Lubricating-oil viscosity index improver and preparation method thereof

A technology for improving viscosity index and lubricating oil, used in lubricating compositions, additives, petroleum industry, etc., can solve the problems of narrow molecular weight distribution, poor low temperature fluidity, low viscosity index, etc., and achieve high shear stability and oxidation resistance. Increase, the effect of excellent low temperature fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add 3000ml of pure cyclohexane (water value2 o 2 Oxidize the glue, stir and react for 30 minutes, then wash with 50mL citric acid, centrifuge, stand still, separate the water to remove the heavy metal ions in the glue, and condense the water vapor of the glue after removing the metal ions to obtain the viscosity index of lubricating oil Improver.

[0042] Add lubricating oil viscosity index improver to 150SN neutral wax-based lubricating oil at a mass fraction of 1%, test its kinematic viscosity at 40°C and 100°C with an automatic capillary viscometer, and measure it with a diesel nozzle shear stability index meter The shear stability index (SSI) of oil products, and the pour point of petroleum products are measured with a pour point apparatus for freezing point.

[0043] The test results are as follows:

[0044] GPC analysis results: the number average molecular weight of the polymer is 138,000, and the molecular weight distribution is 1.06;

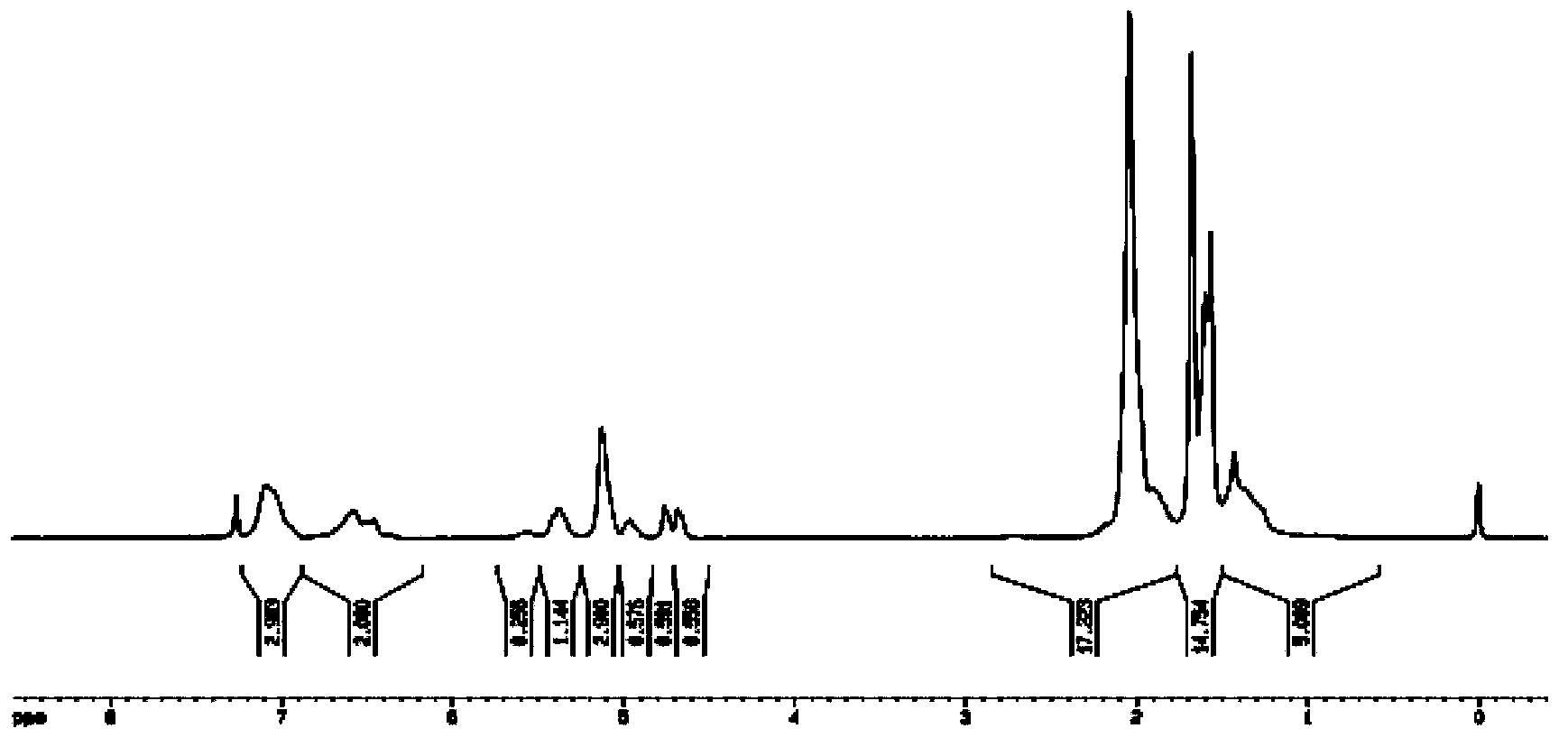

[0045] HNMR analysis r...

