the present invention will be described. figure 1 and figure 2 In the embodiment, three parallel external finned copper tube buried heat exchanger branches are used.

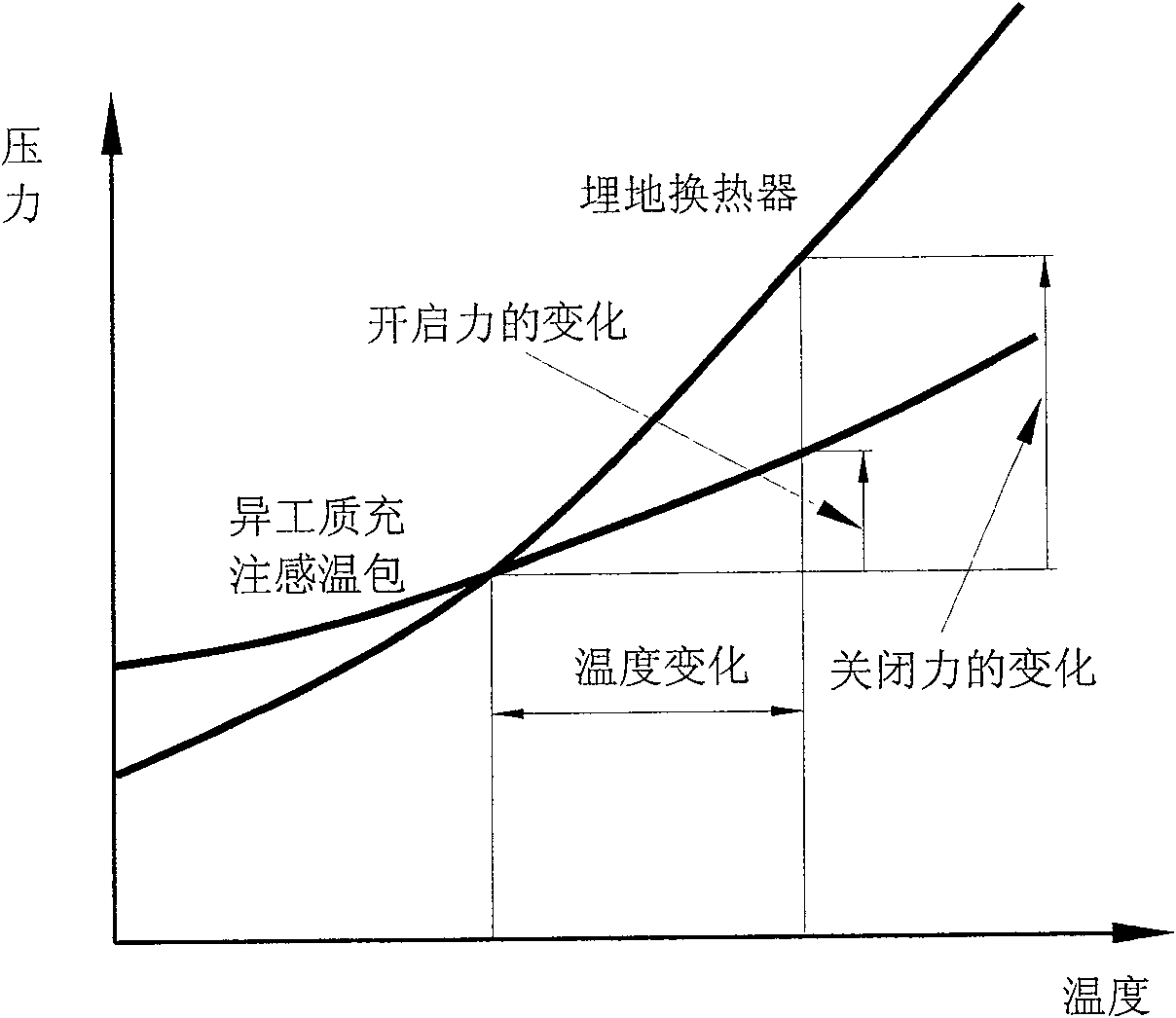

[0024] Such as figure 1 As shown, this embodiment includes a compressor 1, an oil separator 2, a four-way reversing valve 3, a refrigerant / water heat exchanger 4, a water pump 5, a fan coil unit 6, a sight glass 8, and a dry filter 7 And buried heat exchanger branch, gas-liquid separation device 11 and two-way heterogeneous substance charging thermal expansion valve 9; Connected to the 3-4 end of the valve 3, the exhaust pipe of the compressor 1 is connected to the 3-1 end of the four-way reversing valve 3 through the oil separator 2; the oil return pipe 2-1 of the oil separator 2 is connected to the compressor 1 connected to the suction pipe; the 3-2 end of the four-way reversing valve 3 is connected to the refrig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com