Patents

Literature

30results about How to "Reduced tendency to break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

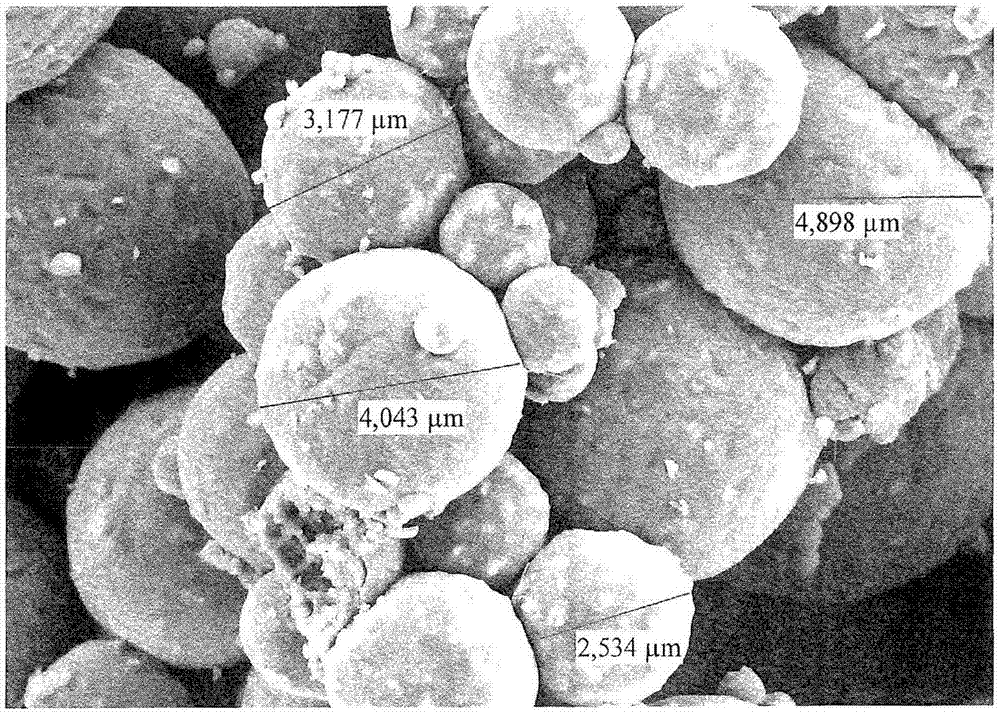

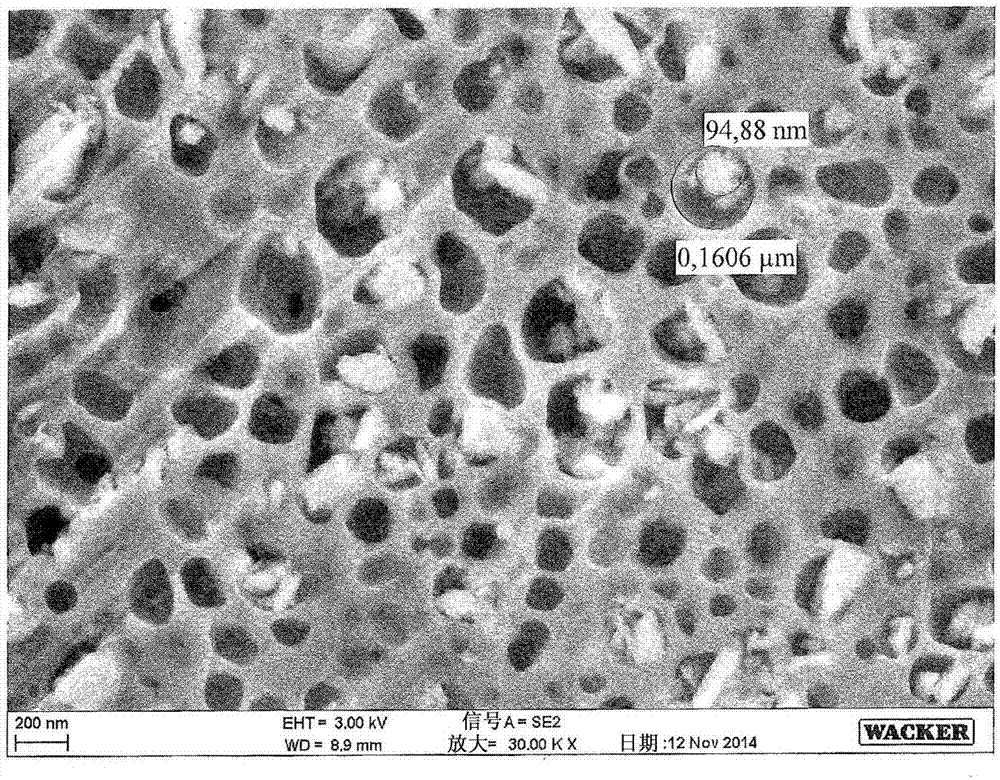

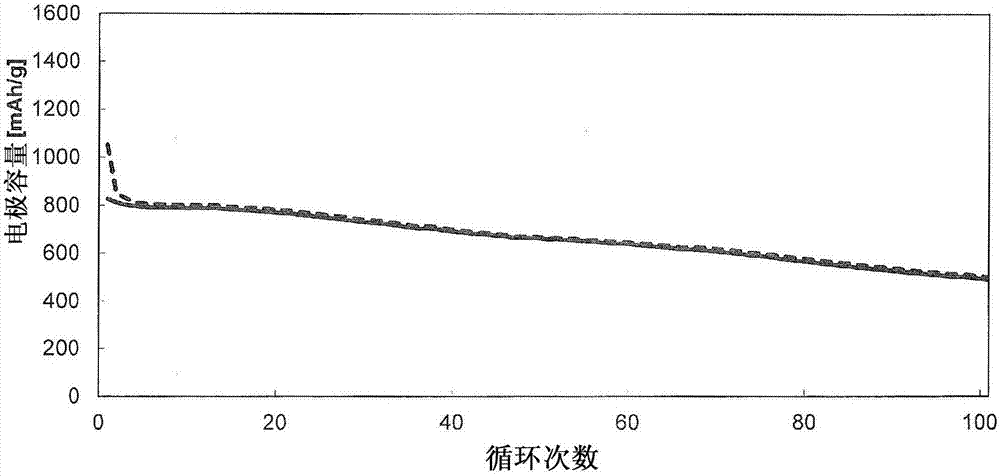

Composite core-shell particles

ActiveCN107431189AIncrease volume capacityImprove cycle stabilitySiliconSecondary cellsPorous carbonCarbonization

The invention relates to composite core-shell particles wherein the core is a porous, carbon-based matrix which contains silicon particles enclosed in pores of the matrix; the pores containing the silicon particles have a diameter of not less than 60 nm as determined by scanning electron microscopy (SEM); the shell can be obtained by carbonizing one or more carbon precursors selected from among the group comprising tars, pitches, hard carbon, soft carbon and hydrocarbons having 1 to 20 carbon atoms, resulting in a non-porous shell.

