Movable type seal splicing assembly

A seal and movable type technology, which is applied in the field of movable type seal splicing components, can solve the problems of high processing cost, high size and precision requirements, low degree of freedom, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

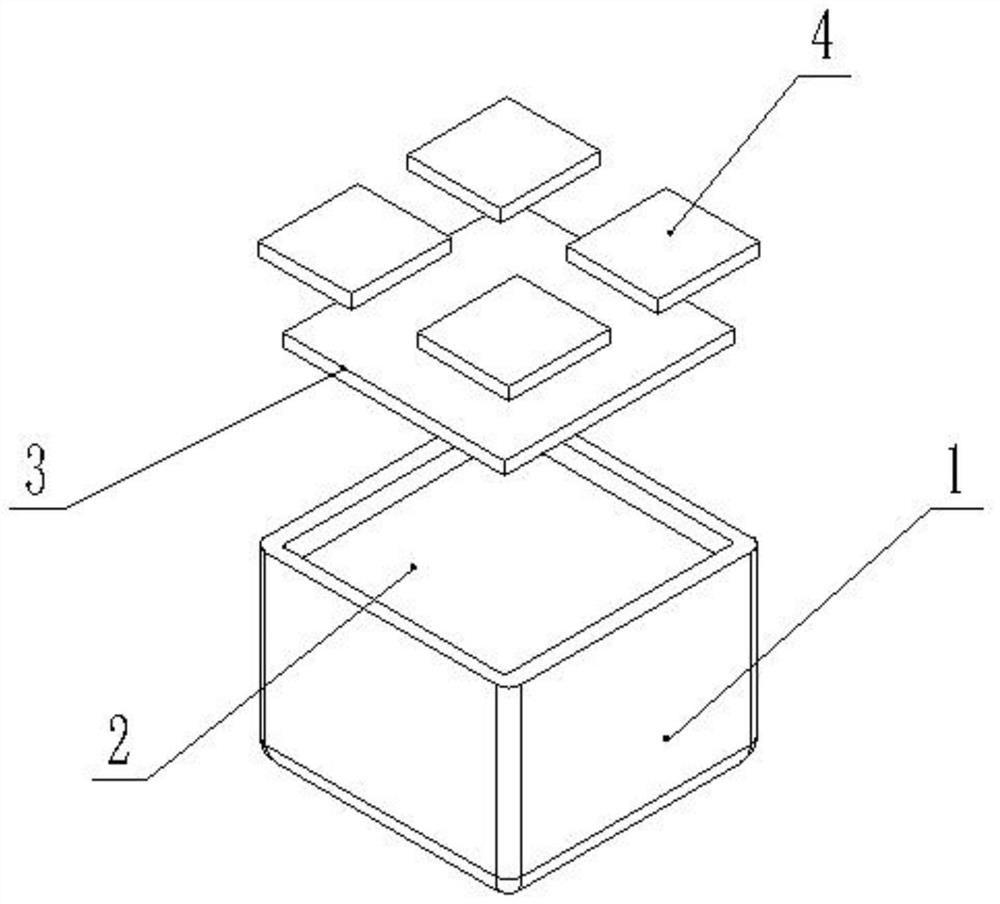

[0019] see figure 1 , in the embodiment of the present invention, a movable type seal splicing assembly includes a seal shell 1, a sticker 3 and stamp characters 4, and a groove is provided on the side of the seal shell 1 close to the sticker 3, so that The self-adhesive 3 is adhered in the groove, and the length and width of the self-adhesive 3 are adapted to the size of the stamp groove 2, so that when the self-adhesive 3 is adhered to the stamp groove 2, it is not necessary to The dry glue 3 will not move in the stamp groove 2, and the stamp characters 4 are set on the side of the sticker 3 away from the stamp groove 2. The stamp characters 4 can be prepared in advance according to the needs of multiple groups of different types of characters or pattern, stick the stamp characters 4 on the sticker 3 according to a certain arrangement, and then dip the stamp characters 4 with inkpad to complete the function of the stamp.

[0020] see figure 1 , the seal character 4 and the...

Embodiment 2

[0024] see figure 1 , in the embodiment of the present invention, the seal groove 2 can be made of wood or metal, and different materials can be selected according to personal preferences and actual needs. It is circular or other shapes, and according to the shape of the actual required stamp, the shapes of the stamp housing 1, the stamp groove 2 and the stamp characters 4 are determined. One side of the stamp characters 4 is engraved with patterns or words, and in addition One side is flat to facilitate adhesion with the self-adhesive 3.

[0025] see figure 1 , the seal character 4 is adhered to the sticker 3 through the sticker 3 when in use, while ensuring the same stamping effect, there is no need for an overly precise combination structure, which can greatly reduce the production of movable type combined seals cost.

[0026] see figure 1 , when the sticker 3 and the stamp characters are in use, you can also stick the sticker 3 to the bottom of the rest of the stamps, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com