Catalytic conversion method for diesel oil and propylene with high yield

A catalytic conversion method and diesel technology, which are applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve problems such as improvement of diesel properties, poor selectivity of dry gas and coke, etc., which are not mentioned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

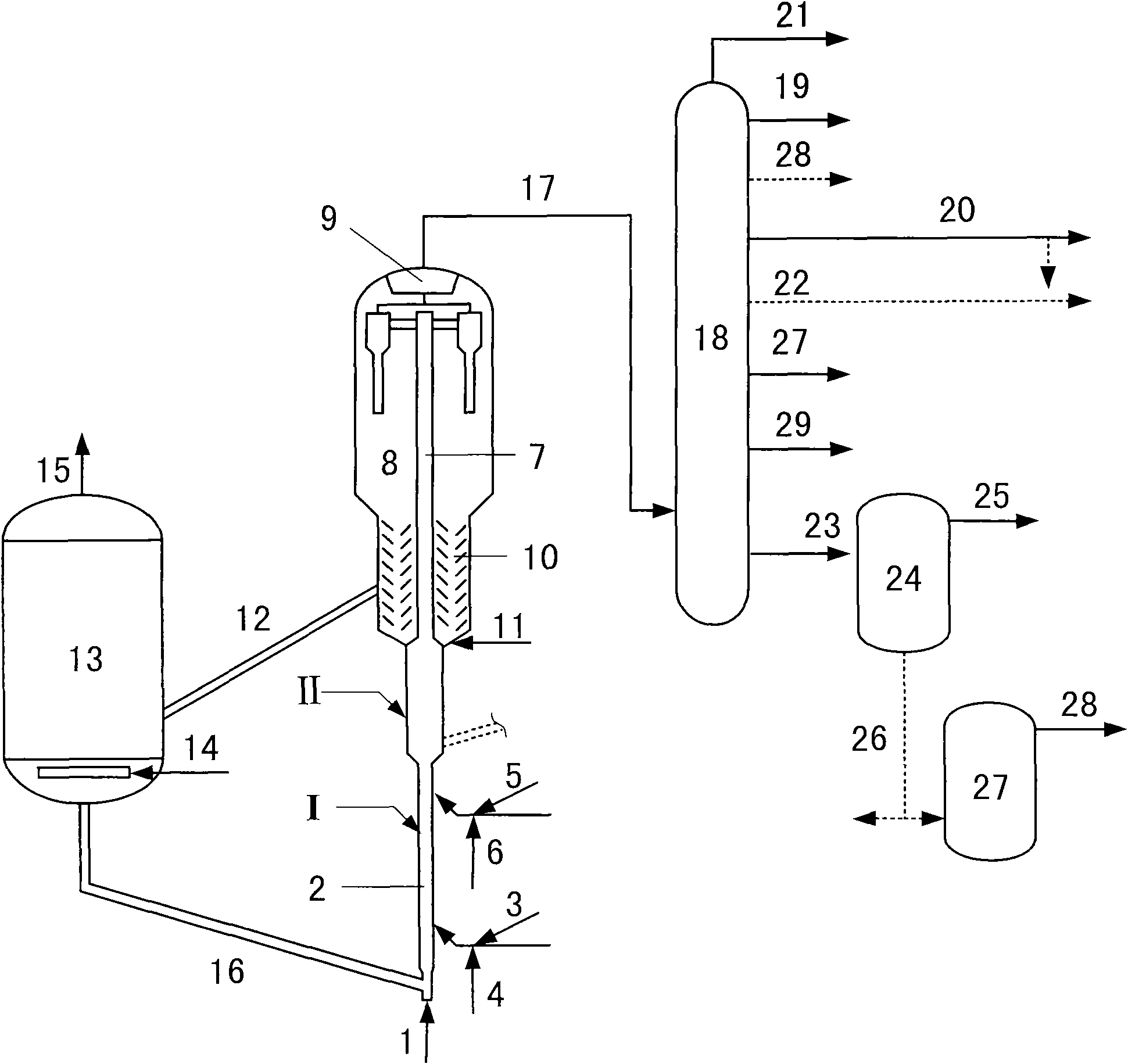

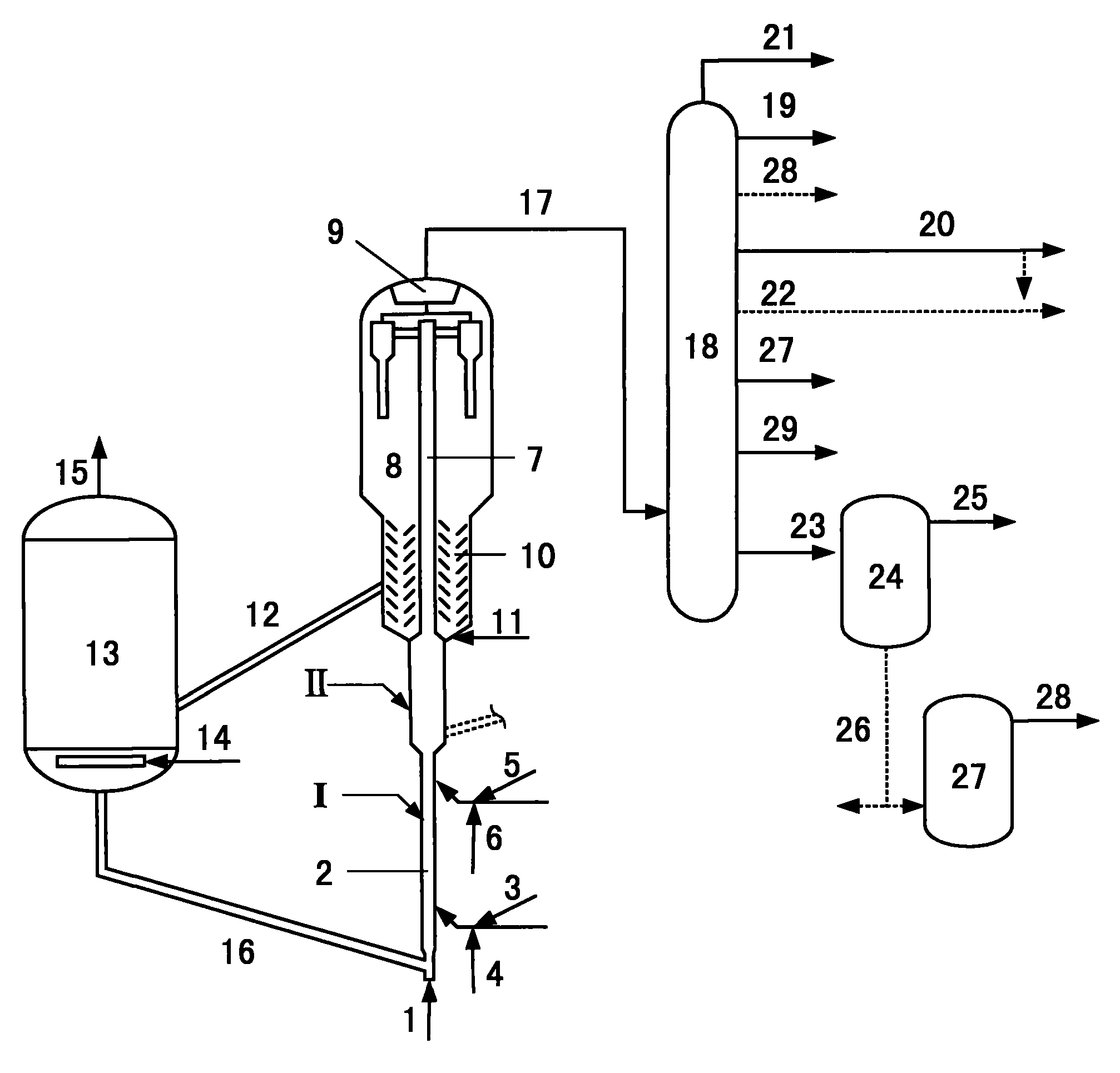

[0099] This embodiment is tested according to the flow process of accompanying drawing, and cracked raw material oil is directly used as the raw material of catalytic cracking, adopts catalyst CAT-MP-2, carries out test on the medium-sized device of riser reactor, and cracked raw material enters the middle and upper part of reaction zone I, Butene enters the bottom of reaction zone I as a re-cracking raw material. At the bottom of reaction zone I, the re-cracked raw material is processed at a reaction temperature of 610°C and a weight hourly space velocity of 175h -1 , the weight ratio of catalytic cracking catalyst to raw material is 70, and the weight ratio of steam to raw material is 0.20 to carry out the cracking reaction; in the upper part of reaction zone I, the catalytic raw material is heated at a reaction temperature of 530°C and a weight hourly space velocity of 40h -1 , the weight ratio of catalytic cracking catalyst to raw material is 4, and the weight ratio of stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com