Owner:WACKER CHEM GMBH

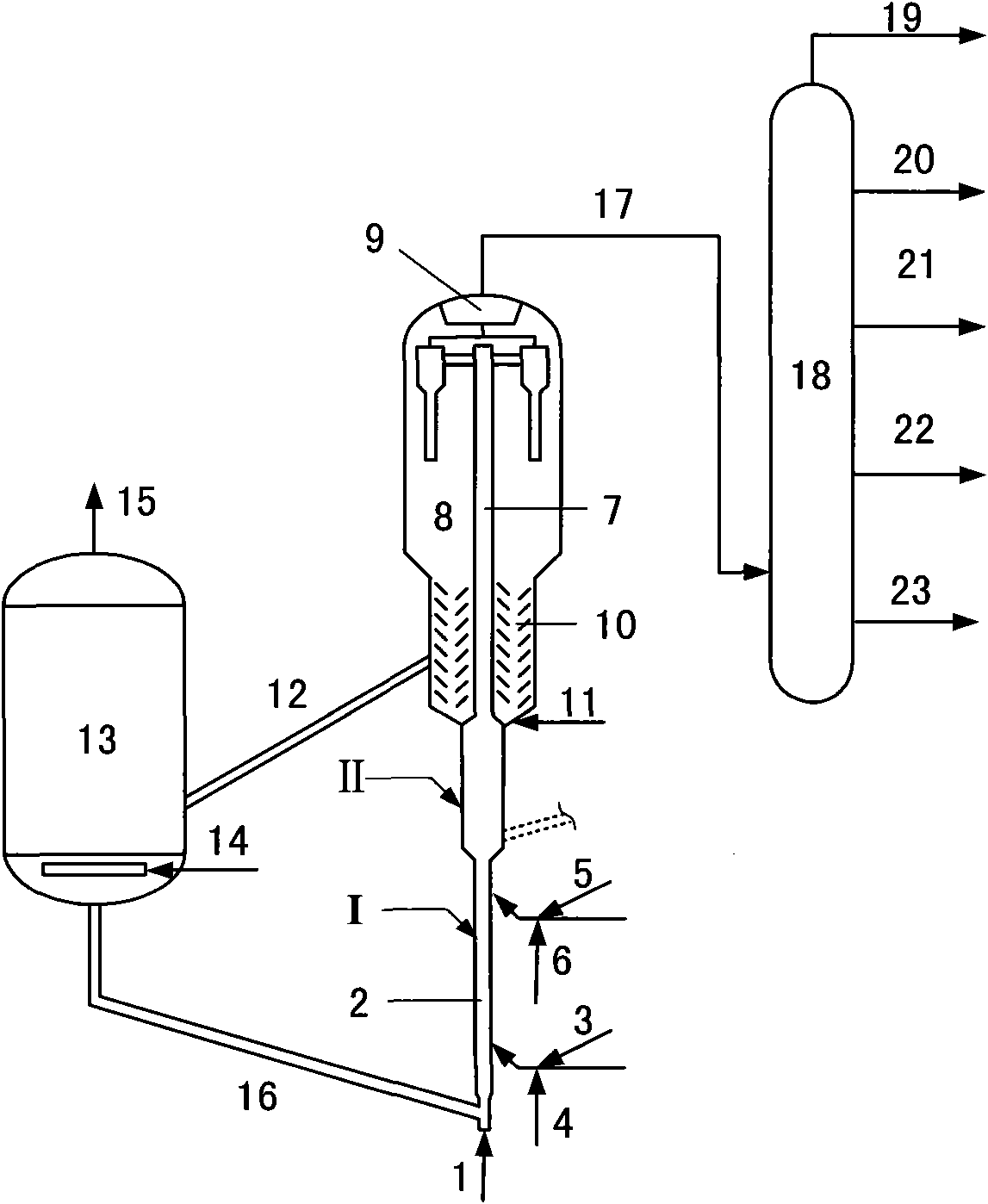

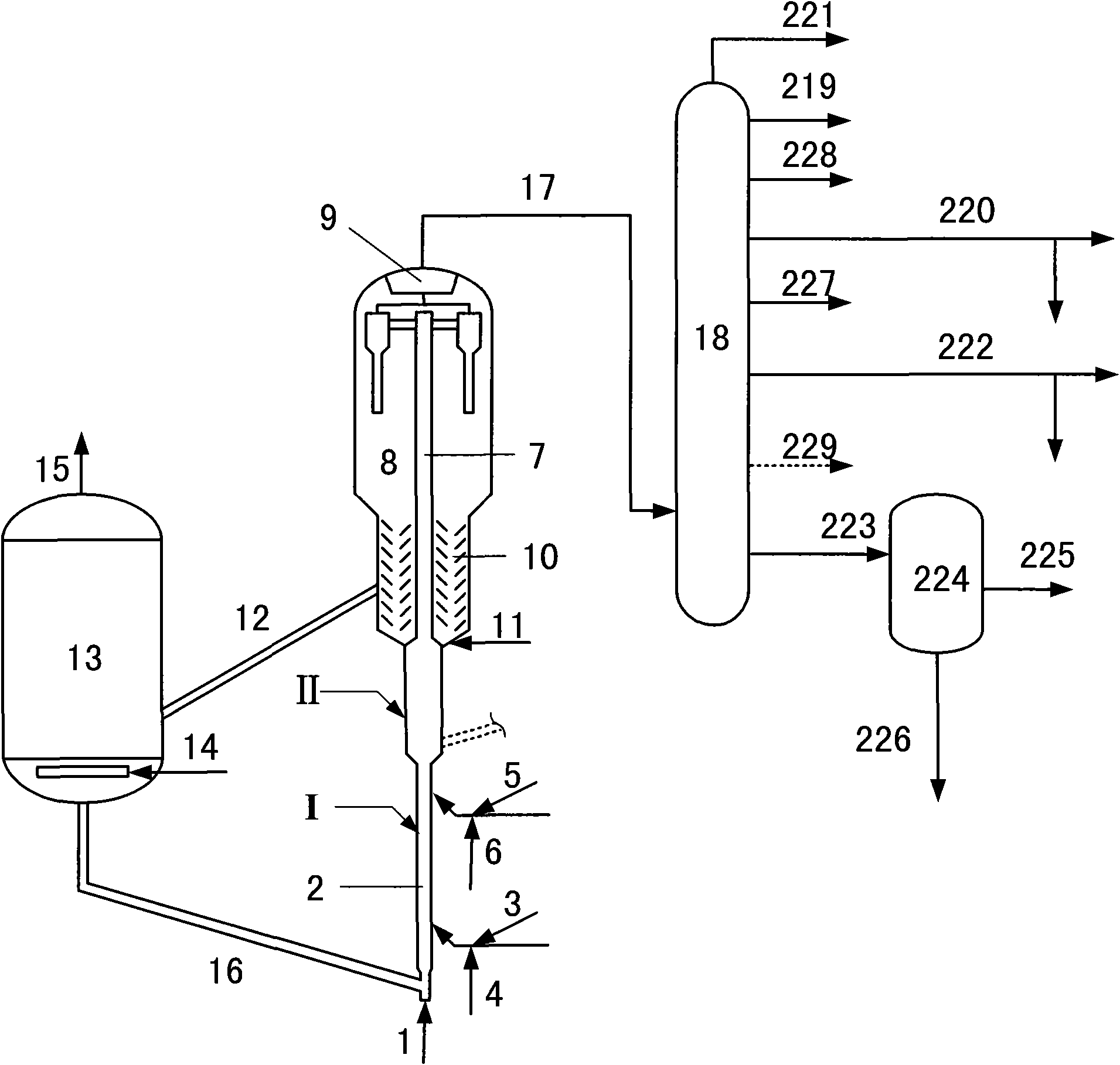

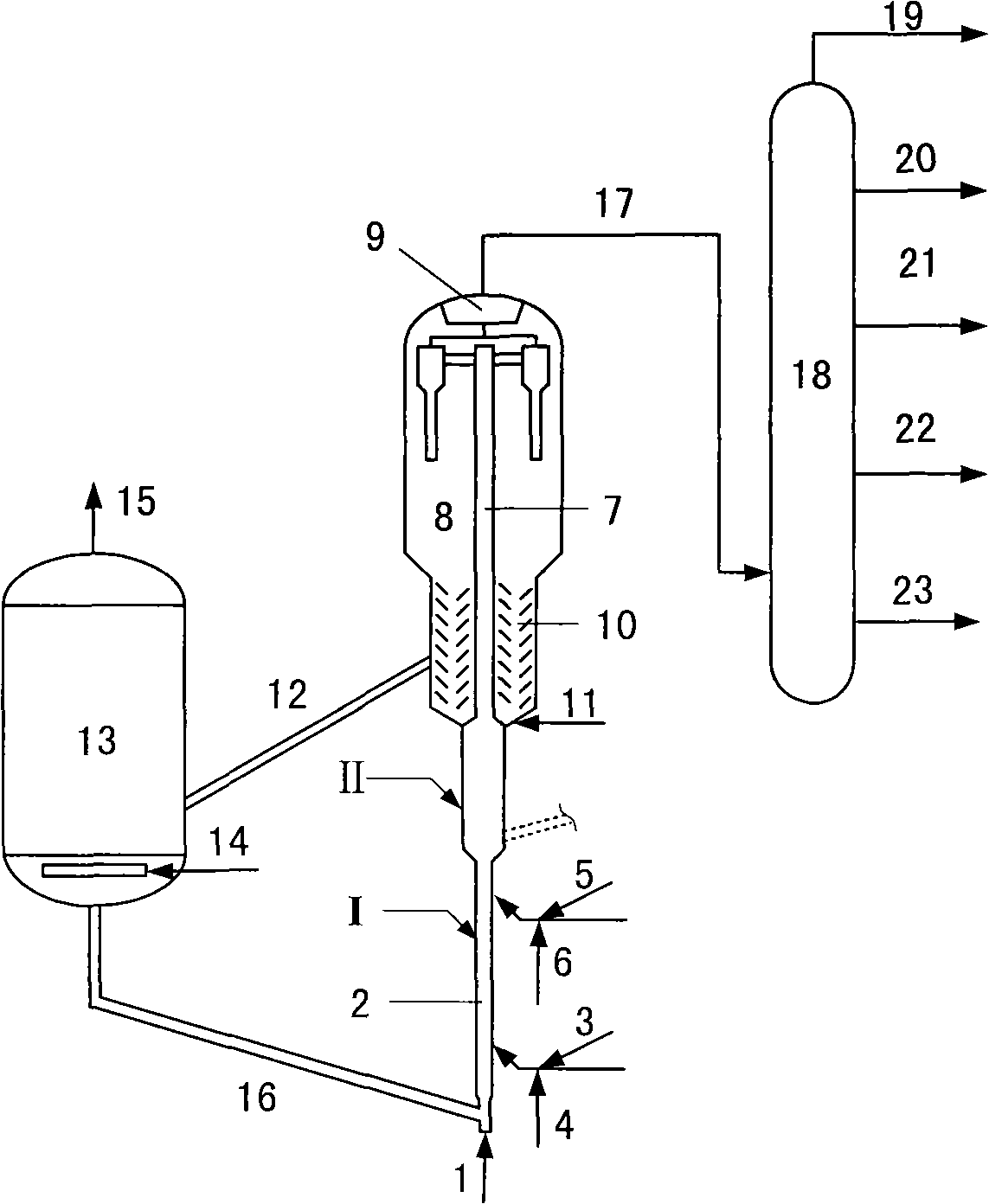

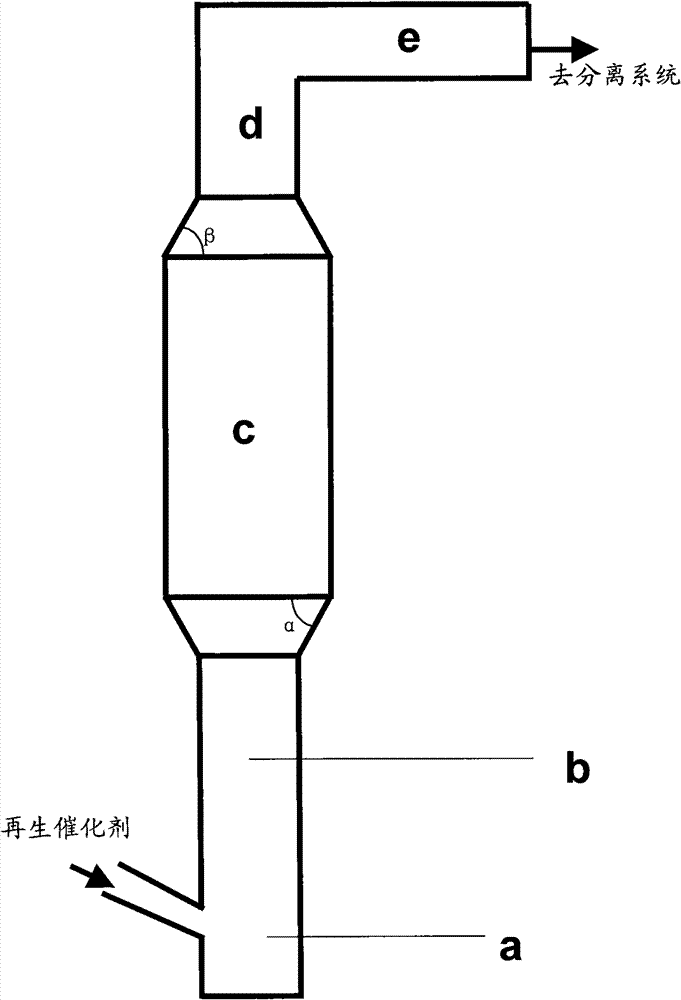

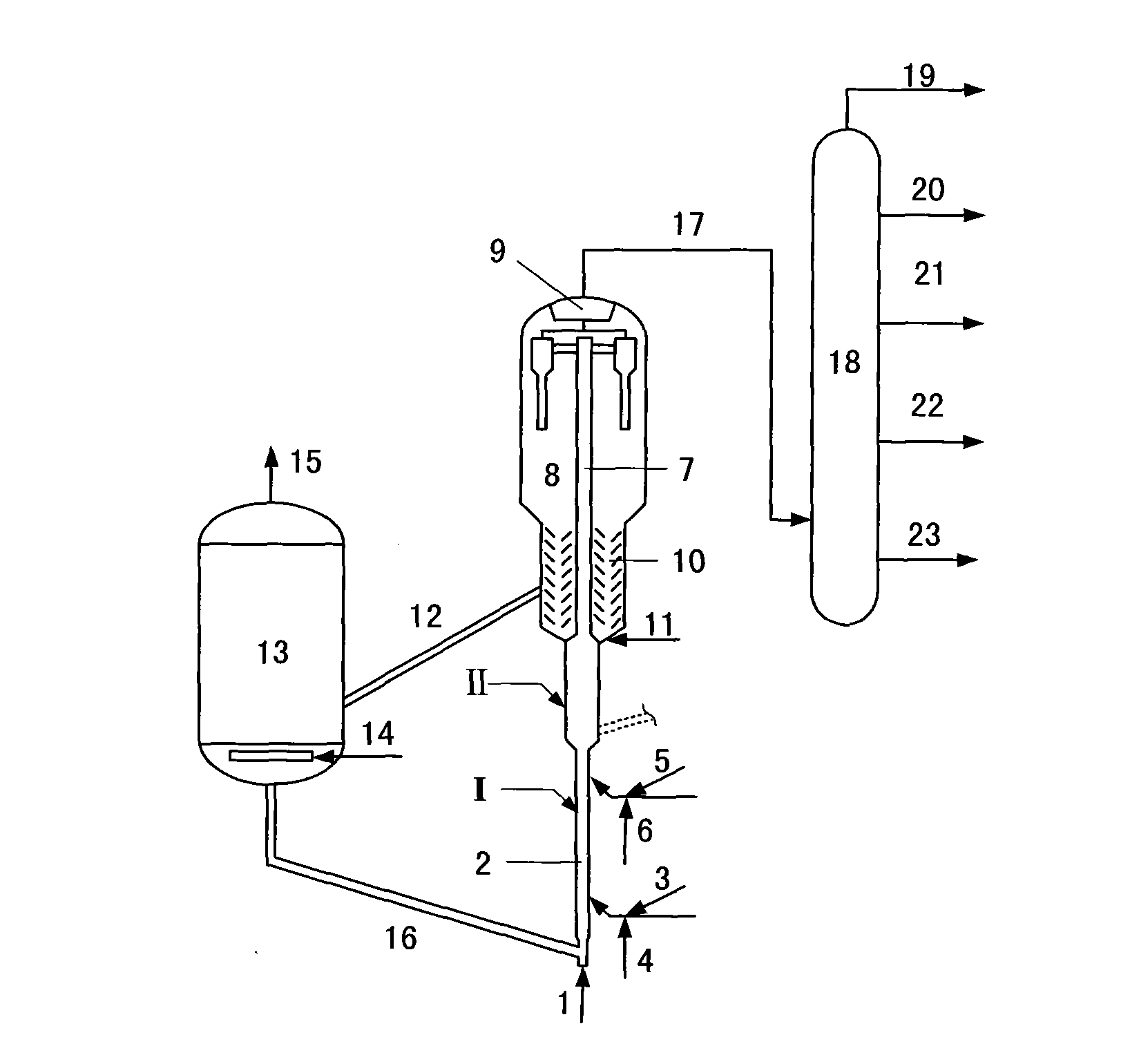

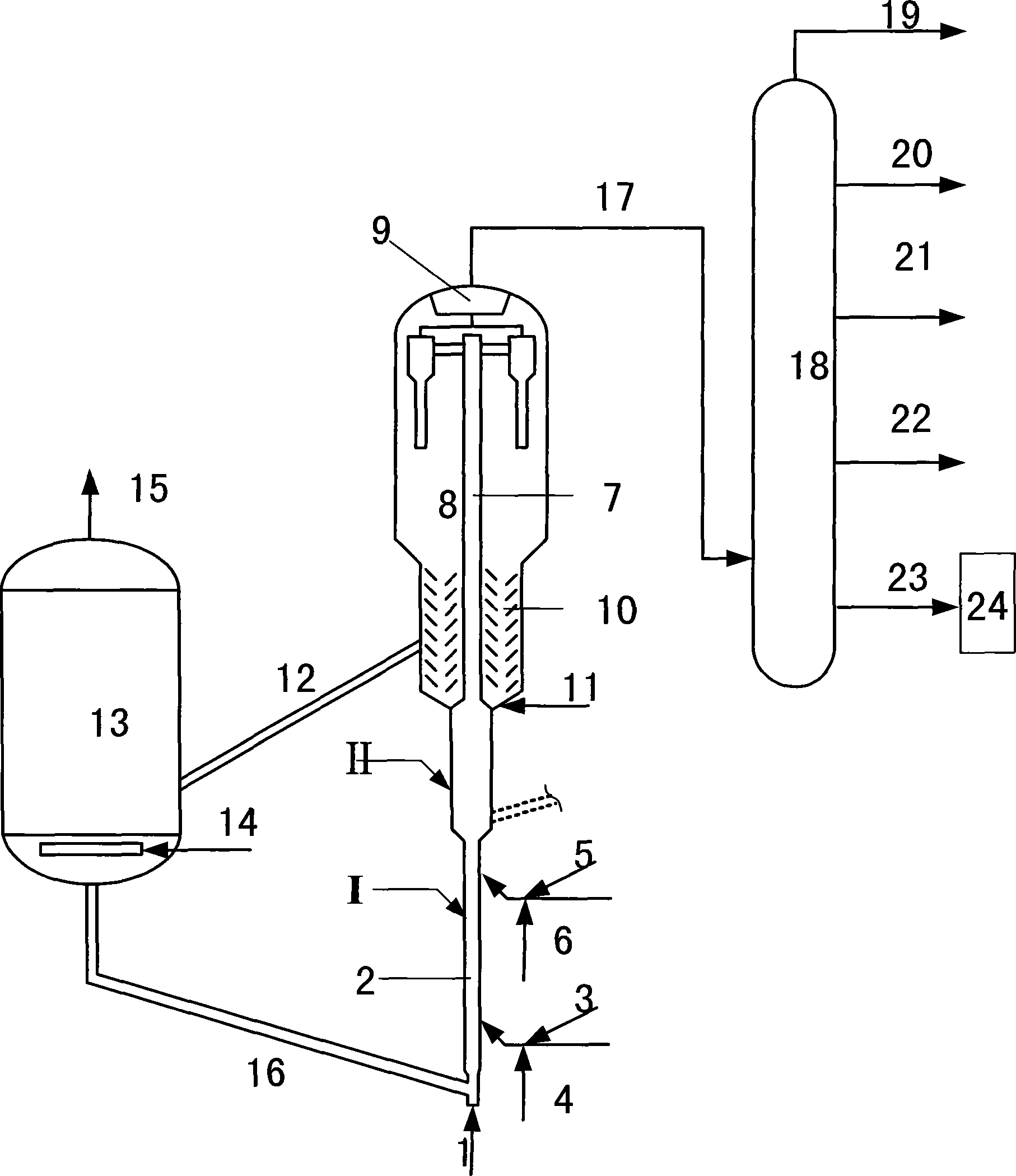

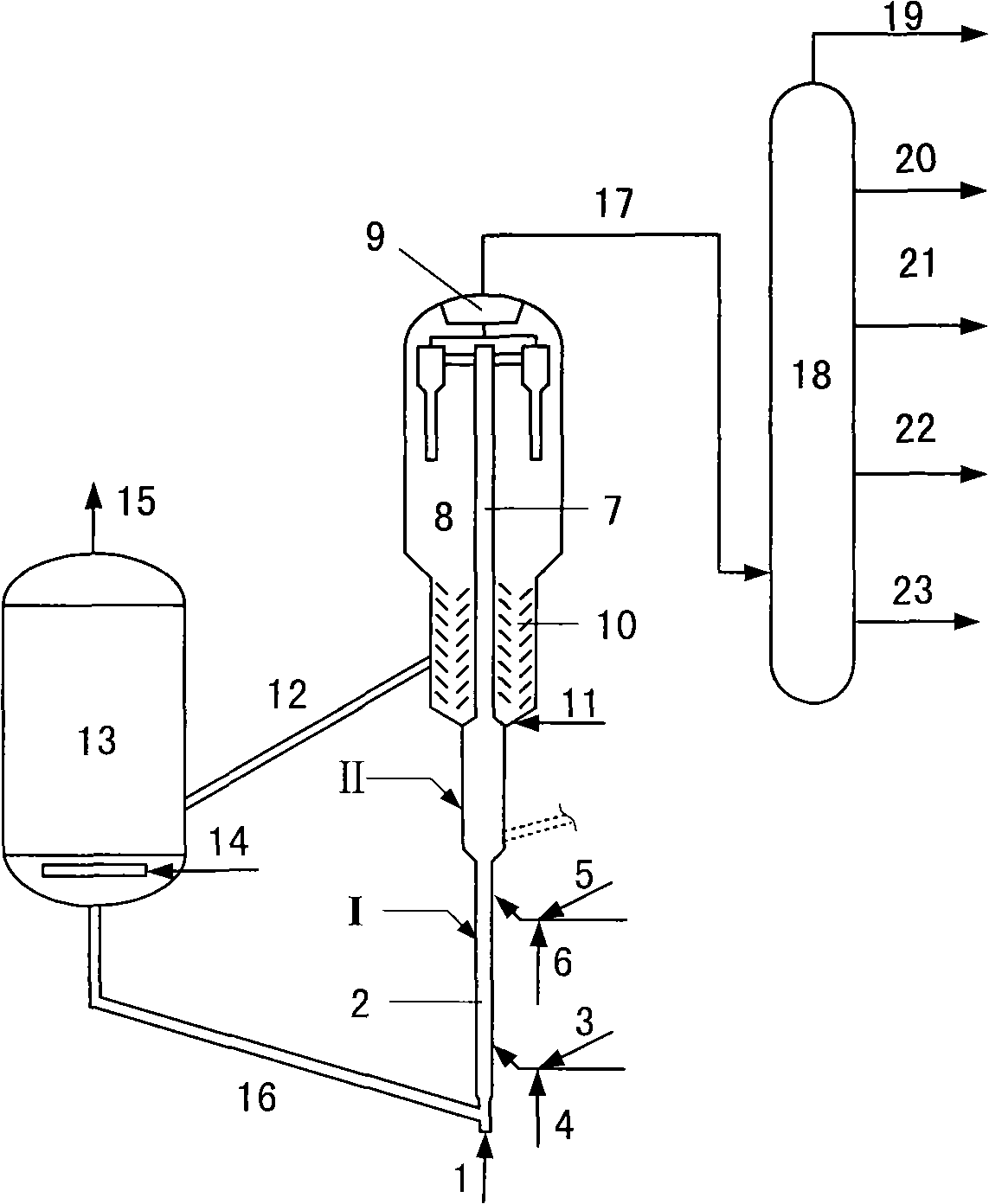

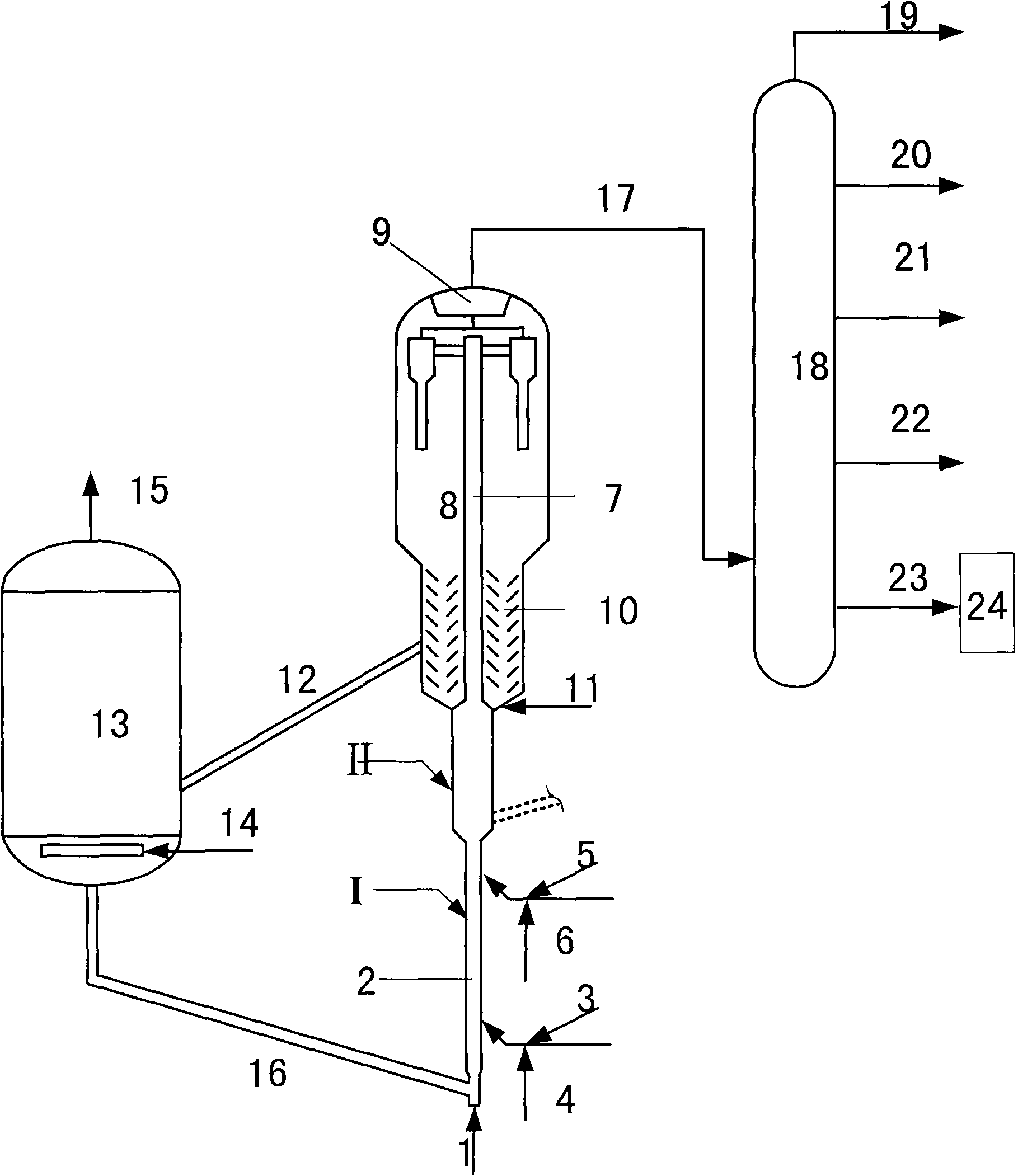

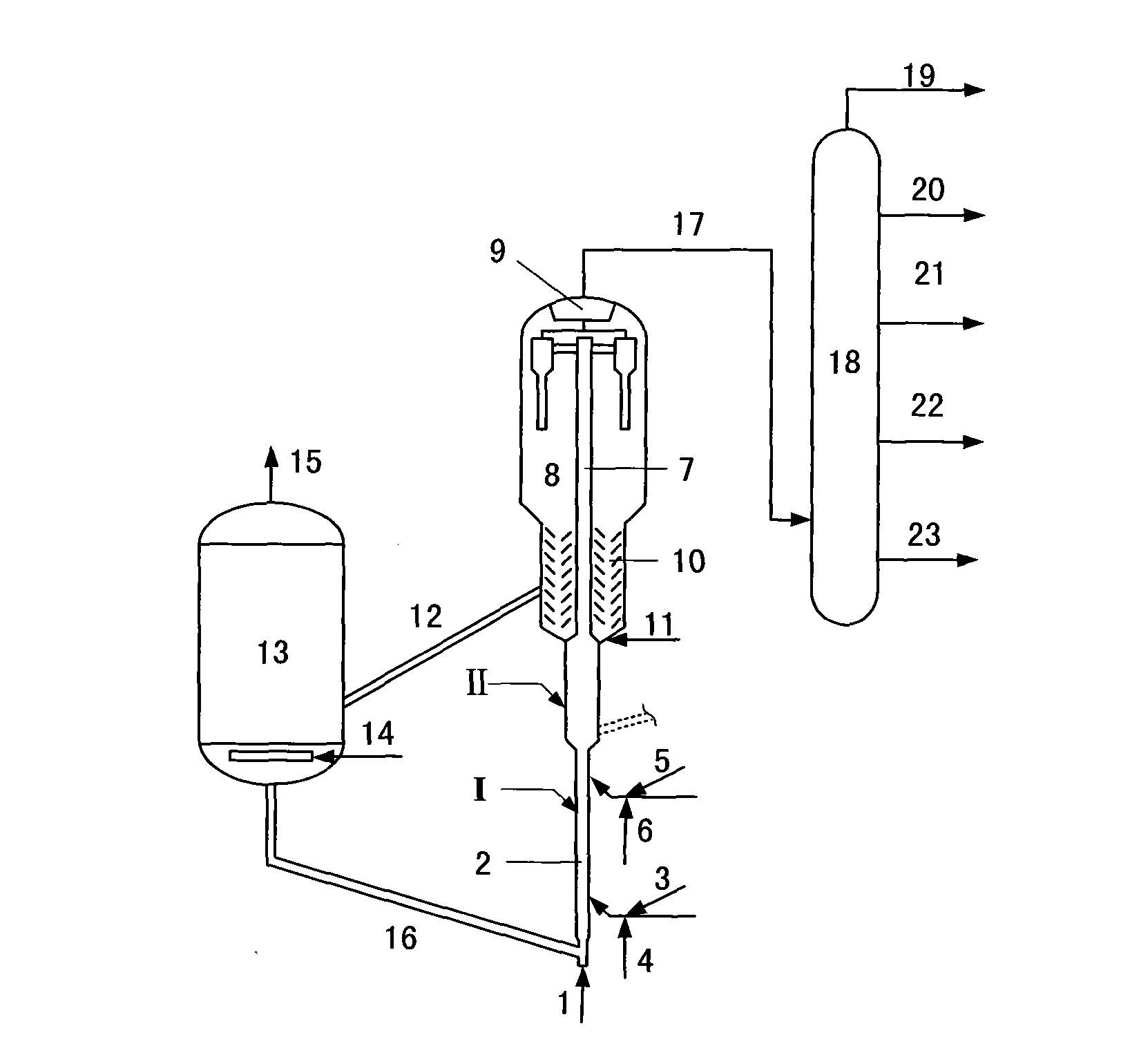

Catalytic conversion method for preparing propylene and high-octane value gasoline

ActiveCN101935266AHigh yieldImprove octaneCatalytic crackingBulk chemical productionWaxReaction temperature