Embodiment 2

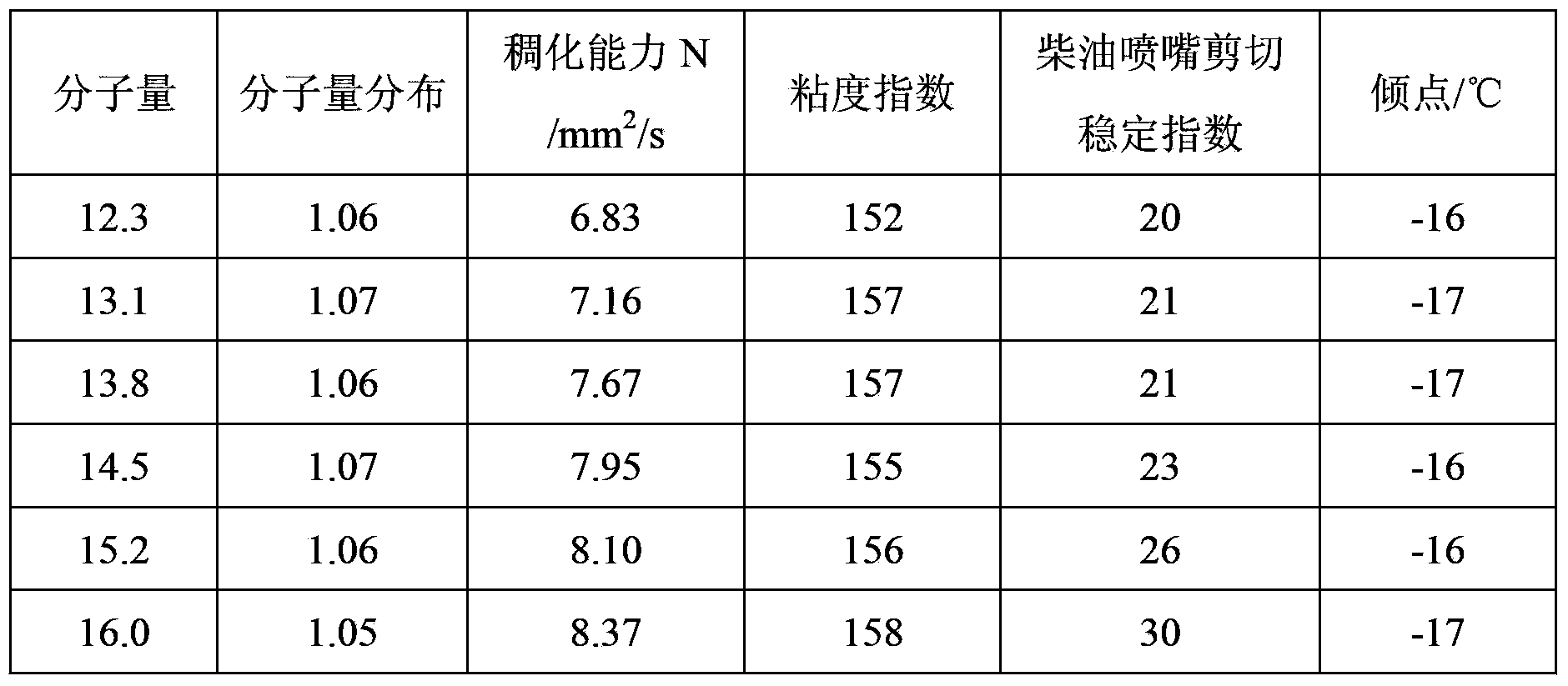

[0066] The preparation process is the same as that in Example 1, and the addition amount of initiator n-butyllithium is changed to synthesize viscosity index modifiers with different molecular weights, which are used for the modification of lubricating oil. The experimental results are shown in Table 1:

[0067] Table 1 Performance Test Results of Viscosity Index Improvers Modified Lubricating Oils with Different Molecular Weights

[0068]

Embodiment 3

