Catalytic conversion method for producing high-cetane number light diesel oil

A technology for the production of high hexadecane and a catalytic conversion method, which is used in catalytic cracking, cracking, petroleum industry, etc., can solve the problem of high cost, and achieve the effects of reduced crushing tendency, uniform temperature distribution, and reduced catalyst content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

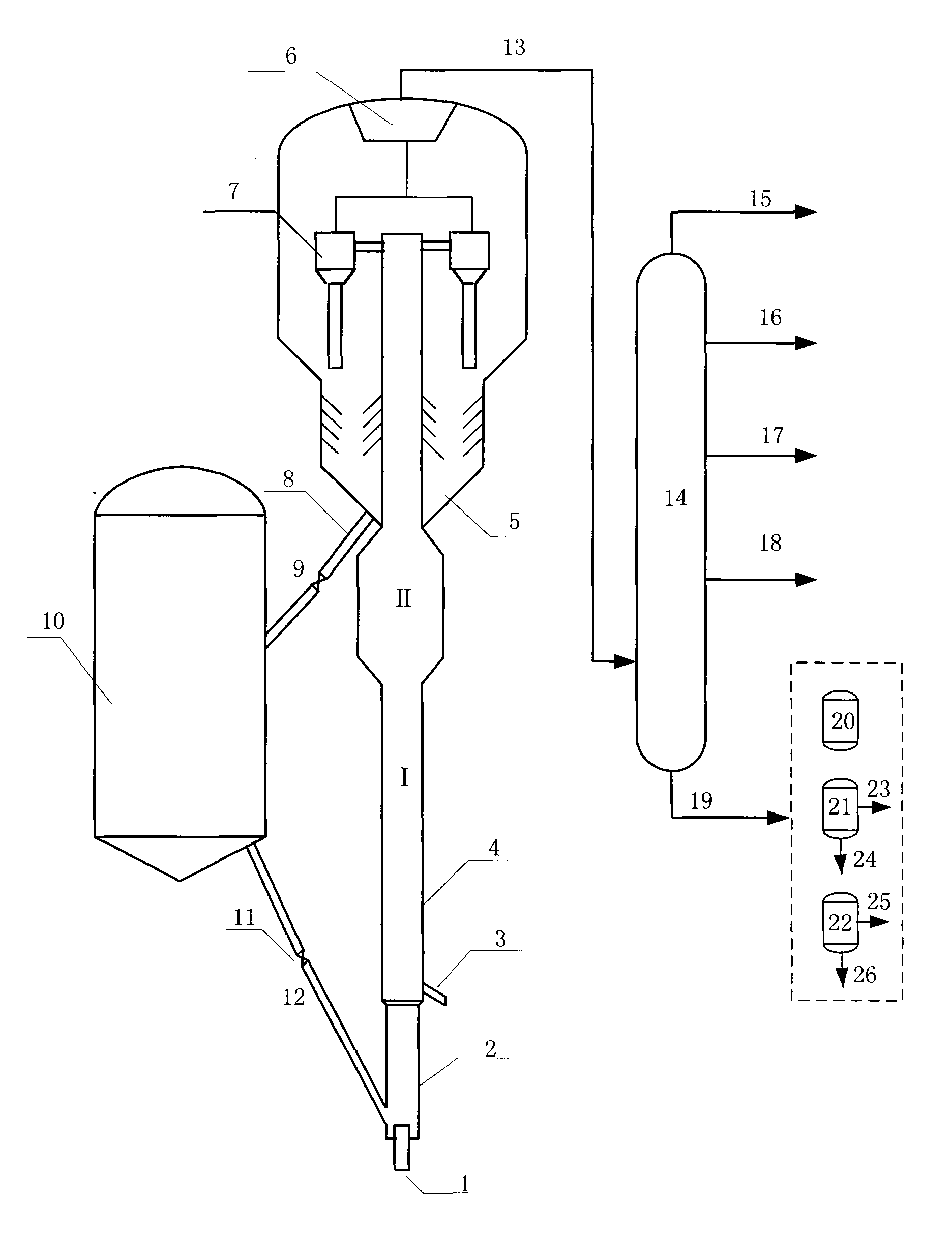

[0044] This example illustrates the production of high-quality light diesel oil by selective cracking reaction using the method provided by the present invention.

[0045] The flow chart of the medium-sized catalytic cracking unit is shown in the attached figure. The feedstock oil is injected into the reaction zone I of the riser reactor through the pipeline 3, and it contacts and reacts with the catalyst A-1 lifted by water vapor at the lower part of the riser reactor. The weight ratio of the catalyst A-1 to the raw oil in the tube reactor is 2:1, the residence time of the raw oil in the riser reactor is 2.6 seconds, and the reaction temperature is 480°C. The pressure of the gas collection chamber is 0.2 MPa. After the oil and gas come out of the riser, they are separated by the cyclone separator and then enter the rear fractionation system. The spent catalyst with carbon enters the stripping section, and the spent catalyst after stripping goes to the regenerator for regenera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com