Second-grade heat radiation insertion piece casing

A secondary heat dissipation and inserting machine technology, which is applied in the direction of casing/housing/support, electromechanical devices, electrical components, etc., can solve the problem of increasing raw material consumption, increasing production costs, and the inability to dissipate the heat of the second insert in time, etc. problems, to achieve the effect of avoiding mutual movement, reducing energy loss and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

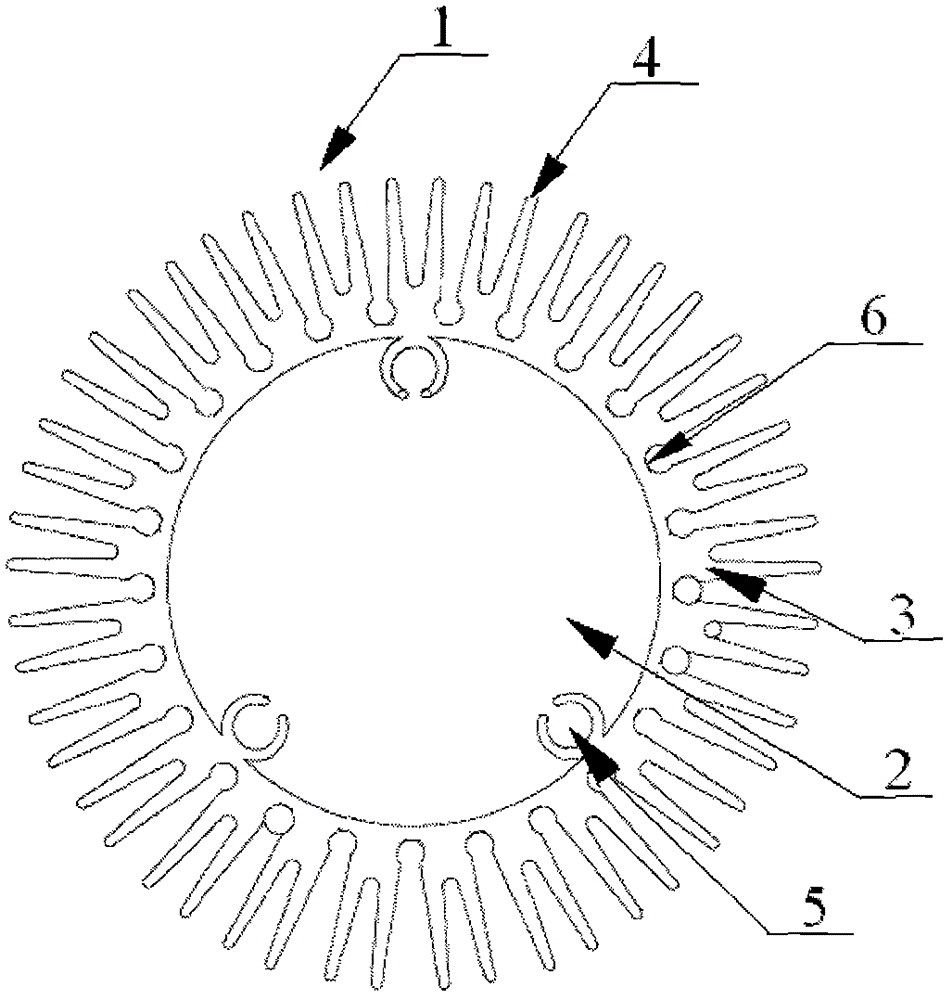

[0010] see figure 1 , the casing 1 has a cavity 2, the outer surface of the casing 1 is provided with several first insertion pieces 3 along the axial direction of the casing 1, the end of the first insertion piece 3 is provided with a second insertion piece 4, inside the casing 1 The surface is also provided with a motor mounting structure; there are two second inserts 4 at the end of each first insert 3, and the first insert 3 and the second insert 4 are divergently arranged around the casing 1; The contour is cylindrical, the outer contour of several second inserts is cylindrical, the bottom surface of cavity 2 and the bottom surface of the outer conto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com