Poly(meth)acrylate-based viscosity index improver, lubricant additive and lubricant composition containing viscosity index improver

A viscosity index improvement, acrylate technology, used in lubricating compositions, additives, base materials, etc., can solve problems such as sintering and oil leakage, and achieve the effects of improving viscosity index, inhibiting viscosity increase, and reducing viscous resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0044] [First Embodiment: First Poly(meth)acrylate Viscosity Index Improver]

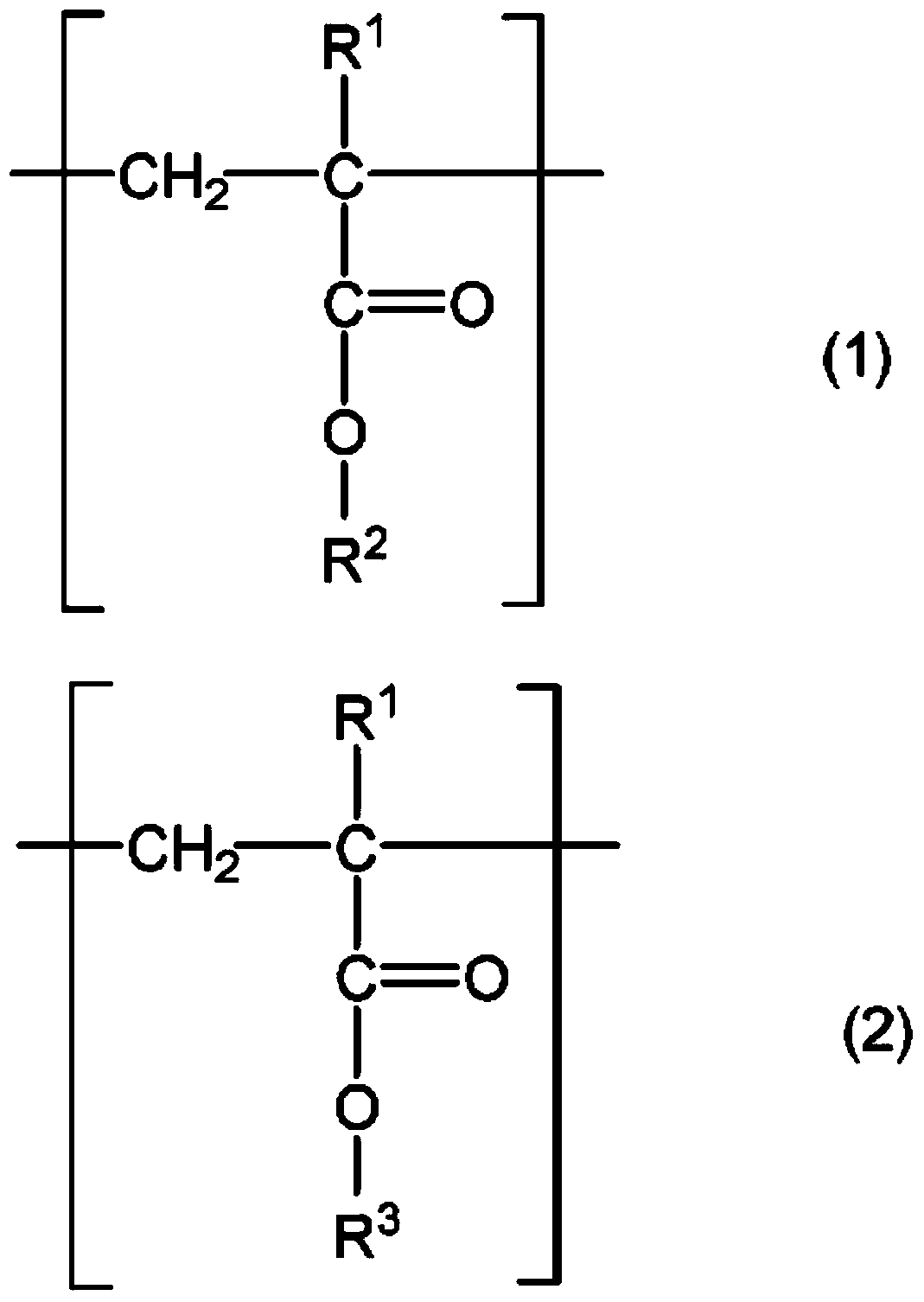

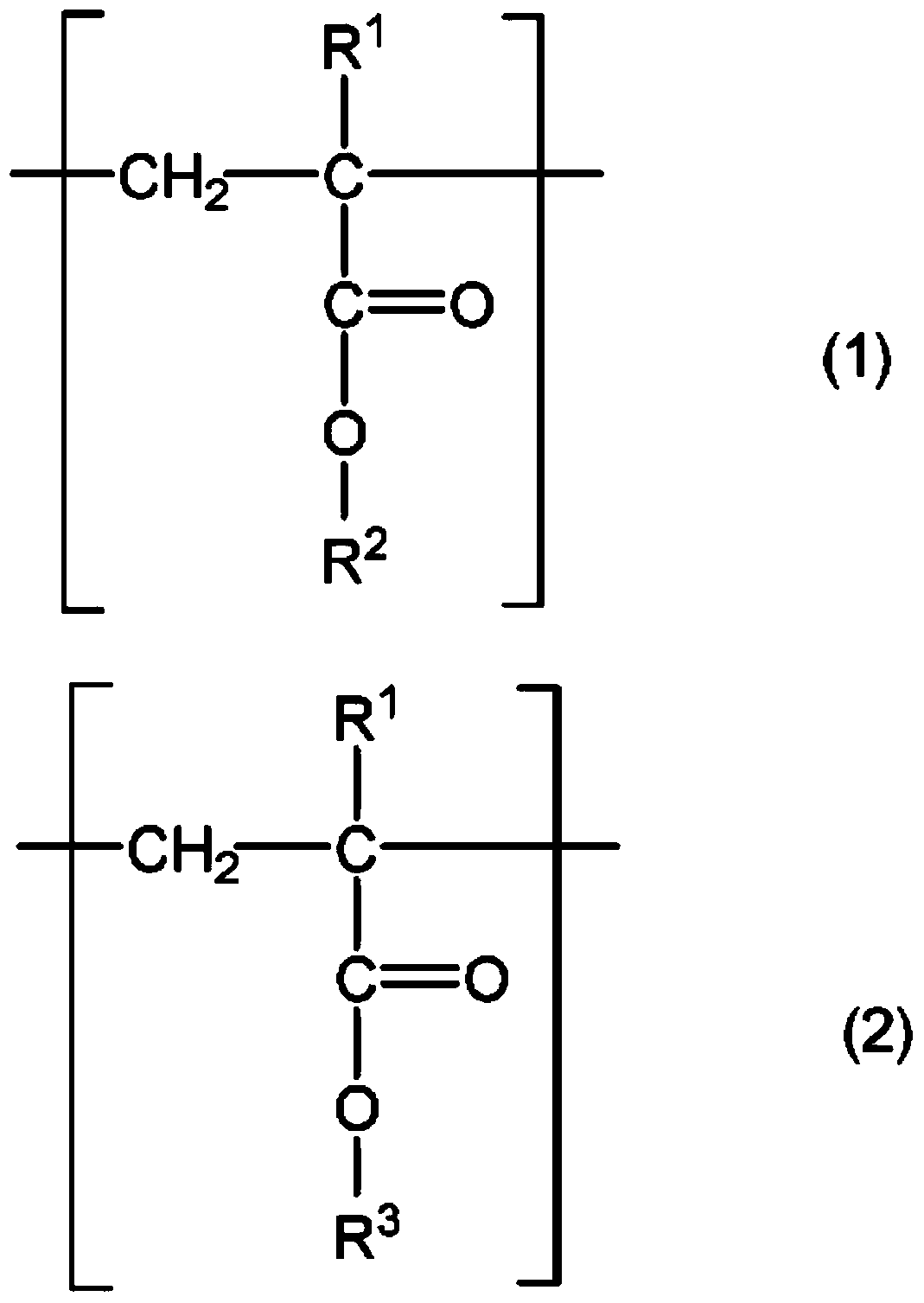

[0045]The poly(meth)acrylate-based viscosity index improver of the first embodiment has a core portion and three or more arm portions, and the arm portions are composed of a structural unit represented by the following general formula (1) and the following general formula A polymer chain of the structural unit shown in (2) is formed. The poly(meth)acrylate-based viscosity index improver has a weight-average molecular weight Mw (hereinafter, sometimes simply referred to as "Mw") of 100,000 or more, and the weight-average molecular weight Mw and the number-average molecular weight Mn (hereinafter, sometimes simply referred to as "Mn".) The ratio Mw / Mn (hereinafter, may be simply referred to as "Mw / Mn") is 1.6 or less.