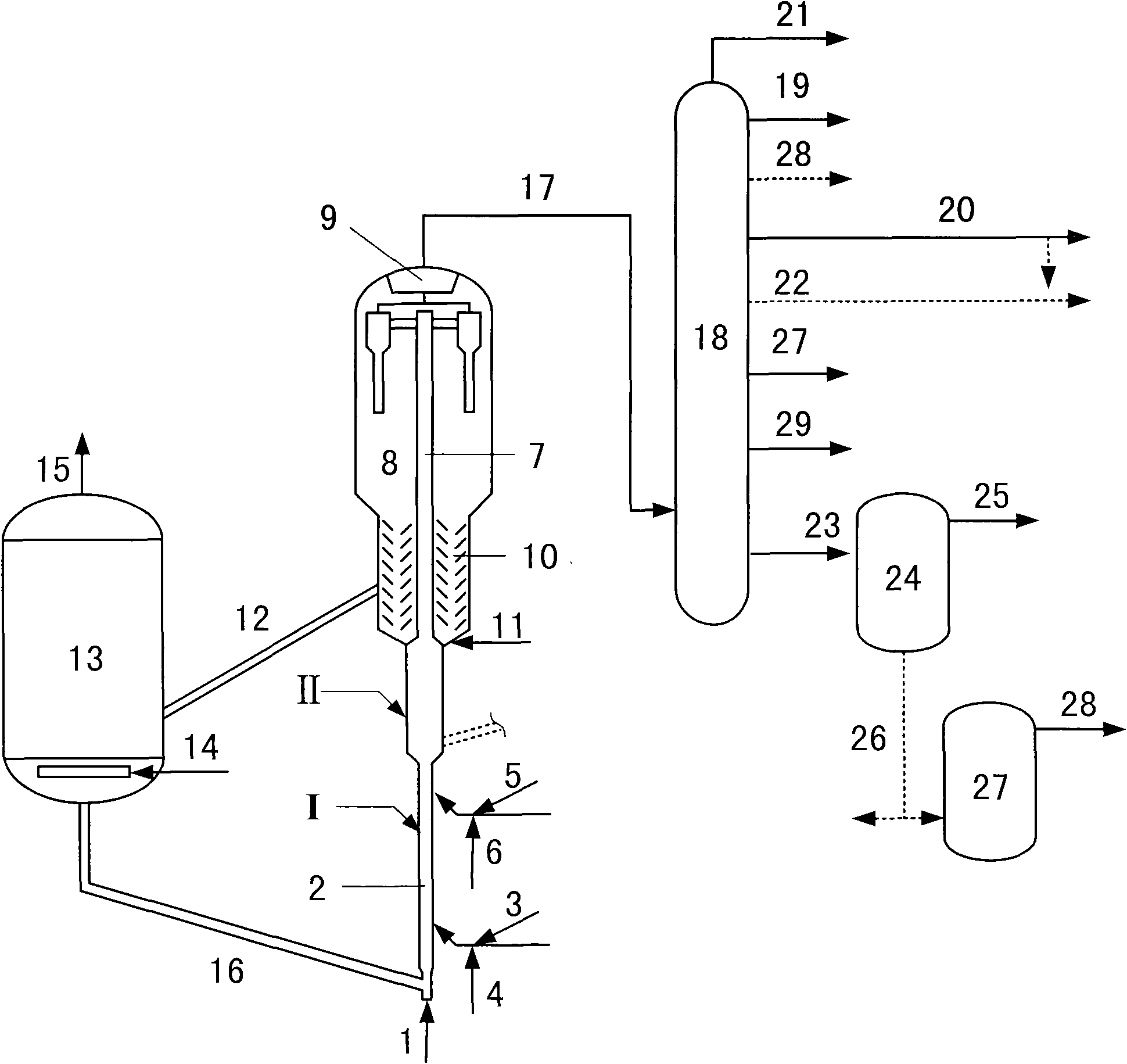

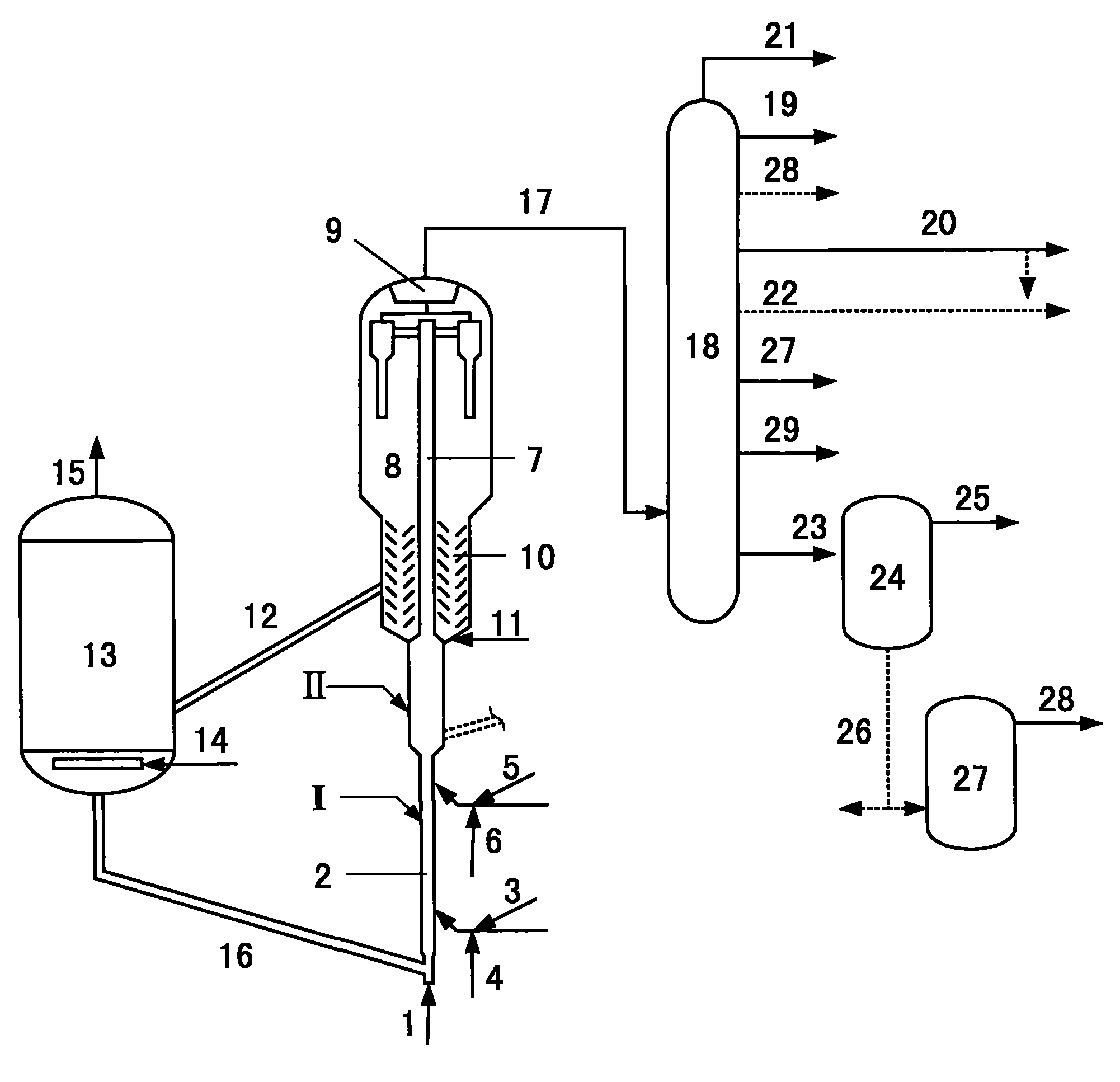

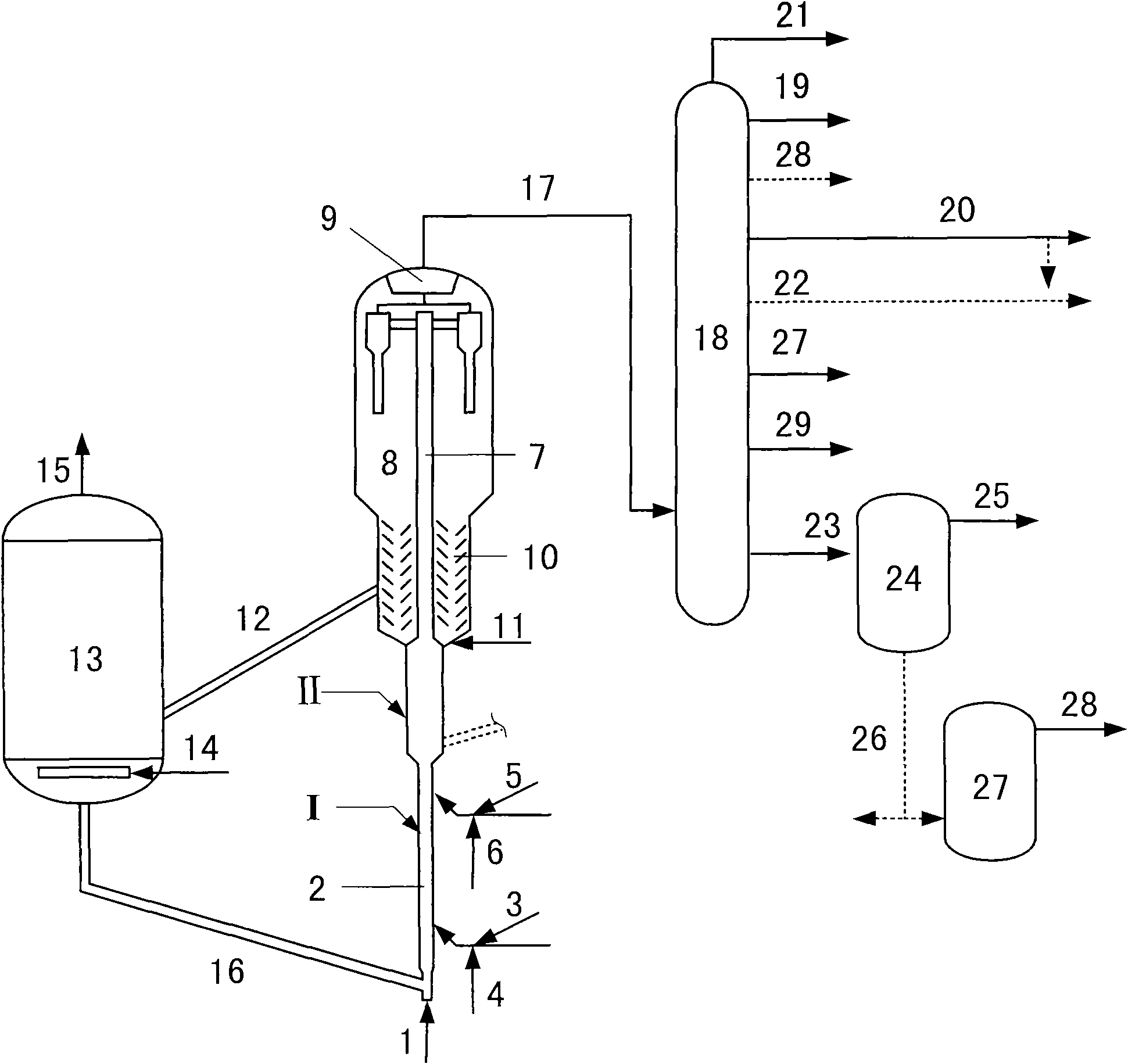

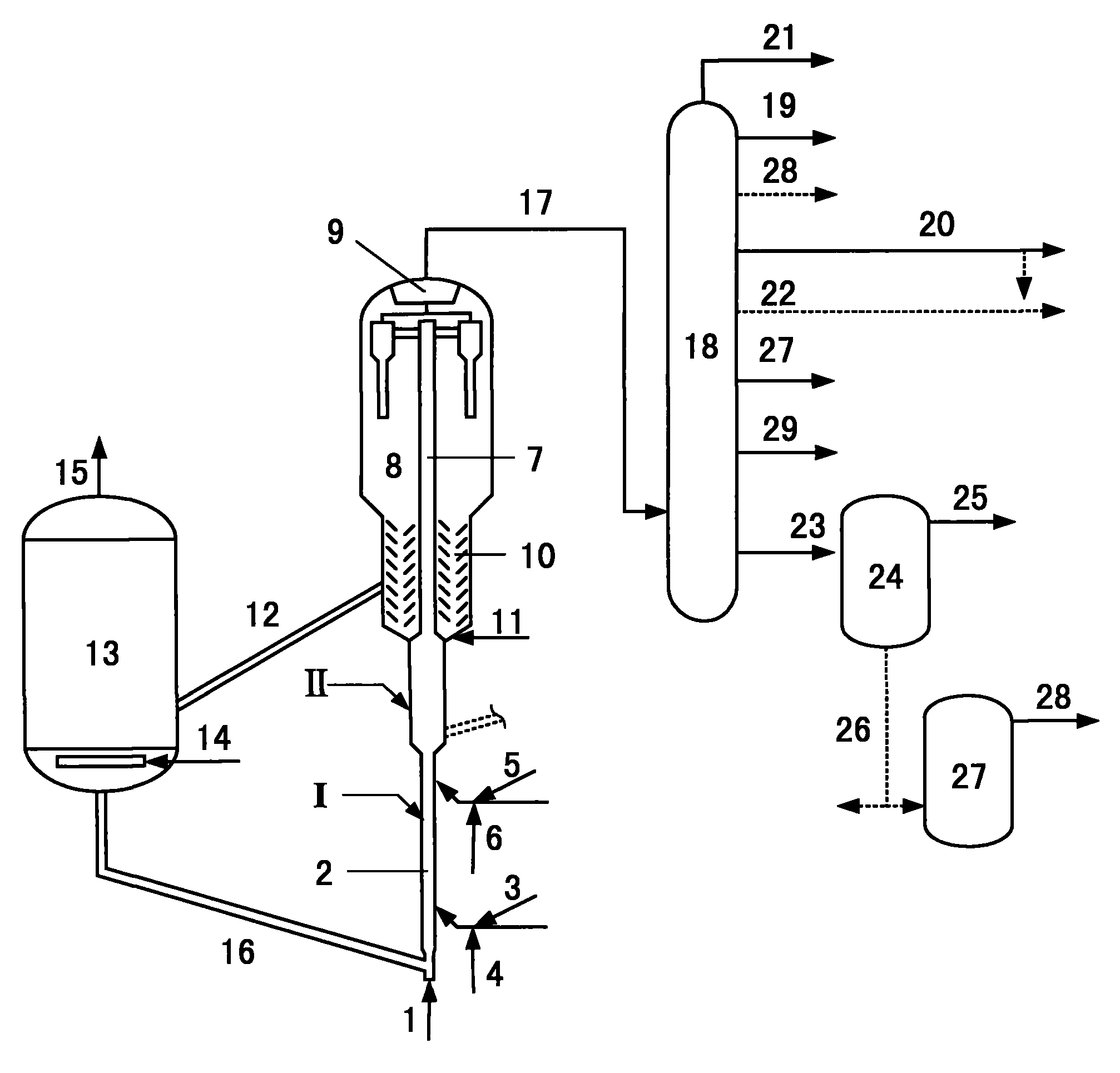

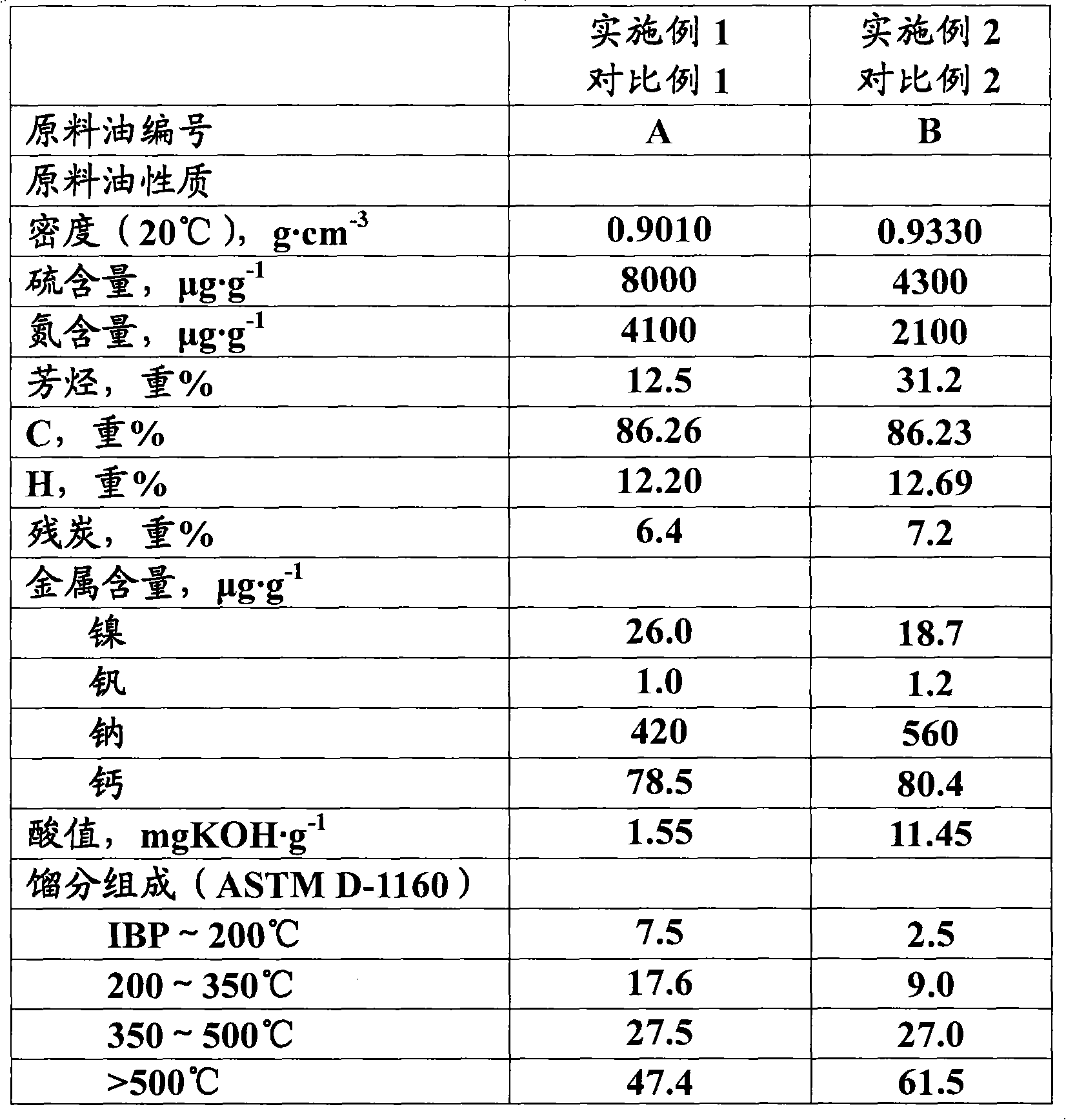

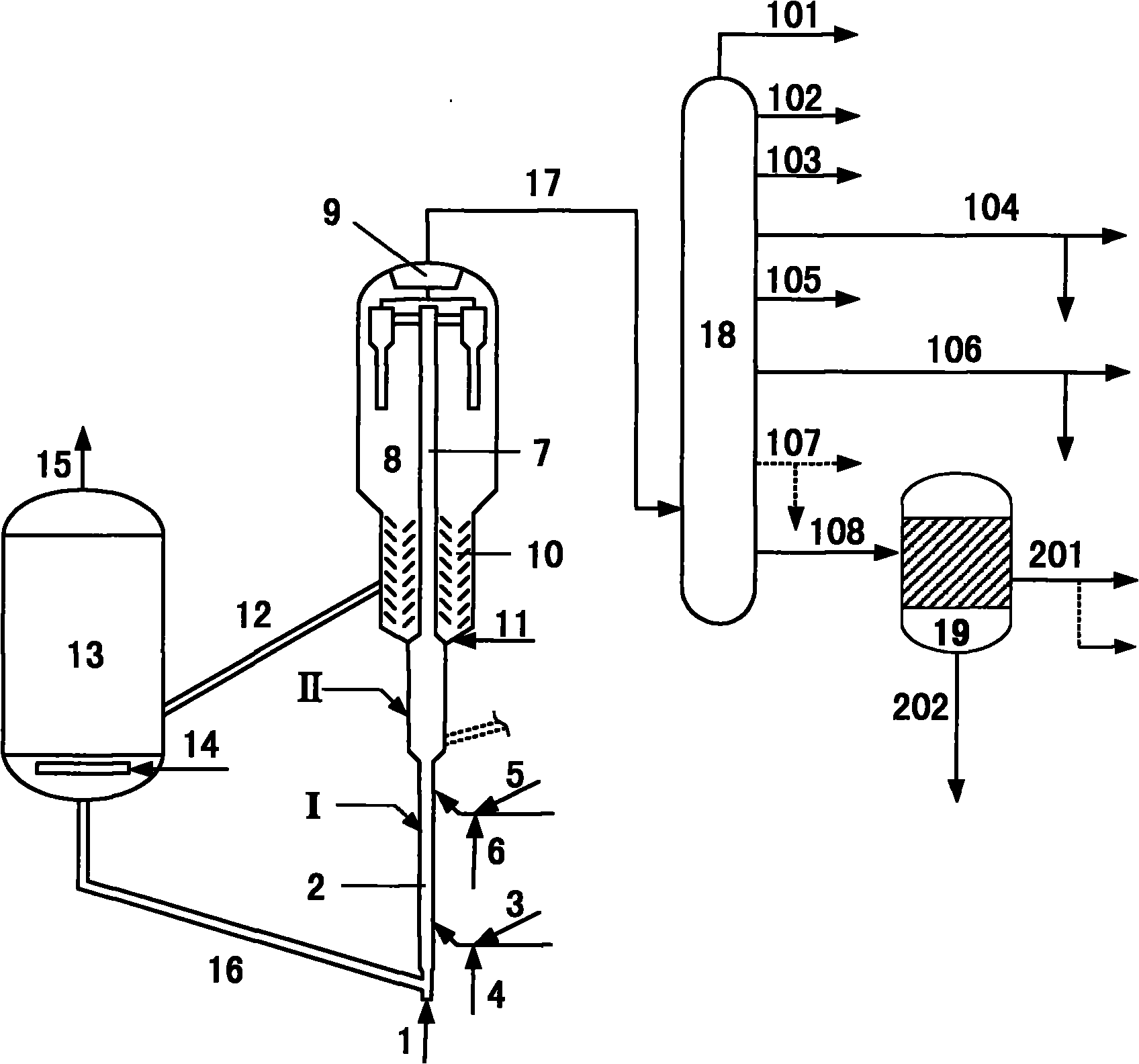

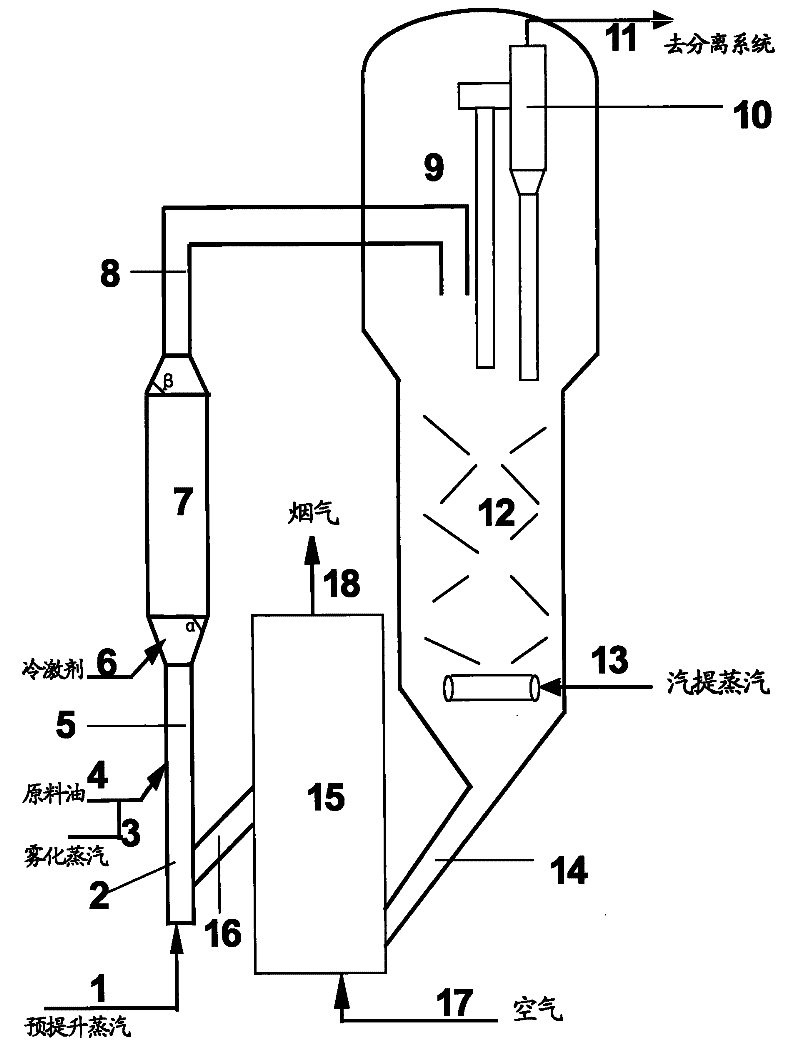

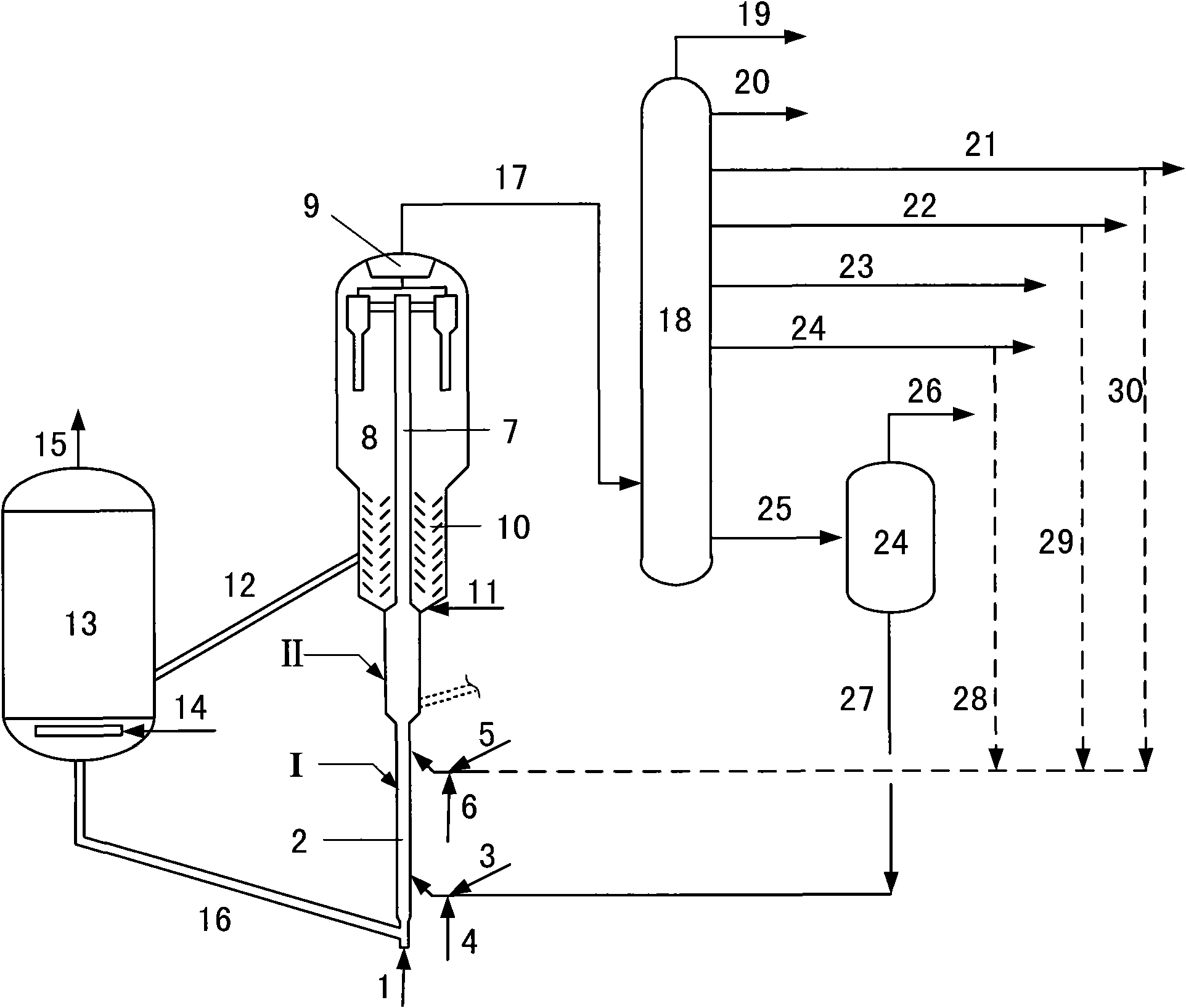

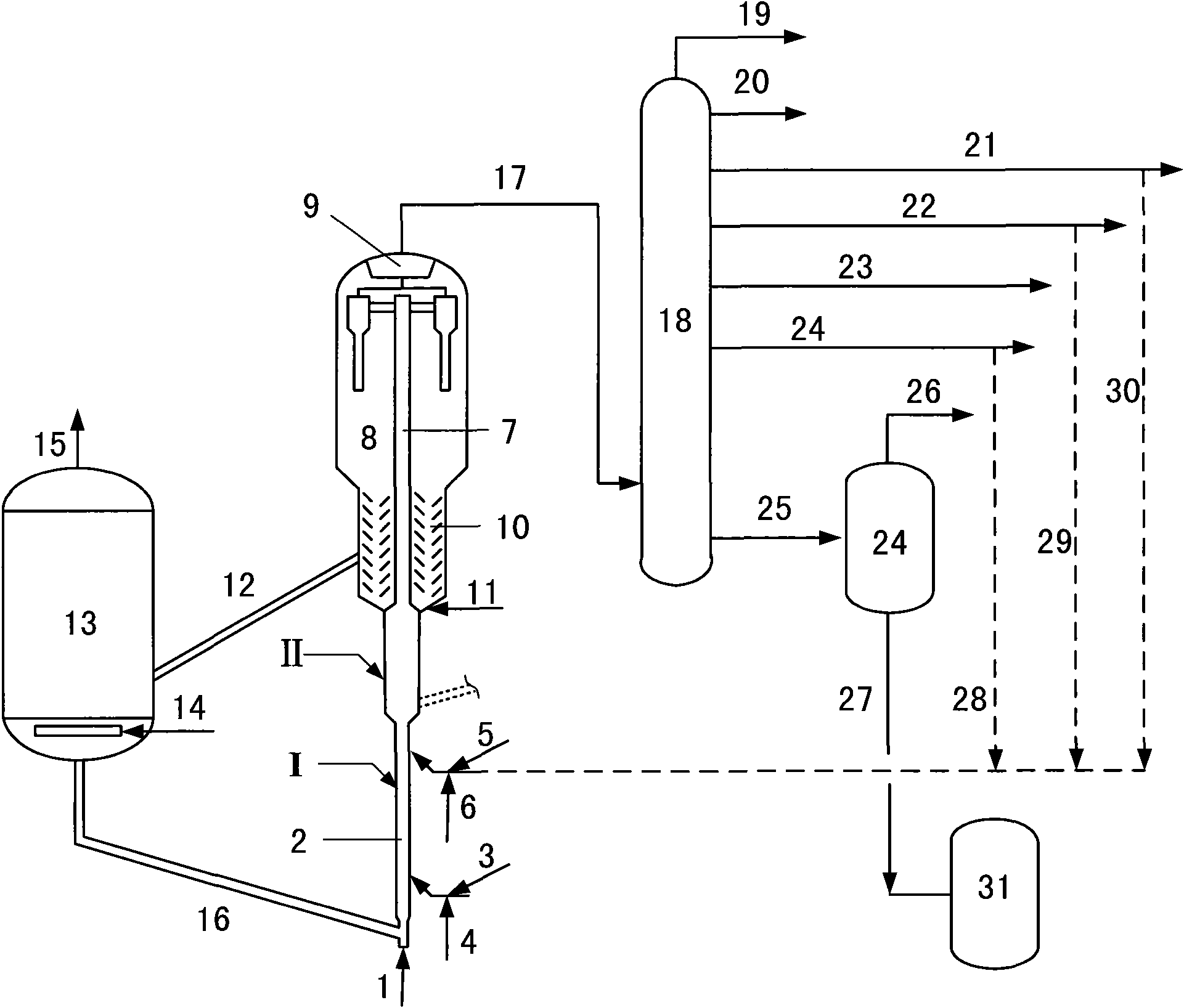

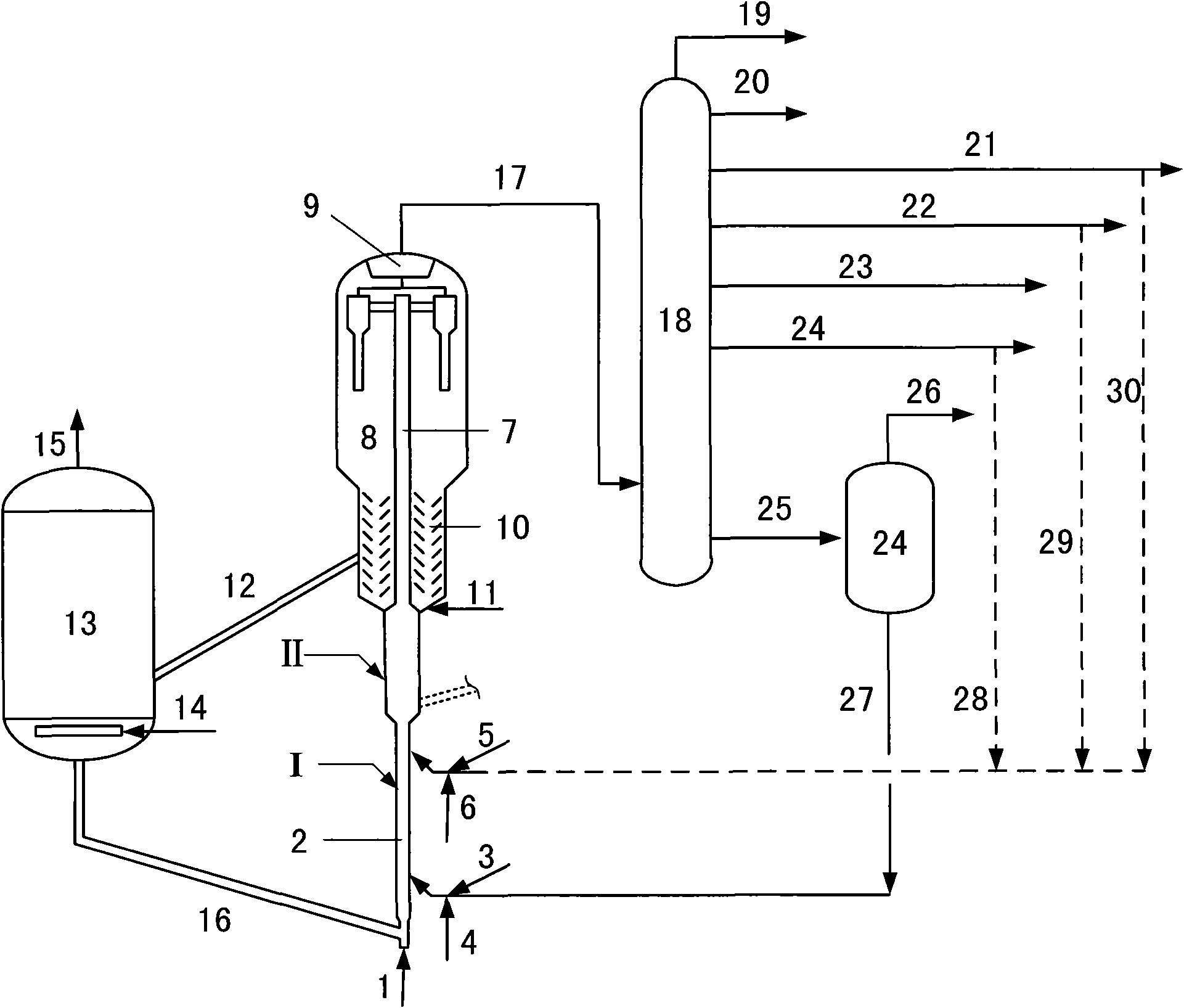

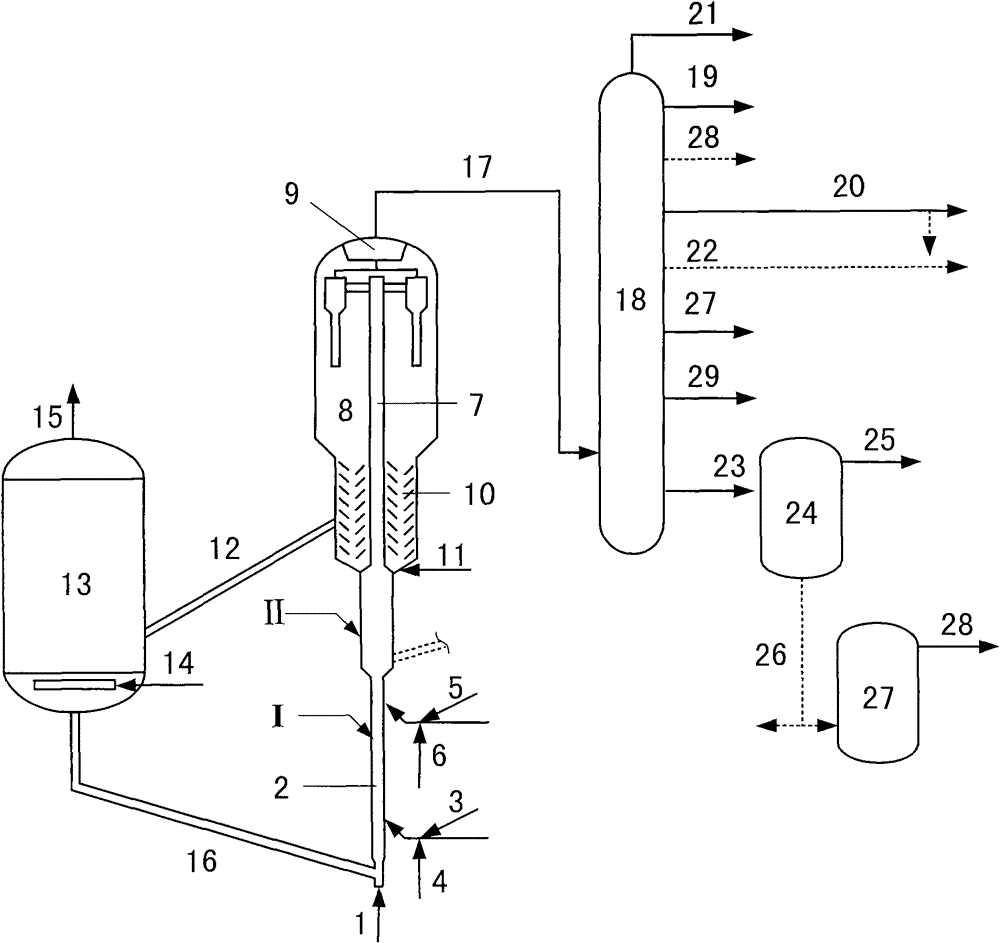

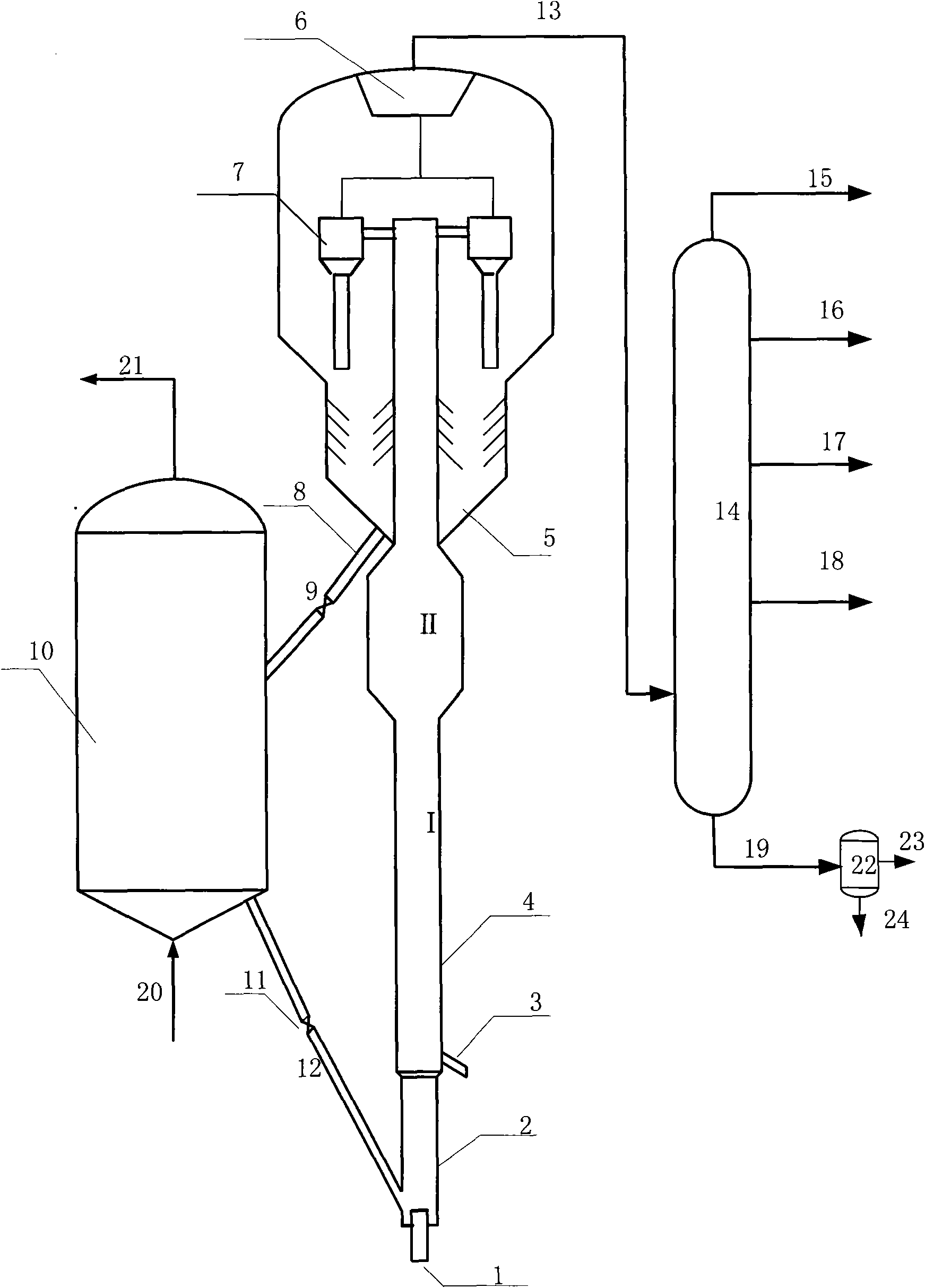

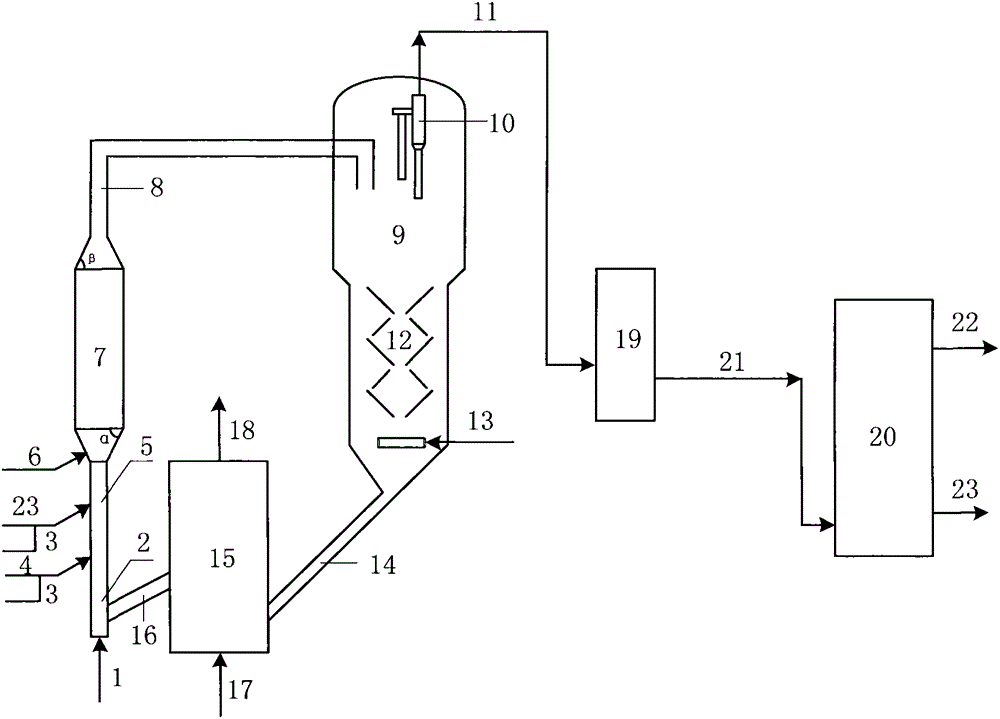

The invention discloses a catalytic conversion method for preparing propylene and high-octane value gasoline. Crude oil contacts a catalyst rich in mesoporous zeolite and with coarse particle size distribution for reaction; and reaction temperature, weight hourly space velocity and the weight ratio of the catalyst to the crude oil are sufficiently proper for preparing a reaction product comprising 12 to 60 percent of catalytic wax oil based on the weight of the crude oil in the reaction, wherein the weight hourly space velocity is 25 to 100 h<-1>; the reaction temperature is 450 to 600 DEG C;and the weight ratio of the catalyst to the crude oil is 1 to 30. The invention provides the catalytic conversion method based on the prior art, which particularly has the advantages of greatly reducing dry gas yield and coke yield at the same time of converting the heavy crude oil into the high-octane value gasoline and the propylene so as to realize the high-efficiency utilization of oil resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

