A kind of separation method of slurry bed Fischer-Tropsch synthesis heavy product and catalyst

A Fischer-Tropsch synthesis, slurry bed technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of too much catalyst carry-out, fine particle catalyst is not easy to settle, etc., to achieve easy implementation, long backwash interval , the effect of high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

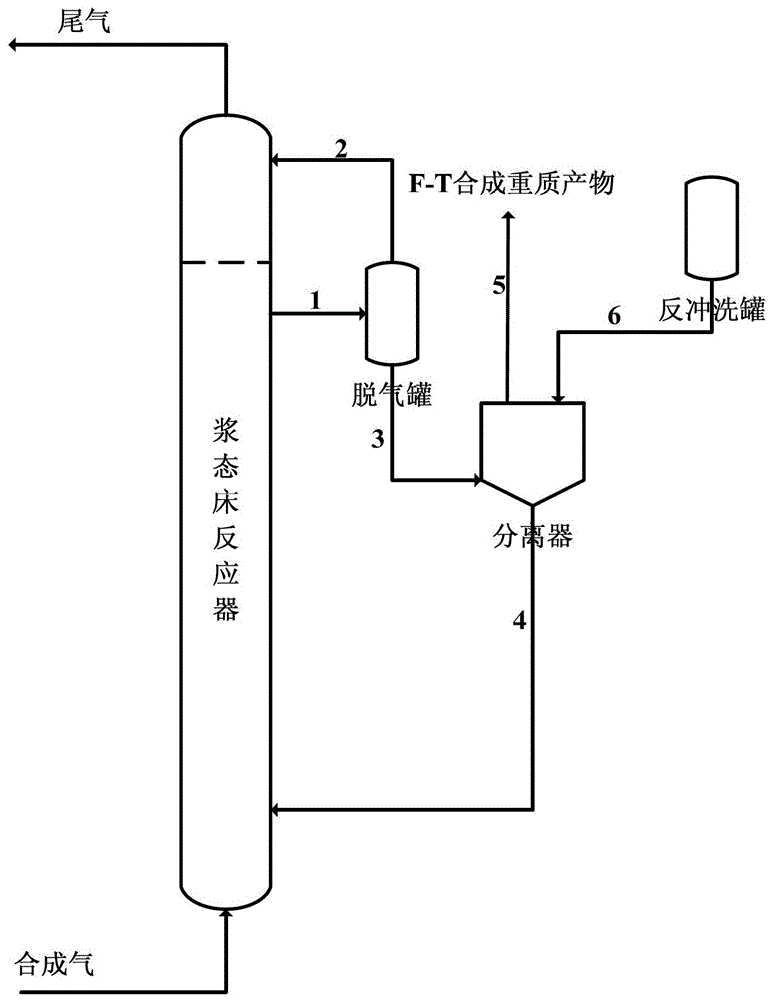

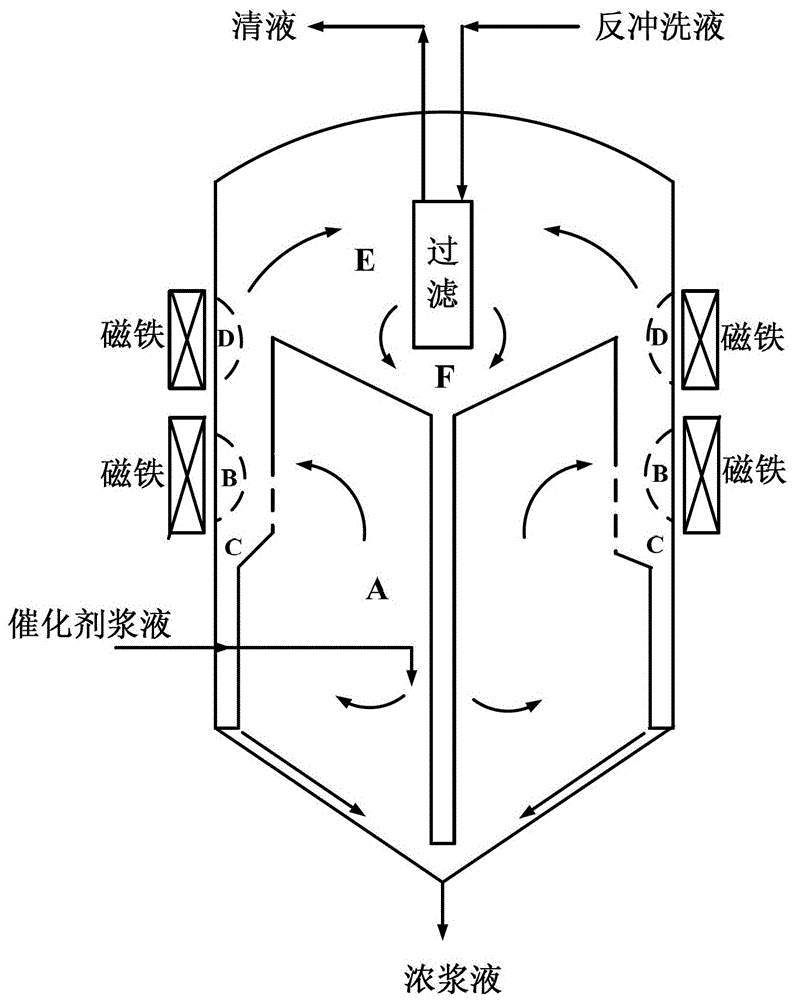

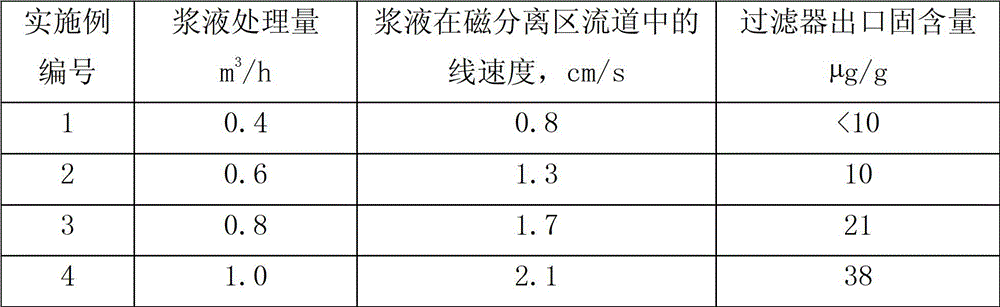

[0028] Embodiment 1-4 flow process is as figure 1 As shown, the structure of the sedimentation / magnetic separator used is as follows figure 2 As shown, the inner diameter of the sedimentation / magnetic separator is 0.6 meters, and two sets of electromagnets are used to achieve magnetic separation. The rinse interval is 30 minutes. The catalyst used is an alumina-supported cobalt-based Fischer-Tropsch synthesis catalyst with a cobalt content of 20% (mass) and an average particle size of 50 microns. The catalyst concentration in the catalyst slurry drawn from the reactor is 26% (mass). From bottom to top, the first electromagnet has a power-on time of 100 seconds and a power-off time of 10 seconds. The power-on time and power-off time are alternately performed; Carry out; the operation mode of the upper and lower electromagnets is: when the lower electromagnet is energized, the upper layer is powered off, and when the lower layer is powered off, the upper layer is powered on. ...

Embodiment 5-7

[0032] Embodiment 5-7 process such as figure 1 As shown, the structure of the sedimentation / magnetic separator used is as follows figure 2 As shown, the inner diameter of the sedimentation / magnetic separator is 0.6 meters, and two sets of electromagnets are used to realize the magnetic separation. The rinse interval is 30 minutes. The catalyst used is a Raney iron catalyst with an iron content of 75% (mass) and an average particle size of 45 microns. The catalyst concentration in the catalyst slurry drawn from the reactor is 32% (mass). From bottom to top, the first electromagnet has a power-on time of 60 seconds and a power-off time of 10 seconds. The power-on time and power-off time are alternately performed; Carry out; the operation mode of the upper and lower electromagnets is: when the lower electromagnet is de-energized, the upper electromagnet is energized. See Table 2 for the slurry treatment capacity and the solid content in the liquid after separation.

[0033] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com