Side body rear supporting column inner plate dividing structure

A block structure, rear pillar technology, applied in the superstructure, superstructure sub-assembly, transportation and packaging, etc., can solve the problems of easy cracking, large drawing depth, and difficulty in stamping and forming in the stamping process. Rigidity, improved connection strength, enhanced torsional stiffness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

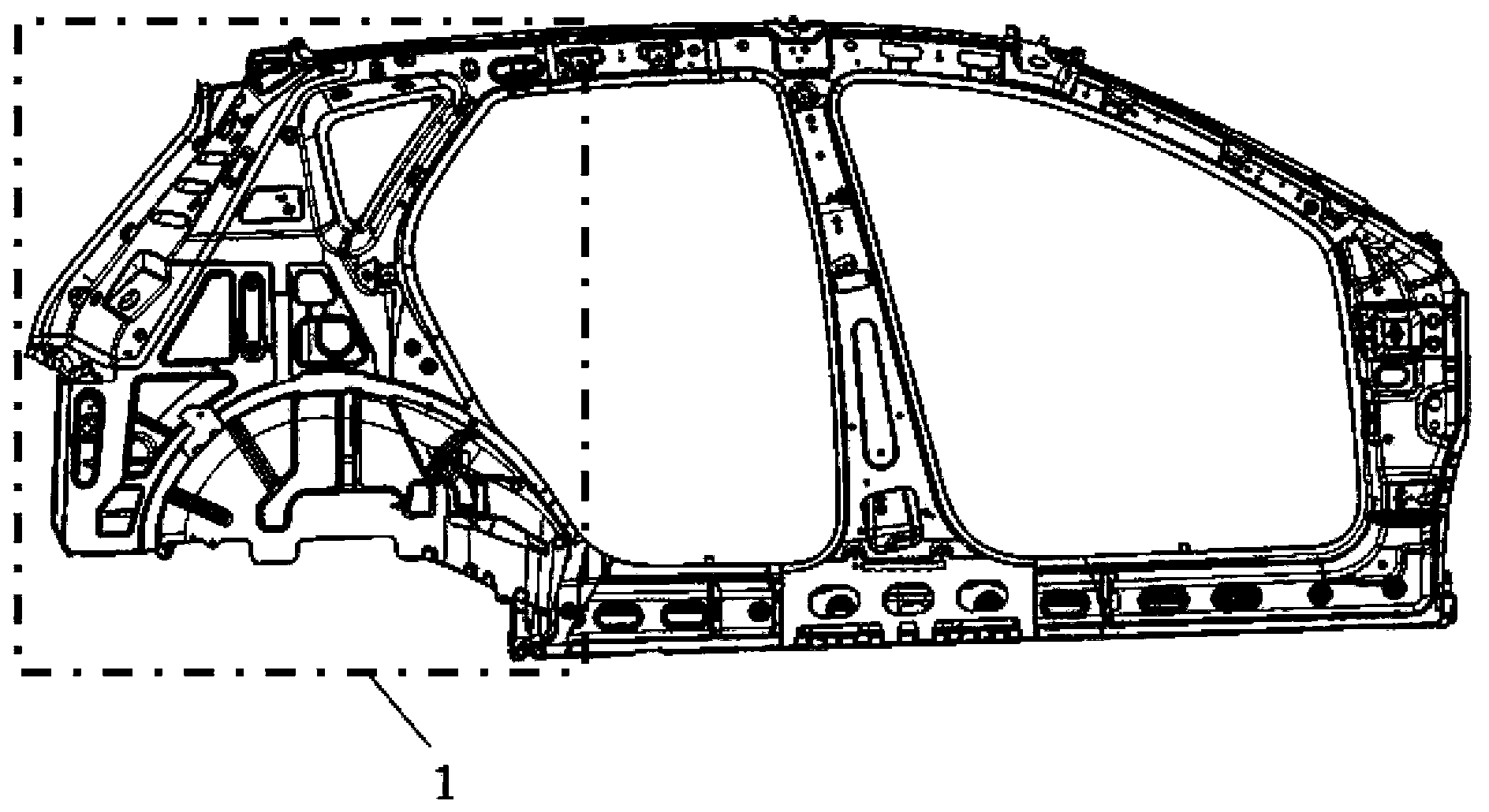

[0017] Such as figure 1 As shown, the area range of the rear pillar inner panel 2 on the side wall welding assembly.