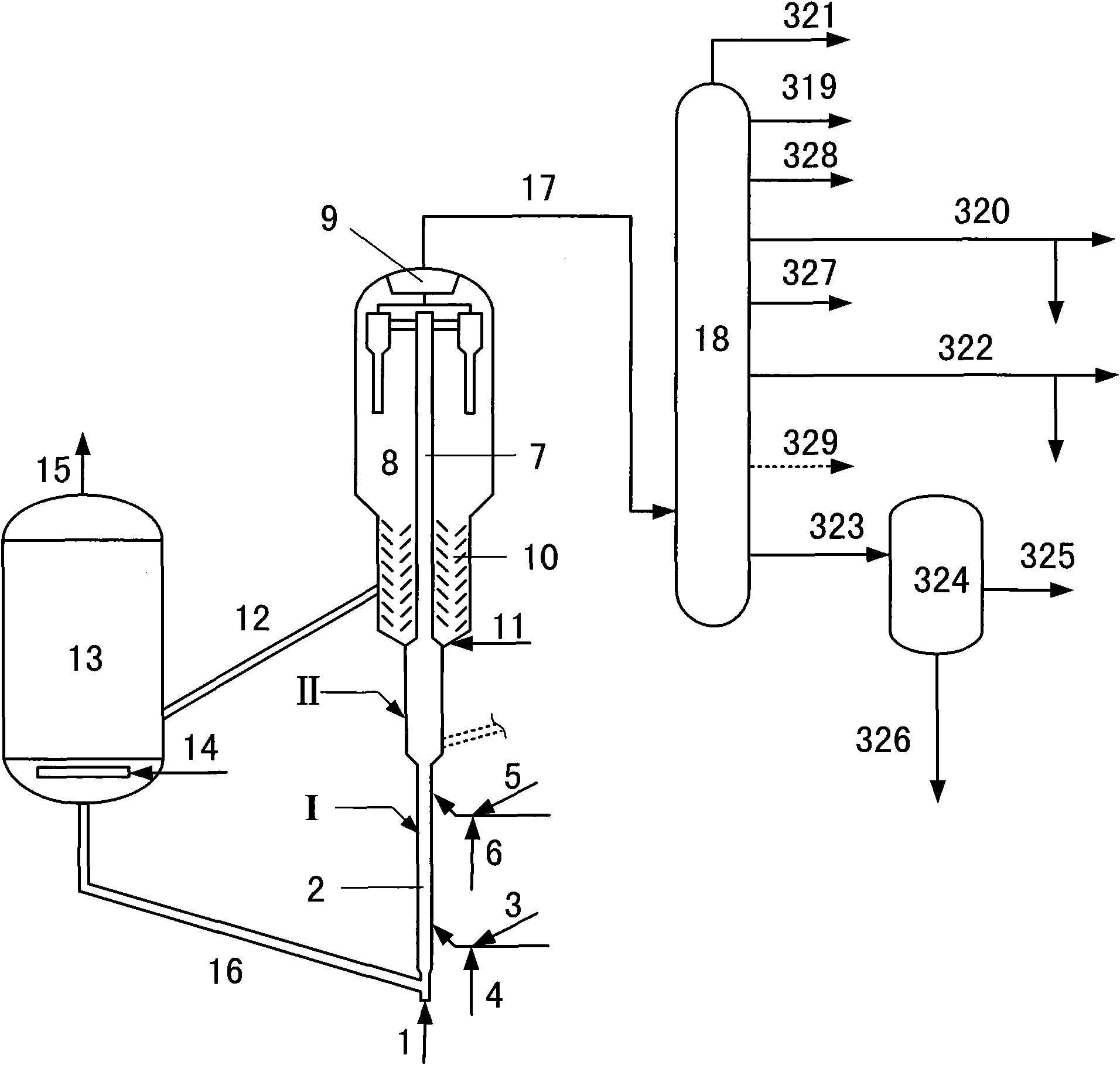

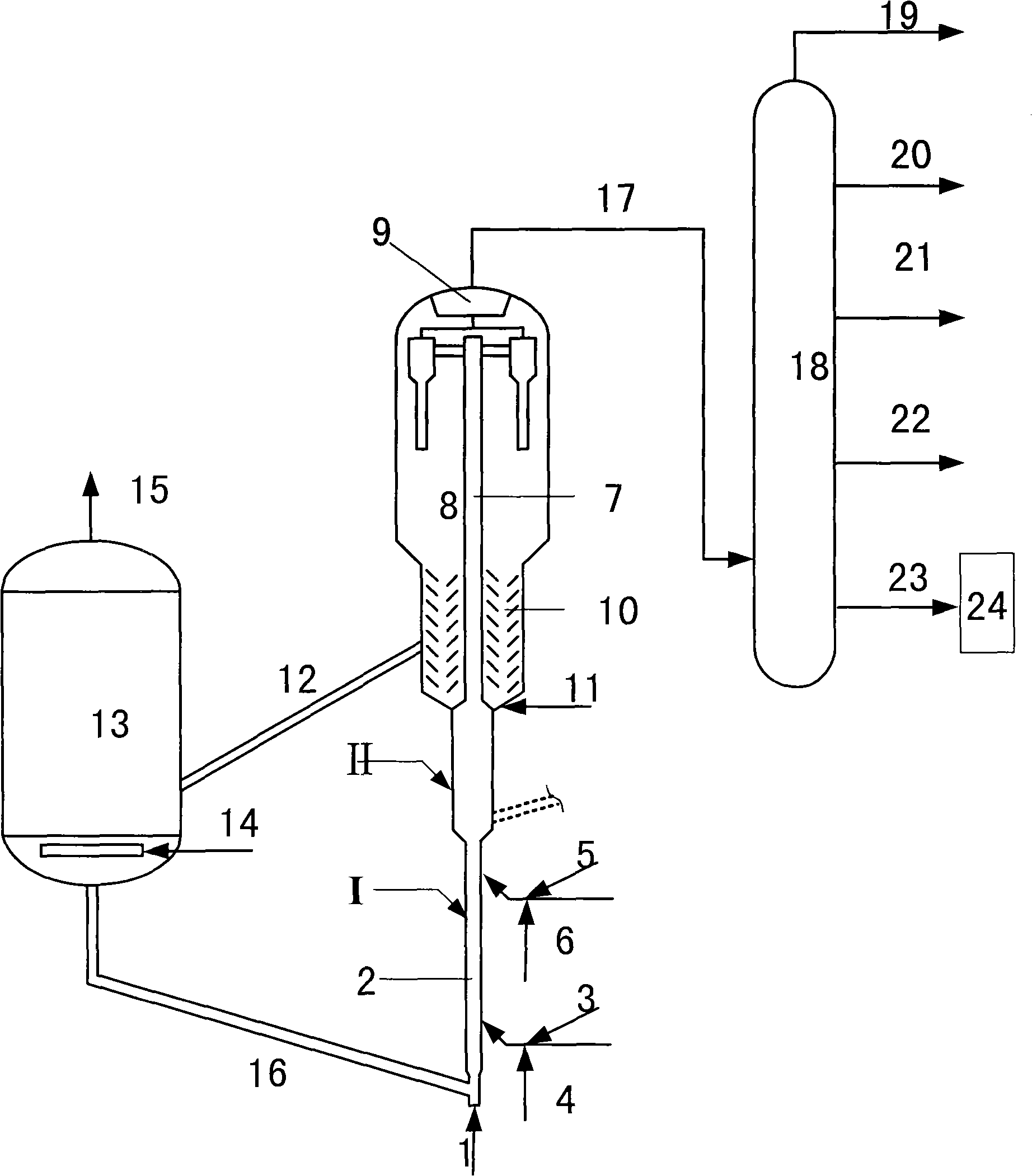

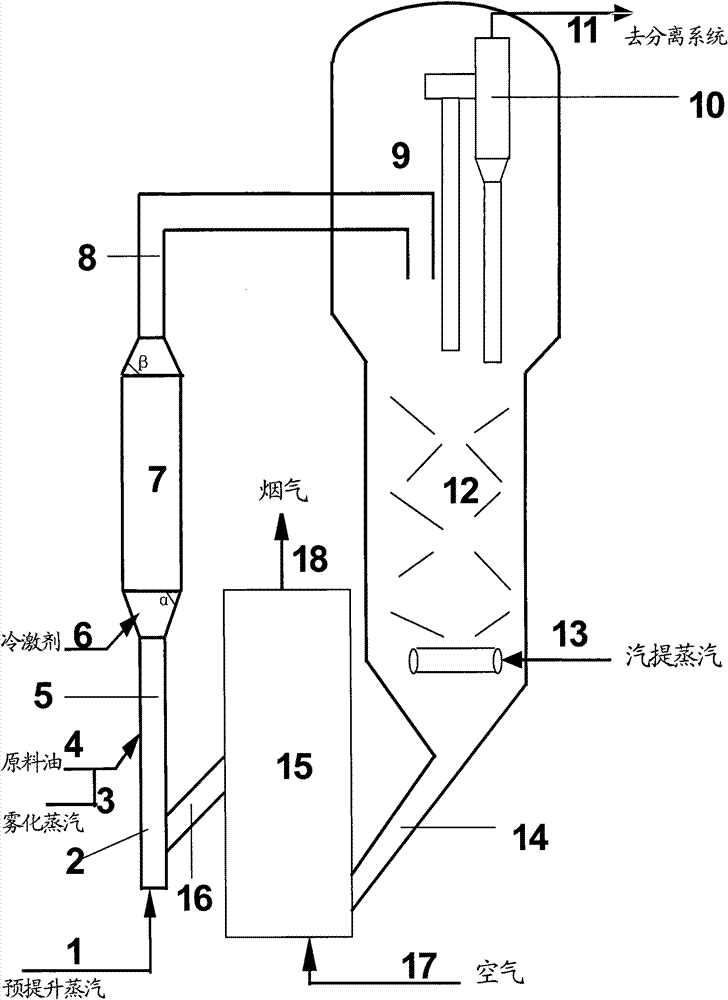

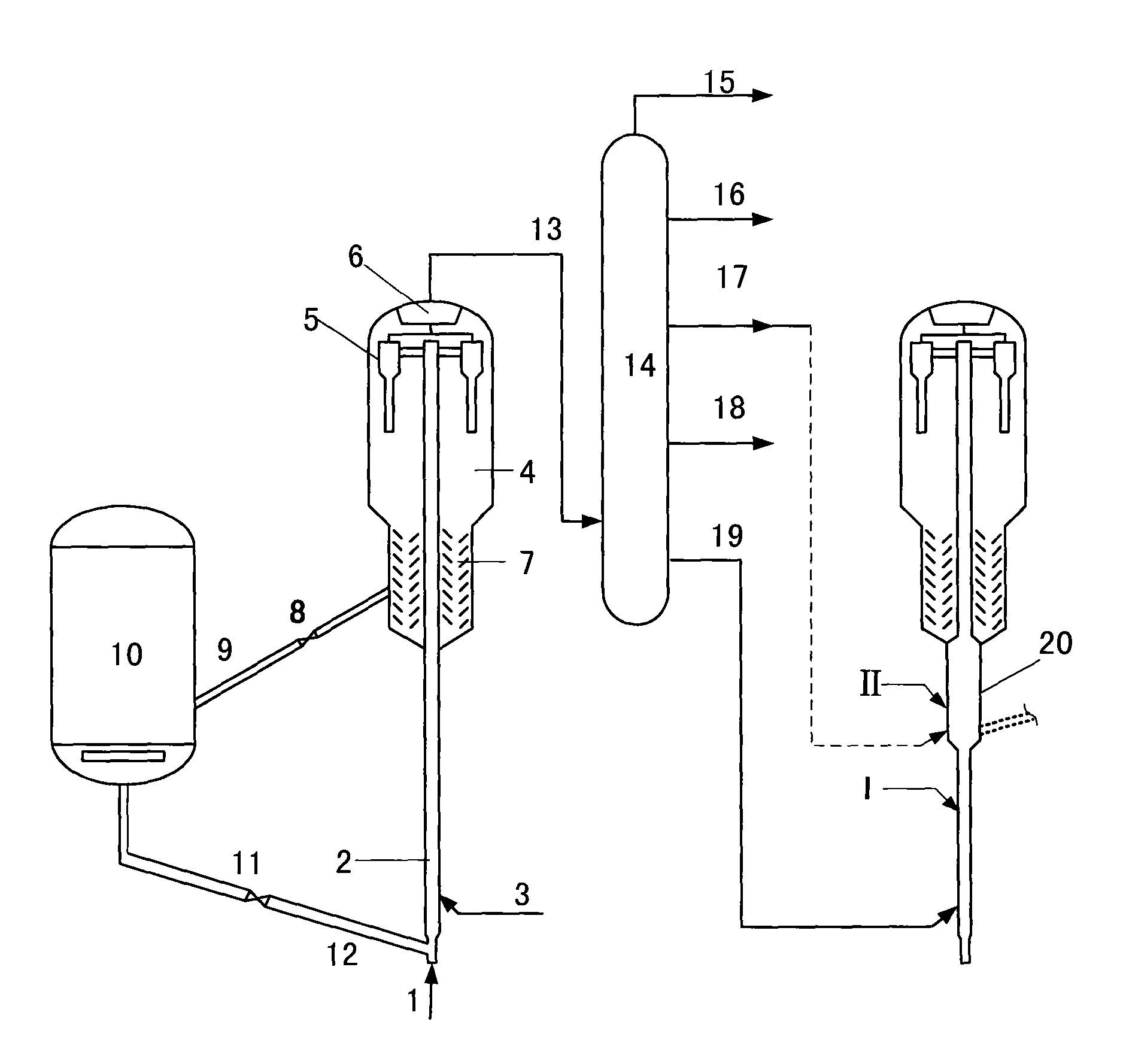

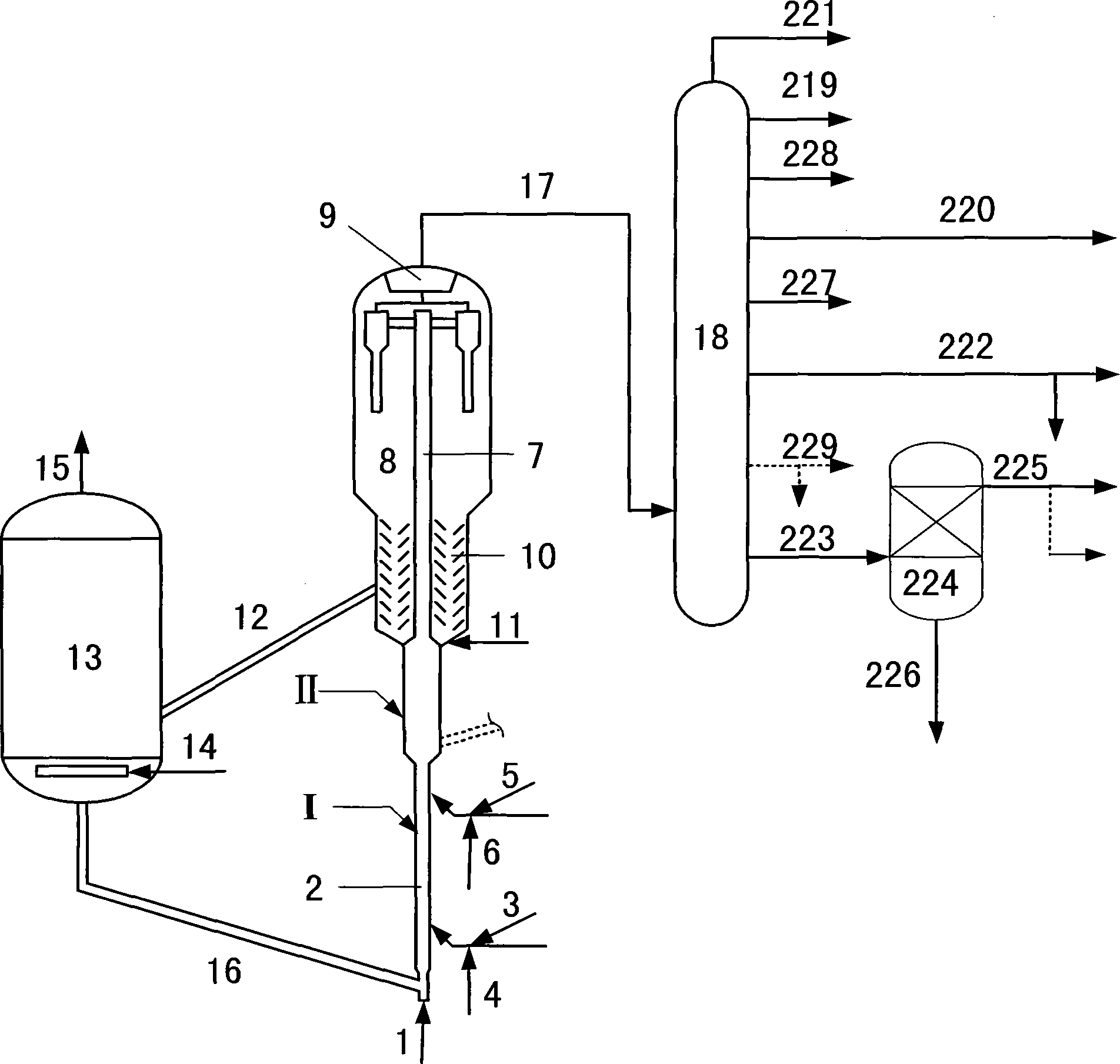

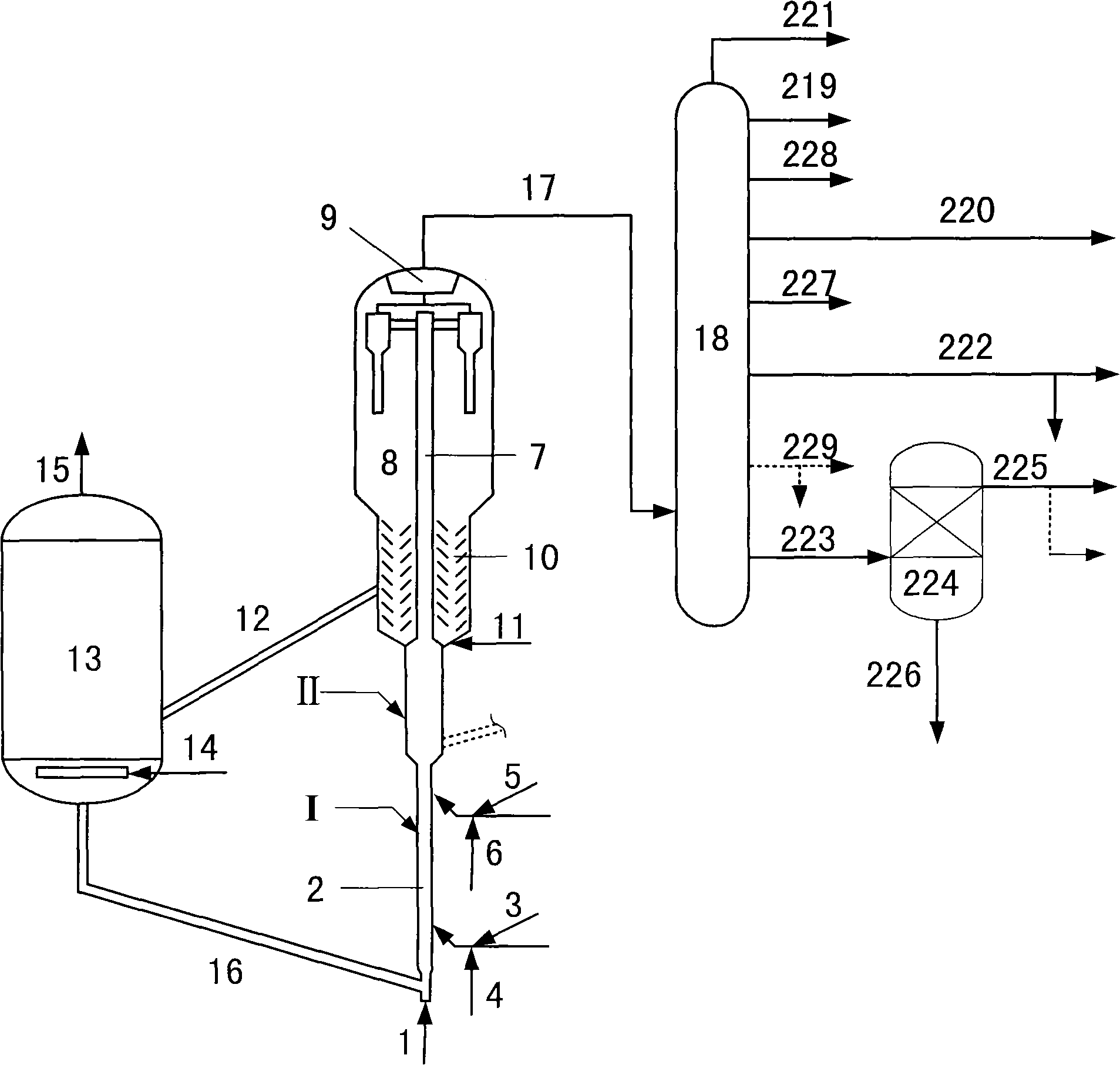

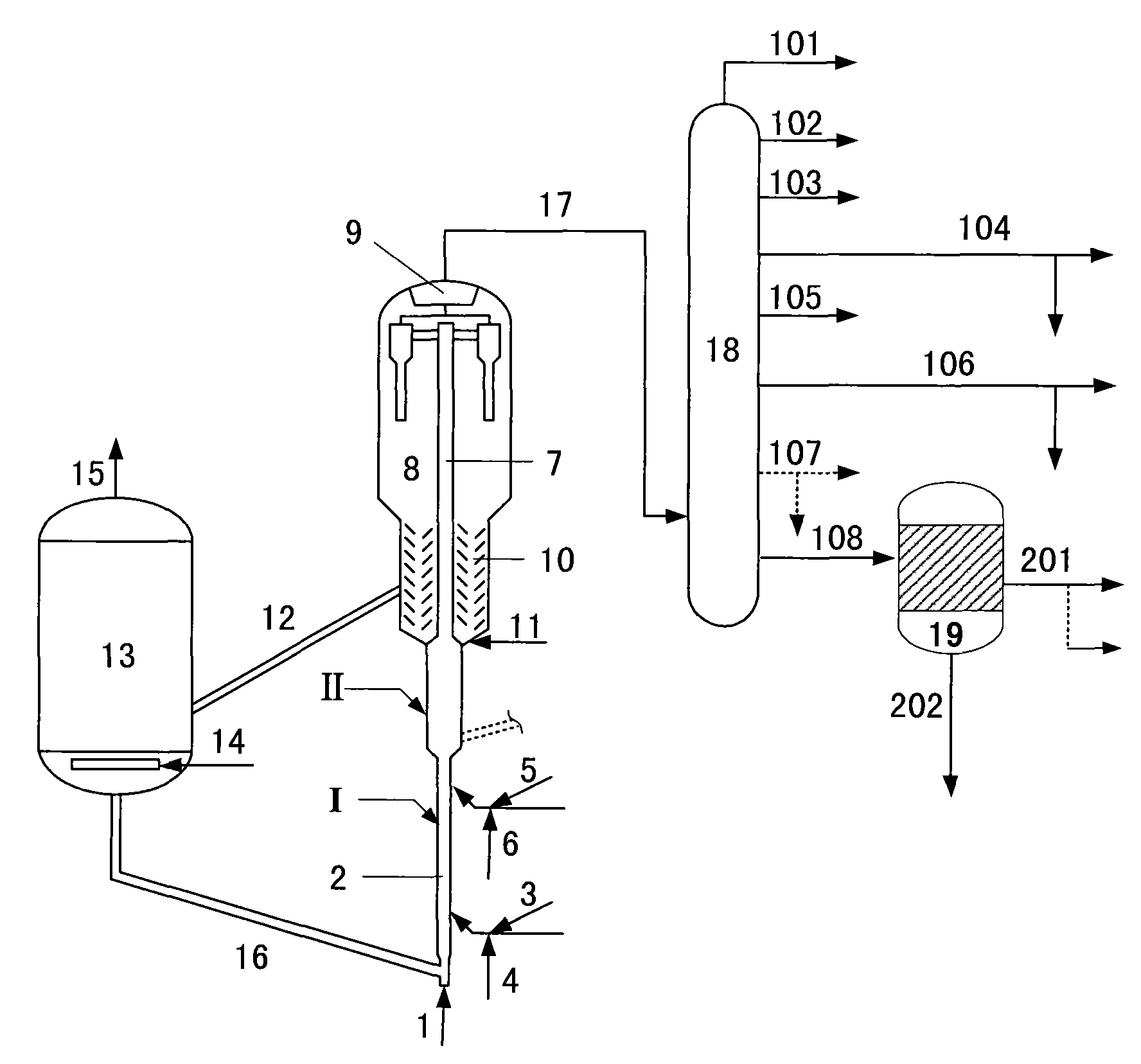

Catalytic conversion method for improving cetane number and yield of diesel

ActiveCN102041093AImprove performanceMaximize productionTreatment with hydrotreatment processesWaxReaction temperature

