Large fermentation tank heat exchange device

A technology of heat exchange device and fermentation tank, which is applied in the direction of bioreactor/fermentation tank combination, specific-purpose bioreactor/fermentation tank, biochemical cleaning device, etc. Problems such as low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

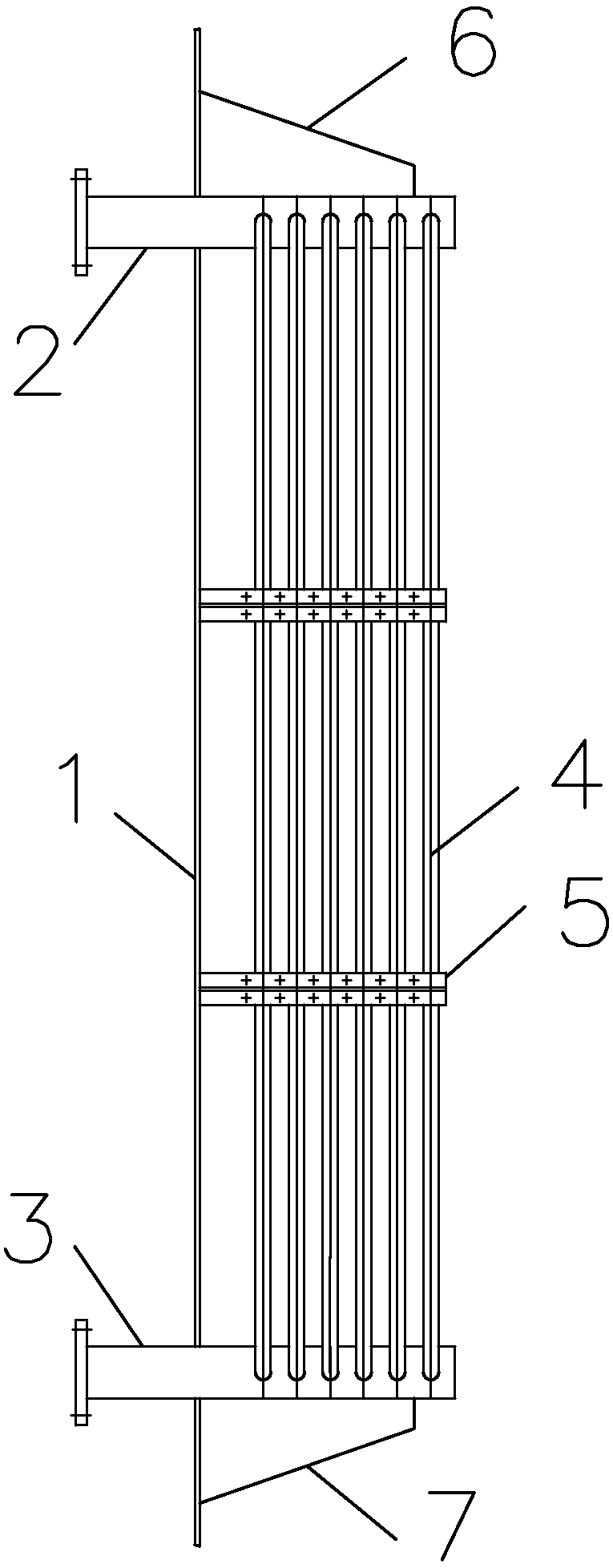

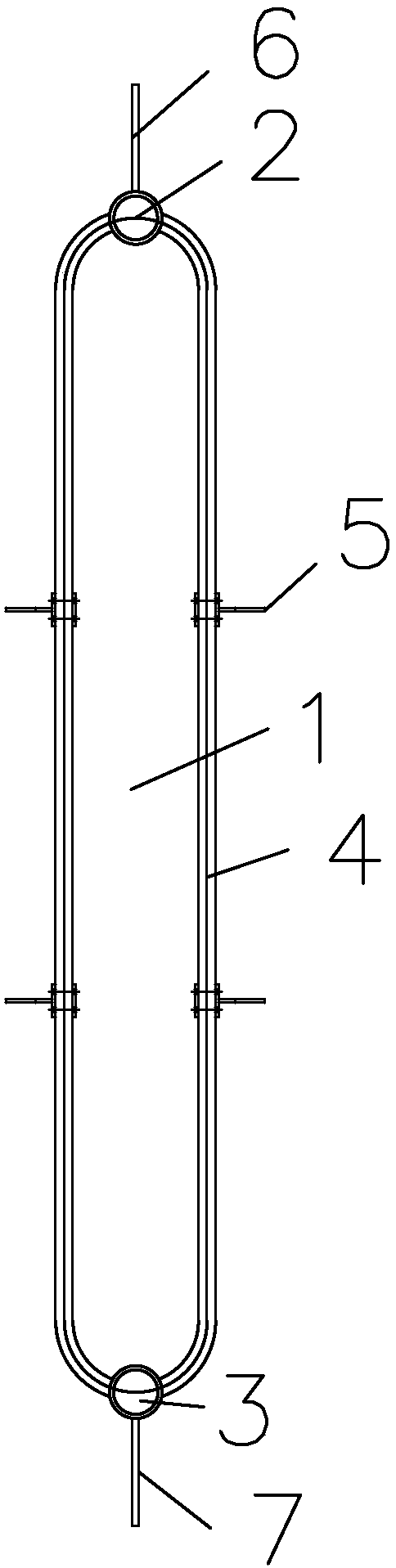

[0016] figure 1 As shown, a large-scale fermenter heat exchange device, the device is wrapped in the periphery of the fermenter tank wall 1, including an upper confluence pipe 2 and a lower confluence pipe 3, between the upper confluence pipe 2 and the lower confluence pipe 3 There are multiple parallel row pipes 4; the upper end of the row pipes 4 communicates with the upper confluence pipe 2, and the lower end communicates with the lower confluence pipe 3.

[0017] In this implementation, two fixing frames 5 are arranged vertically in the middle of the row pipe 4 ; an upper reinforcement plate 6 is arranged above the upper confluence pipe 2 ; and a lower reinforcement plate 7 is provided below the lower confluence pipe 3 .

[0018] In actual use, the heat exchange device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com