Patents

Literature

51results about How to "High shear stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

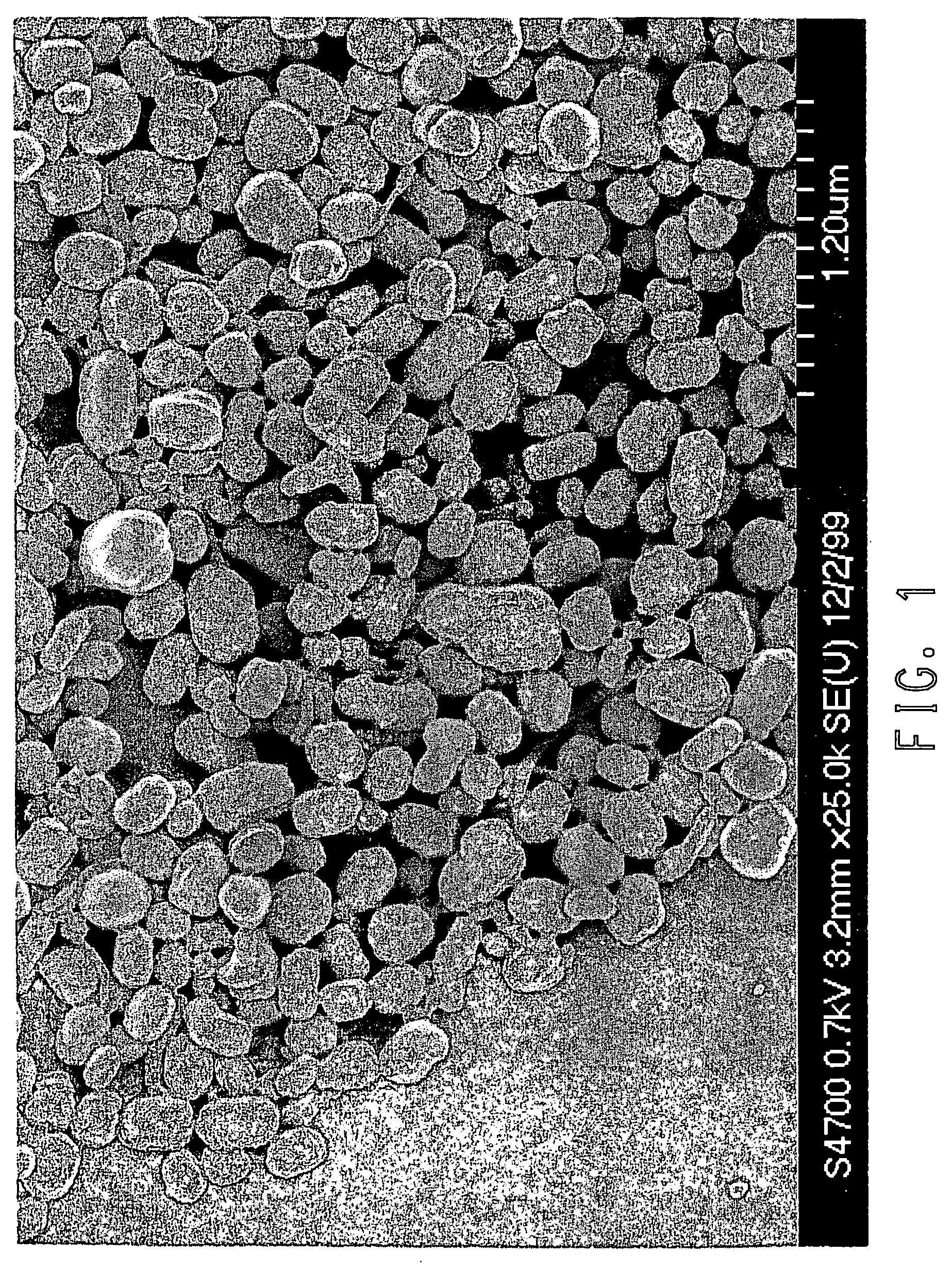

Core-shell fluoropolymer dispersions

InactiveUS6841594B2High shear stabilityExtend elastic lifeSynthetic resin layered productsCellulosic plastic layered productsTetrafluoroethylenePolymer science

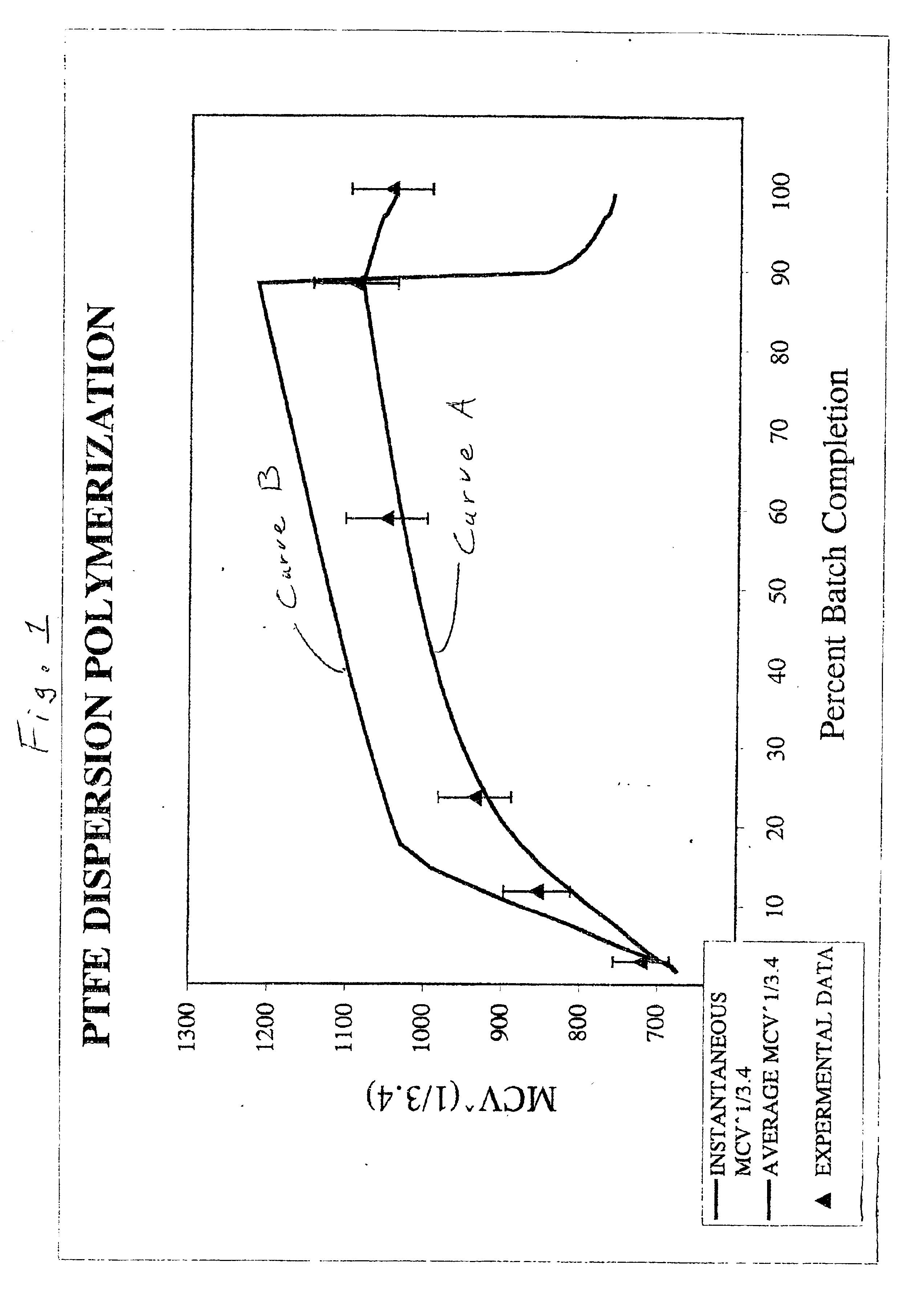

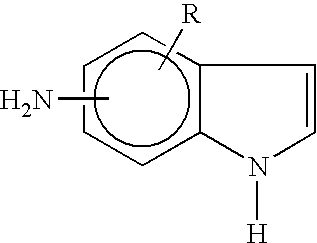

A dispersion of non-melt-processible fluoropolymer particles having an SSG of less than about 2.225 in aqueous medium. The fluoropolymer particles comprise a core of high molecular weight polytetrafluoroethylene having an average melt creep viscosity greater than about 1.5×1010 Pa·s and a shell of lower molecular weight polytetrafluoroethylene or modified polytetrafluoroethylene. The shell has an average melt creep viscosity greater than about 9×109 Pa·s and comprises about 5 to about 30% by weight of the particles. The fluoropolymer in the dispersion of the invention is fibrillating.

Owner:THE CHEMOURS CO FC LLC

Wood treatment process

InactiveUS6274199B1High shear stabilityImprove permeabilityWood treatment detailsPretreated surfacesWater basedMolten state

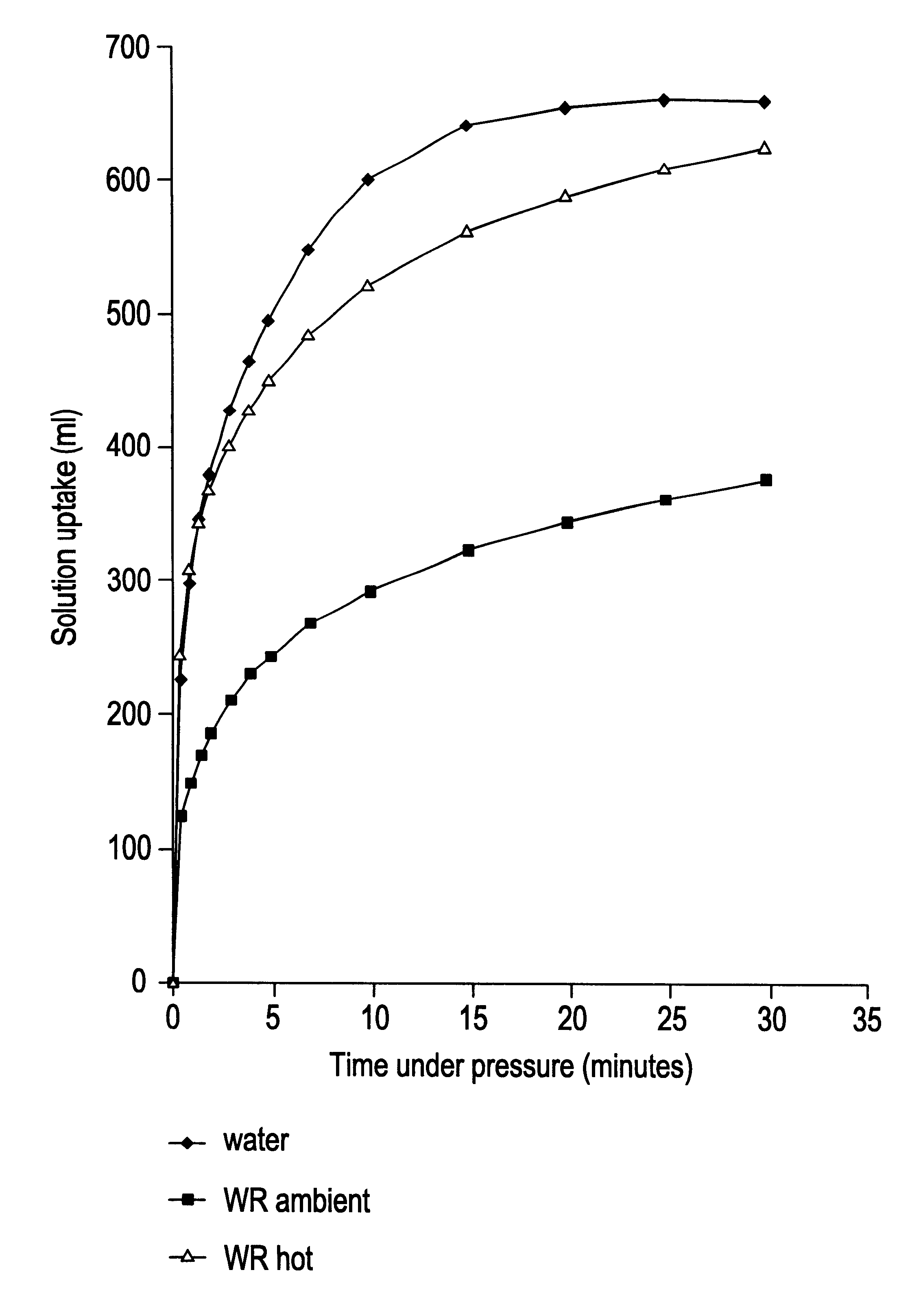

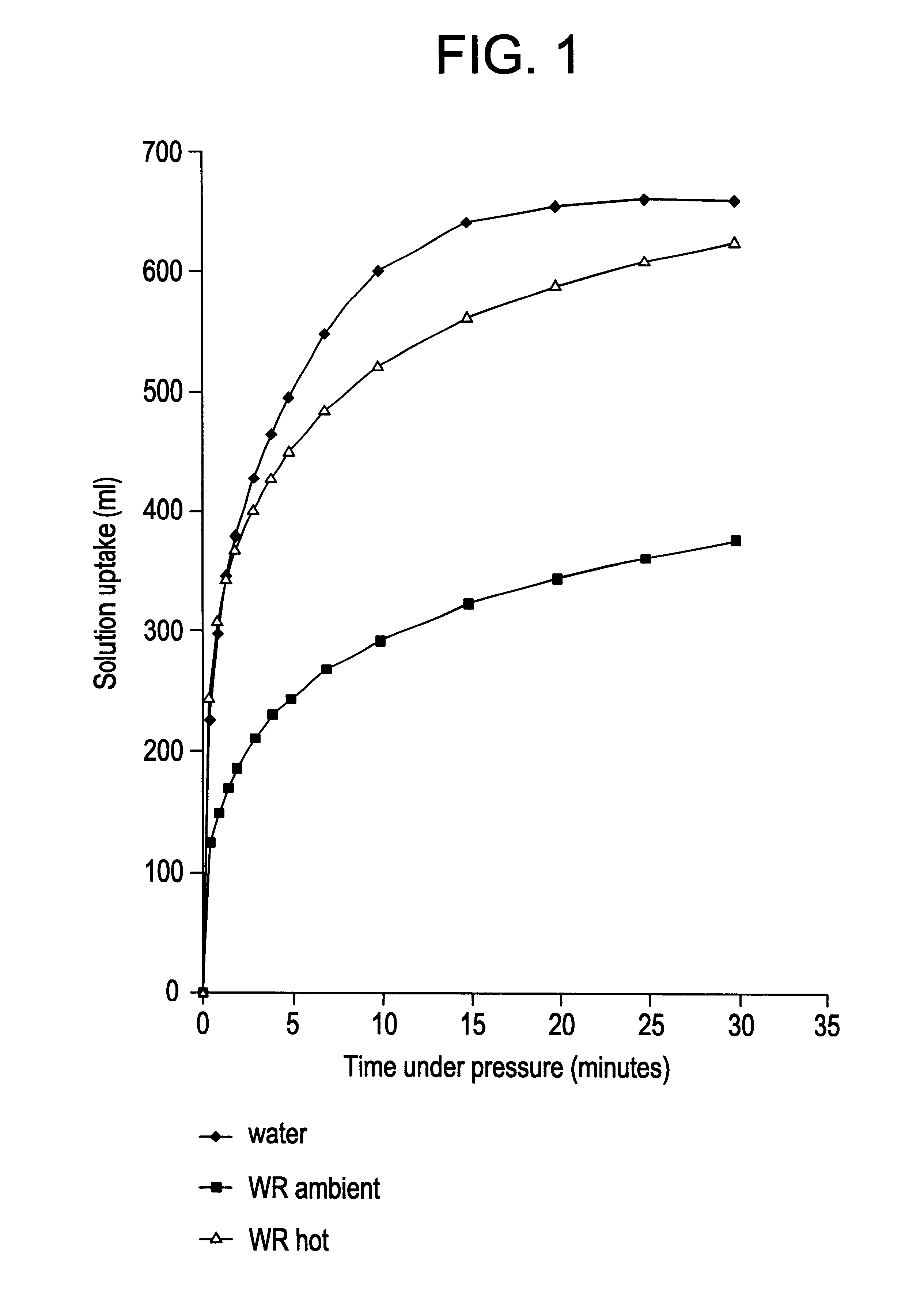

A process for treating a wood substrate with a water-based formulation containing a wax in order to confer water repellency to the substrate comprising the steps of:(a) placing the substrate in a treatment vessel and reducing the pressure in the vessel to remove air in the pores of the substrate;(b) contacting the substrate in the vessel, while reduced pressure is present in the vessel, with the formulation to allow the formulation to flow into said pores, said contacting being carried out at a temperature at or above that required to cause the wax to change into a molten state;(c) applying a positive pressure to the vessel to force the formulation into said pores; and(d) releasing the pressure in the vessel and removing the resultant wood substrate from the vessel.