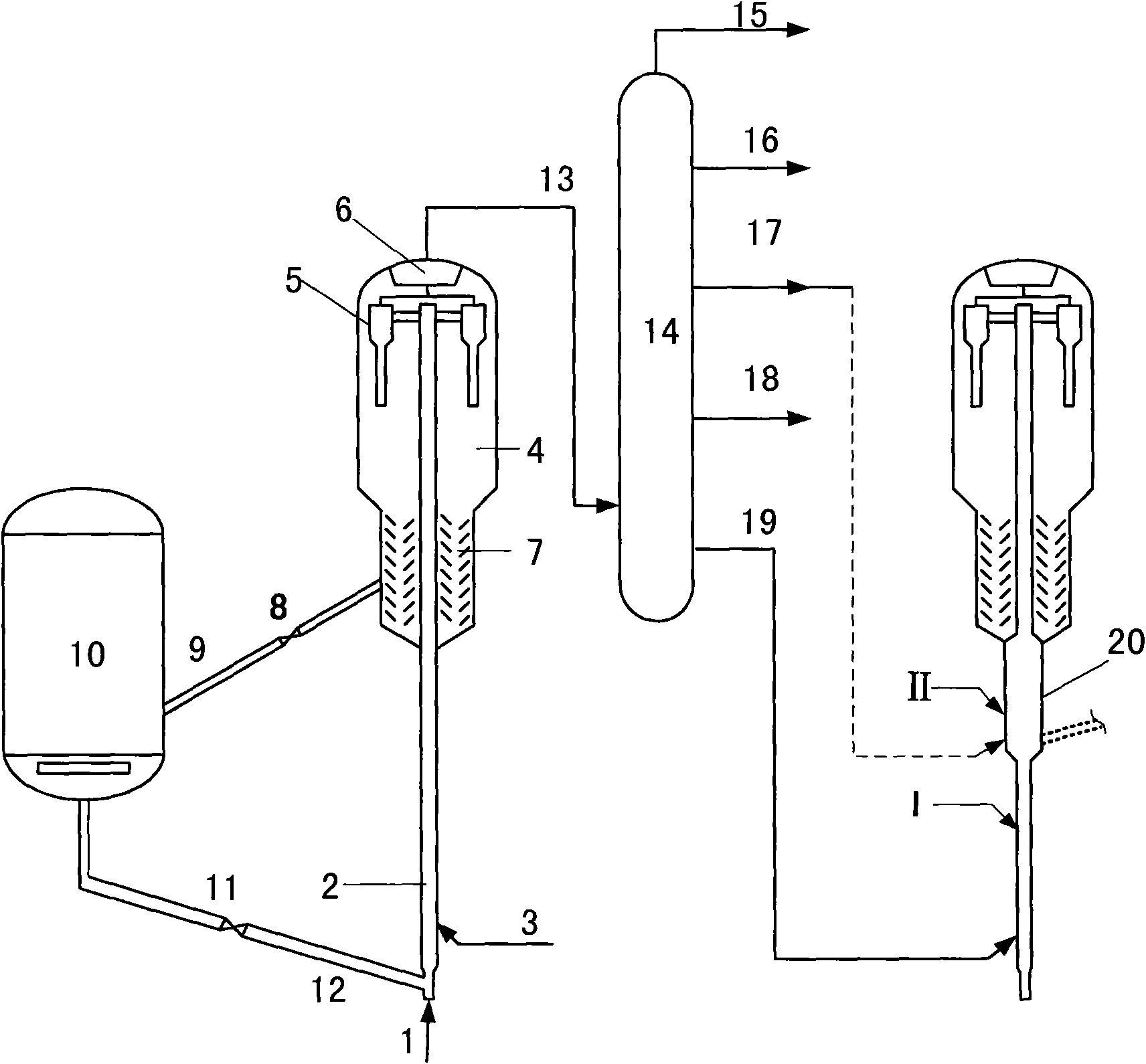

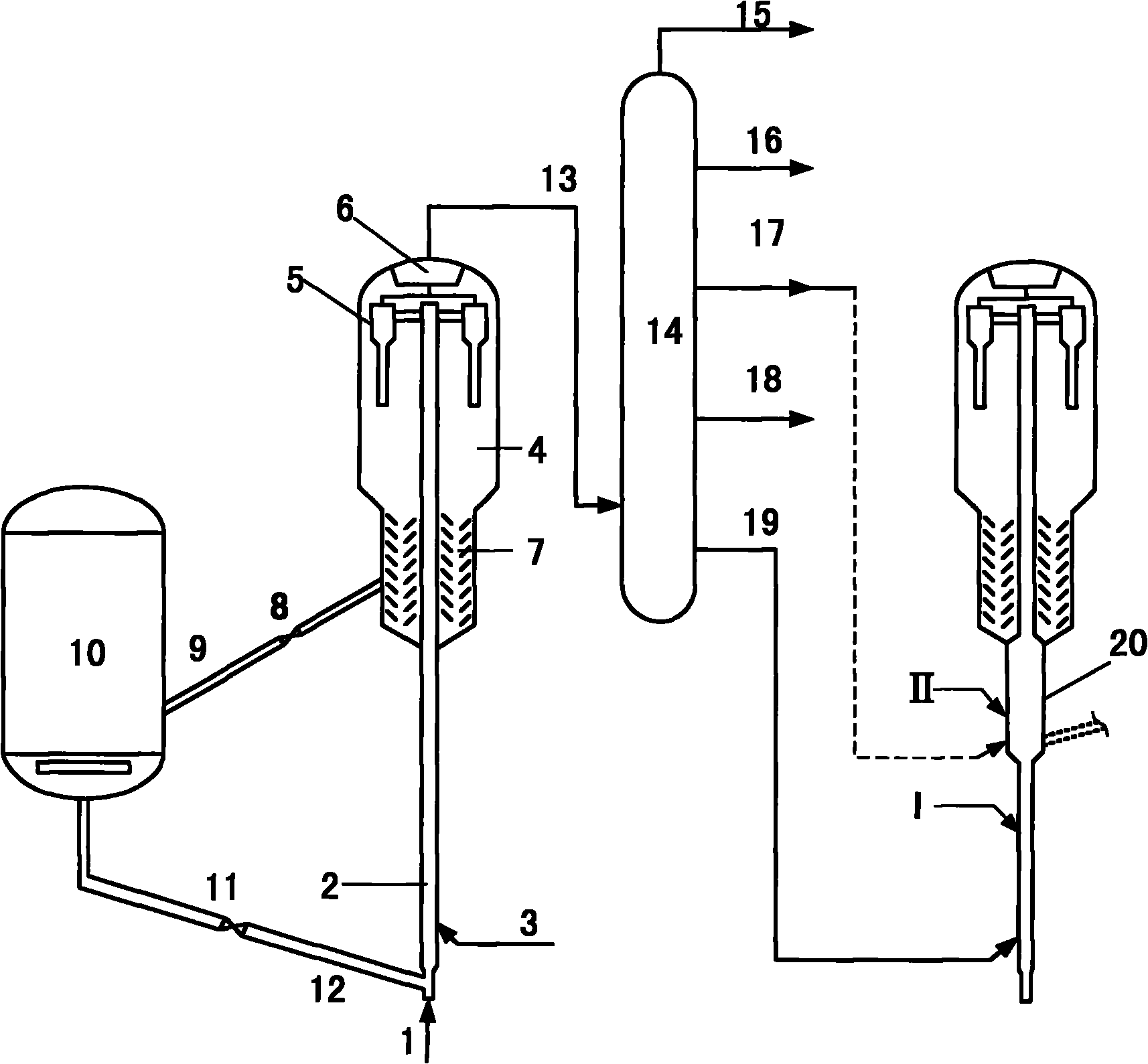

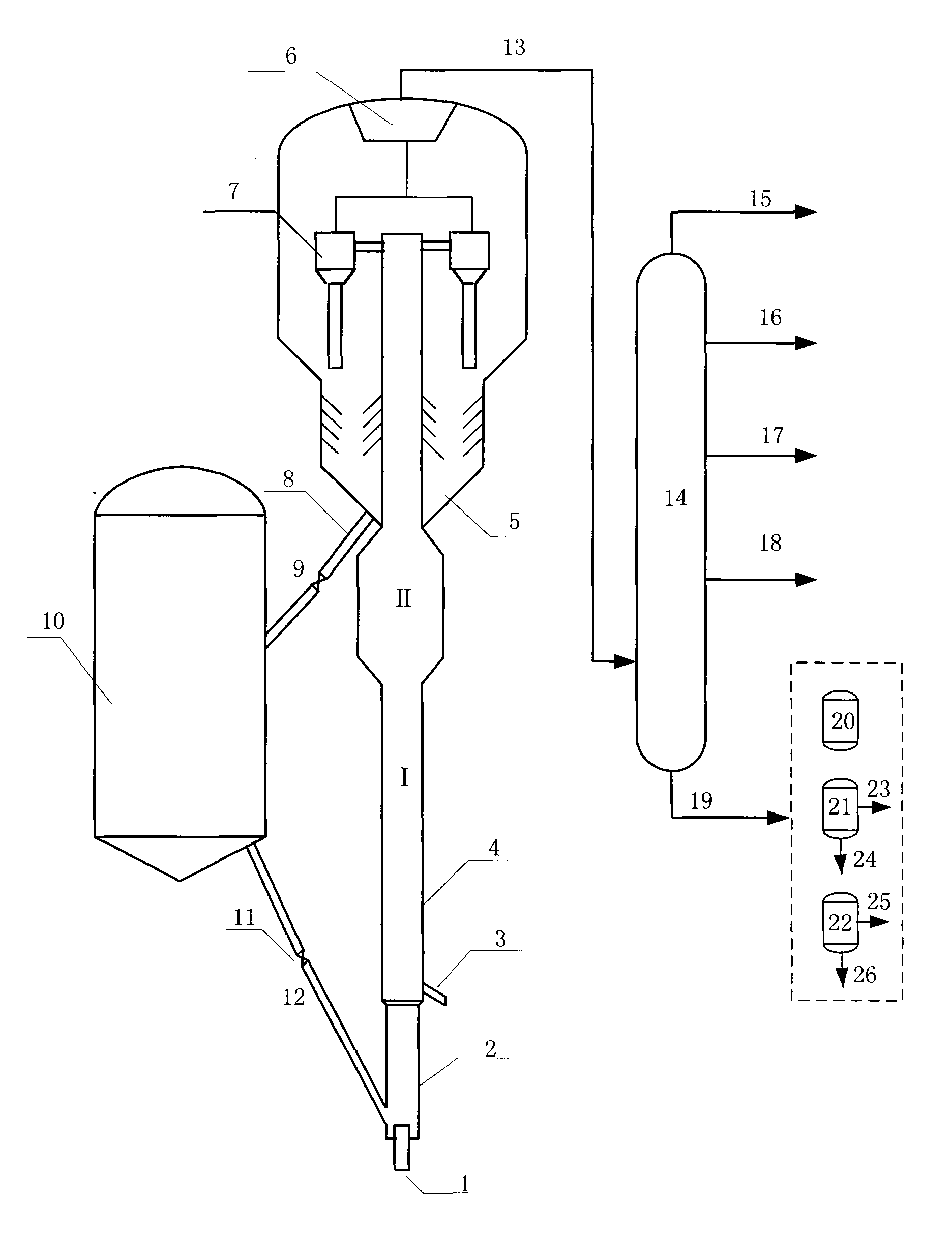

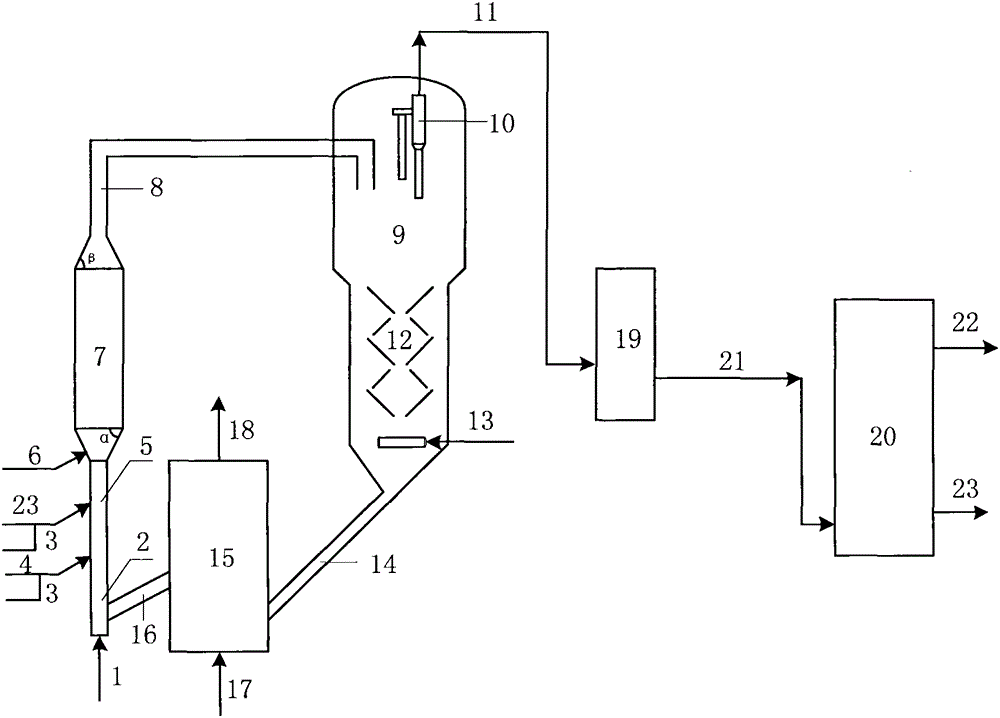

The invention discloses a catalytic conversion method for improving cetane number and yield of diesel. Raw oil is contacted with a catalyst containing large pore zeolite in a catalytic conversion reactor for reaction, and the reaction temperature, oil gas retention period, and the weight ratio of the catalyst to the raw oil sufficiently ensure that a reaction product containing catalytic wax oil which is 12 to 60 weight percent of the raw oil is obtained in the reaction, wherein the reaction temperature is 420 to 550DEG C, the oil gas retention period is 0.1 to 5 seconds and the weight ratio of the catalyst to the raw oil is 1-10; and the catalytic wax oil enters a hydrogenation unit, and the obtained hydrogenated catalytic wax oil returns to the catalytic conversion reactor. By the method, the diesel with high cetane number is produced maximally, the cracking catalyst with coarse particle size distribution can further improve the selectivity of dry gas and coke, and the catalyst breaking tendency and the catalyst consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

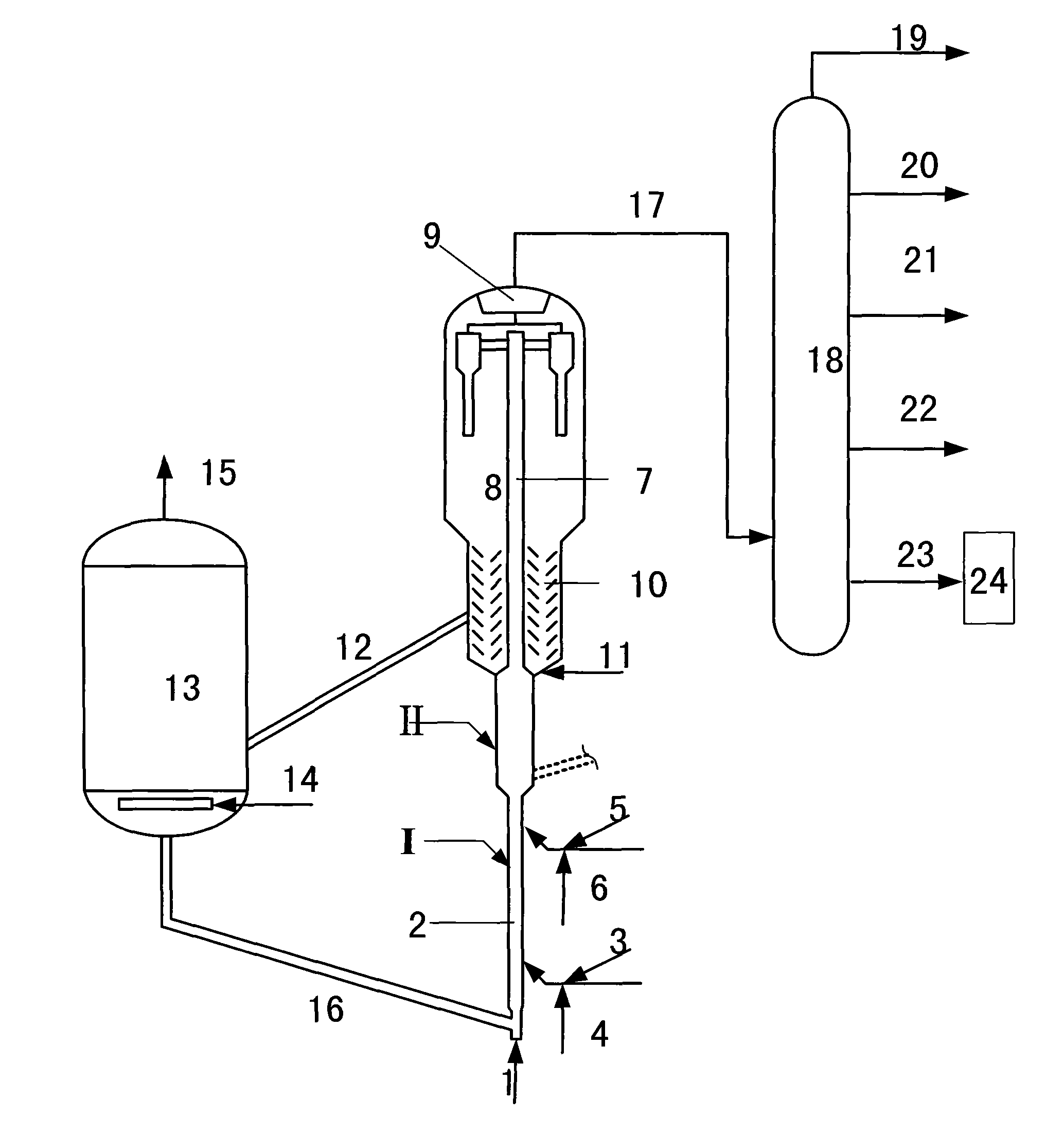

Catalytic conversion method for producing diesel and propylene in high yield

The invention discloses a catalytic conversion method for producing diesel and propylene in high yield. Raw oil is contacted with a catalyst in coarse particle size distribution in a reactor for reaction, the reaction temperature, weight hourly space velocity, and the weight ratio of the catalyst to the raw oil sufficiently ensures that a reaction product comprising catalytic wax oil which is 12 to 60 weight percent of the raw oil is obtained in the reaction, and the catalytic wax oil enters a hydrotreater for further treatment. The catalytic cracking, hydrotreating and a process of producing diesel in high yield are integrated, hydrocarbons such as alkane, alkyl side chain and the like in the raw material are selectively subjected to cracking and isomerization catalysis, aromatic hydrocarbon in the raw material is reduced to the greatest extent to enter diesel fraction, other components in the product are prevented from generating aromatic hydrocarbon through aromatization and other reaction so as not to remain the aromatic hydrocarbon in the diesel fraction, the raw material is converted into high cetane number diesel and propylene, the yield of dry gas and coke is greatly reduced, and the catalyst breaking trend and catalyst consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for diesel oil and propylene with high yield

ActiveCN102051226AIncrease cetane numberHigh selectivityTreatment with hydrotreatment processesAlkaneReaction temperature

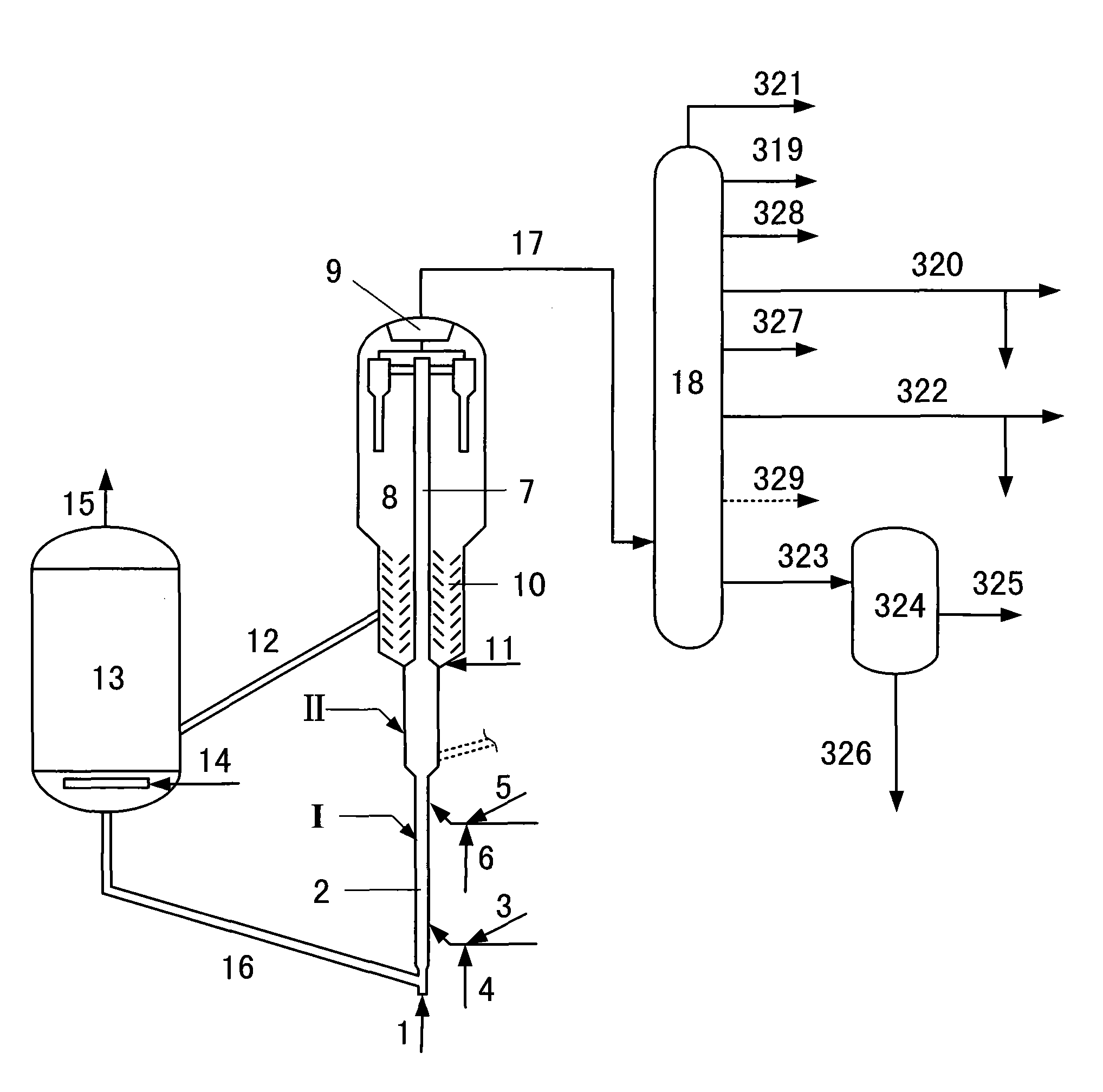

The invention discloses a catalytic conversion method for diesel oil and propylene with high yield. Raw material oil is contacted with a catalyst with coarse particle size distribution in a reactor to react; reaction temperature, weight hourly space velocity and weight ratio of the catalyst to the raw material oil are sufficient so that a reaction product containing catalytic wax oil which is 12 to 60 weight percent of the raw material oil; and the catalytic wax oil is fed into a hydro-cracking device for further treatment. Catalytic cracking, hydro-cracking and high-yield diesel oil processes are organically combined, hydrocarbons such as alkane, alkyl side chain and the like in the catalytic raw materials are selectively cracked and isomerized, meanwhile, aromatic hydrocarbons in the raw materials are furthest reduced to enter the diesel oil fraction, and aromatic hydrocarbons generated by reaction of other components in the product such as aromatization and the like are prevented from being left in the diesel oil fraction; and when the raw materials are transformed into the diesel oil with high cetane number and the propylene, the yields of dry gas and coke are greatly reduced, and catalyst crushing tendency and catalyst consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst conversion method for producing high-octane gasoline by using crude oil

ActiveCN102108308ALess investmentReduce corrosion costsCatalytic crackingTreatment with plural serial stages onlyWaxPetroleum

The invention provides a catalytic conversion method for producing high-octane gasoline by using crude oil, which comprises: contacting pretreated crude oil serving as raw material oil with a catalyst which contains macroporous zeolite and is distributed according to a coarse particle size in a catalytic conversion reactor to perform a reaction according to reaction temperature, oil gas dwell time and catalyst to raw material oil weight ratio, which are proper enough to enable the reaction to obtain a reaction product containing catalytic wax oil which accounts for 15 to 60 percent of the weight of the raw material oil, wherein the weight hourly space velocity is 25 to 100h<-1>, the reaction temperature is 450 to 600 DEG C, and he weight ratio of the catalyst to the raw material oil is 1 to 30. In the method, while low-quality crude oil is converted into high-octane gasoline, the dry gas and coke yields are reduced considerably, the high-efficient utilization of oil resources is realized, and the higher particle uniformity of the catalyst makes the local temperature distribution in a regeneration process more uniform and the breakage orientation of the catalyst lowered correspondingly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for producing high-quality light fuels from crude oil

ActiveCN102079996ALess investmentReduce corrosion costsTreatment with hydrotreatment processesReaction temperaturePetroleum

The invention discloses a catalytic conversion method for producing high-quality light fuels from crude oil. The crude oil contacts and reacts with a catalyst which is rich in mesoporous zeolite and in coarse particle size distribution. The catalytic conversion method is characterized in that a reaction product containing catalytic wax oil which accounts for 12-60 wt% of the weight of raw material is obtained by the reaction temperature, weight hourly space velocity and the weight ratio of raw oil to catalyst, wherein the reaction temperature is 420-600 DEG C, the weight hourly space velocity is 25-100 hours<-1>, the weight ratio of catalyst to raw oil is 1 to 30, and the wax is catalyzed before hydrocracks. In the invention, crude oil catalytic converter and hydrocracking methods are provided, which, in particular, reduces dry gas and coke yield significantly while converting the poor quality of crude oil into high octane gasoline and high-cetane diesel fuel so as to achieve efficient use of oil resources, and reduce the broken tendency of the catalyst and the catalyst consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

