75W-90 viscosity grade oil composition special for urban rail gear box

A composition and gear box technology, applied in the field of lubricating oil, can solve the problem that the lubricating oil of the gear box cannot be applied to the urban rail gear box and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

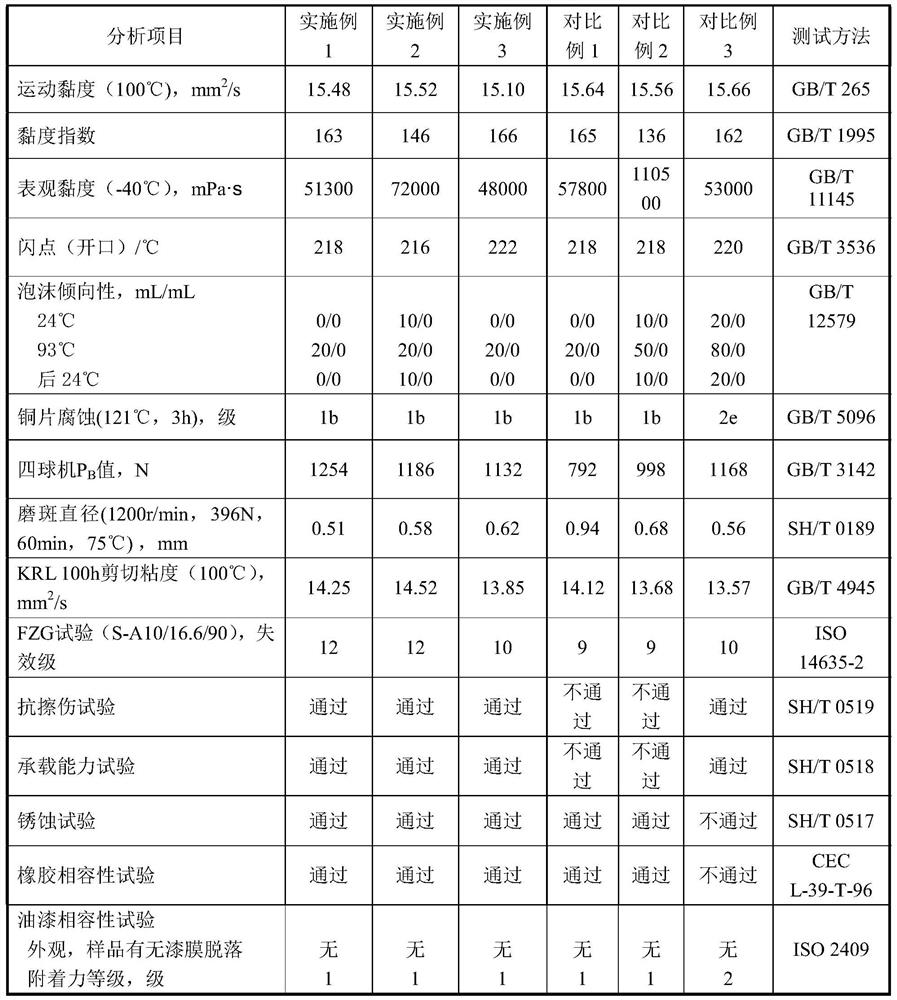

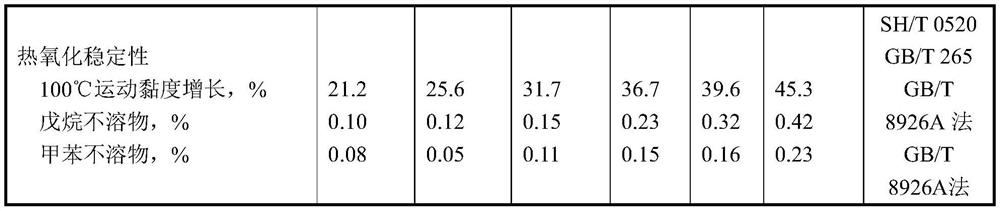

Examples

Embodiment 1

[0051] The invention relates to a 75W-90 viscosity level oil composition for urban rail gearboxes, comprising the following components in parts by weight:

[0052] 40 parts of synthetic oil PAO8, 15 parts of PAO40 and 10 parts of polyol ester;

[0053] Viscosity index improver polymethacrylate 20 parts, extreme pressure antiwear agent thiophosphoric acid double ester amine salt 0.5 parts, sulfurized olefin 6 parts, antiwear agent phosphite 3 parts, metal deactivator benzotriazole fatty amine 0.12 parts of salt, 3 parts of polyisobutylene succinimide as detergent and dispersant, 0.2 parts of dialkyl diphenylamine as antioxidant, 0.3 parts of condensate of amine and ethylene oxide as anti-emulsifier and 0.05 parts of non-silicon antifoaming agent .

Embodiment 2

[0055] The invention relates to a 75W-90 viscosity level oil composition for urban rail gearboxes, comprising the following components in parts by weight:

[0056] 30 parts of PAO6, 17 parts of PAO100, 8 parts of polyol ester and 8 parts of monoalkyl naphthalene;

[0057] Viscosity index improver polymethacrylate 23 parts, extreme pressure antiwear agent thiophosphoric acid complex ester amine salt 0.5 part, sulfurized olefin 6 parts, antiwear agent phosphite 3 parts, metal deactivator benzotriazole fatty amine 0.12 parts of salt, 3 parts of polyisobutylene succinimide as detergent and dispersant, 0.2 parts of dialkyl diphenylamine as antioxidant, 0.3 parts of condensate of amine and ethylene oxide as anti-emulsifier and 0.05 parts of non-silicon antifoaming agent .

Embodiment 3

[0059] The invention relates to a 75W-90 viscosity level oil composition for urban rail gearboxes, comprising the following components in parts by weight:

[0060] 40 parts of synthetic oil PAO8, 15 parts of PAO40 and 10 parts of polyol ester;

[0061] 20 parts of viscosity index improver polymethacrylate, 0.5 part of extreme pressure and antiwear agent amine phosphate, 5 parts of sulfurized olefin, 3 parts of antiwear agent thiophosphate, 0.12 part of metal deactivator benzotriazole fatty amine salt, 2 parts of polyisobutylene succinimide as detergent and dispersant, 0.3 part of di-tert-butyl p-cresol as antioxidant, 0.3 part of condensate of amine and ethylene oxide as anti-emulsifier and 0.05 part of non-silicon antifoaming agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com