Owner:VIANCE

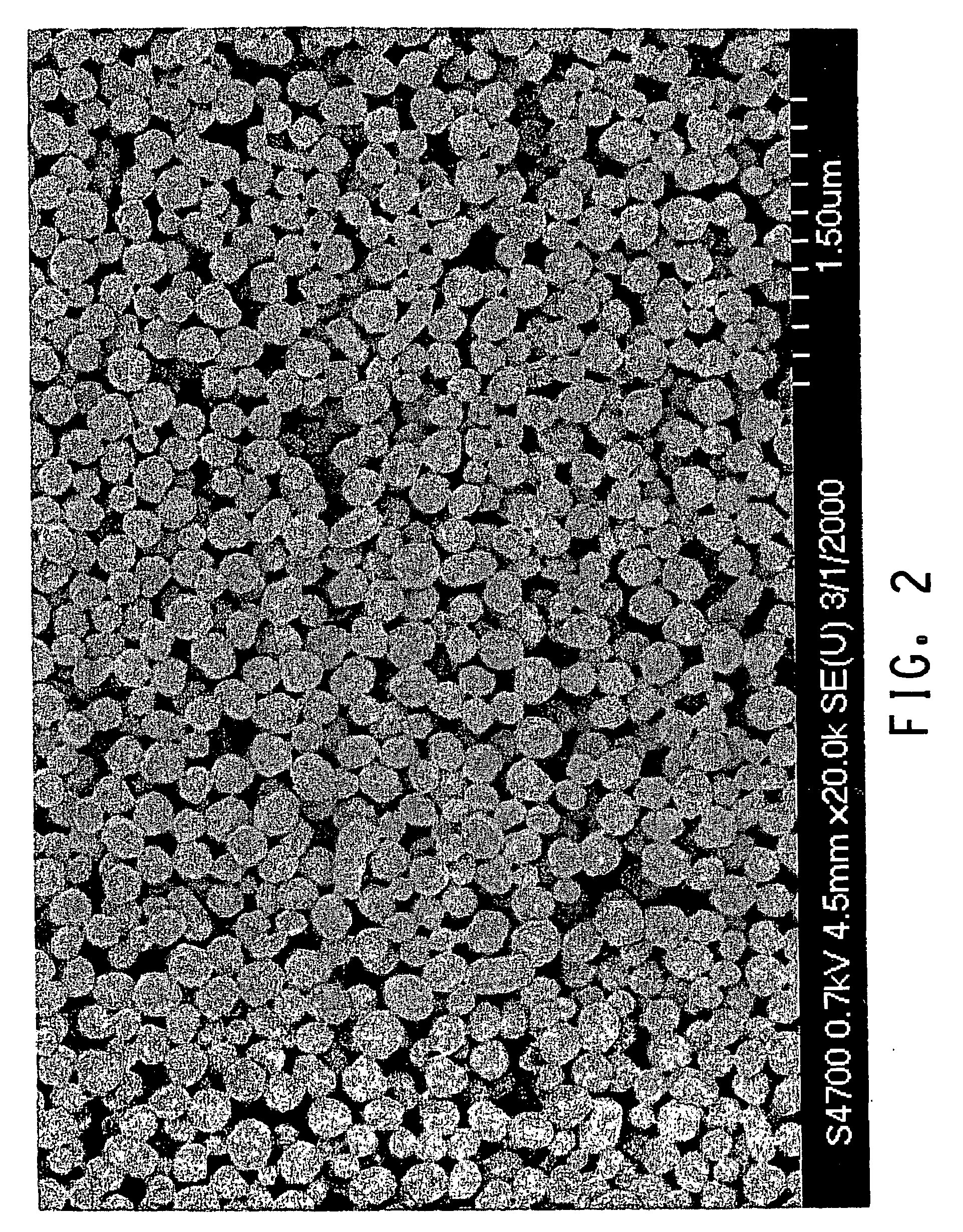

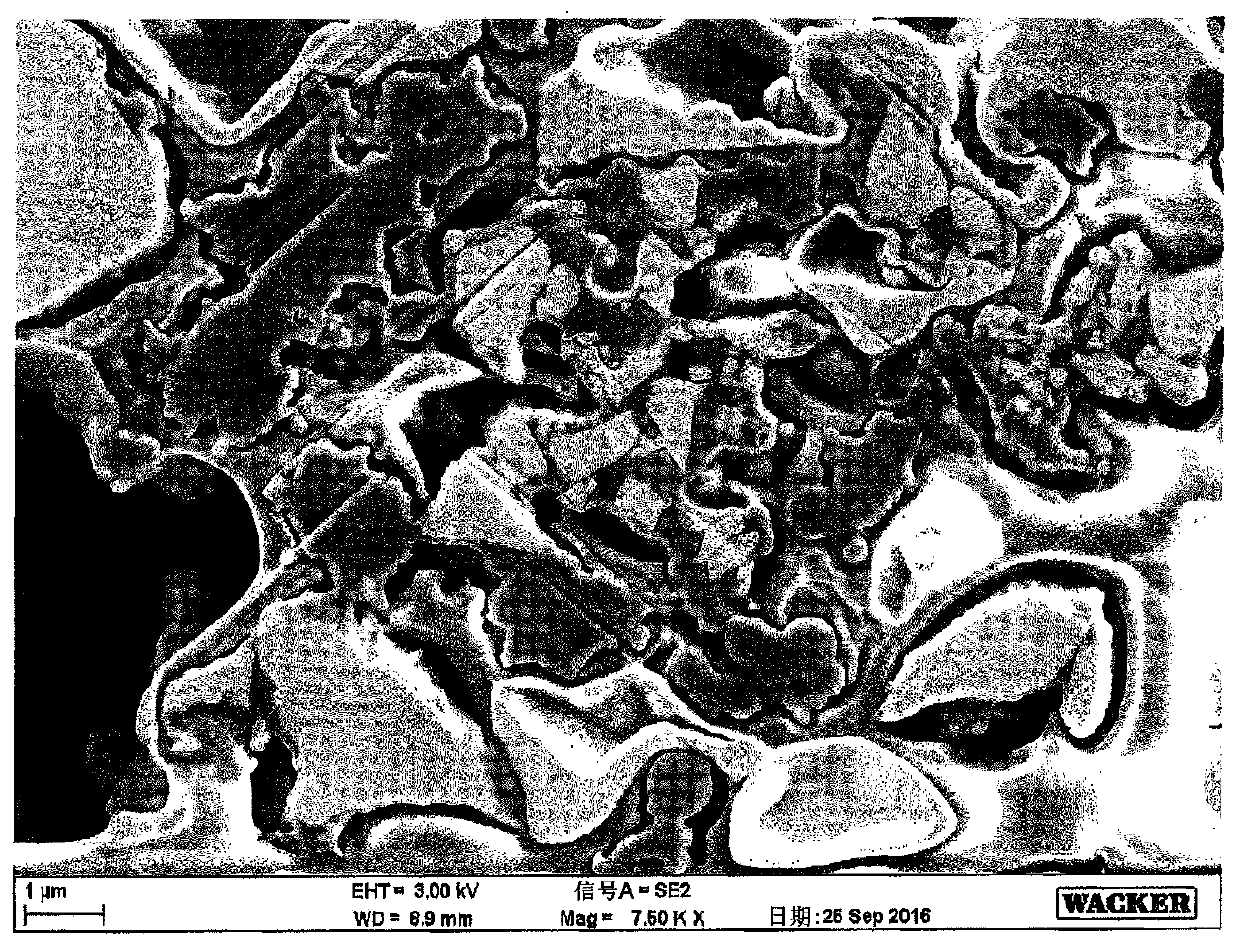

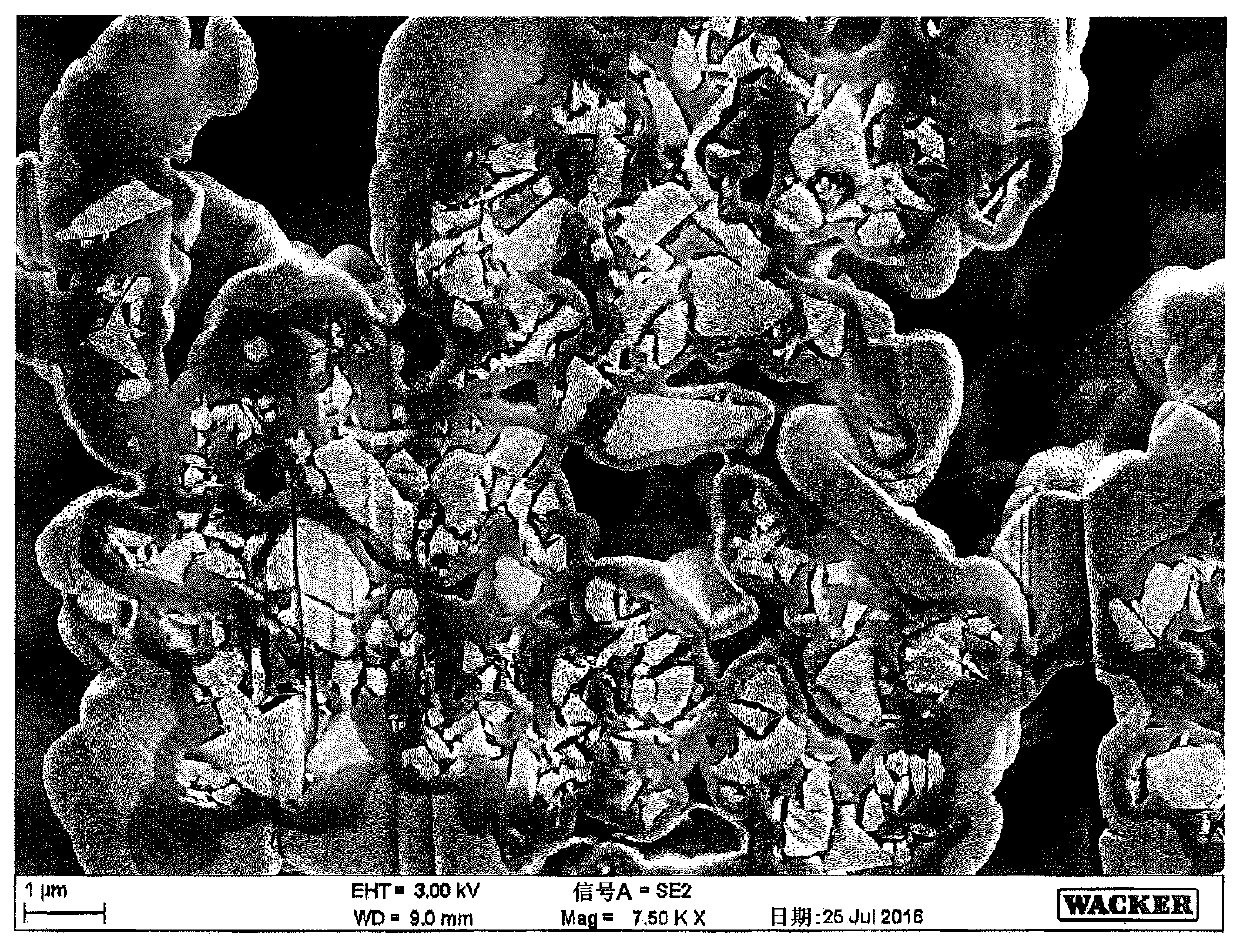

Composite core-shell particles

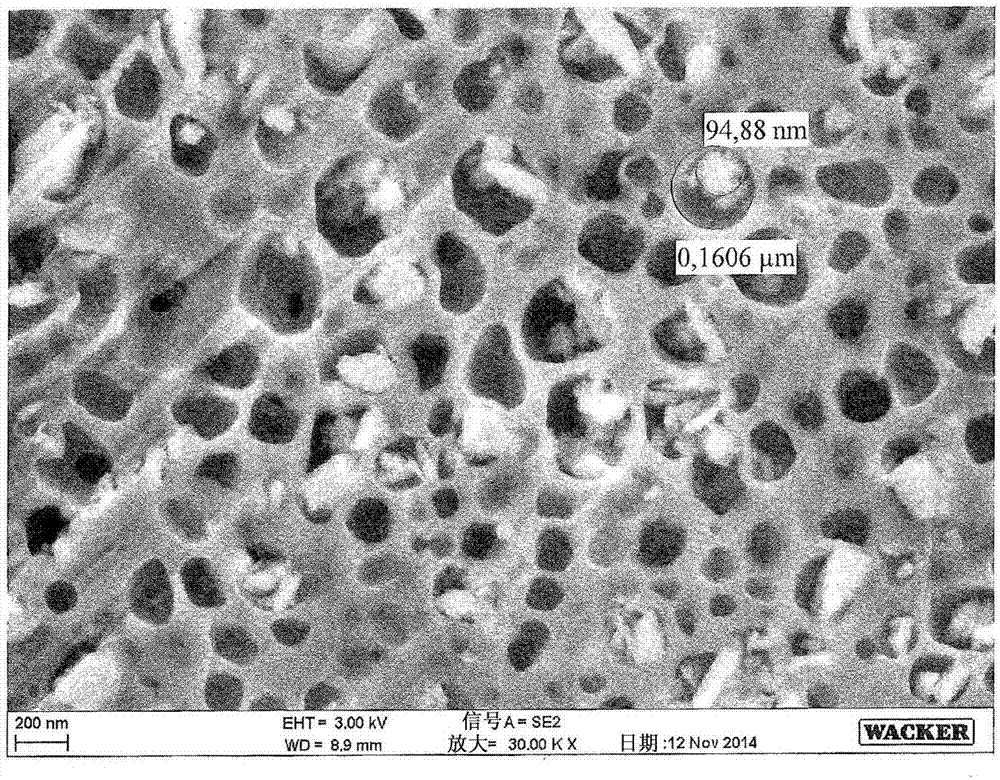

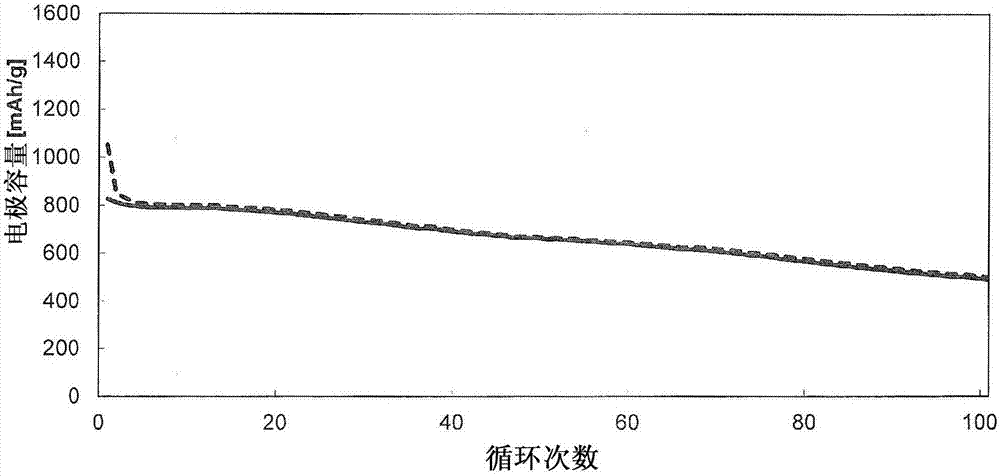

ActiveCN107431189AIncrease volume capacityImprove cycle stabilitySiliconSecondary cellsPorous carbonCarbonization