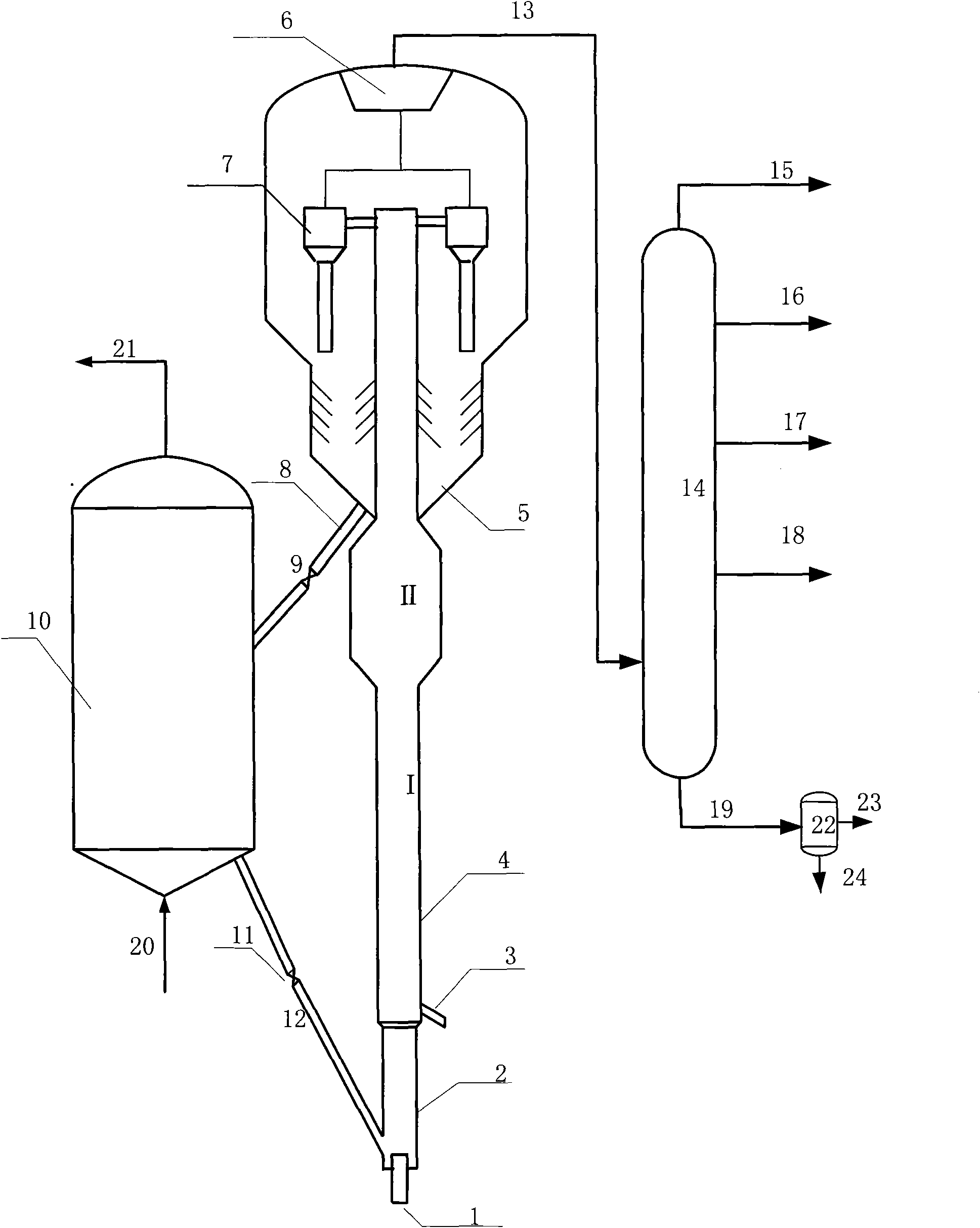

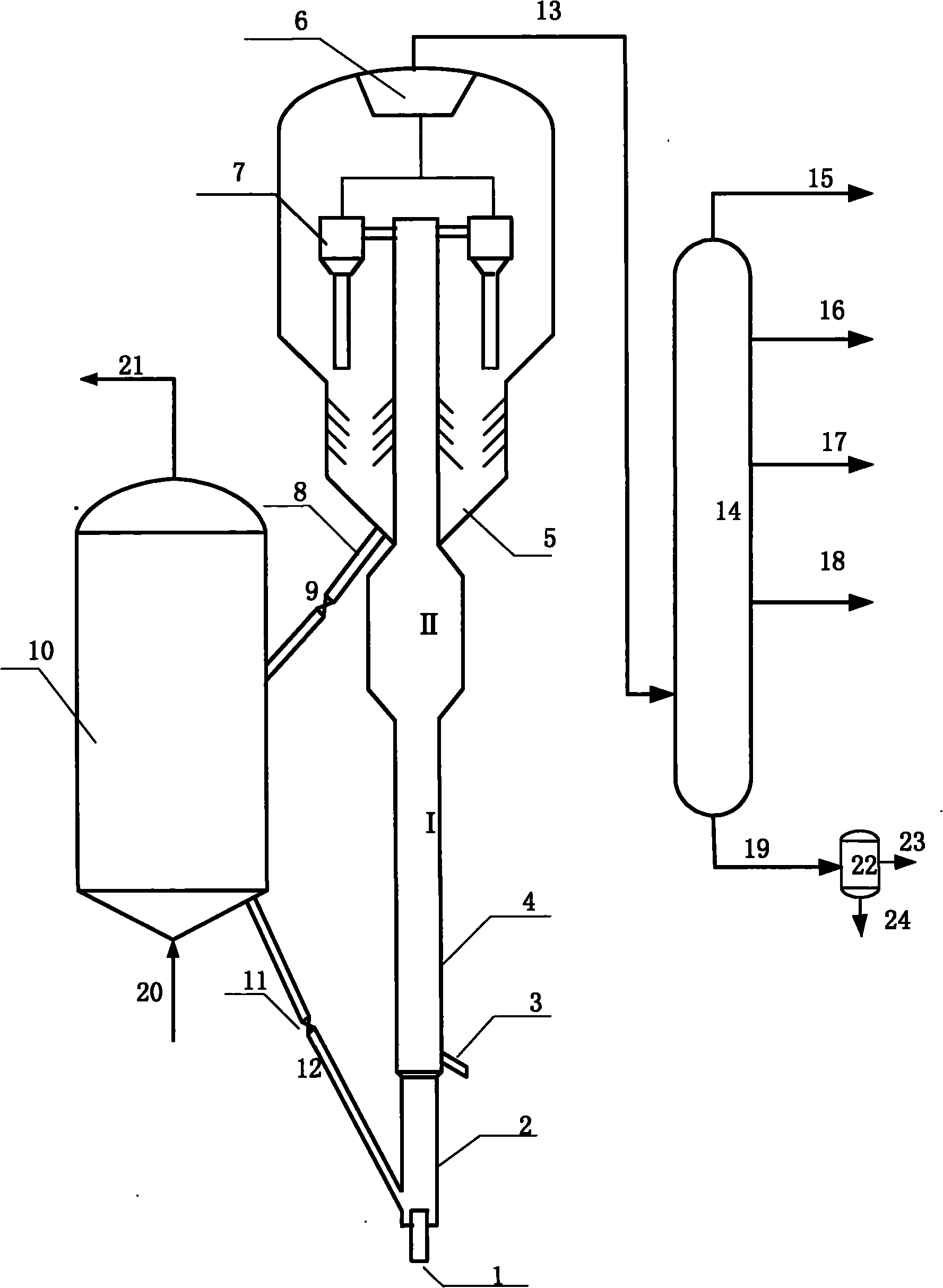

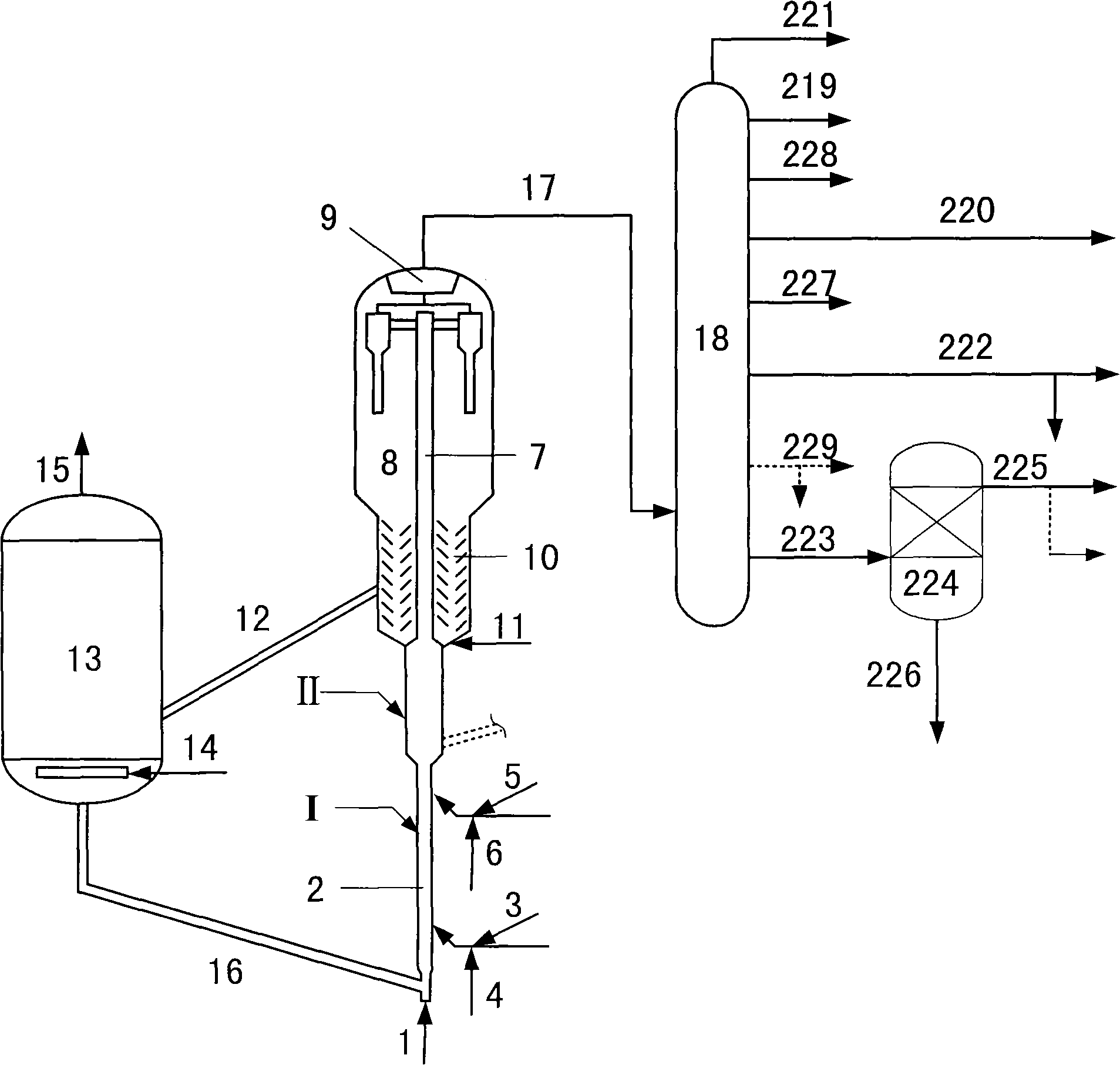

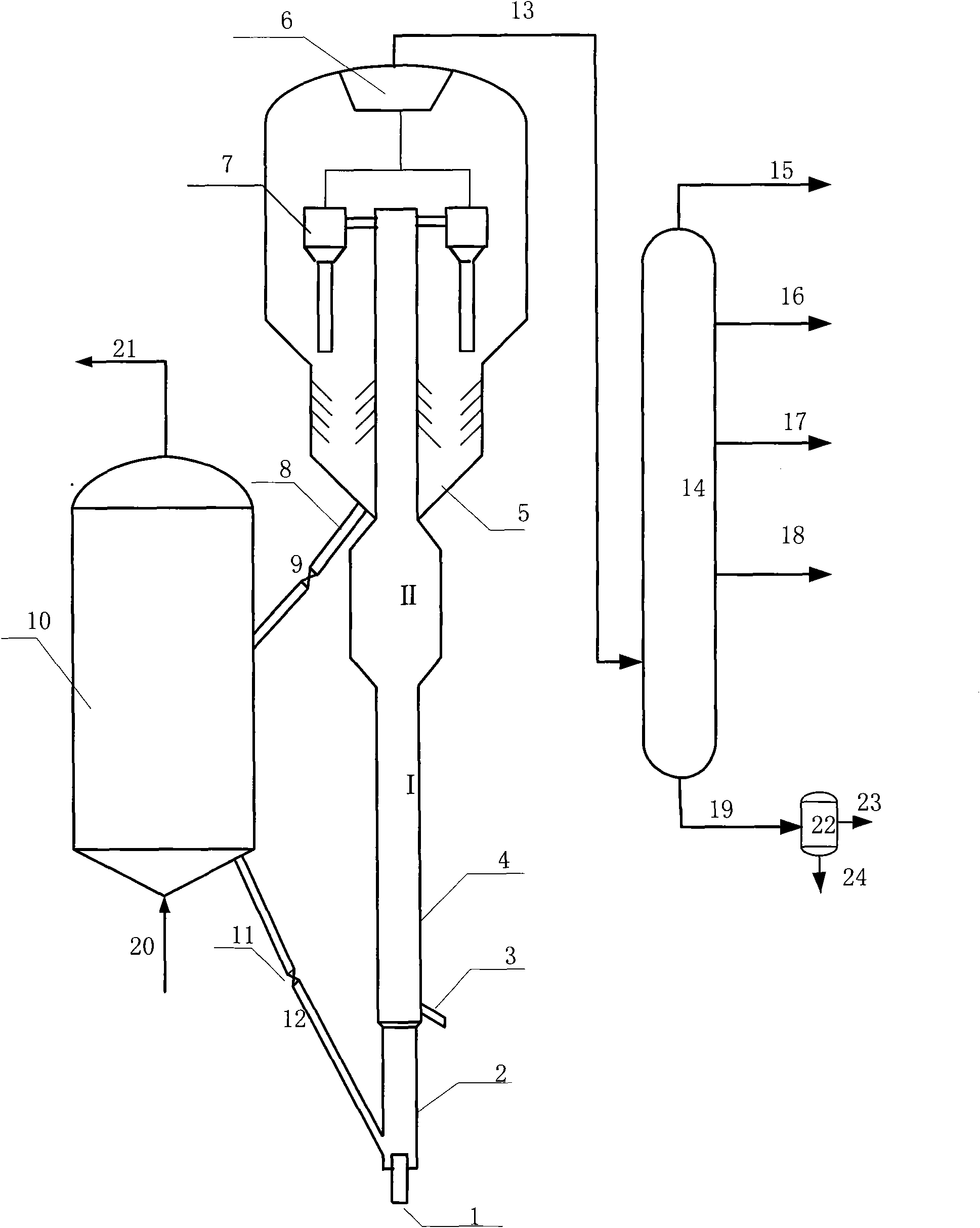

Catalytic conversion method for producing high-cetane number light diesel oil and low-olefin gasoline

ActiveCN102079992AReduce production processGood choiceCatalytic crackingTreatment with plural serial stages onlyWaxIsomerization

The invention relates to a catalytic conversion method for producing high-cetane number light diesel oil and low-olefin gasoline, which comprises the following steps of: making raw oil contact mitigated converting catalyst with rough grain diameter distribution in a mitigated converting reactor for reacting, wherein the reaction temperature, oil and gas retaining time and the weight ratio of the mitigated converting catalyst to the raw oil are enough to obtain a reaction product containing catalytic wax oil which accounts for 12-60 percent by weight of raw oil, and the reaction product also comprises high-cetane number diesel oil and gasoline; carrying out cracking reaction on the catalytic wax oil in a harsh converting reactor; carrying out hydrogen transfer reaction and isomerization reaction on the generated oil and gas in a certain reaction environment; and separating to obtain a reaction product containing low-olefin gasoline. The method can directly produce high-cetane number light diesel oil and low-olefin gasoline simultaneously by catalytic cracking and reduce the catalyst breakage tendency and catalyst consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

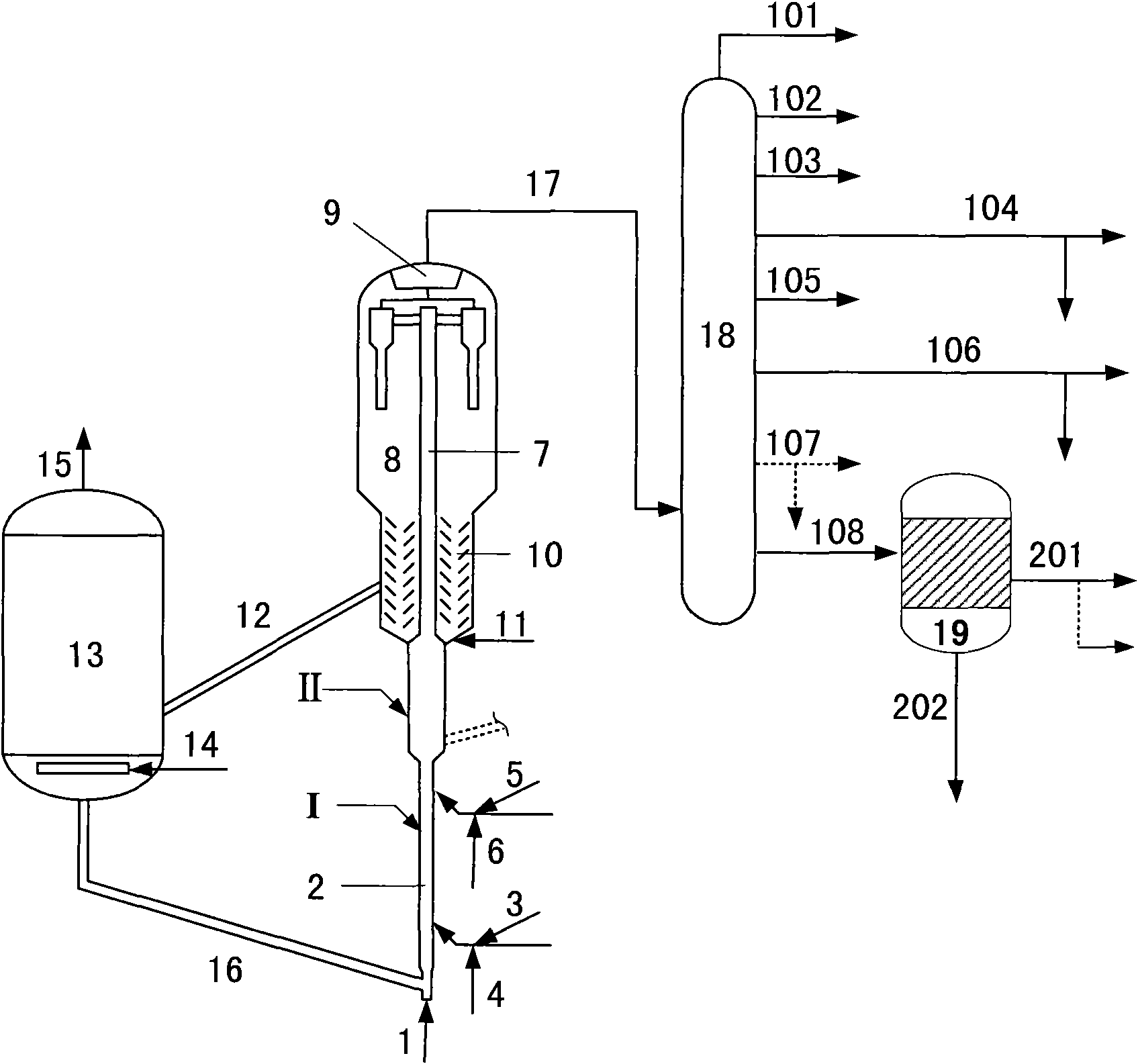

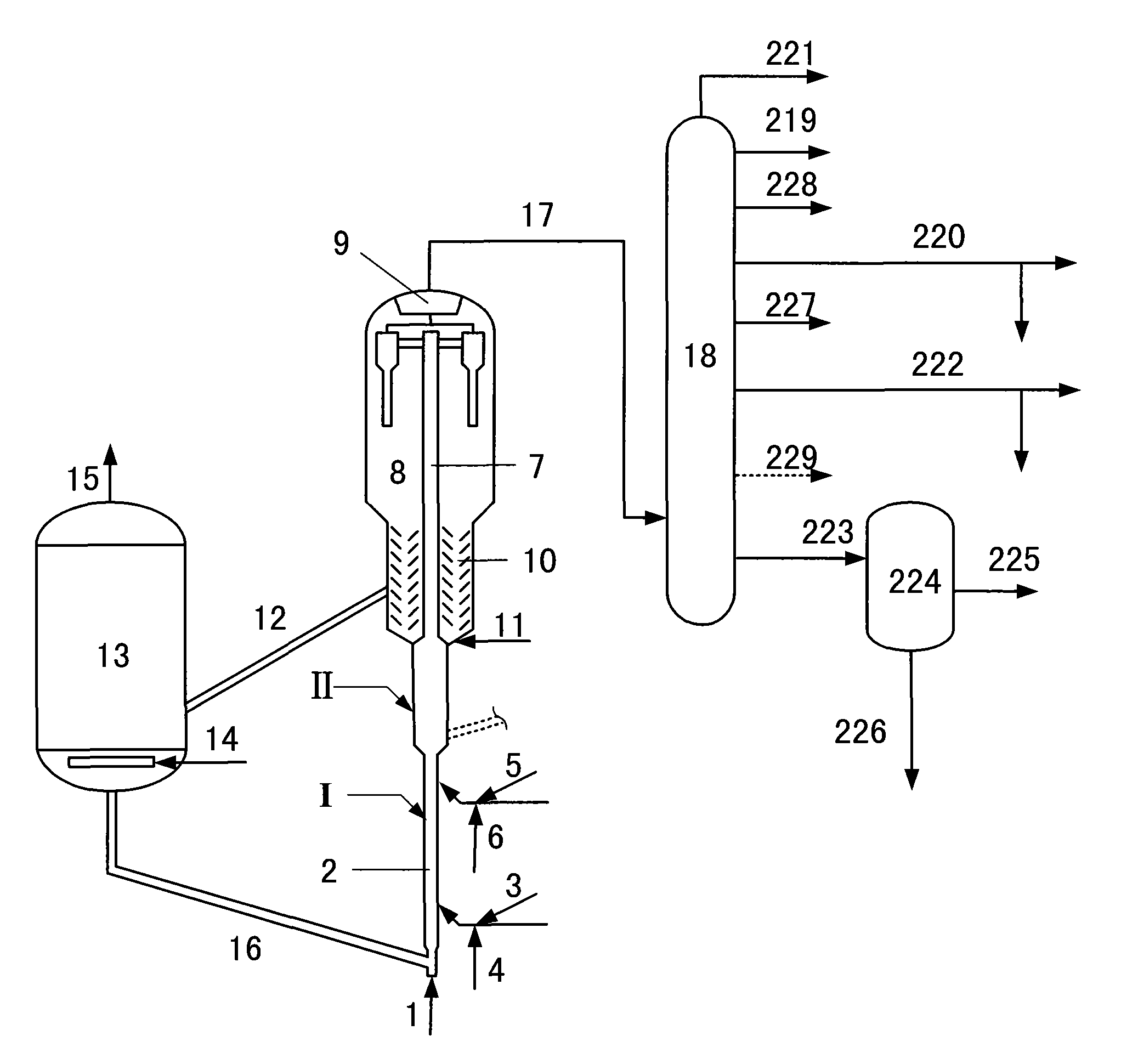

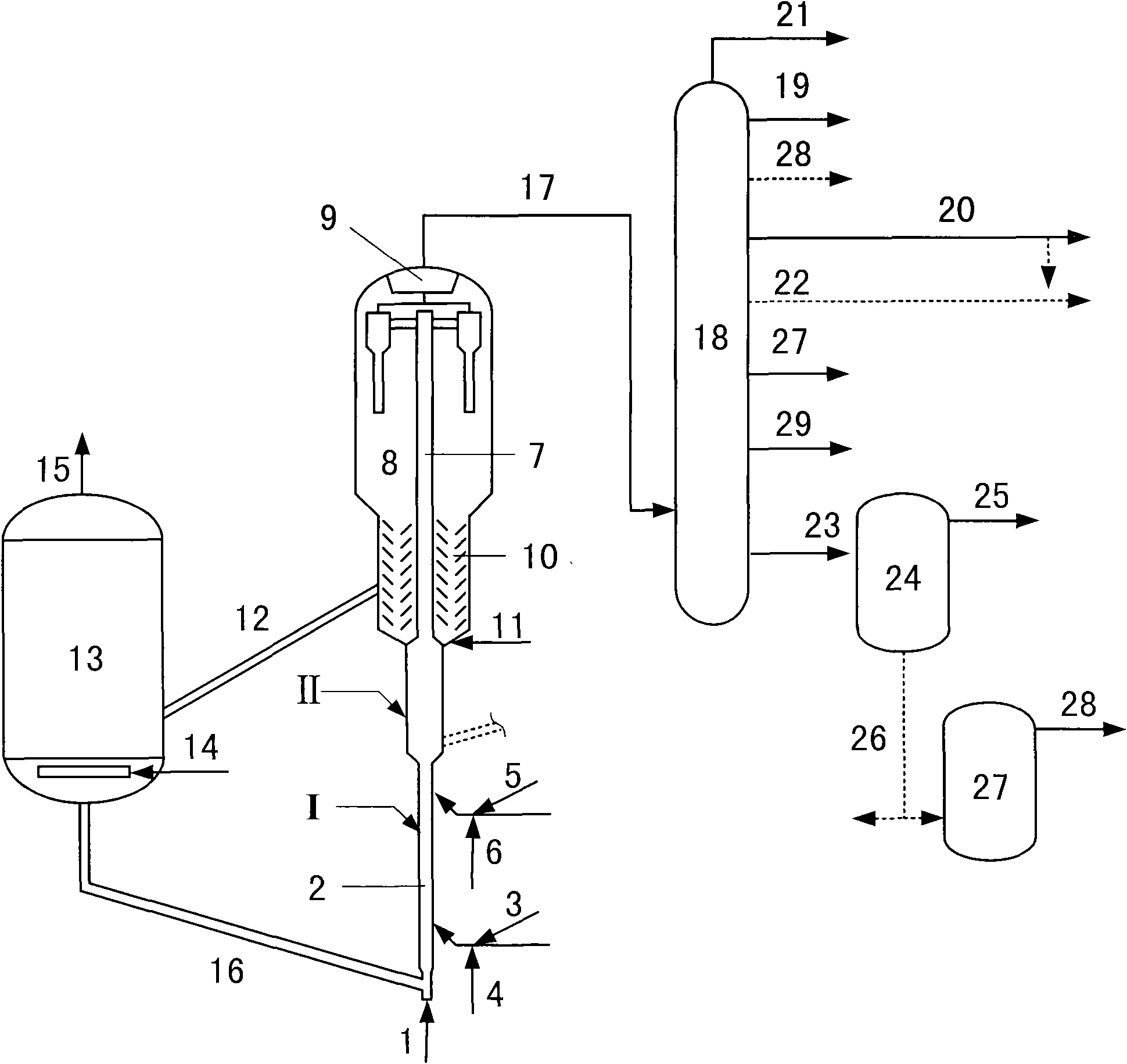

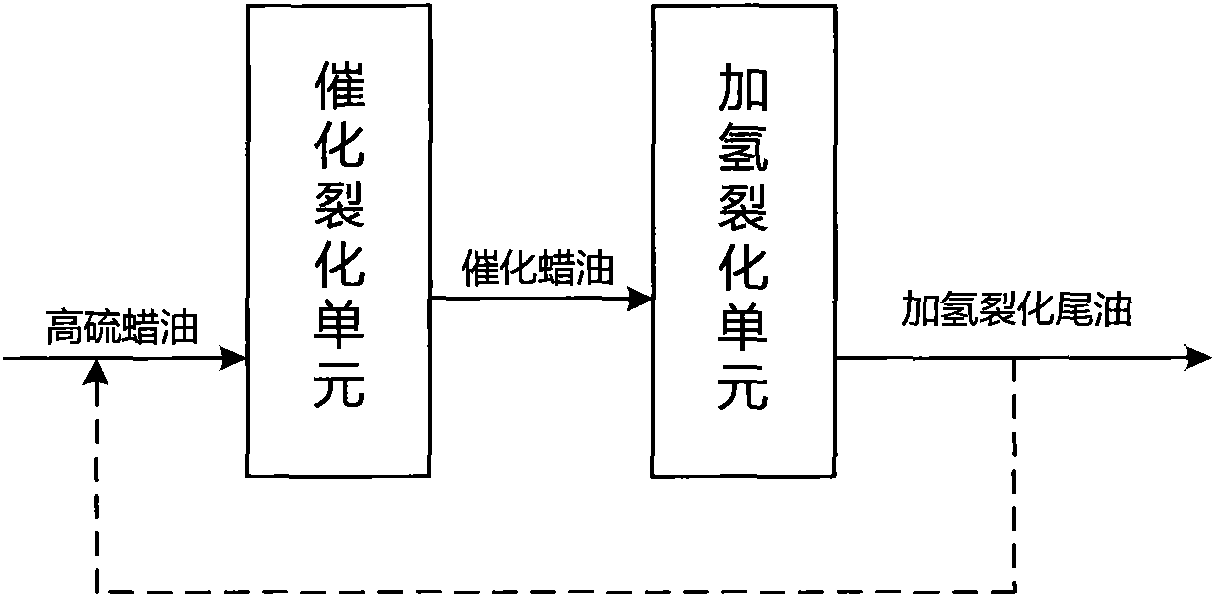

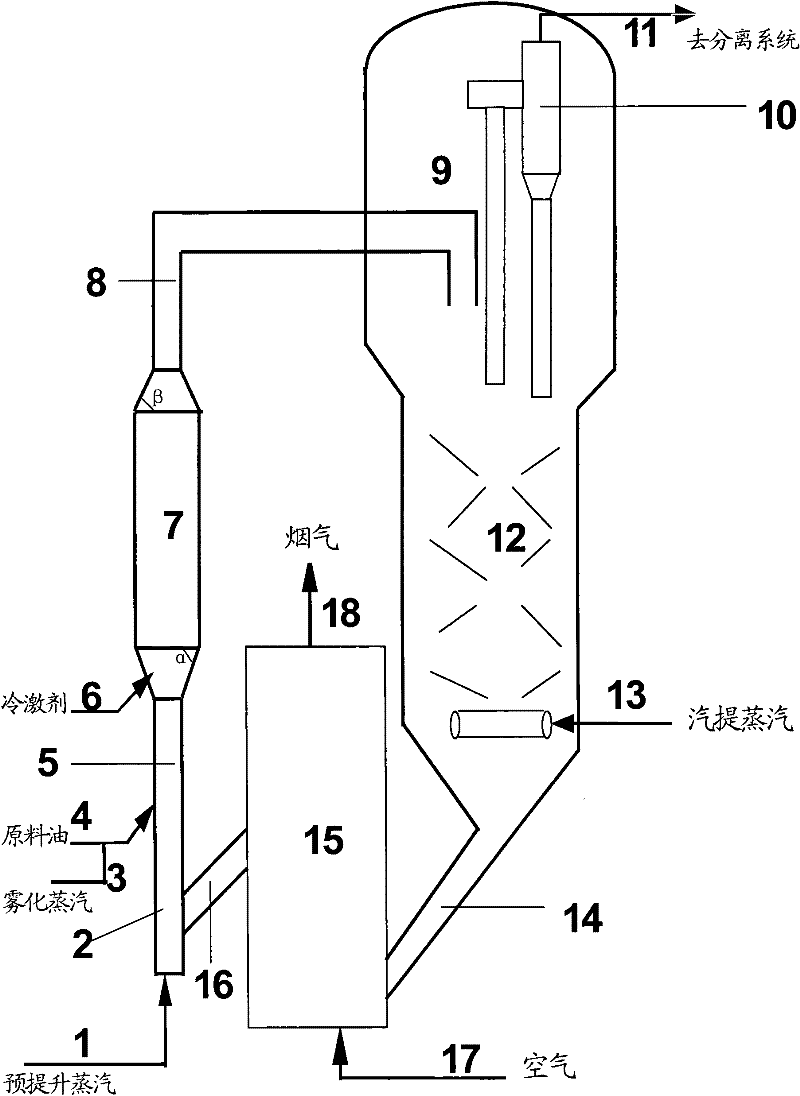

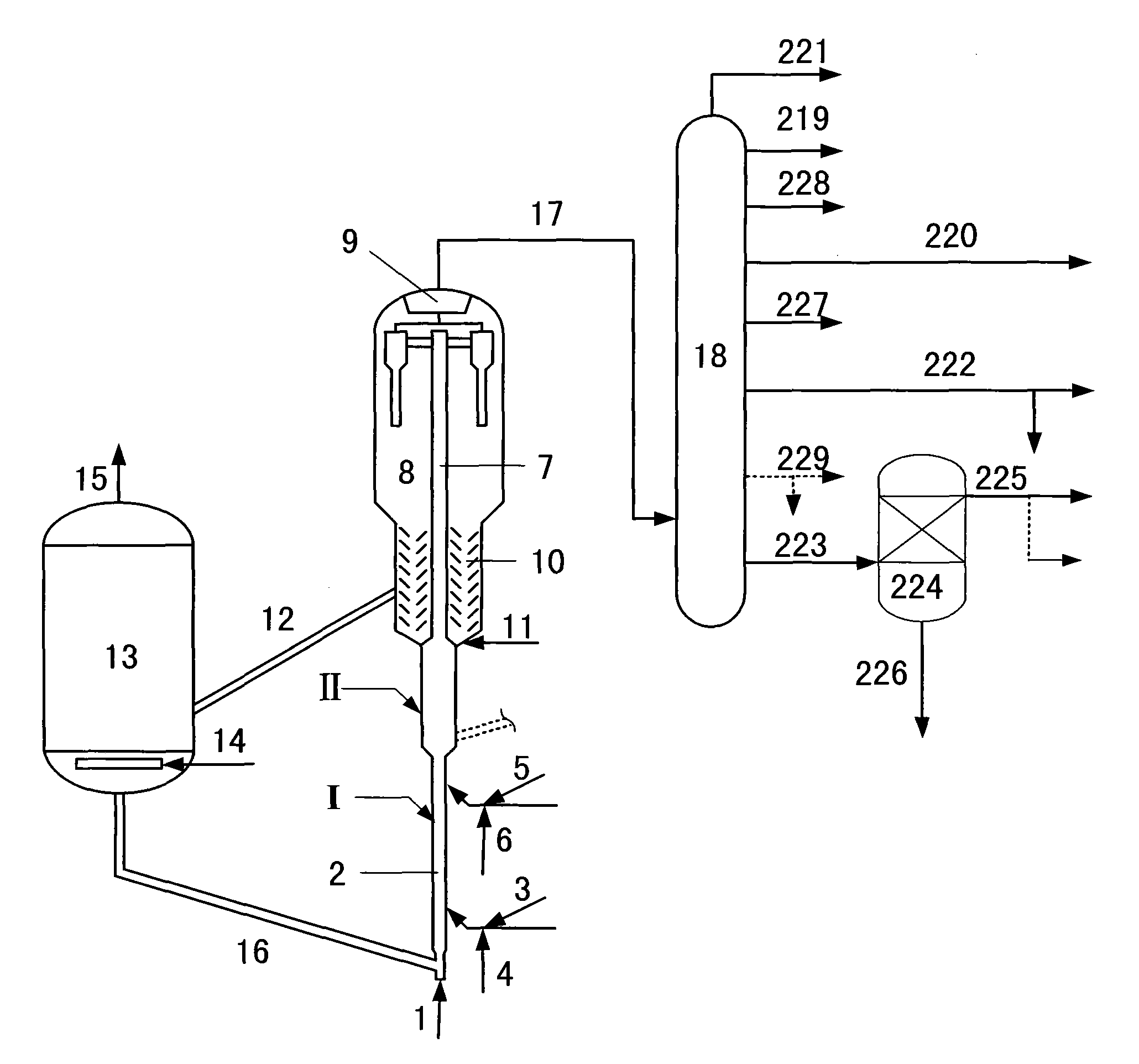

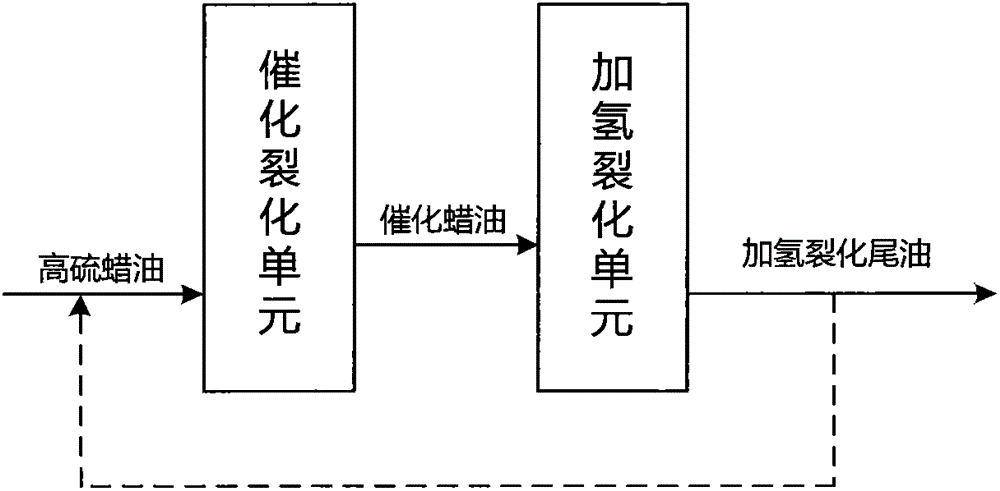

Effective catalytic conversion method of petroleum hydrocarbon

ActiveCN103059995AImprove use efficiencyReasonable integrationTreatment with hydrotreatment processesIsomerizationPetroleum

