Lightly coated craft paper and production method thereof

A production method, kraft cardboard technology, applied in the field of papermaking, can solve the problems that uniformity and openness affect the ink absorption effect, coating coverage and uniformity have a great impact, and affect the printing quality of coated paper, etc., to reduce bleaching Chemical dosage, increase market competitiveness, bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

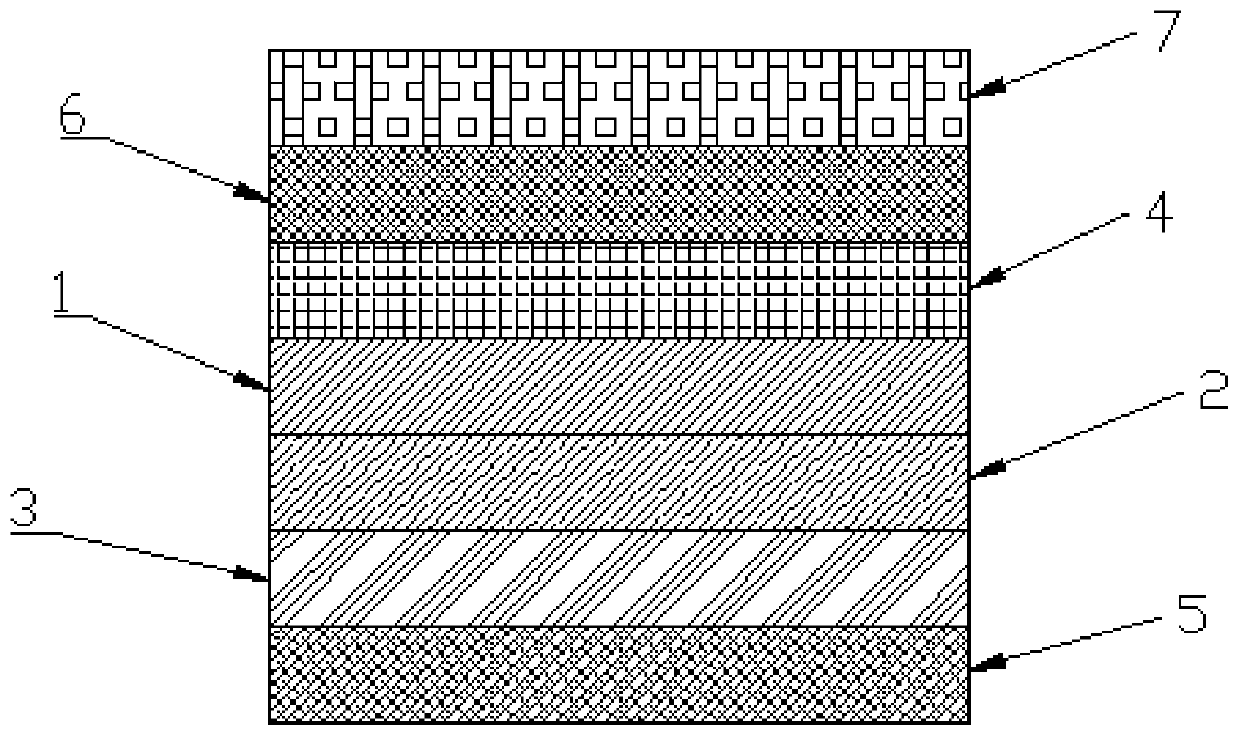

[0036] Such as figure 1 As shown, a light-coated kraft cardboard comprises a surface layer 1, a core layer 2 and a bottom layer 3, the core layer 2 is located between the surface layer 1 and the bottom layer 3, the upper side of the surface layer 1 is a positive surface sizing layer 4, and the bottom layer The lower side of 3 is the back surface sizing layer 5, the upper side of the front surface sizing layer 4 is the precoat coating layer 6, and the upper side of the precoat coating layer 6 is the top coating layer 7.

[0037] The production method of the above-mentioned light-coated kraft cardboard includes: preparing base paper, surface glue, coating and drying, wherein,

[0038] 1. Preparation of base paper: pulping, screening, purification, deinking, bleaching and beating of the pulp of the surface layer, core layer and bottom layer, and then sizing through the paper machine flow delivery system, dehydration and compounding at the wire part to obtain a dryness of 23% bas...

Embodiment 2

[0060] Such as figure 1 As shown, a light-coated kraft cardboard comprises a surface layer 1, a core layer 2 and a bottom layer 3, the core layer 2 is located between the surface layer 1 and the bottom layer 3, the upper side of the surface layer 1 is a positive surface sizing layer 4, and the bottom layer The lower side of 3 is the back surface sizing layer 5, the upper side of the front surface sizing layer 4 is the precoat coating layer 6, and the upper side of the precoat coating layer 6 is the top coating layer 7.

[0061] The production method of the above-mentioned light-coated kraft cardboard includes: preparing base paper, surface glue, coating and drying, wherein,

[0062] 1. Preparation of base paper: pulping, screening, purification, deinking, bleaching and beating of the pulp of the surface layer, core layer and bottom layer, and then sizing through the paper machine flow delivery system, dehydration and compounding at the wire part to obtain a dryness of 20% bas...

Embodiment 3

[0083] Such as figure 1 As shown, a light-coated kraft cardboard comprises a surface layer 1, a core layer 2 and a bottom layer 3, the core layer 2 is located between the surface layer 1 and the bottom layer 3, the upper side of the surface layer 1 is a positive surface sizing layer 4, and the bottom layer The lower side of 3 is the back surface sizing layer 5, the upper side of the front surface sizing layer 4 is the precoat coating layer 6, and the upper side of the precoat coating layer 6 is the top coating layer 7.

[0084] The production method of the above-mentioned light-coated kraft cardboard includes: preparing base paper, surface glue, coating and drying, wherein,

[0085] 1. Preparation of base paper: pulping, screening, purification, deinking, bleaching and beating of the pulp of the surface layer, core layer and bottom layer, and then sizing through the paper machine flow delivery system, dehydration and compounding at the wire part to obtain a dryness of 25% bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com