Catalytic conversion reactor for heavy oil and method for preparing propylene through catalytic cracking of heavy oil

A conversion reactor and heavy oil catalysis technology, applied in chemical instruments and methods, catalytic cracking, hydrocarbon cracking, hydrocarbon production, etc., can solve the problem of catalyst density reduction and propylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

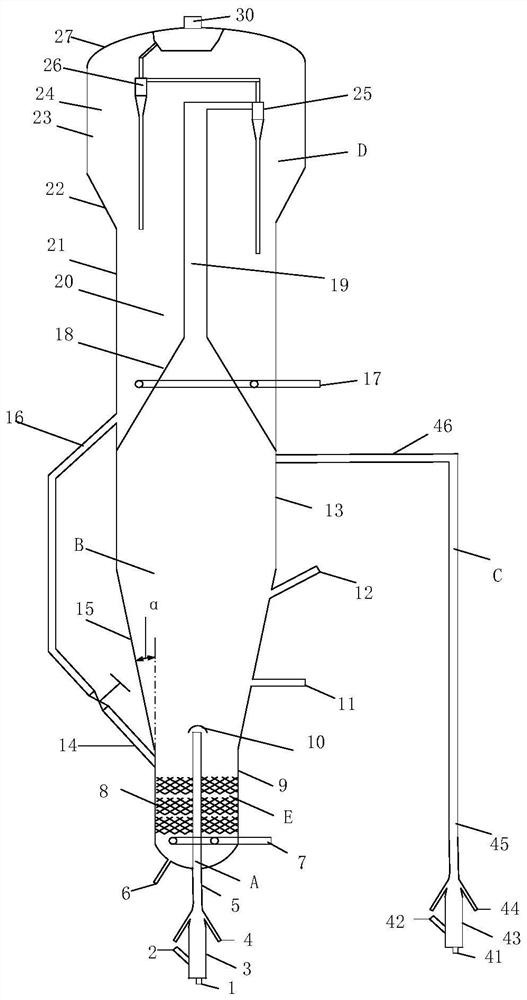

[0129] Example 1 shows that the second reaction zone of the present invention adopts a structure containing a diameter-expanding section, which is beneficial to the production of propylene by catalytic cracking of heavy oil.

[0130] The reactor uses figure 1 The reactor structure shown. The first reaction zone and the third reaction zone are riser structures, the diameter of the first reaction zone is 1.2m, and the height-diameter ratio is 6.7; the pipe diameter of the third reaction zone is 0.8m, and the height-diameter ratio is 20; the first reaction zone The ratio of the diameter of the catalyst pre-lifting section of the zone and the third reaction zone to the diameter of the equal-diameter section of the riser is 1.3, and there are 6 nozzles.

[0131] The second reaction zone B is formed by an enlarged diameter section 15 and an equal-diameter cylinder 13 above. The structural size is that the diameter of the cylinder 13 is 4.2 m and the height is 1 m, and the diameter ...

Embodiment 2

[0142] Example 2 is used to illustrate that feeding a chiller into the transfer pipe after the reaction helps reduce the secondary conversion of propylene.

[0143] Embodiment 2 reactor adopts figure 1 The reactor structure shown differs from the reactor in Example 1 in that: a chiller feed distributor is provided in the inlet section of the delivery pipe 19 to connect with the chiller feed for feeding the chiller. The product of heavy oil cracking—gasoline fraction is used as the chiller, and the temperature at the outlet of feed pipe 19 is controlled to be 530°C. The bed temperature in the stripping zone is controlled at 520°C.

[0144] The product distribution is listed in Table 2.

Embodiment 3

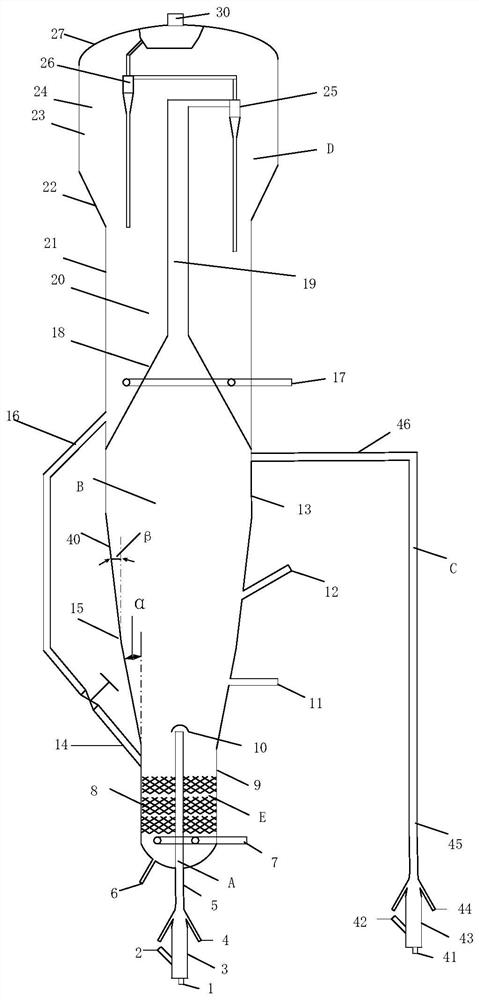

[0146] Example 3 is used to illustrate the reactor structure type in which the second reaction zone adopts multiple diameter-expanding sections.

[0147] Embodiment 3 reactor adopts figure 2 In the reactor structure shown, the total height of the second reaction zone remains unchanged, and the original diameter-expanding section is changed into two diameter-expanding sections, and the expansion angles a and b of the two diameter-expanding sections are 16° to 13°, respectively.

[0148] Other structural parameters and operating conditions are the same as in Example 1.

[0149] The product distribution is listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com