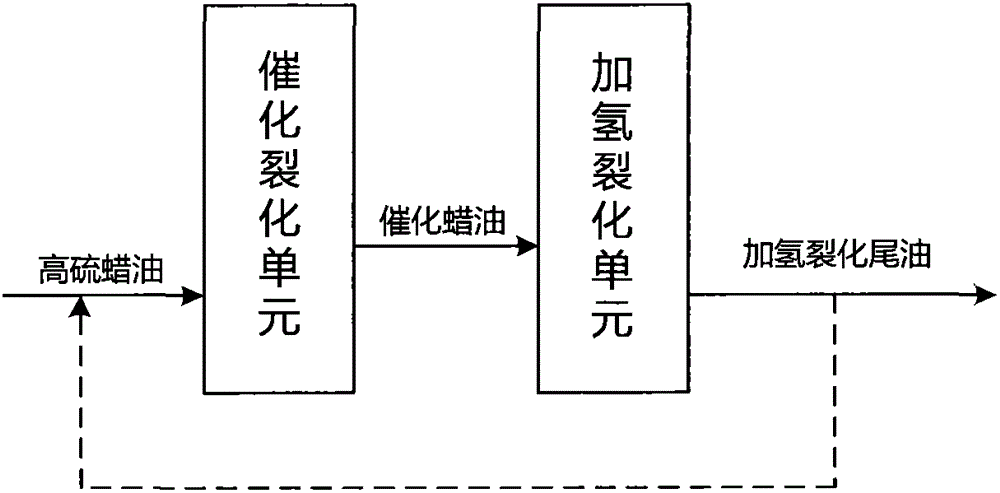

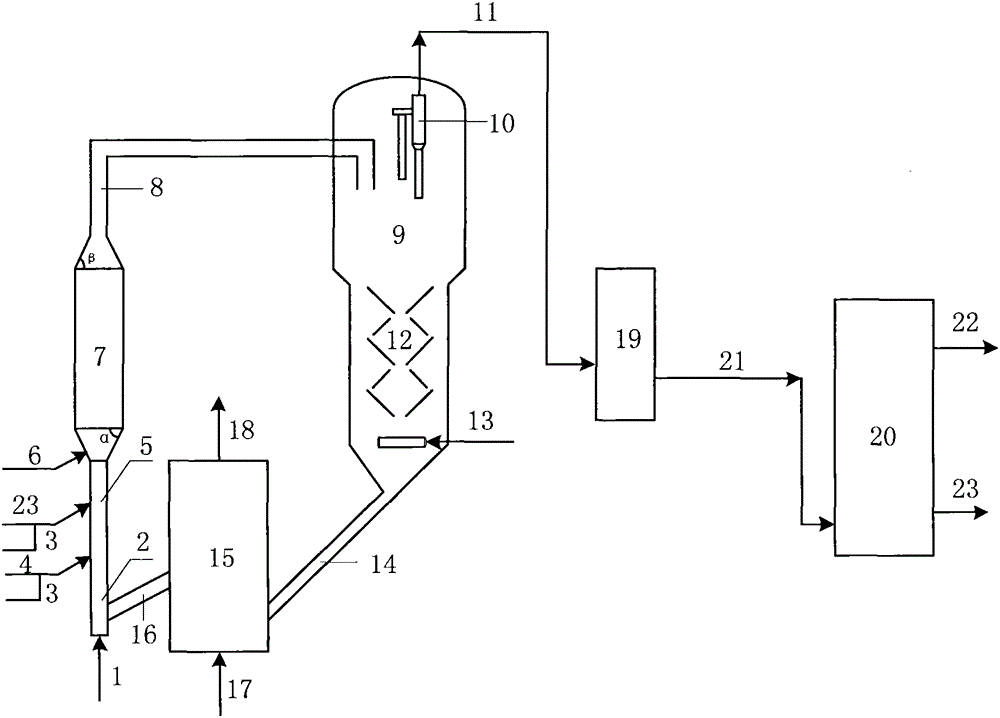

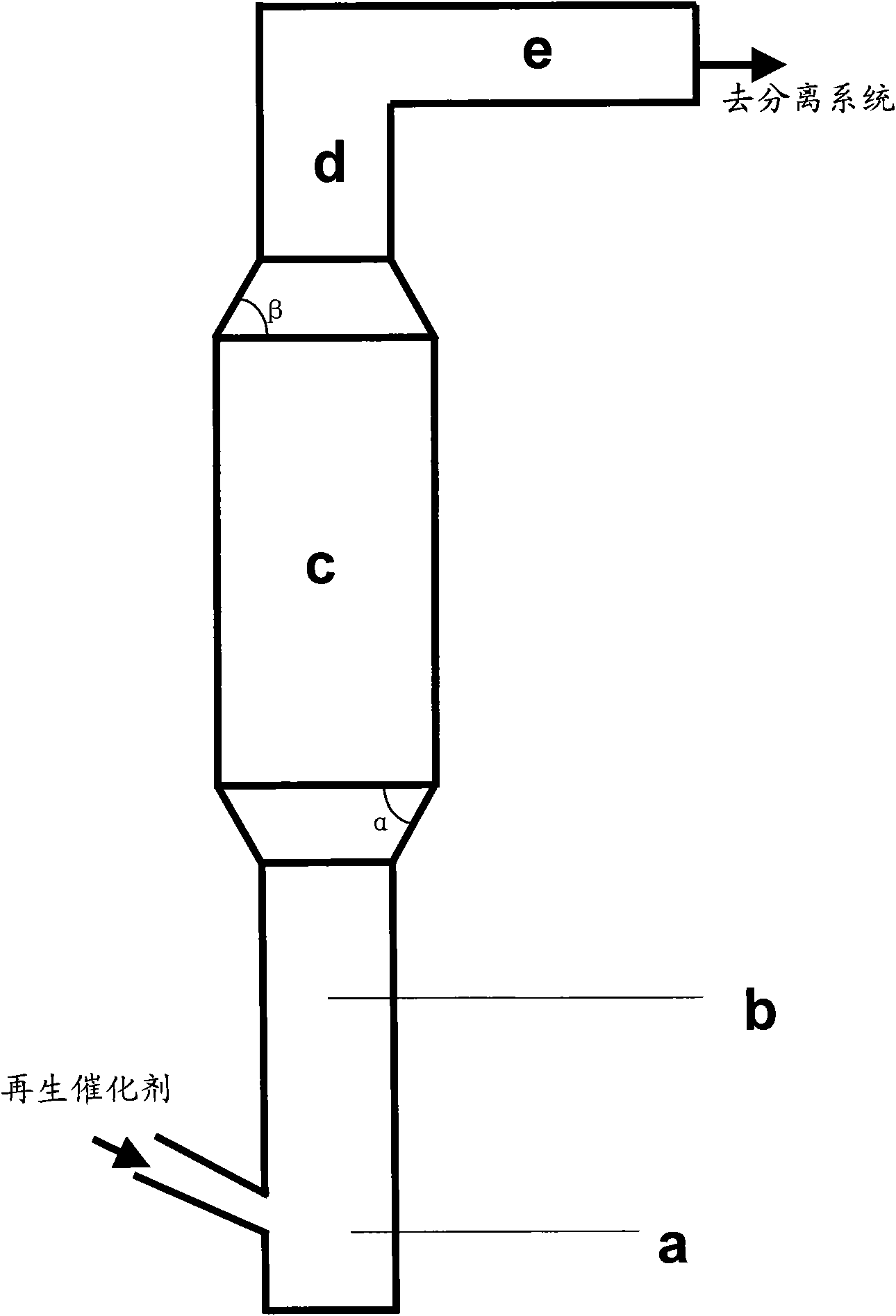

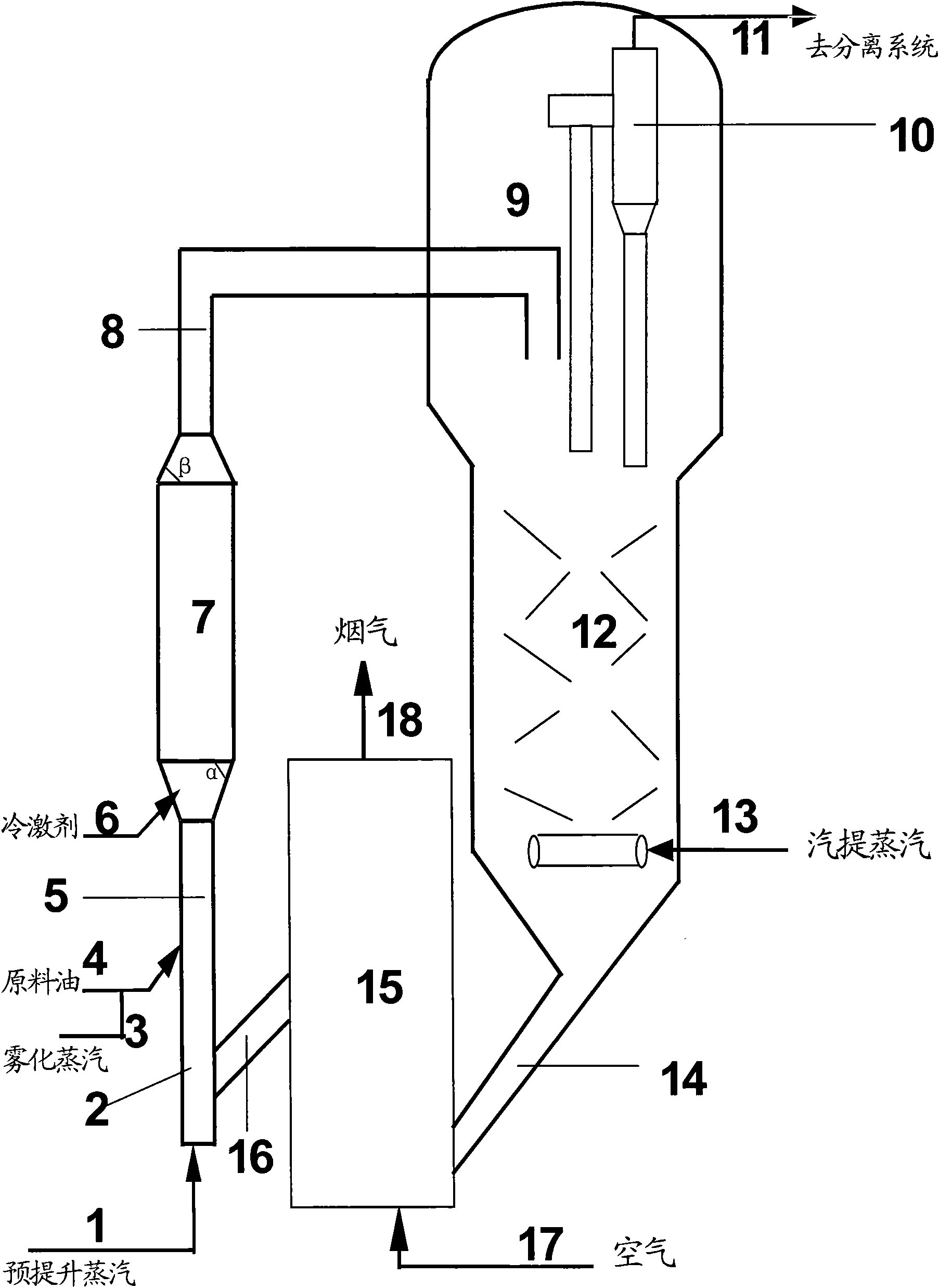

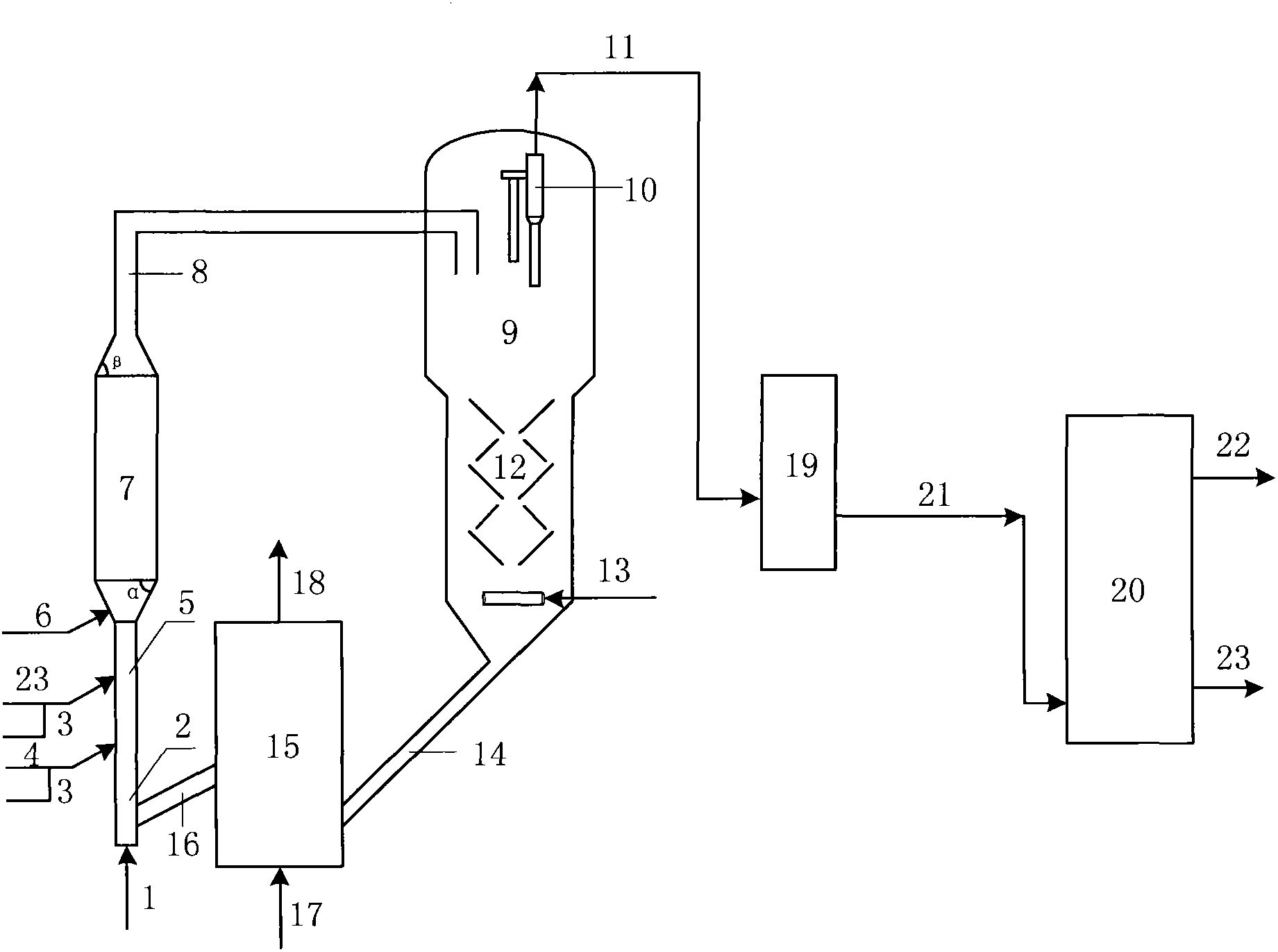

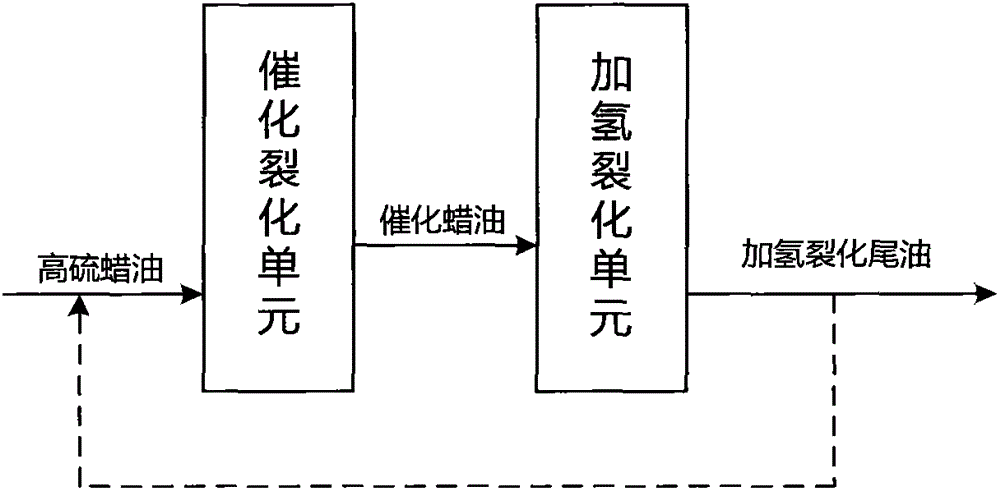

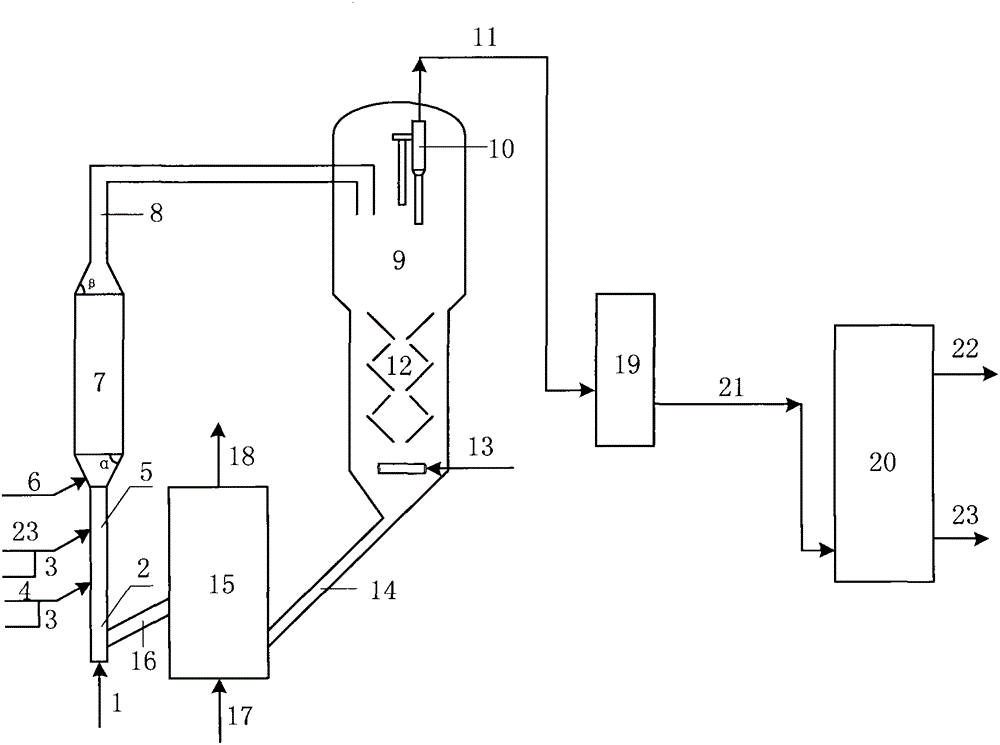

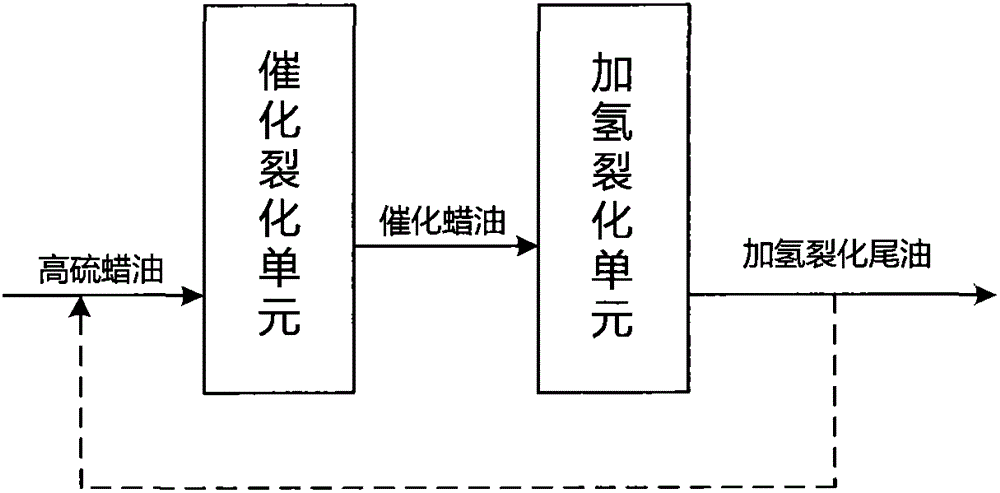

The invention discloses a catalytic conversion method of petroleum hydrocarbon. High-sulfur wax oil is contacted with a heat regeneration catalyst at the lower portion of a catalytic cracking unit reactor and subjected to a cracking reaction, wherein the heat regeneration catalyst has relatively low activity and coarse particle size distribution and contains macropore zeolite and mesopore zeolite, the generated oil gas and a carbon-containing catalyst go up and are subjected to a selective hydrogen transfer reaction and an isomerization reaction under a certain reaction environment, the reaction oil gas is separated to obtain a reaction product containing liquefied gas, gasoline and catalytic wax oil, and the spent catalyst is recycled for use after stripping and regeneration, wherein the catalytic wax oil and optional other secondary processing wax oil are introduced into the hydrocracking unit for reaction, and preferably the hydrocracked tail oil is returned to the catalytic cracking unit. According to the method, the diesel oil yield and the cetane number of the diesel oil are increased, the mass percentages of low carbon olefins such as propylene and butylenes in the liquefied gas are increased, the hydrogen utilization rate of the raw materials is increased, and simultaneously the utilization rate of hydrogen in the raw materials is raised, so that the petroleum resource can be saved, and the method provides a novel approach for cleaning the refining process and the refined oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

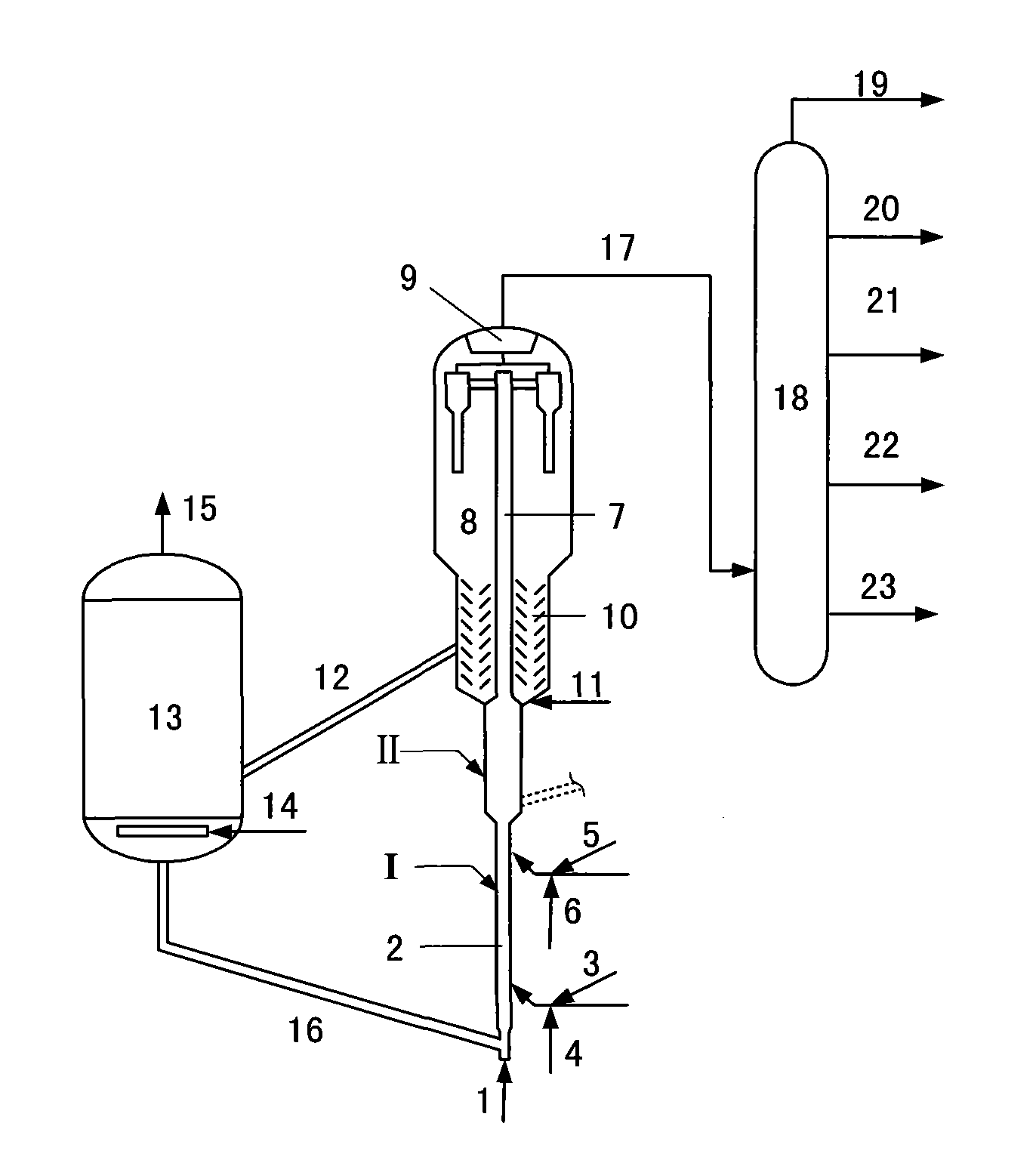

Catalytic conversion method capable of improving product distribution

ActiveCN102453520BImprove distributionReduce yieldHydrocarbon oils treatmentIsomerizationCracking reaction

The invention discloses a catalytic conversion method capable of improving product distribution. The catalytic conversion method capable of improving product distribution is characterized in that high-quality raw oil and a hot-regenerated catalyst having low mean activity, relatively uniform activity distribution and wide particle size distribution contact with each other in a lower part of a reactor and undergo a cracking reaction to produce oil gas and a carbon-containing catalyst; the oil gas and the carbon-containing catalyst are fed upstream and undergo a selective hydrogen transfer reaction and an isomerization reaction under certain reaction conditions; and the reaction products are separated and the catalyst needing to be regenerated is subjected to steam stripping and regeneration and then is recycled. The catalytic conversion method provided by the invention can improve product distribution and reduce dry gas and coke yields. Through the catalytic conversion method capable of improving product distribution, catalyst particles have uniform sizes; local temperature distribution in regeneration is uniform; and catalyst fragmentation is reduced relatively.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for improving product distribution

ActiveCN102453519BReduce processingExtended reaction timeHydrocarbon oils treatmentIsomerizationLiquid gas

The invention discloses a catalytic conversion method for improving product distribution. The method comprises the following steps of: allowing high-quality raw oil and a thermally regenerative catalyst with lower activity and coarse size distribution to contact on the lower part of a reactor to undergo cracking reaction, performing selective hydrogen transfer reaction and isomerization reaction on the generated oil gas and a carbon-containing catalyst in upstream under a certain reaction environment, separating reaction products, and stripping and regenerating spent catalysts for recycle. By the method, under the condition that the isobutene content in the liquefied gas and the olefin content in gasoline group composition are increased, the dry gas yield and coke are obviously reduced; and the particles of the catalysts are more uniform, so the local temperature distribution is more uniform in the regenerating process, and the breaking tendency of the catalysts is correspondingly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for preparing propylene and high-octane value gasoline

ActiveCN101935266BHigh yieldImprove octaneCatalytic crackingBulk chemical productionReaction temperaturePetroleum

The invention discloses a catalytic conversion method for preparing propylene and high-octane value gasoline. Crude oil contacts a catalyst rich in mesoporous zeolite and with coarse particle size distribution for reaction; and reaction temperature, weight hourly space velocity and the weight ratio of the catalyst to the crude oil are sufficiently proper for preparing a reaction product comprising 12 to 60 percent of catalytic wax oil based on the weight of the crude oil in the reaction, wherein the weight hourly space velocity is 25 to 100 h<-1>; the reaction temperature is 450 to 600 DEG C;and the weight ratio of the catalyst to the crude oil is 1 to 30. The invention provides the catalytic conversion method based on the prior art, which particularly has the advantages of greatly reducing dry gas yield and coke yield at the same time of converting the heavy crude oil into the high-octane value gasoline and the propylene so as to realize the high-efficiency utilization of oil resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for producing high-cetane number light diesel oil and low-olefin gasoline

ActiveCN102079992BReduce production processGood choiceCatalytic crackingTreatment with plural serial stages onlyWaxIsomerization

The invention relates to a catalytic conversion method for producing high-cetane number light diesel oil and low-olefin gasoline, which comprises the following steps of: making raw oil contact mitigated converting catalyst with rough grain diameter distribution in a mitigated converting reactor for reacting, wherein the reaction temperature, oil and gas retaining time and the weight ratio of the mitigated converting catalyst to the raw oil are enough to obtain a reaction product containing catalytic wax oil which accounts for 12-60 percent by weight of raw oil, and the reaction product also comprises high-cetane number diesel oil and gasoline; carrying out cracking reaction on the catalytic wax oil in a harsh converting reactor; carrying out hydrogen transfer reaction and isomerization reaction on the generated oil and gas in a certain reaction environment; and separating to obtain a reaction product containing low-olefin gasoline. The method can directly produce high-cetane number light diesel oil and low-olefin gasoline simultaneously by catalytic cracking and reduce the catalyst breakage tendency and catalyst consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for producing diesel and propylene in high yield

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method of petroleum hydrocarbon

ActiveCN103059996BImprove use efficiencyReasonable integrationTreatment with hydrotreatment processesIsomerizationCracking reaction

The invention discloses a catalytic conversion method of petroleum hydrocarbon. High-sulfur wax oil is contacted with a heat regeneration catalyst at the lower portion of a catalytic cracking unit reactor and subjected to a cracking reaction, wherein the heat regeneration catalyst has a coarse particle size distribution and contains macropore zeolite and mesopore zeolite, the generated oil gas and a carbon-containing catalyst go up and are subjected to a selective hydrogen transfer reaction and an isomerization reaction under a certain reaction environment, the reaction oil gas is separated to obtain a reaction product containing liquefied gas, gasoline and catalytic wax oil, and the spent catalyst is recycled for use after stripping and regeneration, wherein the catalytic wax oil and optional other secondary processing wax oil are introduced into the hydrocracking unit for reaction, and preferably the hydrocracked tail oil is returned to the catalytic cracking unit. According to the method, the diesel oil yield and the cetane number of the diesel oil are increased, the yield of low carbon olefins such as propylene and butylene are increased, the hydrogen utilization rate of the raw materials is increased, and simultaneously the utilization rate of hydrogen in the raw materials is raised, so that the petroleum resource can be saved, and the method provides a novel approach for cleaning the refining process and the refined oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method of petroleum hydrocarbon

