Refrigeration adsorber and its manufacturing method

A manufacturing method and technology for adsorbers, which are applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of large heat transfer resistance of solid adsorbents, low heat and mass transfer efficiency of adsorbers, and small loading of adsorbents. , to achieve the effect of compact structure, favorable heat transfer and short mass transfer channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

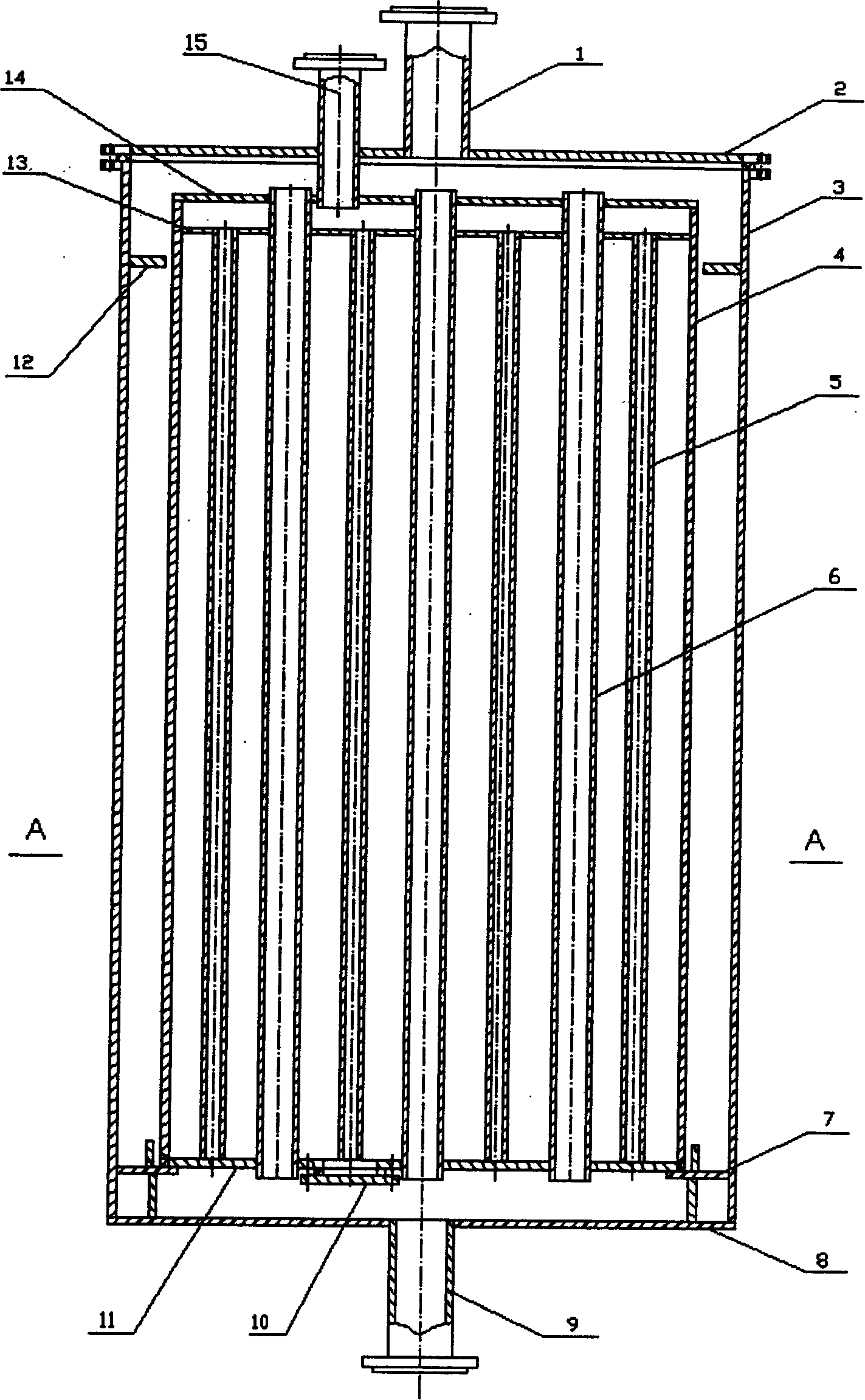

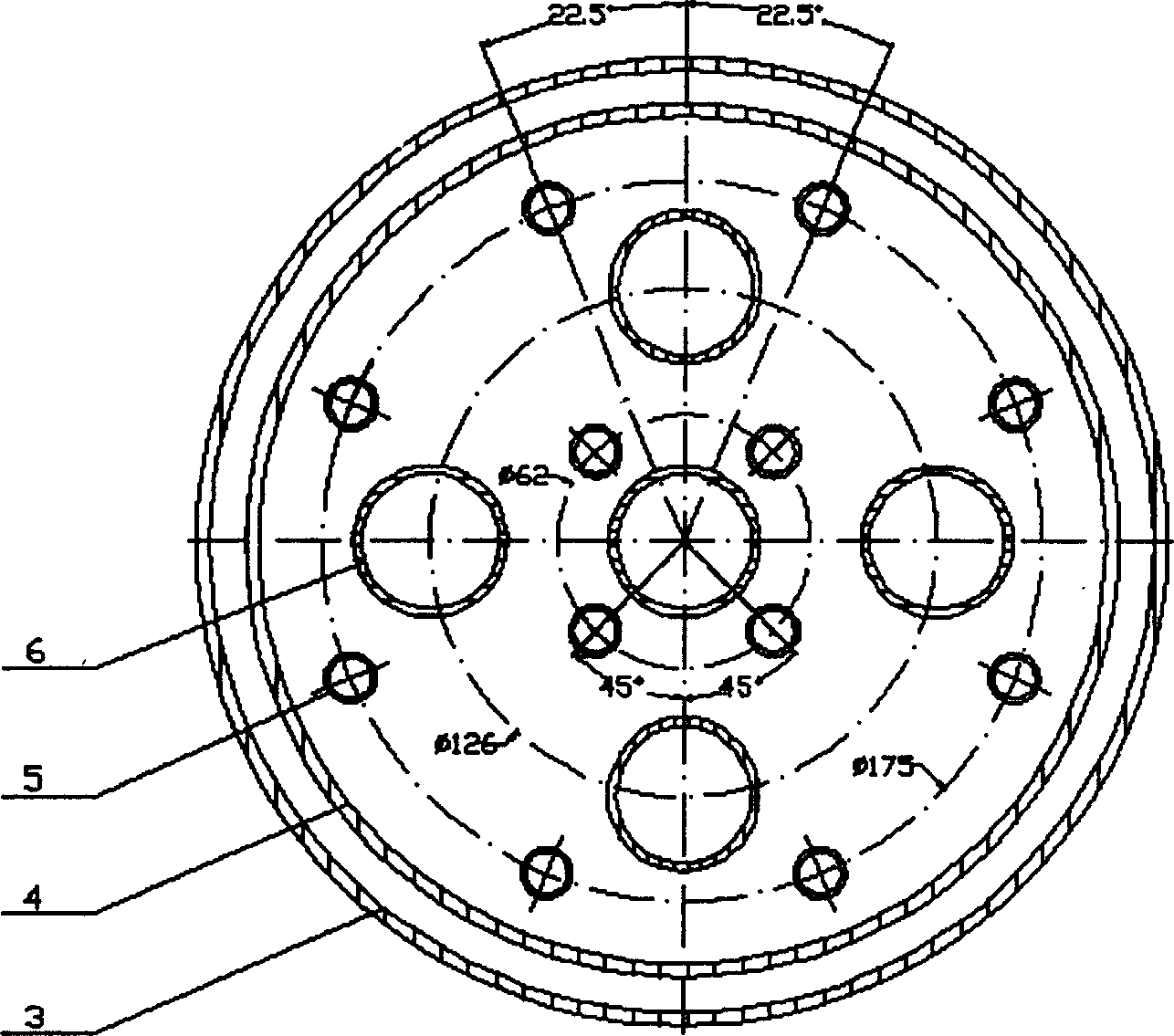

[0025] Such as figure 1 As shown, the refrigeration adsorber includes an outer tube 3 and an inner tube 4 fitted therein. The outer circular pipe 3 is made of seamless steel pipe made of stainless steel, with an outer diameter of 255mm, a thickness of 6mm, and a length of 1000mm. The cover plate 8, the upper cover plate 2 has a hot (cold) carrier outlet 1, and the lower cover plate 8 has a hot (cold) carrier inlet 9. The inner circular pipe 4 is made of stainless steel seamless steel pipe with an outer diameter of 219 millimeters, a thickness of 6 millimeters and a length of 940 millimeters. The two ends are respectively fixed with upper and lower end covers 14, 11, and a heat seal is fixed between the upper and lower end covers 14, 11. (cold) carrier channel 6 (upper and lower end caps 14, 11 are equivalent to the tube plate of the carrier channel), and a tube plate 13 parallel to it is fixed at 30 mm below the upper end cover 14 (refrigerant channel 5 and heat (cold) The t...

Embodiment 2

[0036] Such as figure 1 and 2As shown, the outer diameter of the outer tube 3 is 250 mm, the thickness is 3 mm, and the length is 560 mm; the outer diameter of the inner tube 4 is 219 mm, the thickness is 8 mm, and the length is 500 mm; the refrigerant channel 5 Outer diameter is 10 millimeters, and thickness is 1 millimeter, and its surface drills out the through hole that diameter is 1 millimeter, hole spacing is 4 millimeters by equilateral triangle; The outer diameter of hot (cold) carrier channel 6 is 25 millimeters, and thickness is 2 mm. Other implementation modes are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com