Catalytic conversion method capable of improving product distribution

A catalytic conversion method and product technology, which can be used in the petroleum industry, hydrocarbon oil treatment, etc., and can solve the problems of poor selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] This example illustrates the situation of improving product distribution in a medium-sized variable-diameter riser reactor by adopting the method provided by the present invention and using catalysts with coarse particle size distribution at different activity levels.

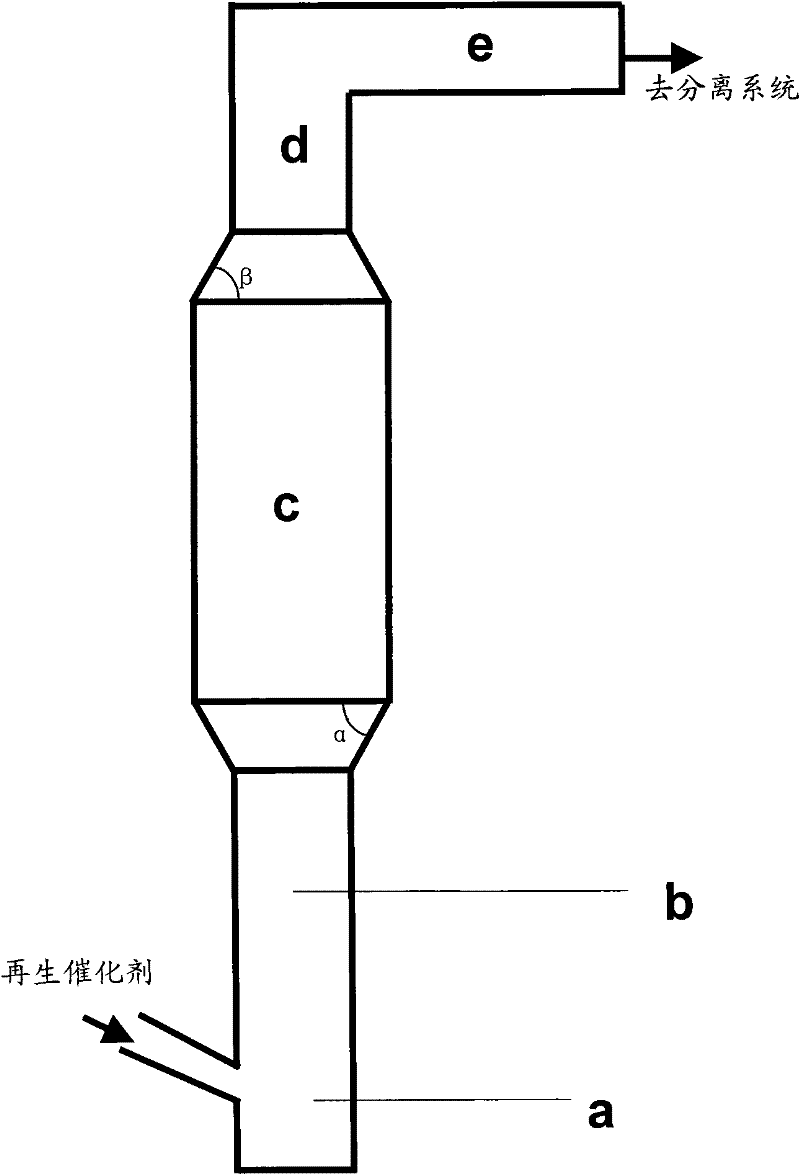

[0074] The total height of the pre-lift section, the first reaction zone, the second reaction zone and the outlet zone of the reactor is 15 meters, the diameter of the pre-lift section is 0.025 meters, and its height is 1.5 meters; the diameter of the first reaction zone is 0.025 meters, and its height It is 4 meters; the diameter of the second reaction zone is 0.1 meters, and its height is 6.5 meters; the diameter of the outlet zone is 0.025 meters, and its height is 3 meters; is 45°; the base angle of the isosceles trapezoid in the longitudinal section of the junction of the second reaction zone and the outlet zone is 60°.

[0075] The raw material oil A listed in the preheated table 1 enters in this r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com