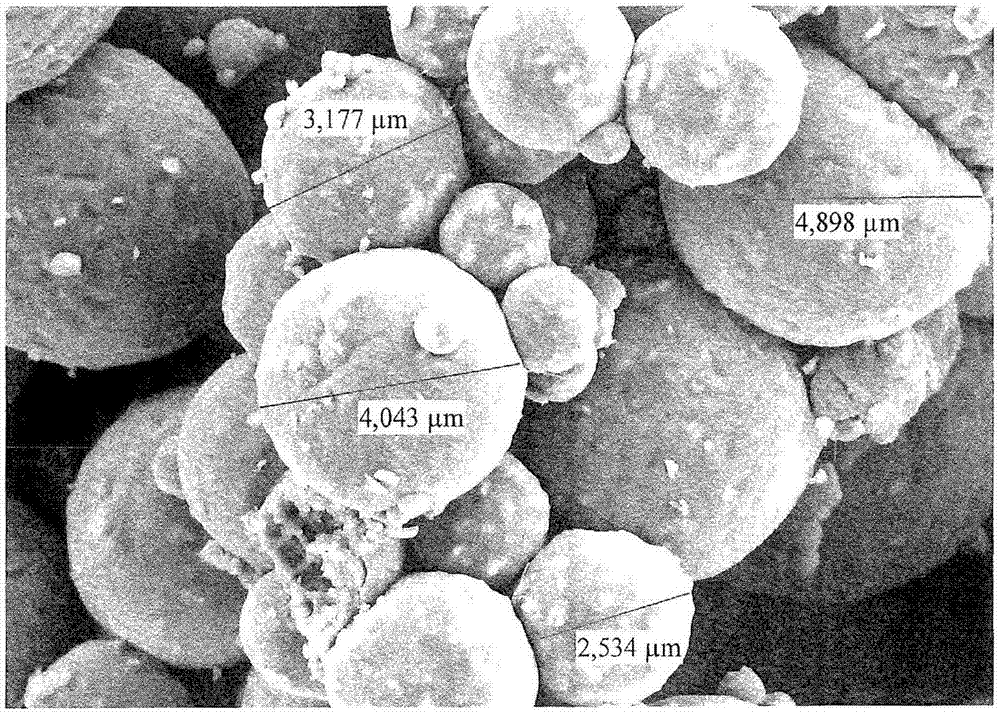

The invention relates to composite core-shell particles wherein the core is a porous, carbon-based matrix which contains silicon particles enclosed in pores of the matrix; the pores containing the silicon particles have a diameter of not less than 60 nm as determined by scanning electron microscopy (SEM); the shell can be obtained by carbonizing one or more carbon precursors selected from among the group comprising tars, pitches, hard carbon, soft carbon and hydrocarbons having 1 to 20 carbon atoms, resulting in a non-porous shell.

Owner:WACKER CHEM GMBH

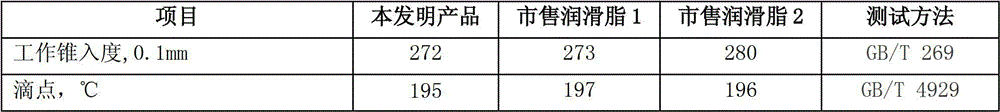

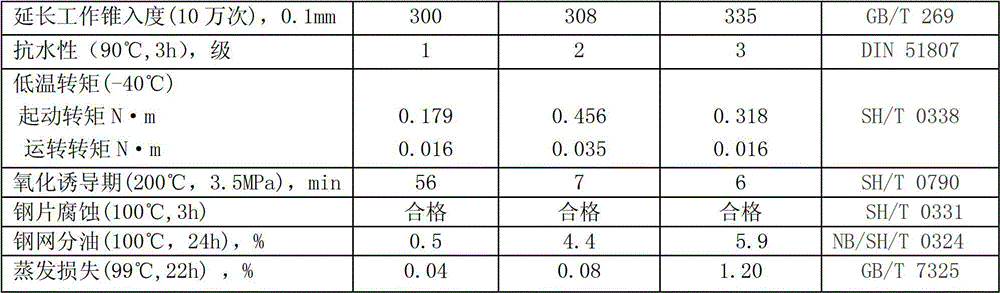

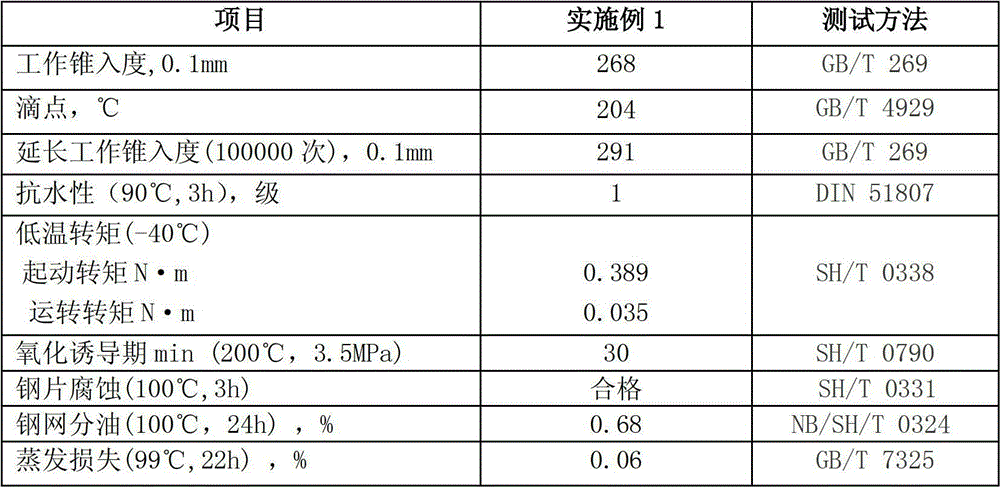

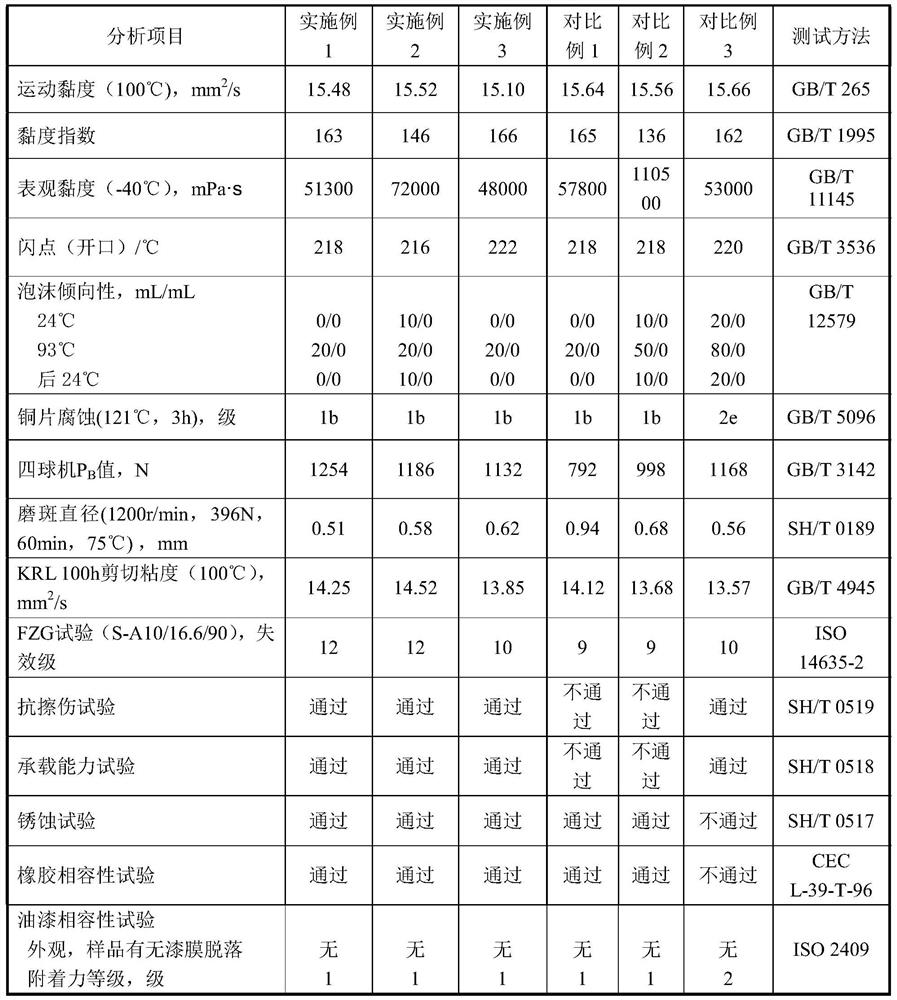

Lubricating grease composition for automobile glass lifter and preparation method of lubricating grease composition

ActiveCN102876434AOutstanding water resistanceOutstanding shear performanceLubricant compositionAntioxidantEvaporation

The invention provides a lubricating grease composition for an automobile glass lifter and a preparation method of the lubricating grease composition. The lubricating grease for the automobile glass lifter comprises the following ingredients in percentage by weight: 87 to 91.5 percent of basic oil, 7.5 to 12 percent of thickening agents, 0.5 percent of antioxidants, 0.03 percent of anti-rust agents and 0.5 percent of structure improving agents. The unique mixed thickening agent type is adopted, so the water-resistance and shearing performance of the lubricating grease are excellent, good low-temperature and viscosity-temperature performance is given to the lubricating agent through the proper basic oil type and mixture ratio, and the wide temperature use requirement being minus 40 DEG C to 70 DEG C of the automobile glass lifter accessories can be perfectly met. The prepared lubricating grease has the characteristics that the water resistance and the oxidation resistance are excellent, the oil rate is low, the evaporation loss is small, the shearing stability is high, the high-low temperature performance and the anti-corrosion protection effect are good, and the like, the use requirements of the automobile glass lifter can be perfectly met, and the use temperature range of the lubricating grease is minus 40 DEG C to 130 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP

Core/shell fluoropolymer dispersions with low fluorosurfactant content

InactiveUS20060264537A1High shear stabilityProcessingFibre treatmentCoatingsFluoropolymerSURFACTANT BLEND

A stabilized aqueous fluoropolymer dispersion comprising: about 30 to about 70 weight % non-melt-processible fluoropolymer particles having an SSG of less than about 2.225, said fluoropolymer particles comprising a core of high molecular weight polytetrafluoroethylene and a shell of lower molecular weight polytetrafluoroethylene or modified polytetrafluoroethylene; and about 2 to about 11 weight % of aliphatic alcohol ethoxylate nonionic surfactant based on the weight of said fluoropolymer, wherein said dispersion is essentially free of surfactants containing aromatic groups and contains less than 300 ppm of fluorosurfactant based on the weight of said dispersion.

Owner:THE CHEMOURS CO FC LLC

Production method of aromatic home textile fabric

InactiveCN103668999APure aromaWashableFibre treatmentArtifical filament manufactureMethod selectionSkin surfaces

The invention provides a production method of an aromatic home textile fabric. The production method comprises the following production steps: preparation of aromatic fibers, namely performing melt spinning on perfume and spinning raw materials by a blending process or a composite spinning process, and melting the perfume molecules in ultrafine fibers to obtain the aromatic fibers; and finishing of an aromatic textile, namely after the aromatic textile is prepared from the aromatic fibers, finishing the aromatic textile by a padding process or an impregnation process to obtain the aromatic home textile fabric. By the production method of the aromatic home textile fabric, a good fixation effect of a flavoring agent on the home textile fabric can be guaranteed, the aroma of the home textile fabric is kept for a long time, and a lasting aromatic effect of the home textile fabric is guaranteed. In the production method of the aromatic home textile fabric, the selected flavoring agent and other auxiliaries do not influence the color and strength of the textile, the comfort of the home textile fabric can be guaranteed without irritating the skin of a human body to generate allergic reaction, and environmental pollution is avoided.

