Emulsion stabilizer for preventing excessive emulsification of ink

An emulsion stabilizer, ink technology, applied in ink, household appliances, applications, etc., can solve the problems of ink emulsion stabilization effect to be improved, single emulsifier composition, etc., to achieve excellent hydrophobic performance, improved leveling performance, good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

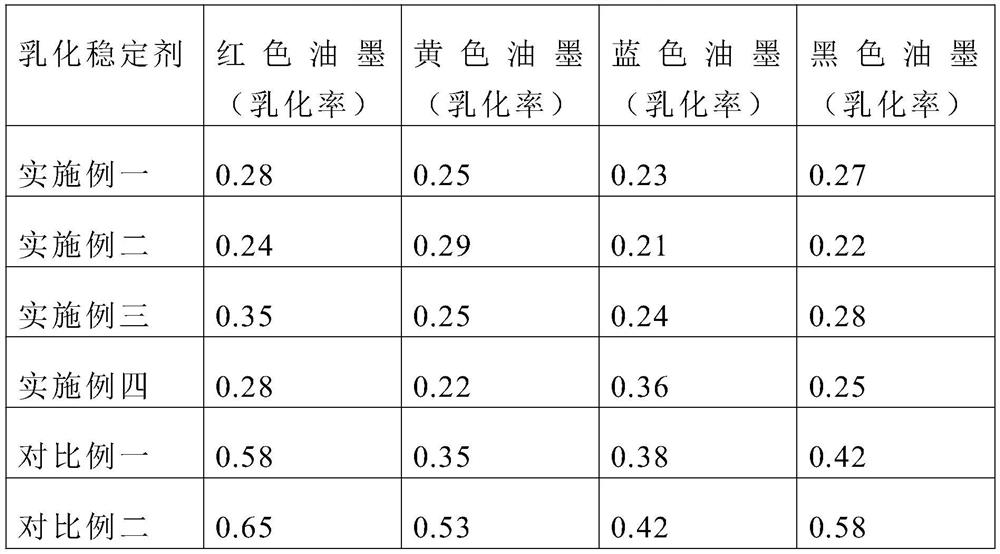

Examples

Embodiment 1

[0024] An emulsion stabilizer to prevent excessive emulsification of ink, composed of 20 parts by weight of polydimethylsiloxane, 20 parts by weight of (Z,Z)-polyethylene oxide polymethyl ethylene oxide dioleate, 10 parts It consists of parts by weight of lecithin and 50 parts by weight of polyglycerol-10 polyricinoleate.

[0025] Among them, the average molecular weight of polydimethylsiloxane (CAS No. 106214-84-0) is 1000-2000. The average molecular weight of (Z,Z)-polyethylene oxide polymethyl ethylene oxide dioleate (CAS No. 67167-17-3) is 4000-8000. The average molecular weight of polyglycerol-10 polyricinoleate (CAS No. 114355-43-0) is 5000-6000. Lecithin was purchased from Changzhou Yangsen Biotechnology Co., Ltd.'s mixed phospholipids.

Embodiment 2

[0027] An emulsion stabilizer to prevent excessive emulsification of ink, composed of 30 parts by weight polydimethylsiloxane, 15 parts by weight (Z,Z)-polyethylene oxide polymethyl ethylene oxide dioleate, 10 parts It consists of parts by weight of lecithin, 20 parts by weight of Span and 25 parts by weight of lauric acid monoglyceride.

[0028] Among them, the average molecular weight of polydimethylsiloxane (CAS No. 106214-84-0) is 1000-2000. The average molecular weight of (Z,Z)-polyethylene oxide polymethyl ethylene oxide dioleate (CAS No. 67167-17-3) is 4000-8000. Span is Span 80 (CAS No. 1338-43-8) purchased from Haian Petrochemical Plant in Jiangsu Province. Lauric acid monoglyceride (CAS No. 142-18-7) purchased from West Asia Reagent Lecithin was purchased from Changzhou Yangsen Biotechnology Co., Ltd.'s mixed phospholipids.

Embodiment 3

[0030] An emulsion stabilizer to prevent ink from overemulsification, composed of 40 parts by weight of asymmetrically substituted polyorganosiloxane derivatives, 10 parts by weight of lecithin, 20 parts by weight of Span, and 30 parts by weight of N,N-dimethylhexyl Amide composition.

[0031] Among them, the preparation method of the asymmetrically substituted polyorganosiloxane derivative adopts the method in the patent application document with the publication number CN108026279A. Span is Span 80 (CAS No. 1338-43-8) purchased from Haian Petrochemical Plant in Jiangsu Province. N,N-Dimethylhexanamide (CAS No. 5830-30-8) was purchased from Shanghai Yiji Industrial Co., Ltd. Phosphatidylcholine (CAS number 8002-43-5) is used as lecithin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com