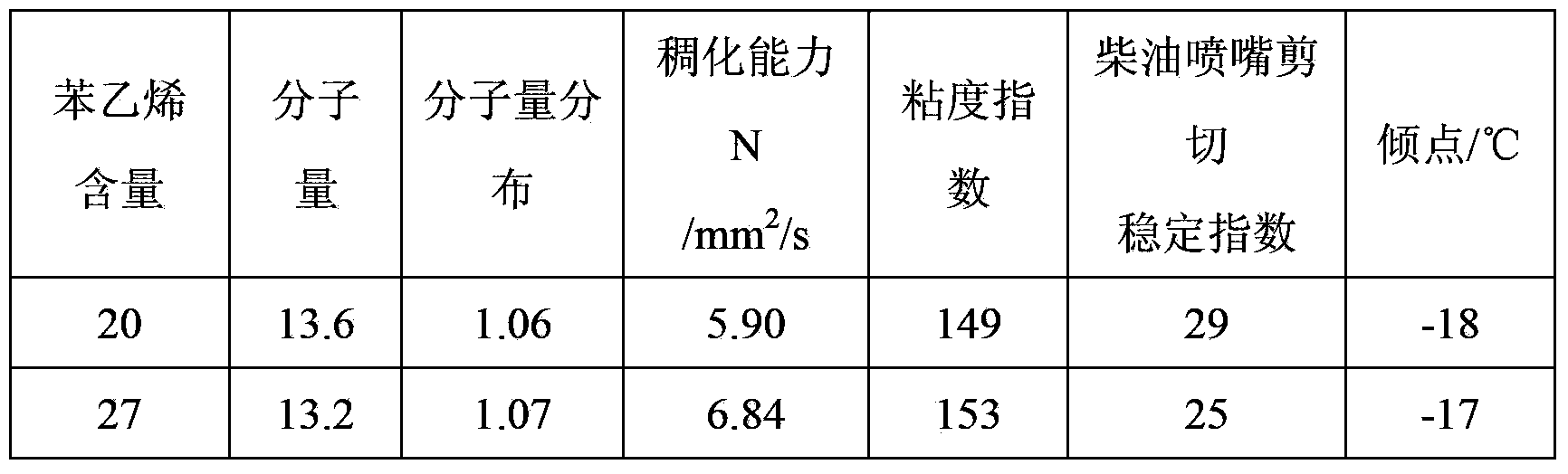

[0070] The preparation process is the same as in Example 1, changing the ratio of diene and styrene to synthesize viscosity index modifiers with different styrene contents, which are used to modify lubricating oil. The experimental results are shown in Table 3:

[0071] Table 3 Performance Test Results of Viscosity Index Improver Modified Lubricating Oils with Different Styrene Contents

[0072]

[0073]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com