Owner:JIANGSU AUDIANO HOME TEXTILES

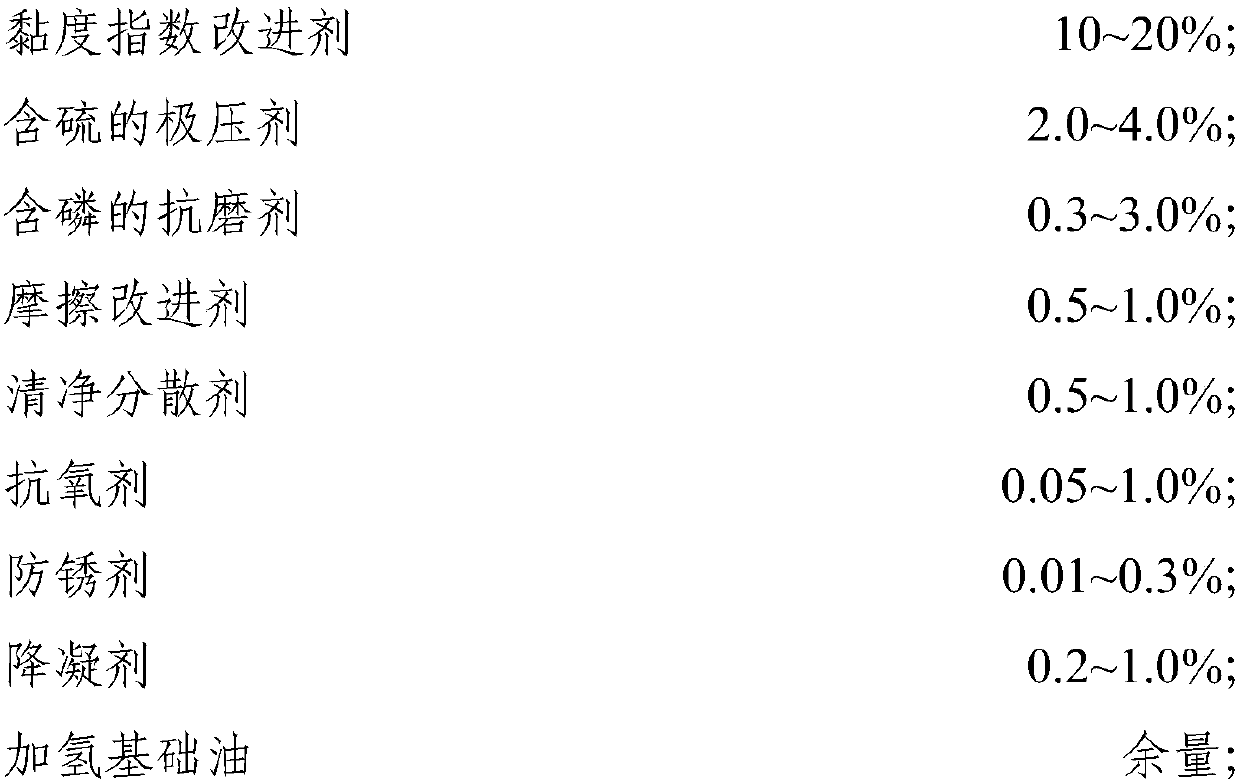

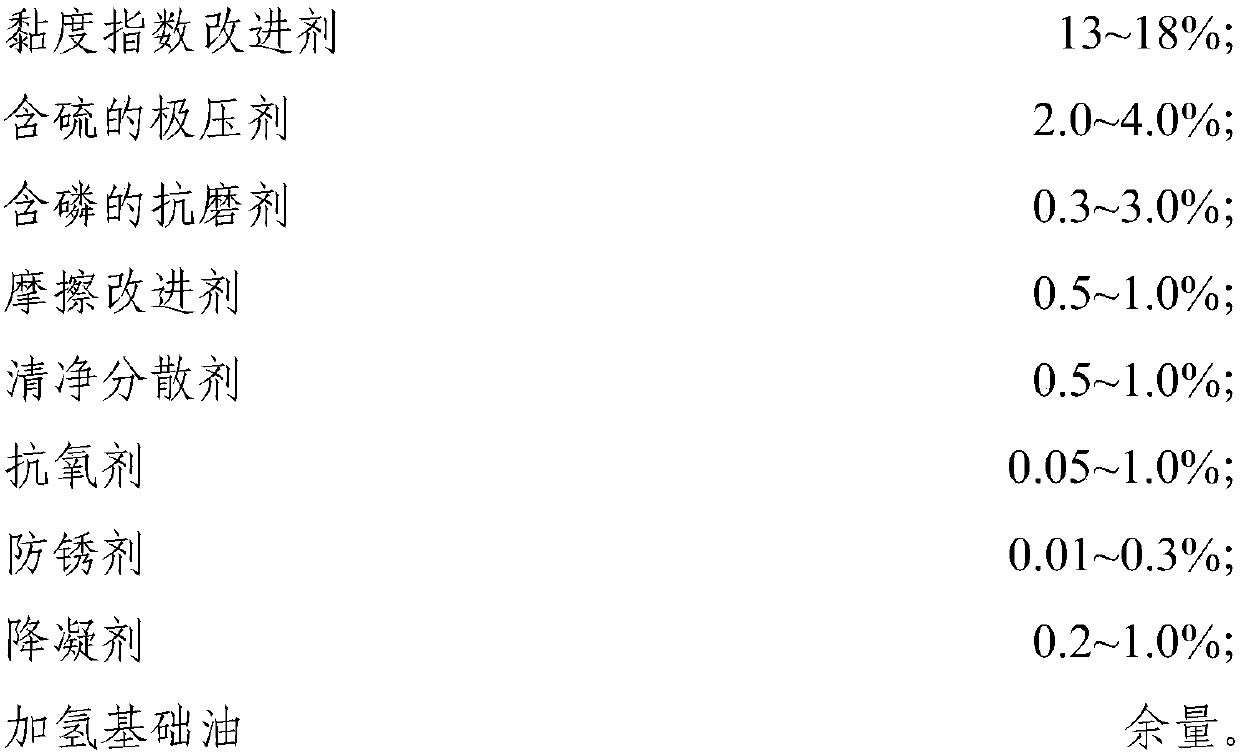

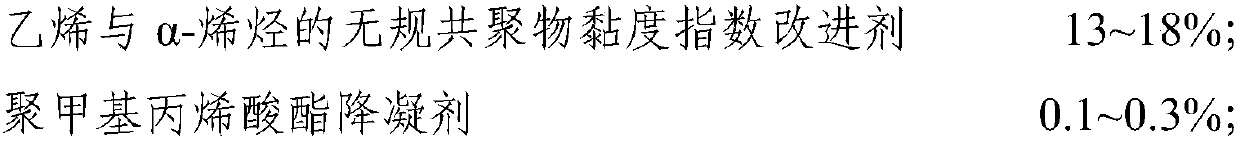

Heavy-duty vehicle gear oil composition with viscosity grade of 75W-90 and application thereof

InactiveCN107868691ASimple ingredientsRaw materials are easy to getLubricant compositionAntioxidantSimple component

The invention relates to a heavy-duty vehicle gear oil composition with a viscosity grade of 75W-90. The composition is composed of the following components in parts by weight: 70-80 parts of hydrogenated base oil, 10-20 parts of a viscosity index improver and 1-20 parts of a complexing agent, wherein the viscosity index improver is a random copolymer of ethylene and alpha-olefin, and the complexing agent comprises one or more selected from a sulfur-containing extreme pressure agent, a phosphorus-containing anti-wear agent, a friction modifier, a detergent dispersant, an antioxidant, an antirust agent and a pour point depressant. The heavy-duty vehicle gear oil composition provided by the invention has excellent performance and a wide application range; the shearing stability performance of heavy-duty vehicle gear oil can be improved to a large extent; and special requirements of clients to the heavy-duty vehicle gear oil with a viscosity grade of 75W-90 can be met. The composition isgood in stability and excellent in low-temperature performance. In addition, the heavy-duty vehicle gear oil composition with a viscosity grade of 75W-90 provided by the invention has simple components, easily acquired raw materials, and a simple and easy preparation method, and has a wide large-scale application prospect.