ActiveCN103059996AImprove use efficiencyReasonable integrationTreatment with hydrotreatment processesIsomerizationCracking reaction

The invention discloses a catalytic conversion method of petroleum hydrocarbon. High-sulfur wax oil is contacted with a heat regeneration catalyst at the lower portion of a catalytic cracking unit reactor and subjected to a cracking reaction, wherein the heat regeneration catalyst has a coarse particle size distribution and contains macropore zeolite and mesopore zeolite, the generated oil gas and a carbon-containing catalyst go up and are subjected to a selective hydrogen transfer reaction and an isomerization reaction under a certain reaction environment, the reaction oil gas is separated to obtain a reaction product containing liquefied gas, gasoline and catalytic wax oil, and the spent catalyst is recycled for use after stripping and regeneration, wherein the catalytic wax oil and optional other secondary processing wax oil are introduced into the hydrocracking unit for reaction, and preferably the hydrocracked tail oil is returned to the catalytic cracking unit. According to the method, the diesel oil yield and the cetane number of the diesel oil are increased, the yield of low carbon olefins such as propylene and butylene are increased, the hydrogen utilization rate of the raw materials is increased, and simultaneously the utilization rate of hydrogen in the raw materials is raised, so that the petroleum resource can be saved, and the method provides a novel approach for cleaning the refining process and the refined oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for producing high-cetane number light diesel oil

Owner:CHINA PETROLEUM & CHEM CORP +1

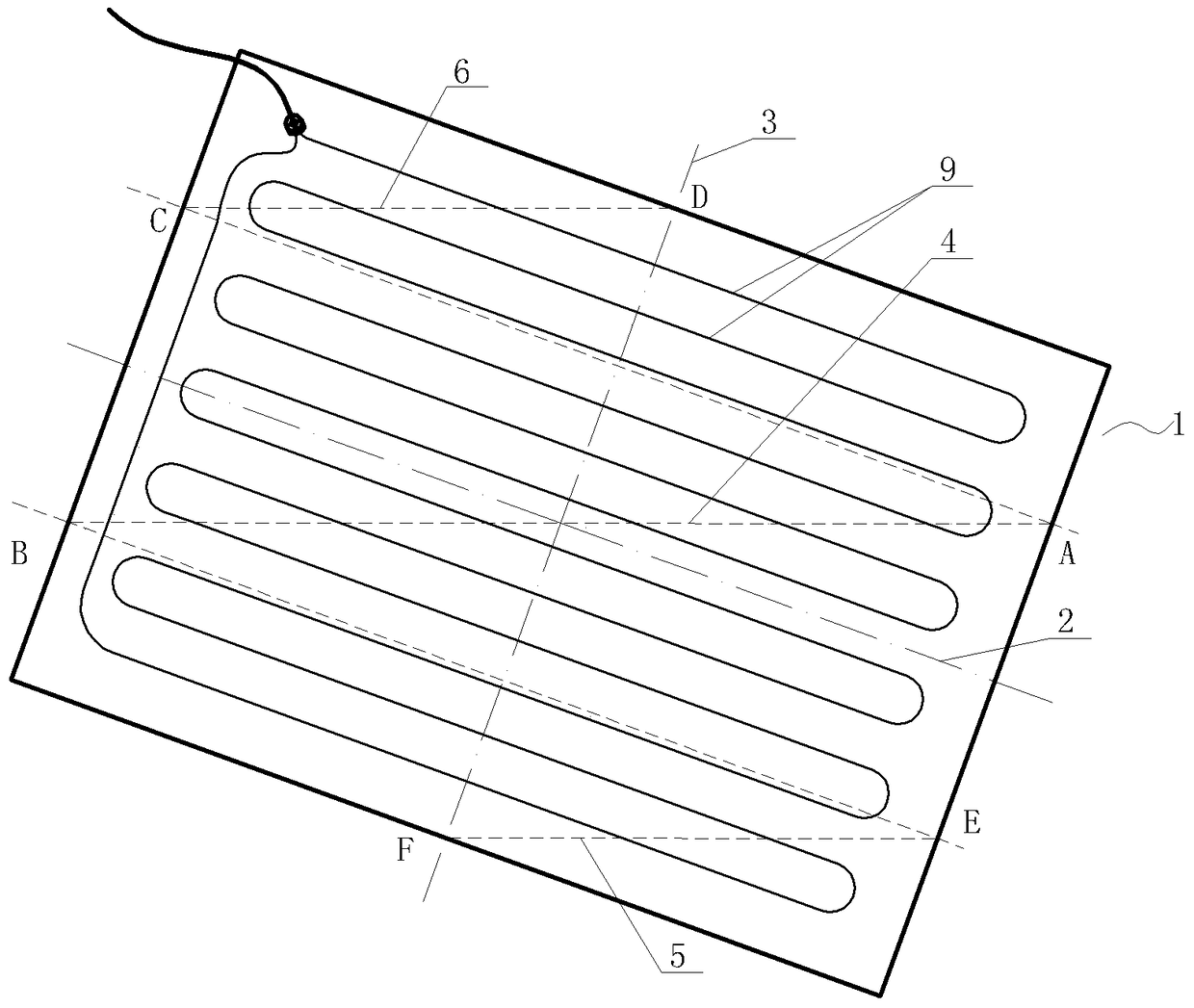

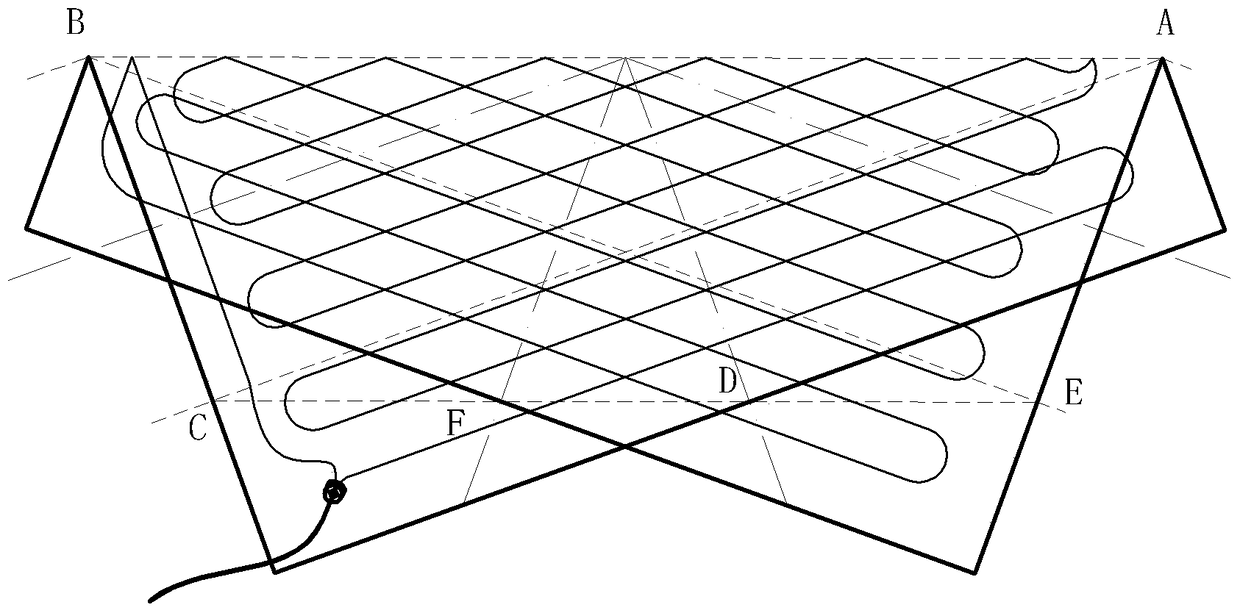

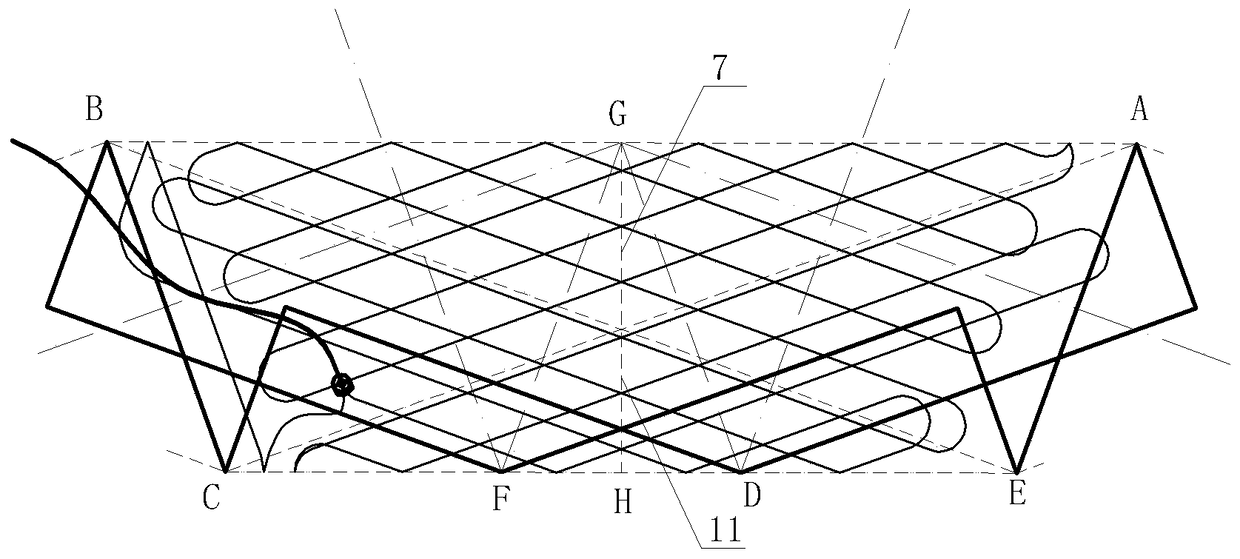

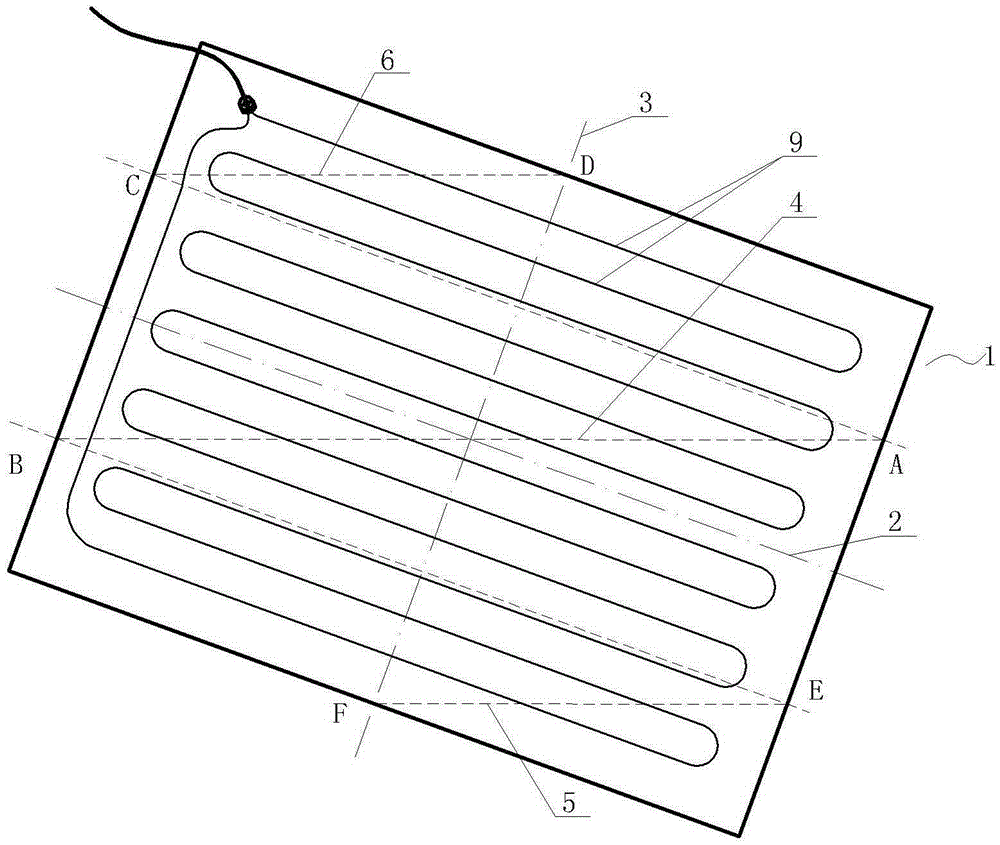

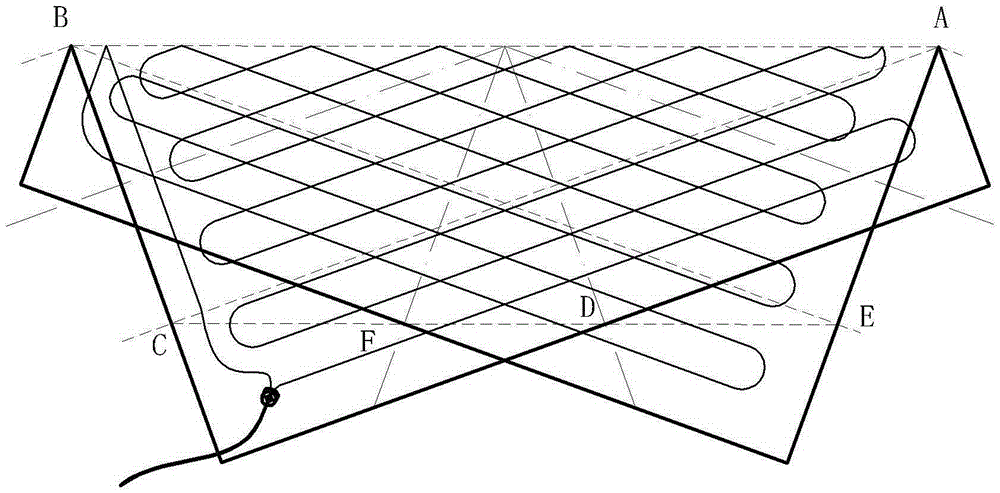

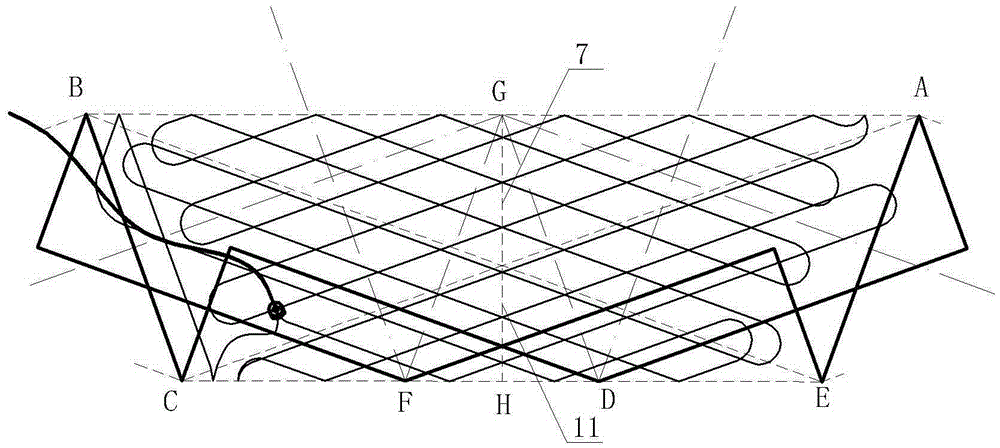

A kind of folding method of electric blanket

ActiveCN105292627BCrease lengthShallow creaseFolding thin materialsPackagingPolygonal lineElectrical and Electronics engineering

The invention provides a folding method of an electric blanket. Creases of the electric blanket are inclined creases and are shallow through the folding method. The folding method comprises the specific steps that a, a first crease line AB, a second crease line I-section CD and a second crease line II-section EF are positioned on the electric blanket; b, a complete second crease line CFDE with part of areas overlapped is formed by the second crease line I-section CD and the second crease line II-section EF of the electric blanket folded along the first crease line AB; c, the electric blanket is folded along the second crease line CFDE, and then the electric blanket is divided into two symmetrical parts with the perpendicular bisector GH perpendicular to the first crease line AB as the center line; d, the two parts of the electric blanket obtained in the above step are each divided into three equidistant parts by two crease lines, and the crease lines are parallel to the perpendicular bisector GH; and e, the two sides of the perpendicular bisector GH are folded in the sequence of the crease lines from outside to inside, so that the two sides of the perpendicular bisector GH form two independent rectangular areas, and then the electric blanket is oppositely folded according to the perpendicular bisector GH to form a small rectangle.

Owner:徐州阳森建设科技有限公司

Catalytic conversion method for production of propylene and high-octane-value gasoline by crude oil

ActiveCN102134510BLess investmentReduce corrosion costsCatalytic crackingTreatment with plural serial stages onlyReaction temperaturePetroleum

The invention discloses a catalytic conversion method for production of propylene and high-octane-value gasoline by crude oil, which is characterized in that: pretreated crude oil is used as raw oil and comes into contact with a catalyst, featured by rich mesopore zeolite and coarse particle diameter distribution, in a catalytic conversion reactor, reaction temperature, oil gas residence time and the weight ratio of the catalyst to the raw oil guarantee that the reaction results in a reaction product containing catalytic wax oil accounting for 12 to 60% of the raw oil by weight, wherein the weight hourly space velocity is 25 to 100h<-1>, the reaction temperature is 450 to 700 DEG C and the weight ratio of the catalyst to the raw oil is 1 to 30. The method achieves the conversion of low-quality crude oil into propylene and high-octane-value gasoline and simultaneously reduces the yield of dry gas and coke remarkably so as to realize the effective utilization of petroleum resources; and local temperature distribution is more uniform in the process of regeneration owing to more homogeneous particles of the catalyst, and the crushing tendency of the catalyst is correspondingly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method capable of improving product distribution

ActiveCN102453520AImprove distributionReduce yieldHydrocarbon oils treatmentIsomerizationCracking reaction

The invention discloses a catalytic conversion method capable of improving product distribution. The catalytic conversion method capable of improving product distribution is characterized in that high-quality raw oil and a hot-regenerated catalyst having low mean activity, relatively uniform activity distribution and wide particle size distribution contact with each other in a lower part of a reactor and undergo a cracking reaction to produce oil gas and a carbon-containing catalyst; the oil gas and the carbon-containing catalyst are fed upstream and undergo a selective hydrogen transfer reaction and an isomerization reaction under certain reaction conditions; and the reaction products are separated and the catalyst needing to be regenerated is subjected to steam stripping and regeneration and then is recycled. The catalytic conversion method provided by the invention can improve product distribution and reduce dry gas and coke yields. Through the catalytic conversion method capable of improving product distribution, catalyst particles have uniform sizes; local temperature distribution in regeneration is uniform; and catalyst fragmentation is reduced relatively.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing light fuel oil and propylene from inferior raw material oil

ActiveCN101942340BImproved raw material propertiesExtended operating cycleTreatment with plural serial stages onlyTreatment with hydrotreatment processesWaxLighter fuel

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for diesel oil and propylene with high yield

ActiveCN102051226BIncrease cetane numberHigh selectivityTreatment with hydrotreatment processesAlkaneReaction temperature

The invention discloses a catalytic conversion method for diesel oil and propylene with high yield. Raw material oil is contacted with a catalyst with coarse particle size distribution in a reactor to react; reaction temperature, weight hourly space velocity and weight ratio of the catalyst to the raw material oil are sufficient so that a reaction product containing catalytic wax oil which is 12 to 60 weight percent of the raw material oil; and the catalytic wax oil is fed into a hydro-cracking device for further treatment. Catalytic cracking, hydro-cracking and high-yield diesel oil processes are organically combined, hydrocarbons such as alkane, alkyl side chain and the like in the catalytic raw materials are selectively cracked and isomerized, meanwhile, aromatic hydrocarbons in the raw materials are furthest reduced to enter the diesel oil fraction, and aromatic hydrocarbons generated by reaction of other components in the product such as aromatization and the like are prevented from being left in the diesel oil fraction; and when the raw materials are transformed into the diesel oil with high cetane number and the propylene, the yields of dry gas and coke are greatly reduced, and catalyst crushing tendency and catalyst consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Effective catalytic conversion method of petroleum hydrocarbon

ActiveCN103059995BImprove use efficiencyReasonable integrationTreatment with hydrotreatment processesIsomerizationCracking reaction

The invention discloses a catalytic conversion method of petroleum hydrocarbon. High-sulfur wax oil is contacted with a heat regeneration catalyst at the lower portion of a catalytic cracking unit reactor and subjected to a cracking reaction, wherein the heat regeneration catalyst has relatively low activity and coarse particle size distribution and contains macropore zeolite and mesopore zeolite, the generated oil gas and a carbon-containing catalyst go up and are subjected to a selective hydrogen transfer reaction and an isomerization reaction under a certain reaction environment, the reaction oil gas is separated to obtain a reaction product containing liquefied gas, gasoline and catalytic wax oil, and the spent catalyst is recycled for use after stripping and regeneration, wherein the catalytic wax oil and optional other secondary processing wax oil are introduced into the hydrocracking unit for reaction, and preferably the hydrocracked tail oil is returned to the catalytic cracking unit. According to the method, the diesel oil yield and the cetane number of the diesel oil are increased, the mass percentages of low carbon olefins such as propylene and butylenes in the liquefied gas are increased, the hydrogen utilization rate of the raw materials is increased, and simultaneously the utilization rate of hydrogen in the raw materials is raised, so that the petroleum resource can be saved, and the method provides a novel approach for cleaning the refining process and the refined oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Prolific catalytic converting method for high-cetane diesel oil

ActiveCN102041094BImprove performanceMaximize productionTreatment with hydrotreatment processesWaxReaction temperature

The invention relates to a prolific catalytic converting method for high-cetane diesel oil. The method comprises the step that the raw oil is contacted with and reacts with catalyst containing large-pore zeolite in a catalytic conversion reactor, wherein the reaction temperature, the oil gas retention time and the weight ratio of the catalyst to the raw oil ensures that the reaction products contain catalytic wax oil being 12wt.% to 60 wt.% of the raw oil can be obtained; the reaction temperature is from 420 to 550 DEG C; the oil gas retention time is from 0.1 to 5 seconds; the weight ratio of the catalyst to the raw oil is 1 to 10; and the catalytic wax oil is further processed by being added into a hydrocracking device. By using the method, the high-cetane diesel oil can be extremely produced. The cracking catalyst having oversized particle distribution can further improve the selectivity of dry gas and coke and can reduce the breaking tendency of the catalyst and the consumption of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Folding method of electric blanket

ActiveCN105292627ALess prone to chappingReduced tendency to breakFolding thin materialsPackagingEngineeringElectrical and Electronics engineering

The invention provides a folding method of an electric blanket. Creases of the electric blanket are inclined creases and are shallow through the folding method. The folding method comprises the specific steps that a, a first crease line AB, a second crease line I-section CD and a second crease line II-section EF are positioned on the electric blanket; b, a complete second crease line CFDE with part of areas overlapped is formed by the second crease line I-section CD and the second crease line II-section EF of the electric blanket folded along the first crease line AB; c, the electric blanket is folded along the second crease line CFDE, and then the electric blanket is divided into two symmetrical parts with the perpendicular bisector GH perpendicular to the first crease line AB as the center line; d, the two parts of the electric blanket obtained in the above step are each divided into three equidistant parts by two crease lines, and the crease lines are parallel to the perpendicular bisector GH; and e, the two sides of the perpendicular bisector GH are folded in the sequence of the crease lines from outside to inside, so that the two sides of the perpendicular bisector GH form two independent rectangular areas, and then the electric blanket is oppositely folded according to the perpendicular bisector GH to form a small rectangle.

Owner:徐州阳森建设科技有限公司

Catalyst conversion method for producing high-octane gasoline by using crude oil

ActiveCN102108308BLess investmentReduce corrosion costsCatalytic crackingTreatment with plural serial stages onlyReaction temperaturePetroleum

The invention provides a catalytic conversion method for producing high-octane gasoline by using crude oil, which comprises: contacting pretreated crude oil serving as raw material oil with a catalyst which contains macroporous zeolite and is distributed according to a coarse particle size in a catalytic conversion reactor to perform a reaction according to reaction temperature, oil gas dwell time and catalyst to raw material oil weight ratio, which are proper enough to enable the reaction to obtain a reaction product containing catalytic wax oil which accounts for 15 to 60 percent of the weight of the raw material oil, wherein the weight hourly space velocity is 25 to 100h<-1>, the reaction temperature is 450 to 600 DEG C, and he weight ratio of the catalyst to the raw material oil is 1 to 30. In the method, while low-quality crude oil is converted into high-octane gasoline, the dry gas and coke yields are reduced considerably, the high-efficient utilization of oil resources is realized, and the higher particle uniformity of the catalyst makes the local temperature distribution in a regeneration process more uniform and the breakage orientation of the catalyst lowered correspondingly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for producing high-quality light fuels from crude oil

ActiveCN102079996BLess investmentReduce corrosion costsTreatment with hydrotreatment processesReaction temperaturePetroleum

The invention discloses a catalytic conversion method for producing high-quality light fuels from crude oil. The crude oil contacts and reacts with a catalyst which is rich in mesoporous zeolite and in coarse particle size distribution. The catalytic conversion method is characterized in that a reaction product containing catalytic wax oil which accounts for 12-60 wt% of the weight of raw material is obtained by the reaction temperature, weight hourly space velocity and the weight ratio of raw oil to catalyst, wherein the reaction temperature is 420-600 DEG C, the weight hourly space velocity is 25-100 hours<-1>, the weight ratio of catalyst to raw oil is 1 to 30, and the wax is catalyzed before hydrocracks. In the invention, crude oil catalytic converter and hydrocracking methods are provided, which, in particular, reduces dry gas and coke yield significantly while converting the poor quality of crude oil into high octane gasoline and high-cetane diesel fuel so as to achieve efficient use of oil resources, and reduce the broken tendency of the catalyst and the catalyst consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for production of propylene and high-octane-value gasoline by crude oil

ActiveCN102134510ALess investmentReduce corrosion costsCatalytic crackingTreatment with plural serial stages onlyWaxReaction temperature

The invention discloses a catalytic conversion method for production of propylene and high-octane-value gasoline by crude oil, which is characterized in that: pretreated crude oil is used as raw oil and comes into contact with a catalyst, featured by rich mesopore zeolite and coarse particle diameter distribution, in a catalytic conversion reactor, reaction temperature, oil gas residence time and the weight ratio of the catalyst to the raw oil guarantee that the reaction results in a reaction product containing catalytic wax oil accounting for 12 to 60% of the raw oil by weight, wherein the weight hourly space velocity is 25 to 100h<-1>, the reaction temperature is 450 to 700 DEG C and the weight ratio of the catalyst to the raw oil is 1 to 30. The method achieves the conversion of low-quality crude oil into propylene and high-octane-value gasoline and simultaneously reduces the yield of dry gas and coke remarkably so as to realize the effective utilization of petroleum resources; and local temperature distribution is more uniform in the process of regeneration owing to more homogeneous particles of the catalyst, and the crushing tendency of the catalyst is correspondingly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for improving cetane number and yield of diesel

ActiveCN102041093BImprove performanceMaximize productionTreatment with hydrotreatment processesWaxReaction temperature

The invention discloses a catalytic conversion method for improving cetane number and yield of diesel. Raw oil is contacted with a catalyst containing large pore zeolite in a catalytic conversion reactor for reaction, and the reaction temperature, oil gas retention period, and the weight ratio of the catalyst to the raw oil sufficiently ensure that a reaction product containing catalytic wax oil which is 12 to 60 weight percent of the raw oil is obtained in the reaction, wherein the reaction temperature is 420 to 550DEG C, the oil gas retention period is 0.1 to 5 seconds and the weight ratio of the catalyst to the raw oil is 1-10; and the catalytic wax oil enters a hydrogenation unit, and the obtained hydrogenated catalytic wax oil returns to the catalytic conversion reactor. By the method, the diesel with high cetane number is produced maximally, the cracking catalyst with coarse particle size distribution can further improve the selectivity of dry gas and coke, and the catalyst breaking tendency and the catalyst consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method of petroleum hydrocarbon

ActiveCN103059994AImprove use efficiencyReasonable integrationTreatment with hydrotreatment processesIsomerizationCracking reaction

The invention discloses a catalytic conversion method of petroleum hydrocarbon. High-sulfur wax oil is contacted with a heat regeneration catalyst at the lower portion of a catalytic cracking unit reactor and subjected to a cracking reaction, wherein the heat regeneration catalyst has relatively low activity and relatively uniform activity distribution, has a coarse particle size distribution and contains macropore zeolite and mesopore zeolite, the generated oil gas and a carbon-containing catalyst go up and are subjected to a selective hydrogen transfer reaction and an isomerization reaction under a certain reaction environment, the reaction oil gas is separated to obtain a reaction product containing liquefied gas, gasoline and catalytic wax oil, and the spent catalyst is recycled for use after stripping and regeneration, wherein the catalytic wax oil and optional other secondary processing wax oil are introduced into the hydrocracking unit for reaction, and preferably the hydrocracked tail oil is returned to the catalytic cracking unit. According to the method, the diesel oil yield and the cetane number of the diesel oil are increased, the mass percentages of low carbon olefins such as propylene and butylenes in the liquefied gas are increased, the hydrogen utilization rate of the raw materials is increased, and simultaneously the utilization rate of hydrogen in the raw materials is raised, so that the petroleum resource can be saved, and the method provides a novel approach for cleaning the refining process and the refined oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com