Preparation method for new purification material with catalytic oxidation of formaldehyde and sterilization function

A technology for catalytic oxidation and purification of materials, applied in chemical instruments and methods, botanical equipment and methods, fungicides, etc., can solve problems such as waste of precious metal resources, increase in filter resistance, and impact on purification effects, etc., to facilitate removal, Increased adsorption capacity and high sterilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

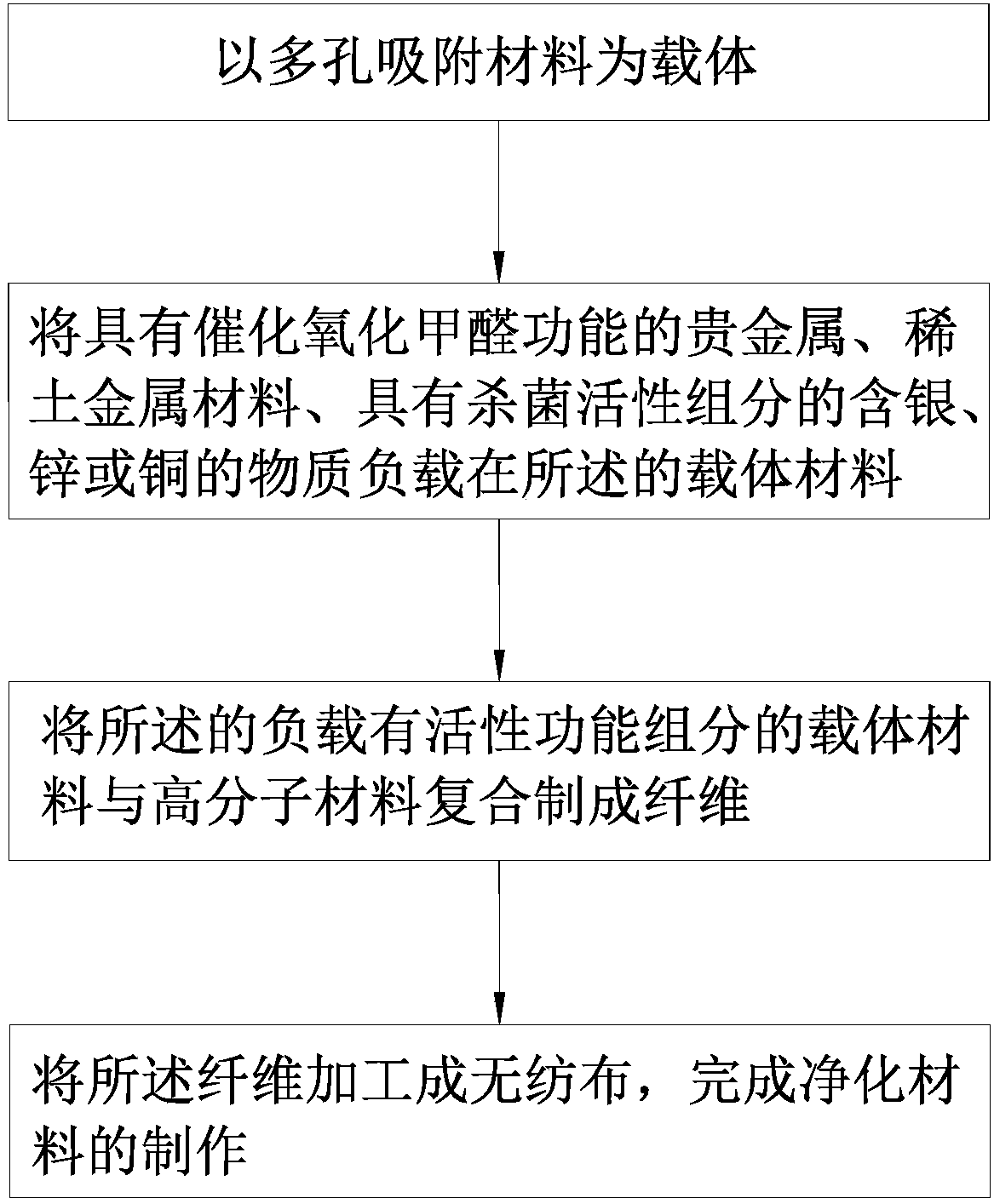

[0033] Such as figure 1 The specific embodiment shown, the present invention discloses the preparation method of the purification new material with catalytic oxidation formaldehyde and bactericidal function, comprises the following steps:

[0034] Step 1, using a porous adsorption material as a carrier;

[0035] Step 2, loading precious metals, rare earth metal materials, silver-, zinc- or copper-containing substances with bactericidal active components on the carrier material;

[0036] Step 3, compounding the carrier material loaded with the active functional components with the polymer material to form fibers;

[0037] Step 4, processing the fibers into non-woven fabrics to complete the production of purification materials.

[0038] The present invention adopts one or more in porous adsorption materials such as zeolite, silica gel, aluminum oxide, active carbon, polydivinylbenzene as carrier; configure precious metal (platinum, palladium, rhodium, ruthenium, gold) and rare...

