Processing device

A processing device and non-processing technology, which is applied in transportation and packaging, gaseous chemical plating, coating, etc., can solve problems such as undocumented, achieve the effect of inhibiting peeling and improving in-plane uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

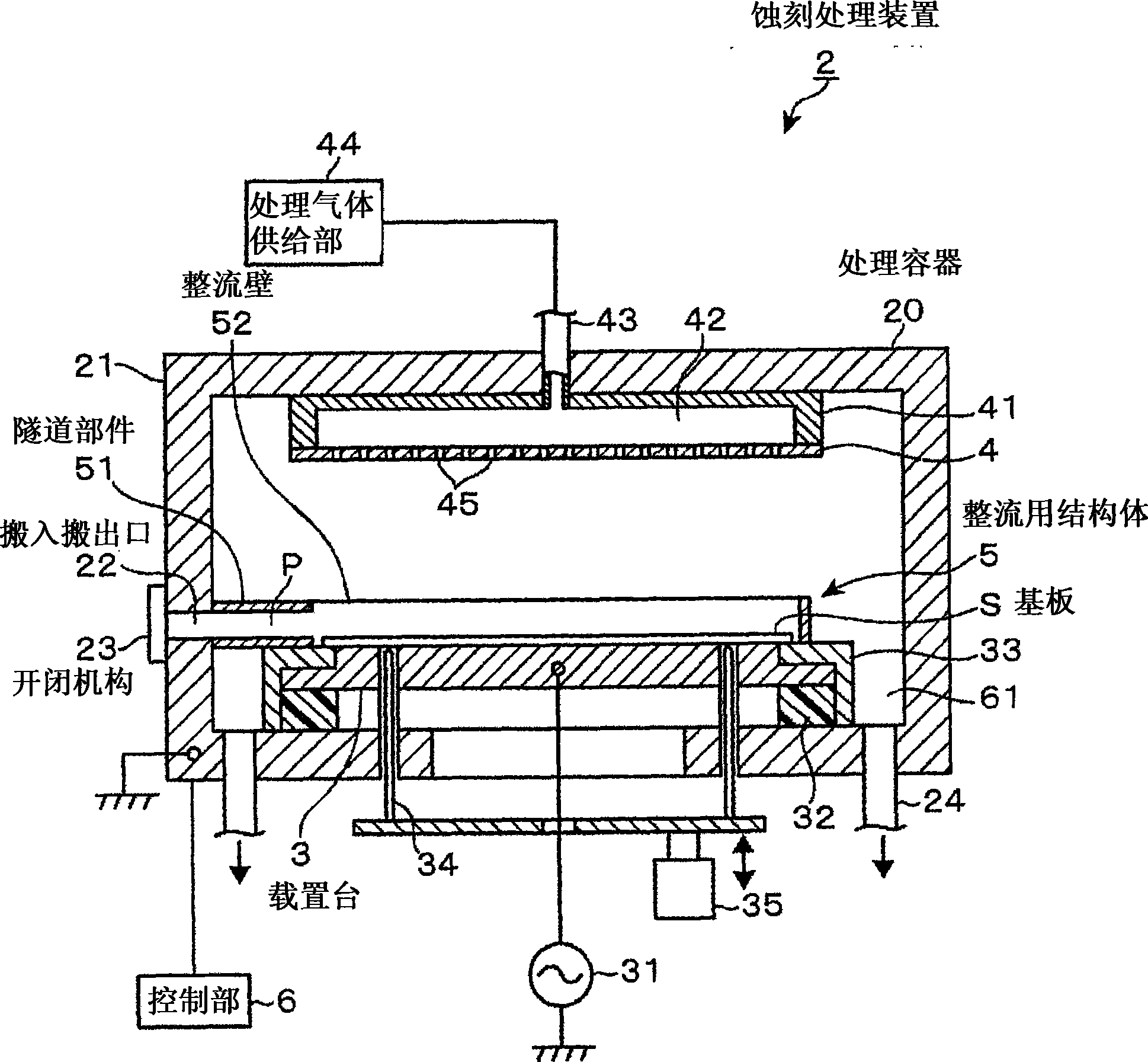

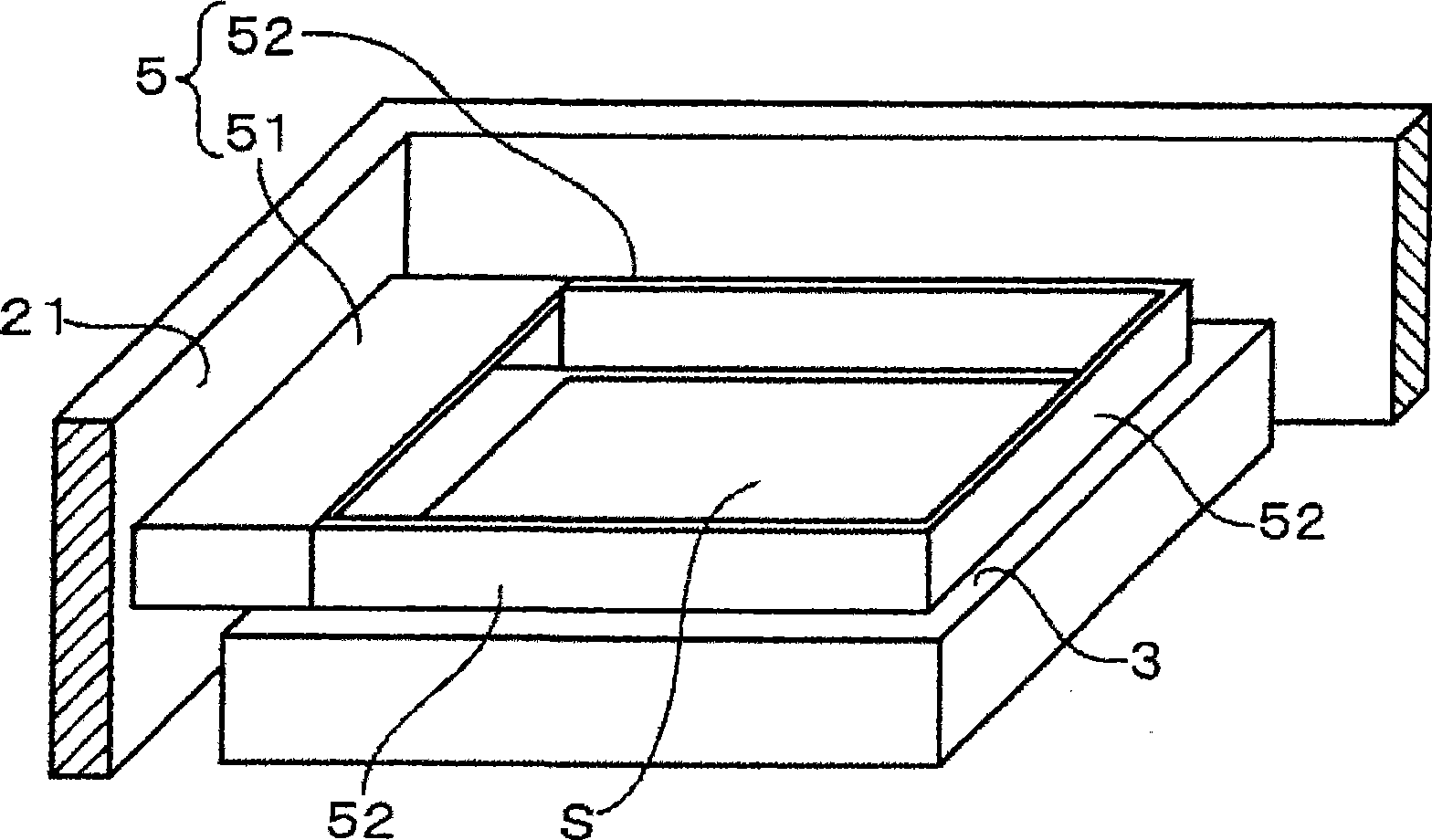

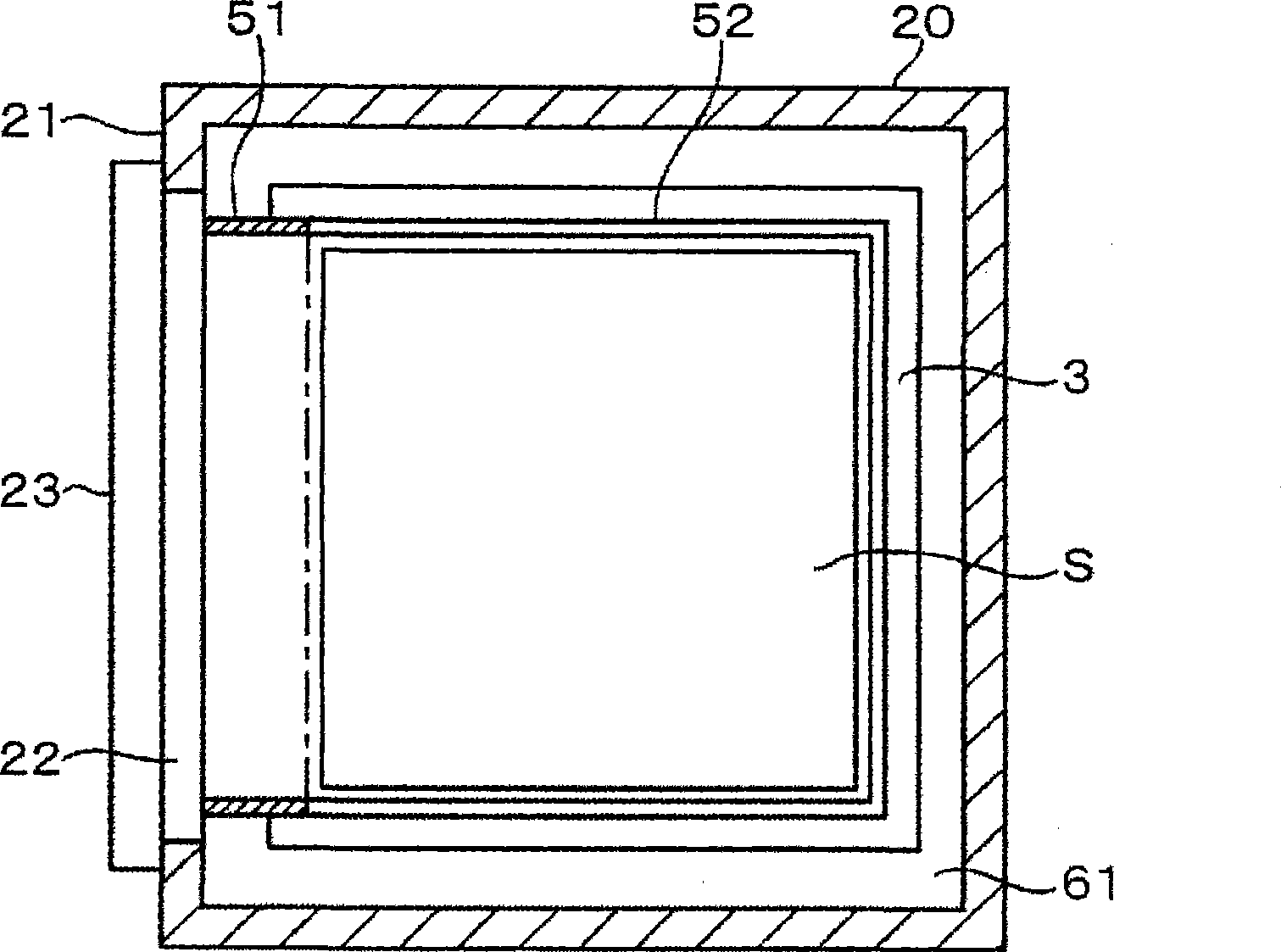

[0097] Hereinafter, examples performed to confirm the effects of the present invention will be described. In the following experiments, use figure 1 The etching processing apparatus shown performs etching processing on a substrate S on which a Ti film and an Al film are stacked on the surface using the following structures as rectification structures: Figure 8 The shown structure (embodiment 1) using the tunnel member 51 and the cylindrical member 73, Figure 10 In the shown structure using the tunnel member 51 and the cylindrical member 73 provided with the non-processing gas supply part 8 (Example 2), the structure without a rectifying structure (Comparative Example 1), and then the inside of the substrate S The etching rate at this time was measured at 22 positions, and the in-plane uniformity of the etching rate was calculated by (maximum value-minimum value) / (maximum value+minimum value). Here, the above maximum value represents the maximum value of the etching rate, ...

Embodiment 1

[0104] Example 1: ±16.5%

Embodiment 2

[0105] Example 2: ±10.1%

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com