Owner:CHINA PETROLEUM & CHEM CORP

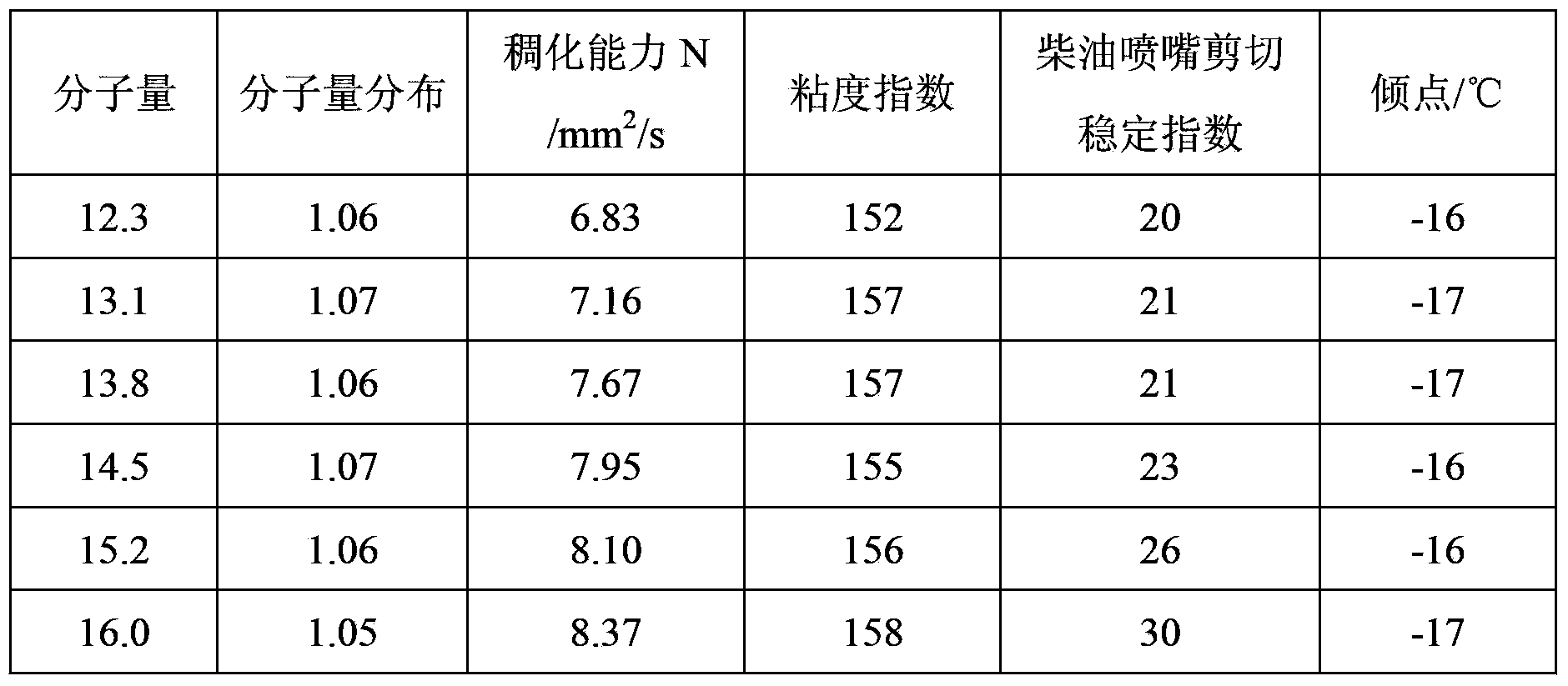

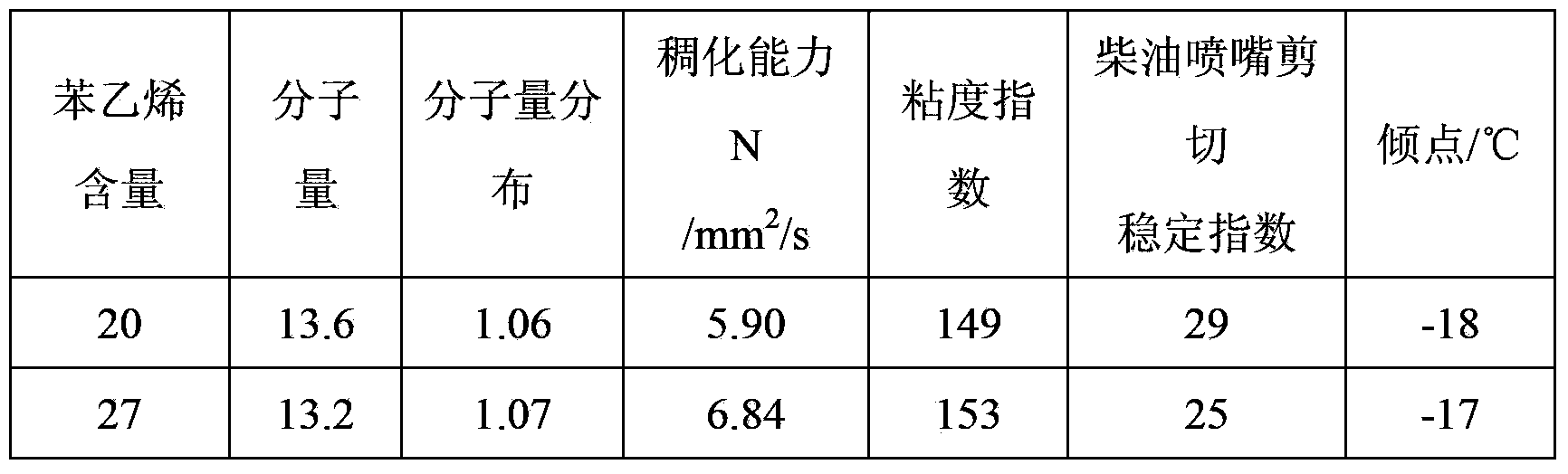

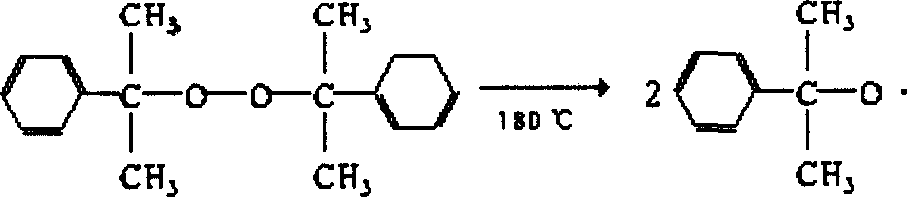

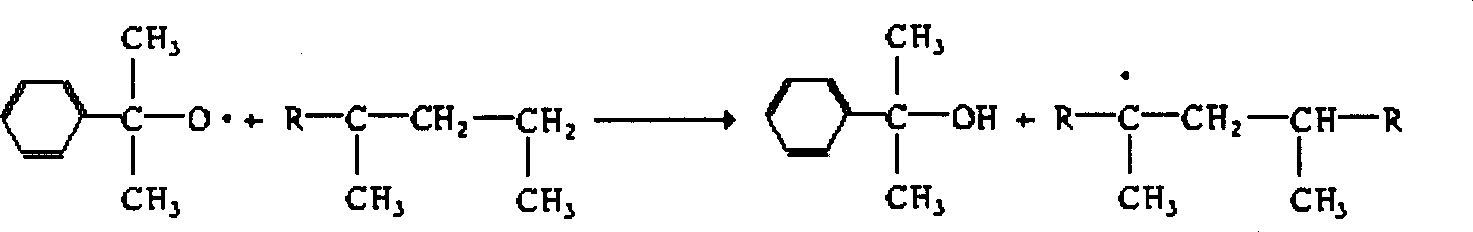

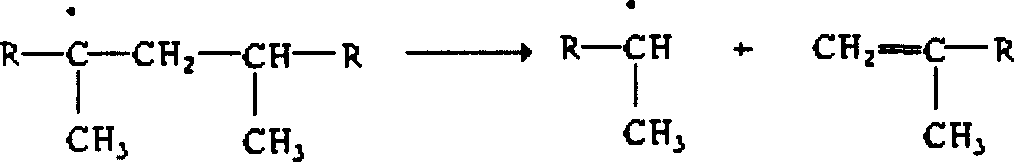

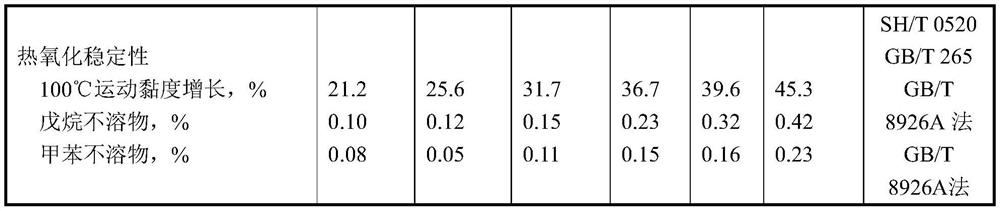

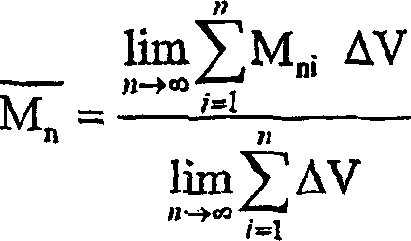

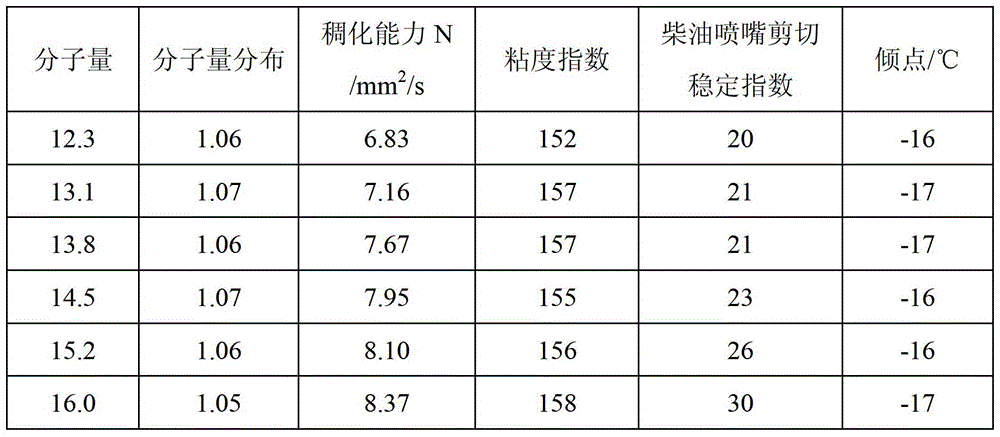

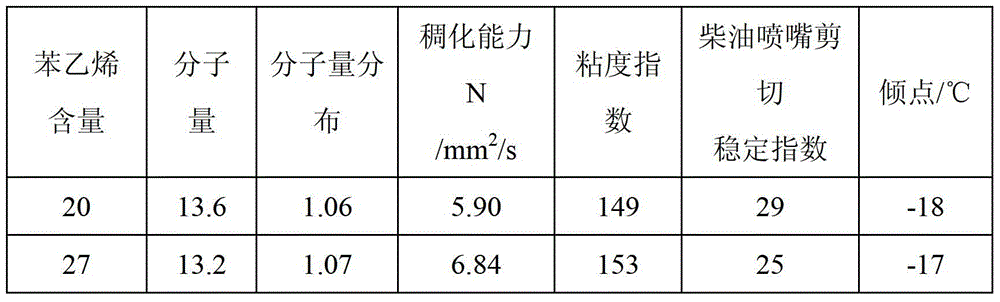

Viscosity index improver of catalytic modified ethylene propylene copolymer and preparation method thereof