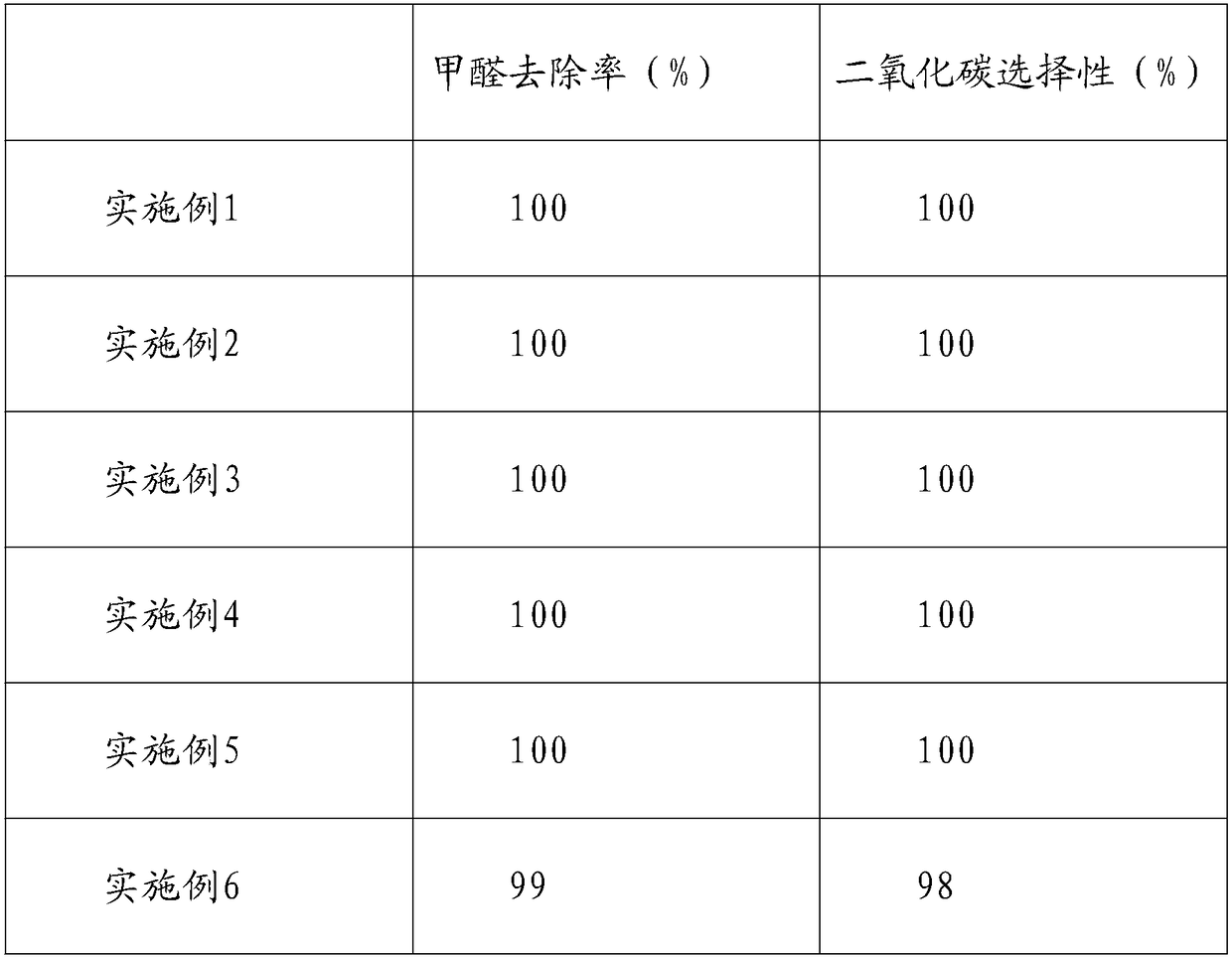

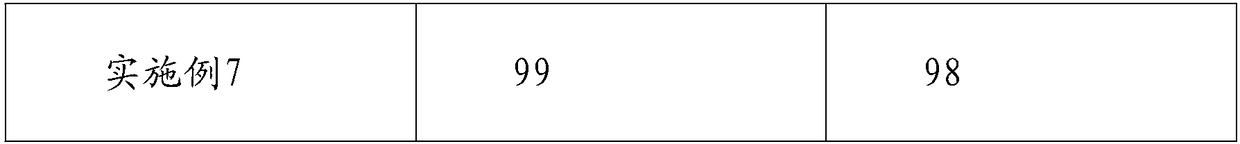

Embodiment 1

[0049] The preparation element Pt content is that the platinum chloride of 0.1 gram, the silver nitrate that the element Ag content is 0.2 gram, the zinc nitrate that the element Zn content is 0.3 gram, the copper nitrate that the element Cu content is 0.5 gram is dissolved in water to form a mixed solution, and then Mix 100g of the zeolite precursor with the mixed aqueous solution evenly to obtain the mixture; then crystallize the mixture at 100°C for 2 hours to prepare zeolite particles loaded with active components for catalytic oxidation of formaldehyde and bactericidal function; then 880g of polyester The fiber and 20g of phosphoric acid ester are placed in an opener with a rotating speed of 2500 rpm, opened and dispersed, and then the zeolite particles loaded with formaldehyde catalytic oxidation and bactericidal functions are added according to the mass percentage of its platinum element at 0.02%, to make the zeolite It is fully melted and mixed with fibers at 290°C, and...

Embodiment 2

[0051] Preparation element Rh content is that rhodium chloride of 0.1 gram, element Ag content are the silver nitrate of 0.2 gram, the element Zn content is the zinc nitrate of 0.3 gram, the copper nitrate that element Cu content is 0.5 gram is dissolved in water and forms mixed solution, then 100g of the zeolite precursor is uniformly mixed with the mixed aqueous solution to obtain a mixed solution. Then, the mixed solution is crystallized under the condition of 100° C. to prepare zeolite particles loaded with the catalyst. Then put 880g of polyester fiber and 20g of phosphoric acid ester in an opener with a rotating speed of 2500 rpm, open and disperse, and then melt and spin out the synthetic fiber through a spinneret. Then, the zeolite particles loaded with the catalyst and the bactericide are sprayed on the surface of the melted fiber at the ratio of 0.02% by mass of the rhodium element. Then, a 2mm mixed fiber web is formed on a rotating web curtain with a number of 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com