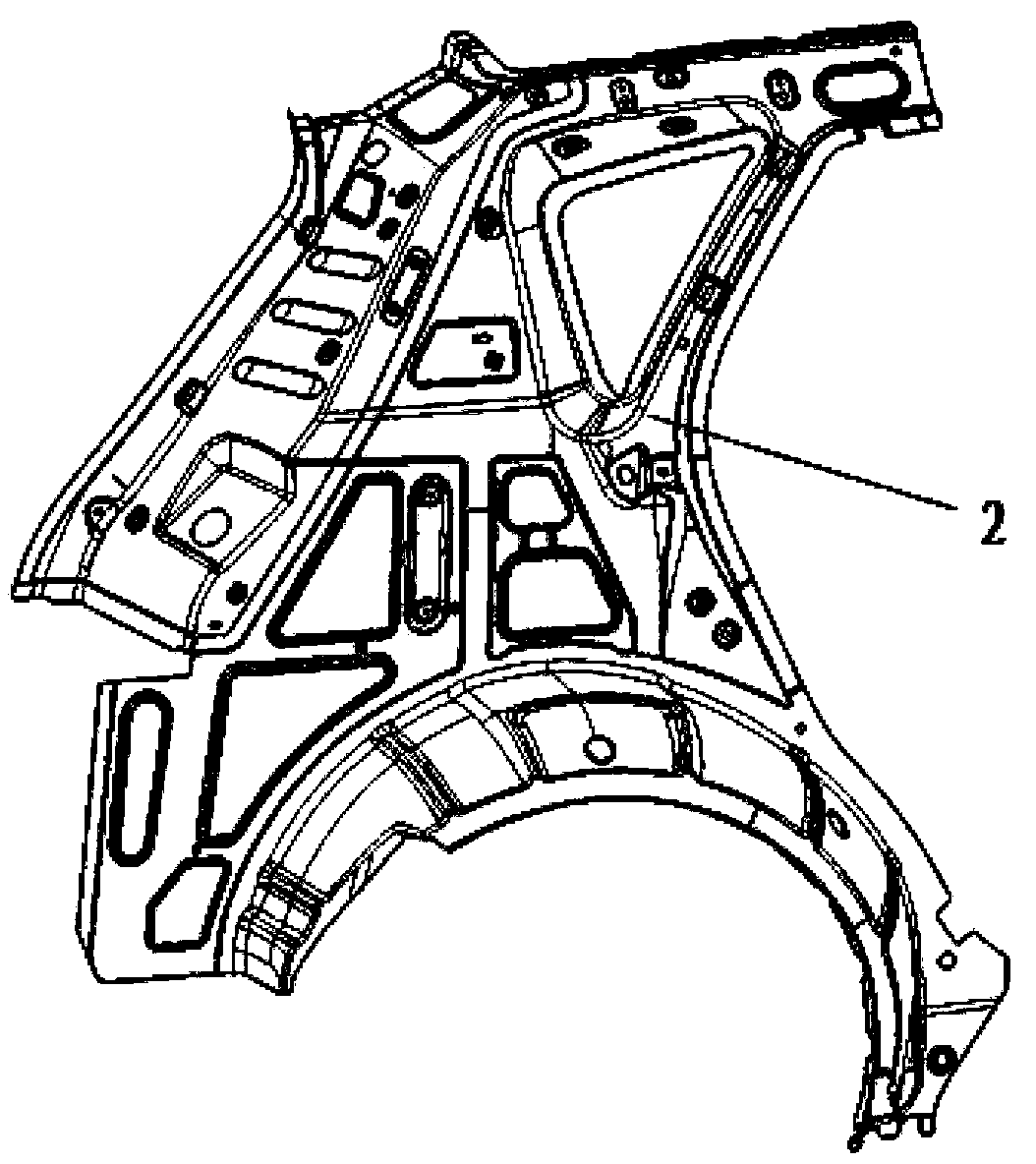

[0018] Such as figure 2 As shown, the structural shape of the rear pillar inner panel 2 of the side wall before it is divided into blocks is a large and complicated piece with a large drawing depth and negative angles, and it is easy to break during drawing.