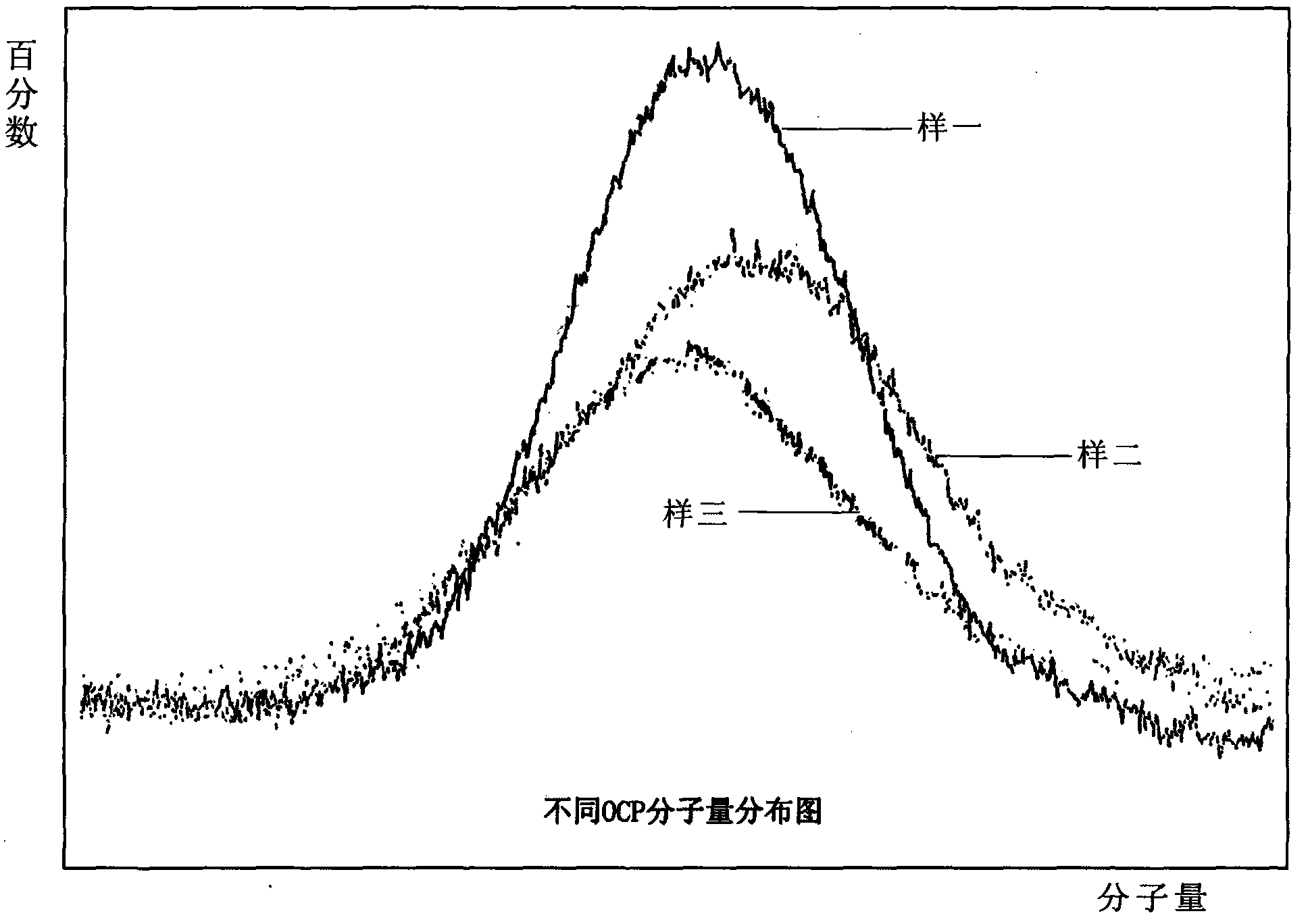

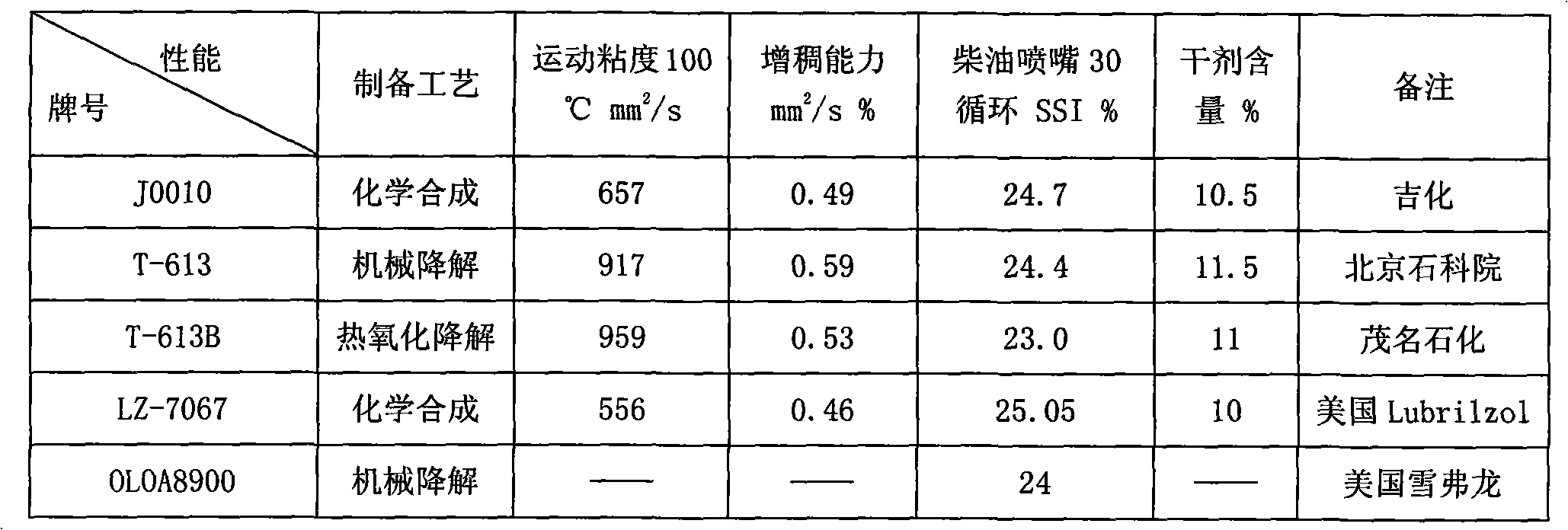

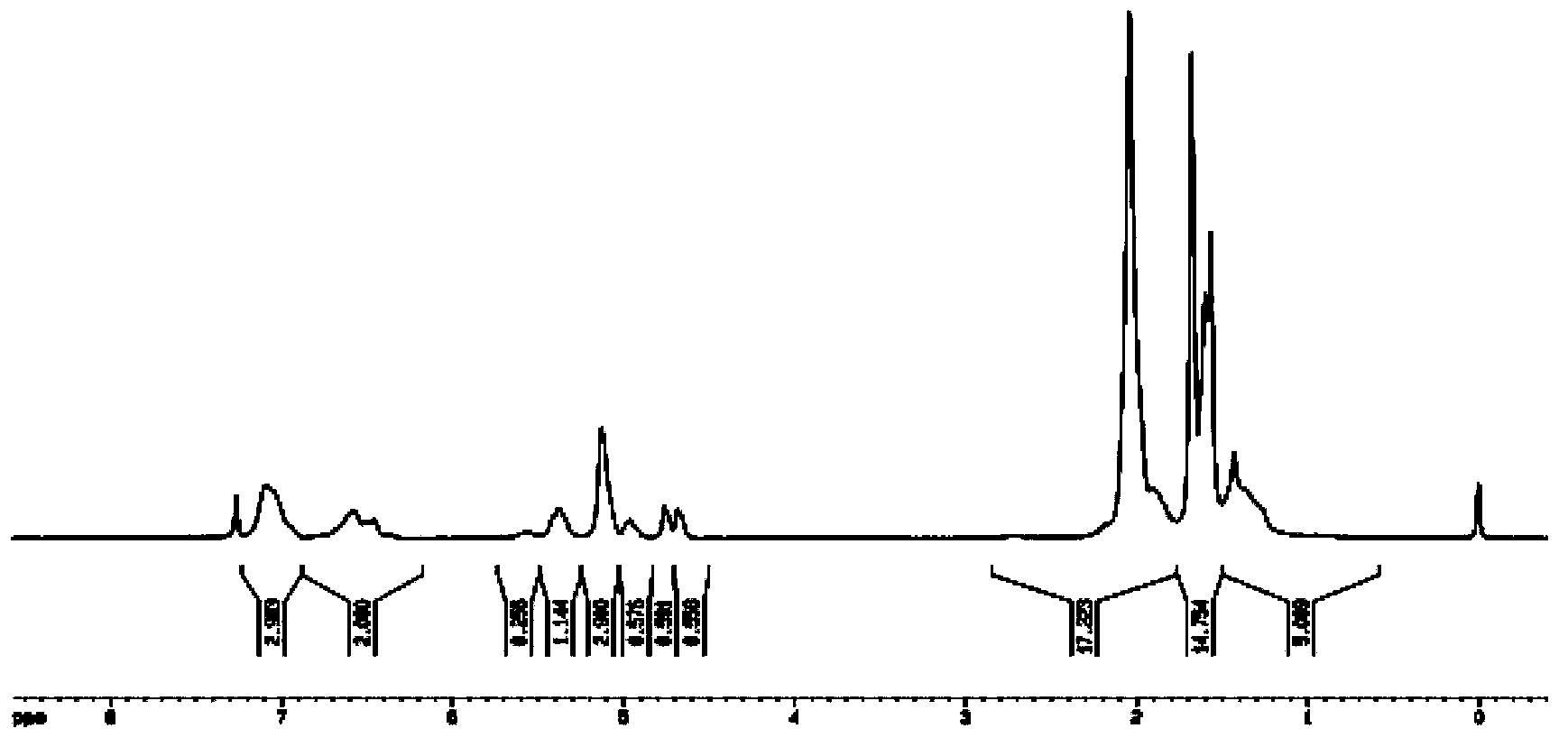

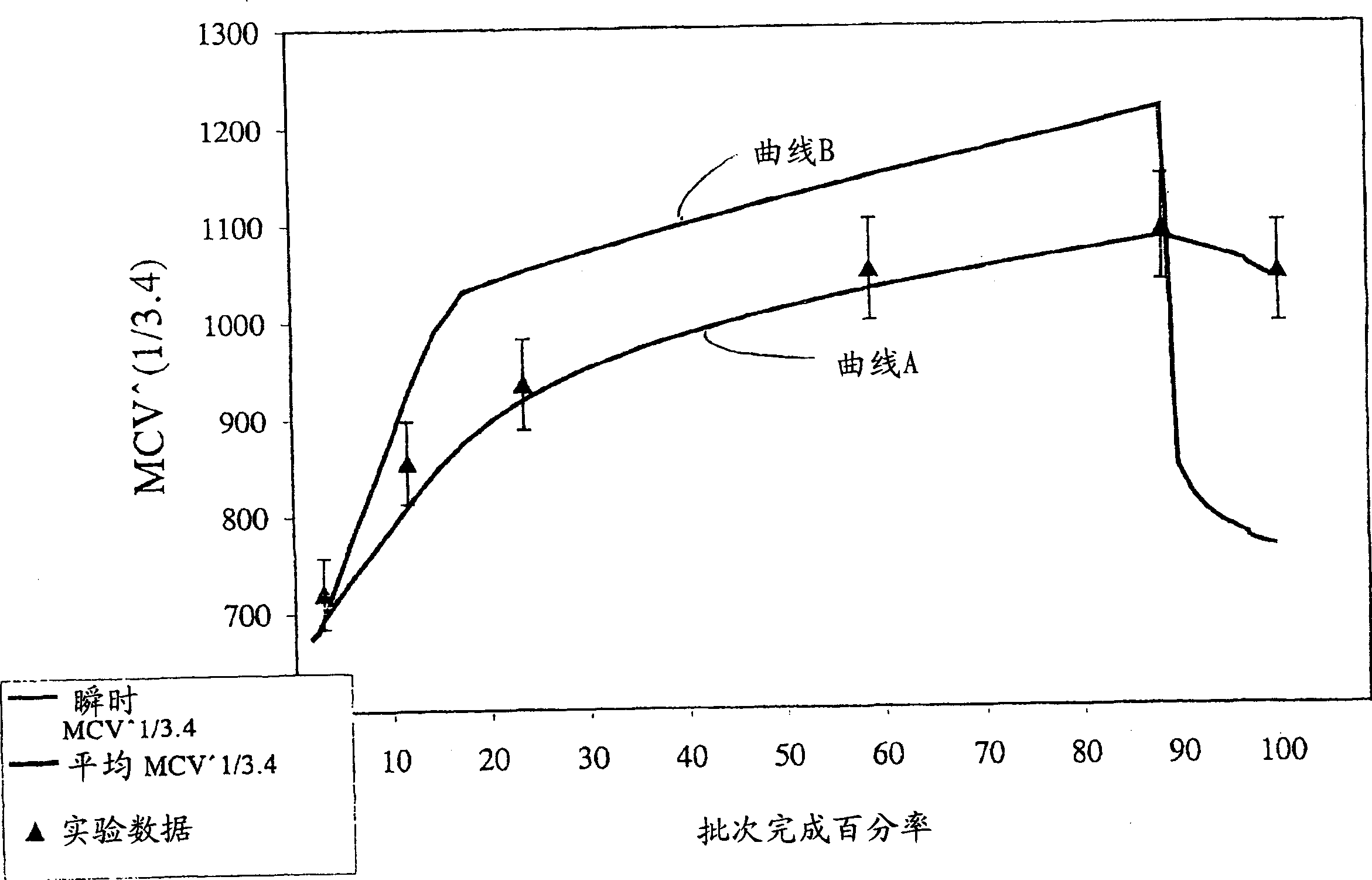

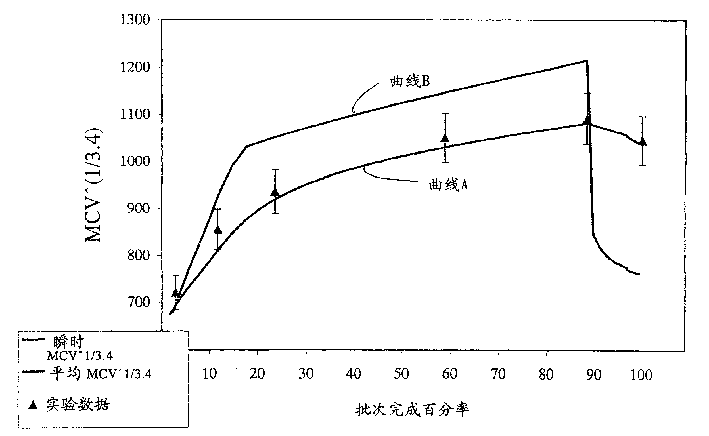

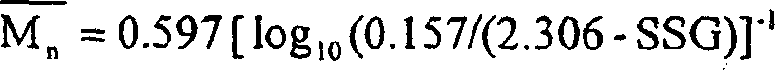

InactiveCN101629120AUniform molecular weight distributionStrong thickening abilityAdditivesStability indexEthylene-propylene-diene-monomer

The invention relates to a viscosity index improver of a catalytic modified ethylene propylene copolymer and a preparation method thereof. The method adopts a whole set of catalytic modified thermal oxidative degradation technique and effectively controls the deep degradation and modification of a high molecular ethylene-propylene copolymer in base oil. The content of the ethylene propylene copolymer in the catalytic modified OCP VII is 8-35%, and the balance is the base oil. The molecular weight of a product has uniform distribution, the molecular structure is accompanied by a product with relatively less macromolecule oxidizing degree of 2-5%, the shearing stability index (SSI) obtained by a diesel oil spray nozzle test method is 2-25%, the thickening capability is 5.0-9.5, the product has the coagulation lowering function of 3-5 degrees, and the application range of the OCP VII is expanded from the original internal combustion engine oil to the fields of low-temperature hydraulic oil and high-grade gear oil.

Owner:赵仲东 +1

Lubricating-oil viscosity index improver and preparation method thereof

ActiveCN104342231AStrong thickening abilityGuaranteed mechanical propertiesAdditivesPolymer sciencePolystyrene

The invention discloses a lubricating-oil viscosity index improver and a preparation method thereof. The lubricating-oil viscosity index improver is obtained by performing hydrogenation modification on a polyisoprene-b-polybutadiene-b-polystyrene triblock copolymer. The preparation method comprises, adding an adjusting agent into a polymerization reaction kettle with the temperature of 60-70 DEG C and the pressure of 0.1-0.5 MPa, and then successively adding an isoprene monomer, a butadiene monomer and a styrene monomer for polymerization reaction; and obtaining the polyisoprene-b-polybutadiene-b-polystyrene triblock copolymer after the polymerization reaction is finished, and performing hydrogenation reaction on the obtained triblock copolymer, so as to obtain the lubricating-oil viscosity index improver. The preparation method is rapid and convenient in operation and simple in process, and the prepared hydrogenated polyisoprene-b-polybutadiene-b-polystyrene triblock copolymer is narrow in molecular weight distribution, complex in structure and good in chemical stability. Lubricating oil modified by the copolymer possesses the characteristics of strong thickening capability, high shearing stability, good oil-product oxidation stability and excellent low-temperature fluidity, and has wide application prospect.

Owner:CHINA PETROLEUM & CHEM CORP

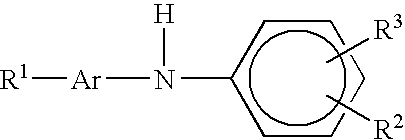

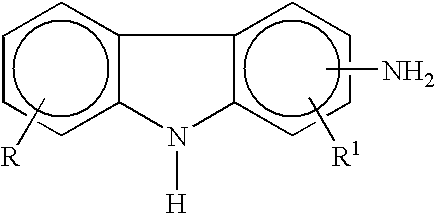

Olefin copolymer dispersant VI improver and lubricant compositions and uses thereof

ActiveUS8420583B2High indexEfficient executionLiquid carbonaceous fuelsAdditivesChemical compositionInternal combustion engine

A lubricating oil composition and methods of operating an internal combustion engine to provide improved engine operation. The lubricating composition includes a major amount of oil of lubricating viscosity; and a minor amount of at least one highly grafted, multi-functional olefin copolymer made by reacting an acylating agent with an olefin copolymer having a number average molecular weight greater than about 10,000 up to about 50,000 in the presence of a free radical initiator to provide an acylated olefin copolymer having a degree of grafting (DOG) of the acylating agent on the olefin copolymer of from above about 1.5 to about 3.0 wt. %. The acylated olefin copolymer is then reacted with an amine to provide the highly grafted, multi-functional olefin copolymer.

Owner:AFTON CHEMICAL

Concentrated fluoroploymer dispersions

InactiveCN1612911AHigh molecular weightHigh shear stabilityFibre treatmentSynthetic resin layered productsTetrafluoroethylenePolymer science

An aqueous dispersion composition of about 30 to about 70 weight % non-melt-processible fluoropolymer particles having a standard specific gravity (SSG) of less than 2.225 and about 2 to about 11 weight % surfactant based on the weight of said fluoropolymer comprising a compound or mixture of compounds of the formula: R(OCH2CH2)nOH wherein R is a branched alkyl, branched alkenyl, cycloalkyl, or cycloalkenyl hydrocarbon group having 8-18 carbon atoms and n is an average value of 5 to 18. The fluoropolymer particles of the dispersion comprise a core of high molecular weight polytetrafluoroethylene and a shell of lower molecular weight polytetrafluoroethylene or modified polytetrafluoroethylene. Preferably, the aqueous dispersion composition comprises about 45 to about 65 weight % non-melt-processible fluoropolymer particles.

Owner:THE CHEMOURS CO FC LLC

Lubricating oil viscosity index improver

InactiveCN1876780AReinforce vulnerable chain partsHigh shear stabilityAdditivesOil viscosityBase oil

The invention relates the lubricating oil viscosity index improver. The invention uses 1-25wt% ethylene-propylene copolymer, 0.0001-1.0wt% carbon chainintensifier and base oil to solve the defects of high price of improver.

Owner:BEIJING KINOVO PETROCHEM PRODS

Powder coating suspensions (powder slurries) and powder coatings, process for producing them and their use

InactiveCN101374594APromote reproductionConforms to specificationsTransportation and packagingMixingDimerMonomer composition

Powder slurries and powder coatings which can be produced in the presence of an emulsifier (A), wherein (1) a liquid component (B) containing a liquid or liquefied constituent of a powder slurry or a powder coating is emulsified in an aqueous medium (C) to give an aqueous emulsion of liquid particles (D), (2) the emulsion is allowed to cool so that a suspension of dimensionally stable particles (D), i.e. the powder slurry, is formed and (3) the dimensionally stable particles (D), i.e. the powder coating, are isolated, with the emulsifier (A) having a hydroxyl number of from 50 to 250 mg KOH / g and being able to be prepared by free-radical copolymerization in an aqueous medium of (a1) hydroxyl-containing, olefinically unsaturated monomers and (a2) olefinically unsaturated monomers selected from the group consisting of (a21) monomers of the general formula (I): R<1>R<2>C=CR<3>R<4>, where at least two of the variables are substituted or unsubstituted aryl, arylalkyl or arylcycloalkyl radicals; (a22) olefinically unsaturated terpene hydrocarbons; and (a23) dimeric alpha-alkylvinylaromatics; a process for producing them and their use.

Owner:BASF AG

Lubricating oil composition viscosity index improver

The invention discloses a lubricating oil composition viscosity index improver. The lubricating oil composition viscosity index improver comprises a hydrogenated block copolymer with minimal crystallinity degree and with at least one control distributed block copolymer. An oil composition of base oil and viscosity index improver is provided and comprises the following components in percentage by weight: 1 to 30 percent of ethylene-propylene copolymer, 0.0001 to 1.0 percent of a controllable degrading catalyst and the balance of base oil; the weight-average molecular weight Mw of the ethylene-propylene copolymer is 0.5*10<5> to 5.0*10<5>, and the ratio Mw / Mn of the weight-average molecular weight Mw to the number-average molecular weight Mn is 1.6 to 3.8; the controllable degrading catalystis selected from at least one of peroxide or azo compounds; and the motion viscosity V100 of the base oil at 100 DEG C is 2.0 to 10.0 centistokes. The lubricating oil composition viscosity index improver has the following advantages: the problems that the lubricating oil viscosity index improver has too high price and the thickening ability, the cutting stability and the oil product clearing property cannot be taken into consideration at the same time are solved, hydrocarbon recombination is conducted, and the thickening ability, the shear stability and the low-temperature viscosity of the viscosity index improver can be improved effectively.

Owner:嵊州市仲明新材料科技有限公司

Lubricating oil composition, method for producing lubricating oil composition, and transmission gear

Provided are: a lubricating oil composition satisfying both high viscosity index and high shear stability, which contains a base oil having a kinematic viscosity at 40° C. of 4.0 mm2 / s or more and less than 6.0 mm2 / s, a kinematic viscosity at 100° C. of 1.0 mm2 / s or more and less than 2.0 mm2 / s, and a flash point of 140° C. or higher, and a polymethacrylate having a specific structure; and a lubrication method and a transmission each using the lubricating oil composition.

Owner:IDEMITSU KOSAN CO LTD

Nano titanium dioxide-type damping grease composition

InactiveCN102433200AWide adaptabilityPrevent intrusionLubricant compositionElectronic instrumentBase oil

The invention relates to the field of damping materials, and more particularly, provides a nano titanium dioxide-type damping grease composition, which comprises, in parts by weight: (A) 100.0 parts of polysiloxane synthetic base oil, (B) 5.0 to 50.0 parts of nano titanium dioxide, (C) 0.5 to 5.0 parts of modified surface treatment agent, (D) 1.0 to 10.0 parts of torsional force intensifier, (E) 3.0 to 10.0 parts of solid lubricant, and (F) 0.2 to 2.0 parts of antioxidant corrosion inhibitor. The finished damping grease prepared by these materials in the above proportions has excellent high / low temperature performance, wide applicable temperature range and high shear stability, is capable of controlling motion accurately and reducing noise, and can be widely applied to any part of a variety of optical instruments, electronic instruments, measurement instruments and the like, which requires the control for free motion. Meanwhile, the production process is simple and easily implementable, so the nano titanium dioxide-type damping grease composition is suitable for large-scale batch production.

Owner:SHENZHEN EUBO NEW MATERIAL TECH

High build dispersions

Owner:THE CHEMOURS CO FC LLC

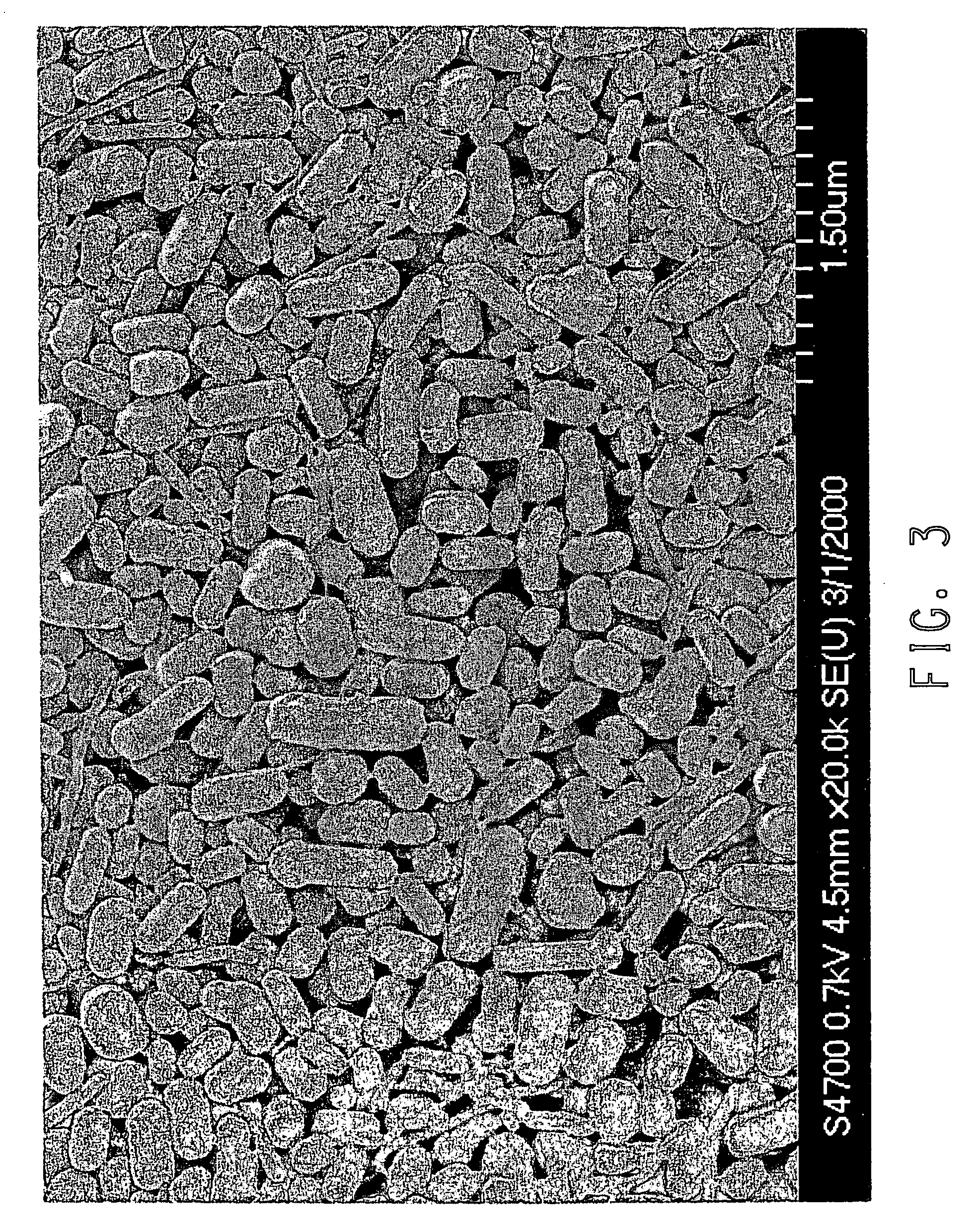

Core-shell composite particles for anode materials of lithium ion batteries

ActiveCN110178251AImprove electrochemical behaviorIncrease volume capacitySiliconNegative electrodesPorous carbonPhysical chemistry

The invention relates to core-shell composite particles, the core being a porous, carbon-based matrix containing silicon particles and the shell being non-porous and being obtainable by the carbonization of one or more carbon precursors, the silicon particles having average particle sizes of 1 to 15 Mum.