[0046]

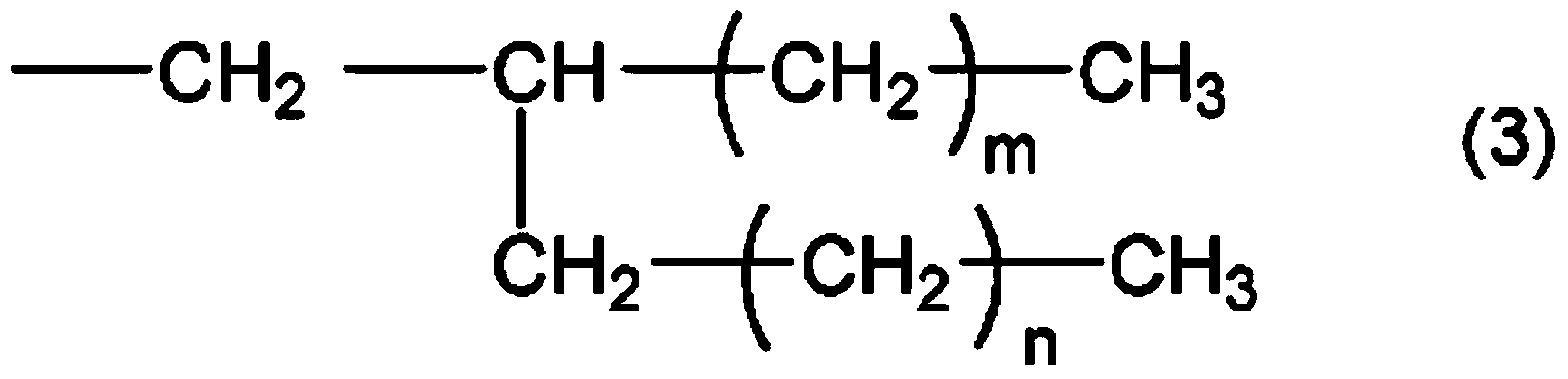

[0047] [In formula (1) and (2), R 1 represents hydrogen or methyl, R 2 represents a group represented by the following general formula (3), R 3 Represents an alkyl grou...

no. 2 approach

[0079] [Second Embodiment: Lubricating Oil Additive]

[0080] The lubricating oil additive according to the second embodiment of the present invention contains a poly(meth)acrylate viscosity index improver having a core portion and an arm portion comprising A polymer chain of the structural unit represented by the above general formula (1) and the structural unit represented by the above general formula (2) is formed and one end of the polymer chain is bonded to the core, and the poly(meth)acrylate viscosity index The weight average molecular weight Mw of the improver is 100,000 or more, and the ratio Mw / Mn of the weight average molecular weight Mw to the number average molecular weight Mn is 1.6 or less. It should be noted that the poly(meth)acrylate-based viscosity index improver in this embodiment is the same as the viscosity index improver in the above-mentioned first embodiment, and repeated descriptions are omitted here.

[0081] The lubricating oil additive may contain...

no. 3 approach

[0093] [Third Embodiment: Lubricating Oil Composition]

[0094] The lubricating oil composition of the third embodiment contains a lubricating oil base oil and a poly(meth)acrylate viscosity index improver. The poly(meth)acrylate viscosity index improver has the following formula (1) The structural units shown and the polymer chains of the structural units represented by the above general formula (2) are formed and the polymer chains are bonded to the core. The weight average of the poly(meth)acrylate viscosity index improver is The molecular weight Mw is 100,000 or more, and the ratio Mw / Mn of the weight average molecular weight Mw to the number average molecular weight Mn is 1.6 or less. Here, the lubricating oil composition of the present embodiment includes an embodiment including the lubricating oil base oil and the lubricating oil additive of the above-mentioned second embodiment. The poly(meth)acrylate-based viscosity index improver in this embodiment is the same as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com