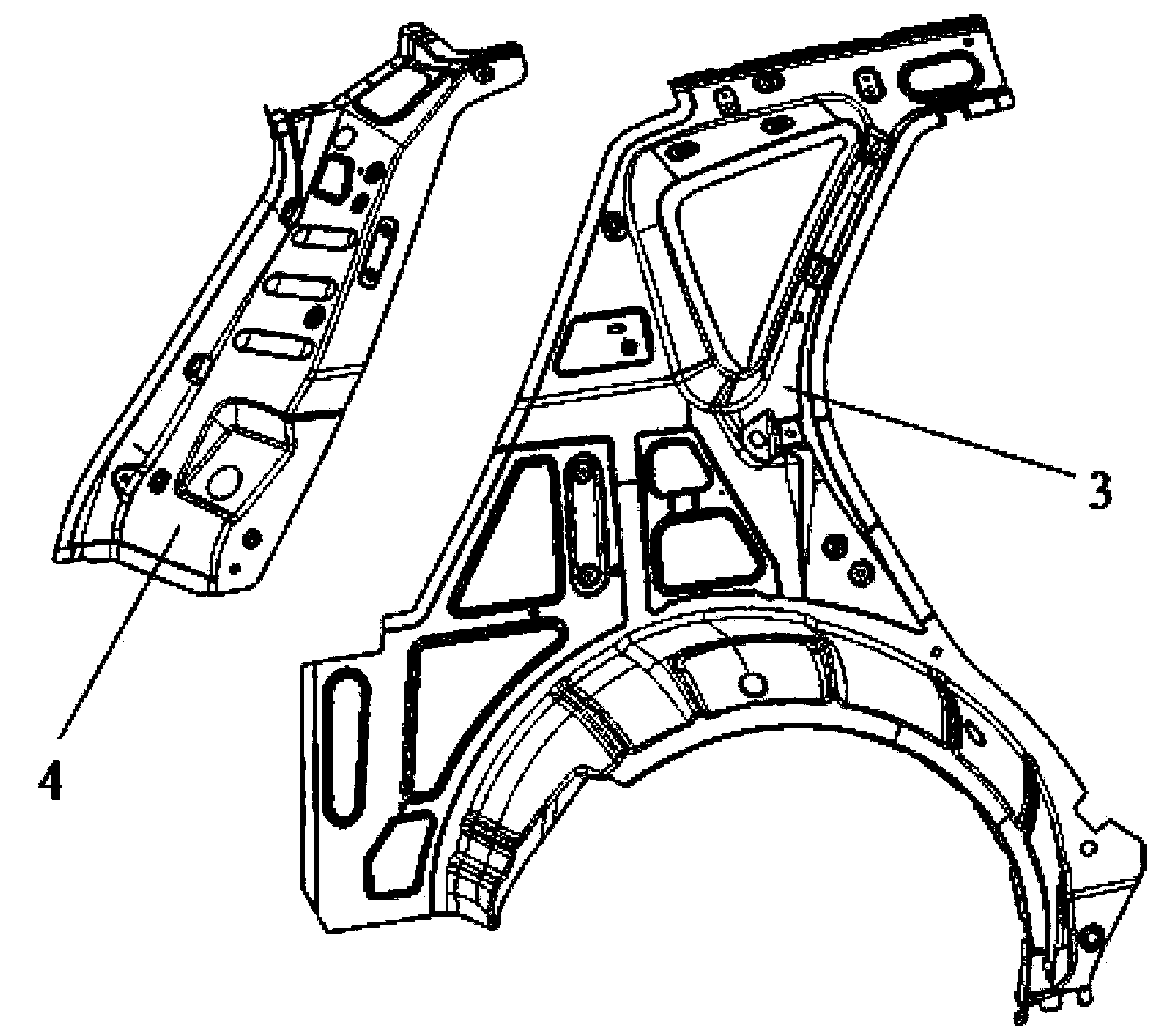

[0019] Such as image 3 As shown, the present invention includes rear pillar inner panel 2, and rear pillar inner panel 2 is divided into rear pillar inner panel body 3 and rear pillar inner panel gusset 4 at a place approximately parallel to the back door stop of the vehicle body. Figure 7 As shown in -8, the rear pillar inner panel body 3 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com