Owner:WACKER CHEM GMBH

75W-90 viscosity grade oil composition special for urban rail gear box

The invention relates to the technical field of lubricating oil, in particular to a 75W-90 viscosity grade oil composition special for an urban rail gear box, and the oil composition comprises the following components by weight: 50-70 parts of synthetic base oil, 10-30 parts of a viscosity index improver, 3-10 parts of an extreme pressure agent composition, 0.1-0.14 part of a metal deactivator, 2-4 parts of a detergent dispersant, 0.15-0.25 part of an antioxidant, 0.2-0.4 part of a demulsifying agent and 0.03-0.07 part of a non-silicon anti-foaming agent. The extreme pressure agent composition comprises 0.4-0.6 part of an extreme pressure anti-wear agent, 4-7 parts of a sulfur-containing extreme pressure agent and 2-4 parts of a phosphorus-containing anti-wear agent. The composition has excellent extreme pressure anti-wear property and material compatibility, and excellent high and low temperature properties and shear stability, and can provide good lubrication protection for urban rail gear boxes. And moreover, the composition is stable in component sources, and the preparation method is simple.

Owner:CHINA PETROLEUM & CHEM CORP

Core-shell fluoropolymer dispersions

InactiveCN1612904AHigh shear stabilityLong flex lifeEmulsion paintsThin material handlingTetrafluoroethylenePolymer science

A dispersion of non-melt-processible fluoropolymer particles having an SSG of less than about 2.225 in aqueous medium. The fluoropolymer particles comprise a core of high molecular weight polytetrafluoroethylene having an average melt creep viscosity greater than about 1.5x10<10 >Pa.s and a shell of lower molecular weight polytetrafluoroethylene or modified polytetrafluoroethylene. The shell has an average melt creep viscosity greater than about 9x10<9 >Pa.s and comprises about 5 to about 30% by weight of the particles. The fluoropolymer in the dispersion of the invention is fibrillating.

Owner:EI DU PONT DE NEMOURS & CO

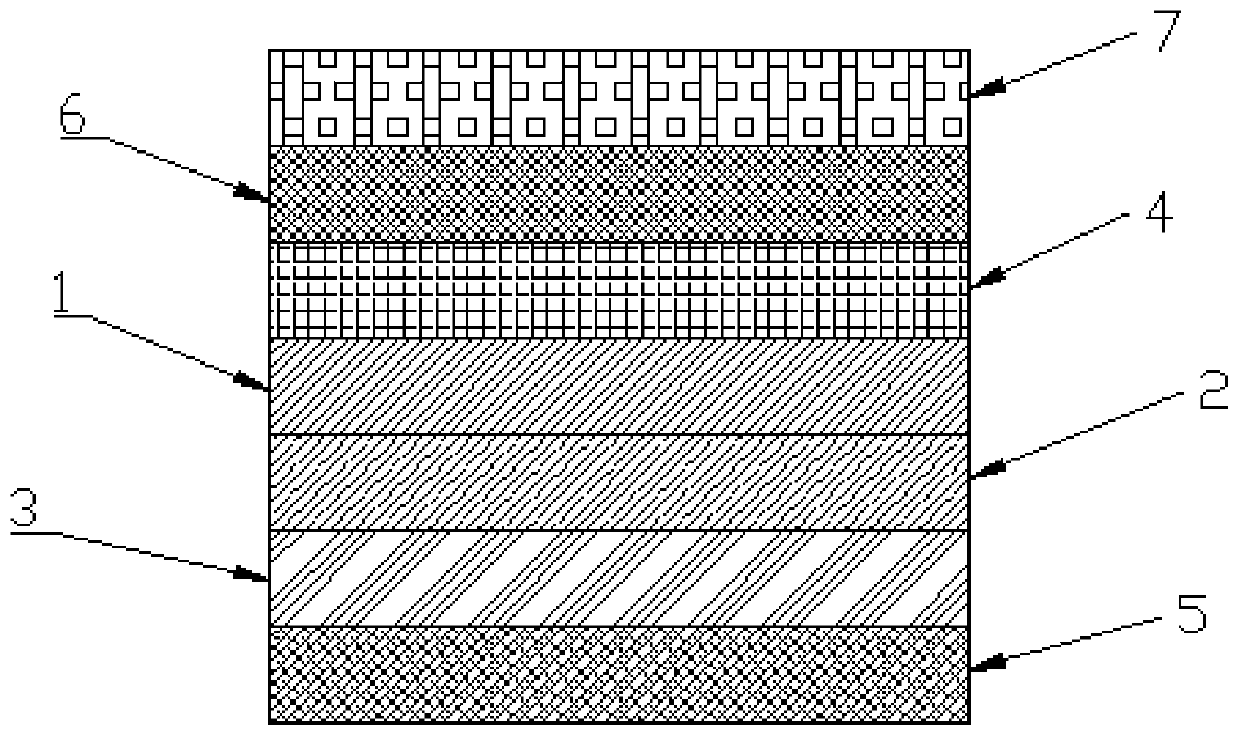

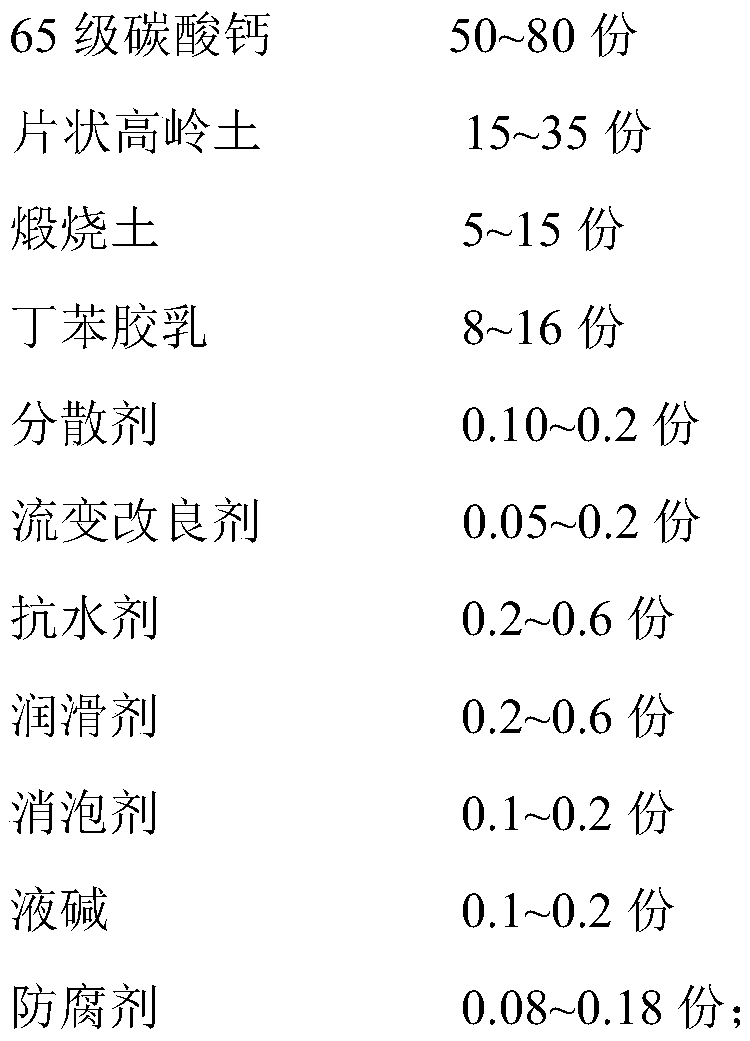

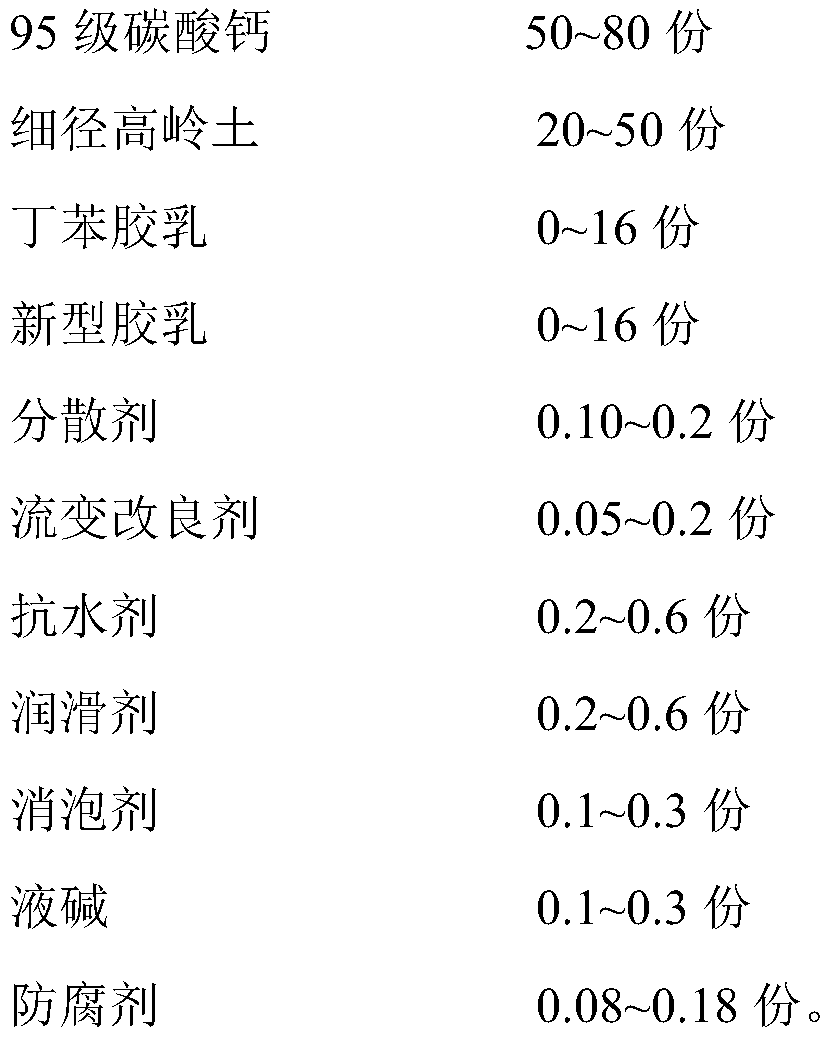

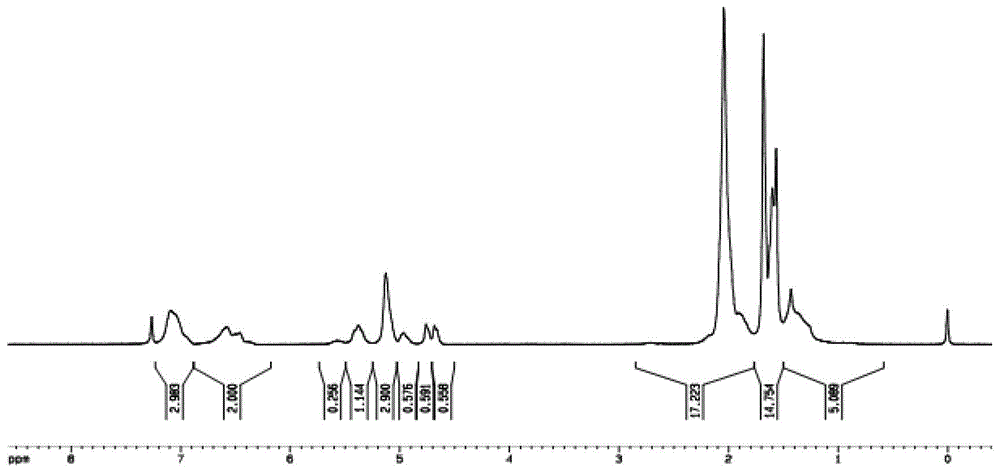

Lightly coated craft paper and production method thereof

ActiveCN111005258APromote absorptionBright colorDefoamers additionSpecial paperPolymer sciencePapermaking

The invention relates to the technical field of papermaking, in particular to a lightly coated craft paper and a production method thereof. The lightly coated craft paper comprises a surface layer, acore layer, a bottom layer, a front surface sizing layer and a back surface sizing layer, the front surface sizing layer and the back surface sizing layer are located on the surface of the surface layer and the surface of the bottom layer respectively, a pre-coating layer is arranged on the front surface sizing layer, and a surface coating layer is arranged on the pre-coating layer. The productionmethod of the lightly coated craft paper comprises the following steps: raw paper preparing, surface sizing, coating and drying. In the coating process, novel latex namely styrene acrylate latex or polyethylene ethyl ester latex is added into a surface coating paint; the ester group reaction can improve the opening degree of the coating, the ink absorbing performance of paper is improved; in addition, the covering property of the coating can be improved, the smoothness and compressibility of finished paper are improved, the problems of white exposure and printing floating are reduced, printedpaper products are not prone to yellowing, the color is brighter and more exquisite, meanwhile, the whiteness of the finished paper can be improved, the use amount of bleaching chemicals is reduced,and the production cost is reduced.

Owner:DONGGUAN NINE DRAGONS PAPER IND

Preparation method of lubricating oil viscosity-temperature improver

The invention relates to a preparation method of a lubricating oil viscosity-temperature improver, belonging to the lubricating oil field. The preparation method of the invention comprises the following steps: adding a solvent, i.e. hexane to a polymerization vessel at the temperature of 10-50 DEG C; continuously introducing ethylene, propylene, styrene and hydrogen to the vessel at a mol ratio of 0.1-0.3:0.45-1:1:0.8-1; stirring to react for 1-3h, and then adding a main catalyst, i.e. benzoyl peroxide and an assistant catalyst, i.e. aluminum triethyl, wherein the addition amount of the main catalyst is 0.01-1wt% of that of the solvent, and the addition amount of the assistant catalyst is 2-10 times that of the main catalyst; after reaction is completed, stopping stirring, and then adding methanol to terminate; and finally washing with alkali solution, and then drying in vacuum to obtain the product, i.e. a copolymer of ethylene, propylene and styrene. The preparation method can change the overall indicators of lubricating oil such as viscosity-temperature property, thickening capability, low-temperature performance, dispersibility and the like, thus the lubricating oil is obviously superior to the current similar products.

Owner:JINAN DEV ZONE XINGHUO SCI & TECH RES INST

Aqueous 1-component silicone composition

InactiveUS6699930B1Long shelf lifeExtended shelf lifeOther chemical processesMixing methodsEmulsionNetwork on

An aqueous 1-component composition which forms a resilient silicone network on drying and is obtained by reaction, at a temperature of at least 40° C., ofI) a surfactant-stabilized dispersion of a highly crosslinked silicone compound which carries reactive groups which are selected from silanol, hydrocarbon-oxy and silanolate groups withII) a surfactant-stabilized emulsion of optionally precrosslinked silicone oil which carries reactive groups which are selected from silanol, hydrocarbon-oxy and silanolate groups.

Owner:WACKER CHEM GMBH

Viscosity-temperature improver for lubricant

The invention belongs to the field of lubricants and particularly relates to a viscosity-temperature improver for a lubricant. The viscosity-temperature improver is prepared by the following steps: adding a solvent (hexane) into a polymerization reaction vessel till the temperature is 10-50 DEG C; continually adding ethylene, propylene, styrene and hydrogen into the reaction vessel, wherein the molar ratio of hydrogen to ethylene to propylene to styrene is (0.1-0.3):(0.45-1):1:(0.8-1); performing stirring for a reaction for 1-3 h; adding a main catalyst (benzoyl peroxide) and an auxiliary catalyst (triethyl aluminum), wherein the addition of the main catalyst is 0.01-1% (by weight) of that of the solvent, and the weight of the auxiliary catalyst is 2-10 times of that of the main catalyst; stopping stirring after finish of the reaction; adding methyl alcohol for termination; washing with an alkaline solution; and performing vacuum drying to obtain a product (an ethylene, propylene and styrene copolymer). The viscosity-temperature improver for the lubricant can change such aggregative indicators as the viscosity-temperature performance, the thickening capability, the low-temperature performance and the dispersity of the lubricant, and ensures that the aggregative indicators are remarkably superior to like products at present.

Owner:如皋市康利化工有限公司

A kind of lubricating oil viscosity index improver and preparation method thereof

ActiveCN104342231BStrong thickening abilityGuaranteed mechanical propertiesAdditivesPolymer scienceHydrogenation reaction

The invention discloses a lubricating-oil viscosity index improver and a preparation method thereof. The lubricating-oil viscosity index improver is obtained by performing hydrogenation modification on a polyisoprene-b-polybutadiene-b-polystyrene triblock copolymer. The preparation method comprises, adding an adjusting agent into a polymerization reaction kettle with the temperature of 60-70 DEG C and the pressure of 0.1-0.5 MPa, and then successively adding an isoprene monomer, a butadiene monomer and a styrene monomer for polymerization reaction; and obtaining the polyisoprene-b-polybutadiene-b-polystyrene triblock copolymer after the polymerization reaction is finished, and performing hydrogenation reaction on the obtained triblock copolymer, so as to obtain the lubricating-oil viscosity index improver. The preparation method is rapid and convenient in operation and simple in process, and the prepared hydrogenated polyisoprene-b-polybutadiene-b-polystyrene triblock copolymer is narrow in molecular weight distribution, complex in structure and good in chemical stability. Lubricating oil modified by the copolymer possesses the characteristics of strong thickening capability, high shearing stability, good oil-product oxidation stability and excellent low-temperature fluidity, and has wide application prospect.

Owner:CHINA PETROLEUM & CHEM CORP

Temporary fence capable of conveniently adjusting length

InactiveCN107366473AIncrease the lengthImprove stabilityFencingSignsEngineeringMechanical engineering

The invention discloses a temporary fence capable of conveniently adjusting length. The temporary fence comprises a temporary fence body and is characterized in that connectors are arranged on one side of the temporary fence body, a connecting insertion hole is formed in the upper surface of each connector, connecting bayonet pins are arranged on the other side of the temporary fence body, bases are arranged at the bottom of the temporary fence body, standing columns are arranged on the inner side of the temporary fence body, a clamp groove is formed in the front surface of each standing column, and a second fixing clamp plate is clamped into each clamp groove through a second limit clamp plate. The temporary fence has the advantages that the connectors are arranged on one side of the temporary fence body, the upper surface of each connector is provided with the connecting insertion hole, the other side of the temporary fence body is provided with connecting bayonet pins, the depth and the inner diameter of each connecting insertion hole are identical with the length and the outer diameter of the corresponding connecting bayonet pin, and accordingly multiple temporary fence bodies can be connected by inserting the connecting bayonet pins into the connecting insertion holes, and the length of the temporary fence can be increased.

Owner:弘毅天承知识产权股份有限公司

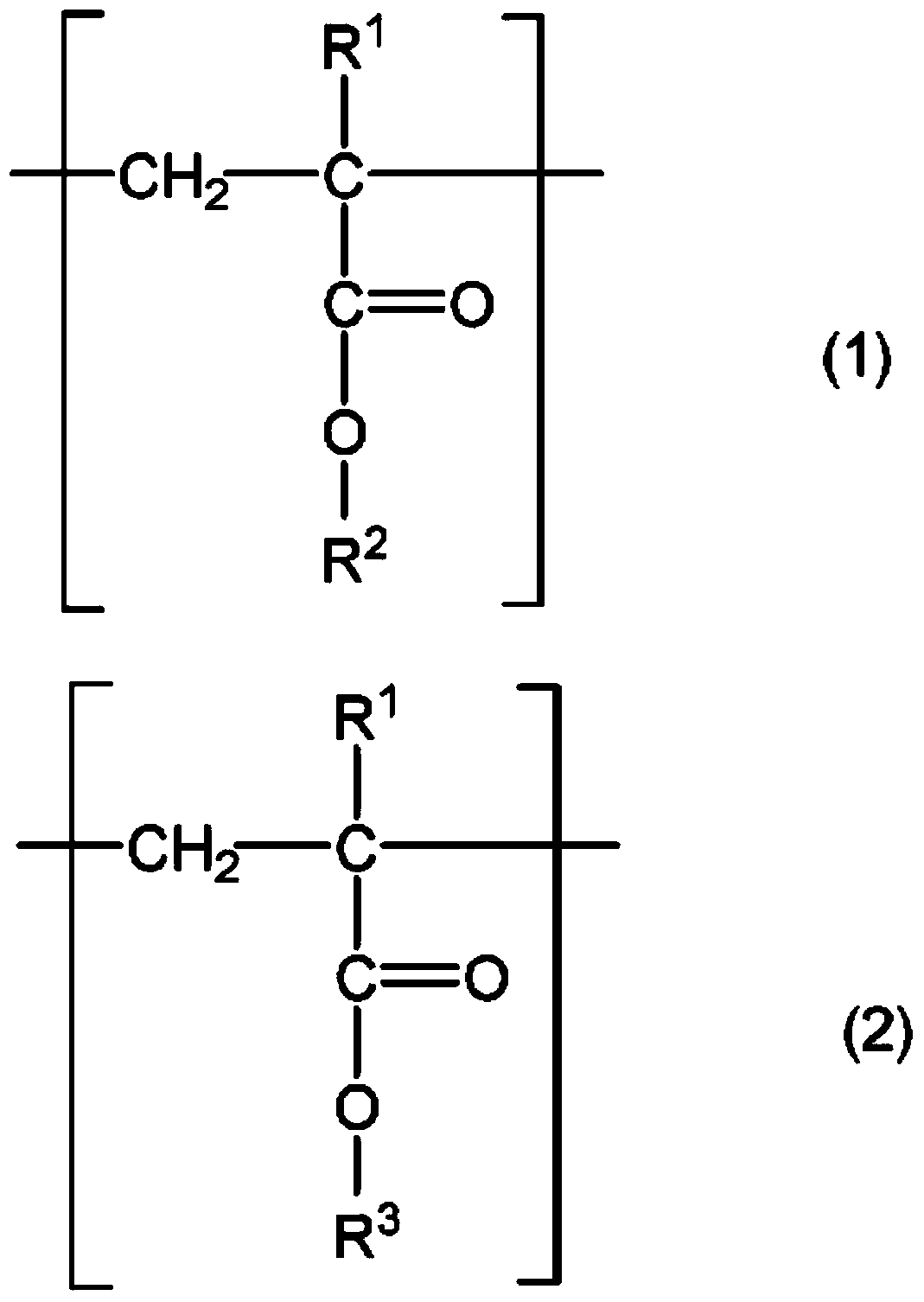

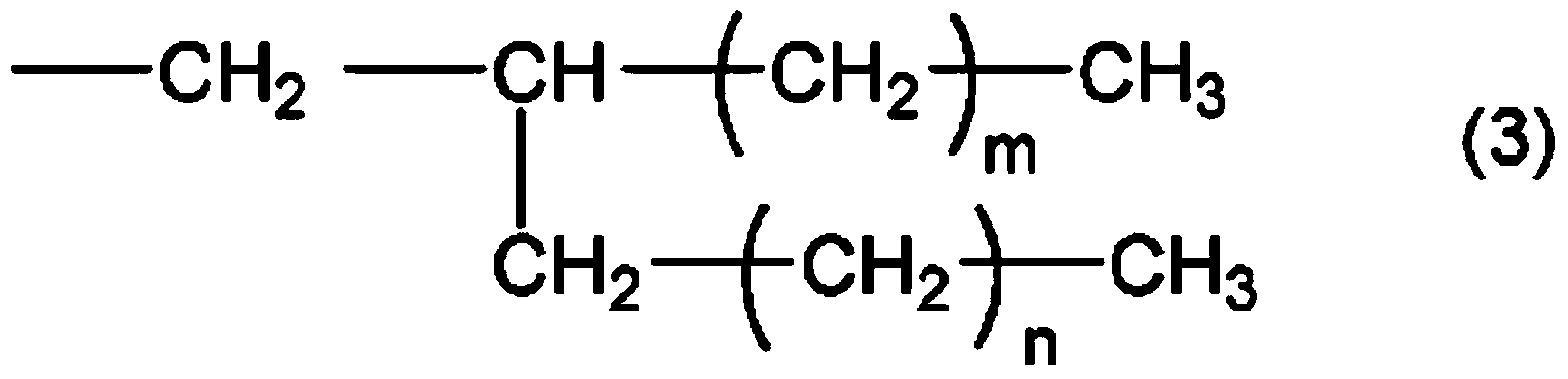

Poly(meth)acrylate-based viscosity index improver, lubricant additive and lubricant composition containing viscosity index improver

InactiveCN104411810AIncrease shear viscosityHigh shear stabilityAdditivesBase-materialsTO-18Polymer science

The present invention provides a poly(meth)acrylate-based viscosity index improver having a core, and three or more arms comprising a polymer chain containing a structural unit represented by formula (1) and a structural unit represented by formula (2), one end of said polymer chain being bonded to the core. The weight-average molecular weight (Mw) of the poly(meth)acrylate-based viscosity index improver is at least 100,000, and the weight-average molecular weight / the number average molecular weight (Mn) is not more than 1.6. [R1 represents hydrogen or a methyl group; R2 represents the group represented by formula (3); and R3 represents an alkyl group with 1 to 18 carbons. m and n are integers that satisfy m >= 5, n >= 4, and m + n <= 31.]

Owner:JX NIPPON OIL & ENERGY CORP

Hydrocarbon refrigerant containing ethanol

InactiveCN101798496AEliminate hidden dangersAwareness of safe use and preventionHeat-exchange elementsAlcoholPhysical chemistry

The invention discloses a hydrocarbon refrigerant containing ethanol, which comprises the components by mass percent: 90-96% of propane, 2-7% of iso-butane, 1.5-2.8% of alcohol fatty oil and 0.2-0.5% of ethanol, wherein 90%, 93% or 96% of propane is preferred, 2%, 4.5% or 7% of iso-butane is preferred, 1.5%, 2.15% or 2.8% of alcohol fatty oil is preferred, and 0.2%, 0.35% or 0.5% of ethanol is preferred. The hydrocarbon refrigerant containing ethanol greatly improves the using safety of the hydrocarbon refrigerant, overcomes the oxidization of moisture inside the hydrocarbon refrigerant for a compressor, improves the efficiency and the lubricating degree of the compressor, is more beneficial to the safety and environmental protection of transition use from R22 refrigerant to the hydrocarbon refrigerant, and greatly improves the stability and the economical efficiency of a system.

Owner:蒋志科

Powder coating suspensions (powder slurries) and powder coating materials, their preparation and use

InactiveUS20100240824A1Meet specificationsHigh shear stabilityTransportation and packagingMixingEmulsionPolymer chemistry

Disclosed herein is a powder coating suspension prepared in the presence of an emulsifier (A) by emulsifying a liquid component (B) in an aqueous medium (C) to give an aqueous emulsion of liquid particles (D); and cooling the emulsion of liquid particles (D); wherein the emulsifier (A) has a hydroxyl number of 50 to 250 mg KOH / g and is a copolymer prepared by copolymerizing in an aqueous medium (a1) a hydroxyl-containing, olefinically unsaturated monomer; and (a2) an olefinically unsaturated monomer selected from the group consisting of (a21) a monomer of the general formula R1R2C═CR3R4, wherein R1, R2, R3, and R4 are independently hydrogen atoms or substituted or unsubstituted alkyl, cycloalkyl, alkylcycloalkyl, cycloalkylalkyl, aryl, alkylaryl, cycloalkylaryl, arylalkyl or arylcycloalkyl radicals, with the proviso that at least two of R1, R2, R3, and R4 are aryl, arylalkyl or arylcycloalkyl radicals; (a22) an olefinically unsaturated terpene hydrocarbon; and (a23) a dimeric alpha-alkylvinylaromatic.

Owner:BASF COATINGS GMBH

Oil soluble frictional reducing polymer and preparing method thereof

InactiveCN1257194CSolve the problem of fragmentationUniform and stable productionPipeline systemsWater bathsHigh carbon

The present invention relates to one kind of oil soluble drag-reducing polymer polymerized with alpha-olefin monomer and / or comonomers under the initiation of homogeneous catalyst system of organic transition metal complex of cyclopentadienyl zirconium or titanium and alkyl alum inoxane. The alpha-olefin monomer is C3-C30 monomer; the comonomers include styrene, vinyl acetate, acrylic acid and high-carbon alcohol ester of acrylic acid; the organic transition metal complex of cyclopentadienyl zirconium or titanium is ethylene bridged diindenyl zirconium dioxide, ethylene bridged hydro diindenyl zirconium dichloride or cyclopentadienyl titanium trichloride; and the alkyl alum inoxane is methyl alum inoxane or ethyl alum inoxane. The preparation process includes purifying monomer, precooling monomer and / or comonomers to -9 to 11 deg.c, adding the catalyst system, vibrating to homogenize catalyst, reaction in water bath at -20 to 30 deg.c and test drag reducing rate.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com