Automatic production equipment for stamping, drawing and flanging middle part of workpiece

A production equipment, stamping and stretching technology, applied in the field of workpiece stamping, can solve the problems of large amount of stamping and stretching oil, cracks at flanging, low efficiency, etc., and achieve the effects of high processing efficiency, high production and processing efficiency, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]In order to make the objectives and advantages of the present invention clearer, the present invention will be specifically described below in conjunction with embodiments. It should be understood that the following text is only used to describe one or several specific embodiments of the present invention, and does not strictly limit the protection scope of the specific claim of the present invention.

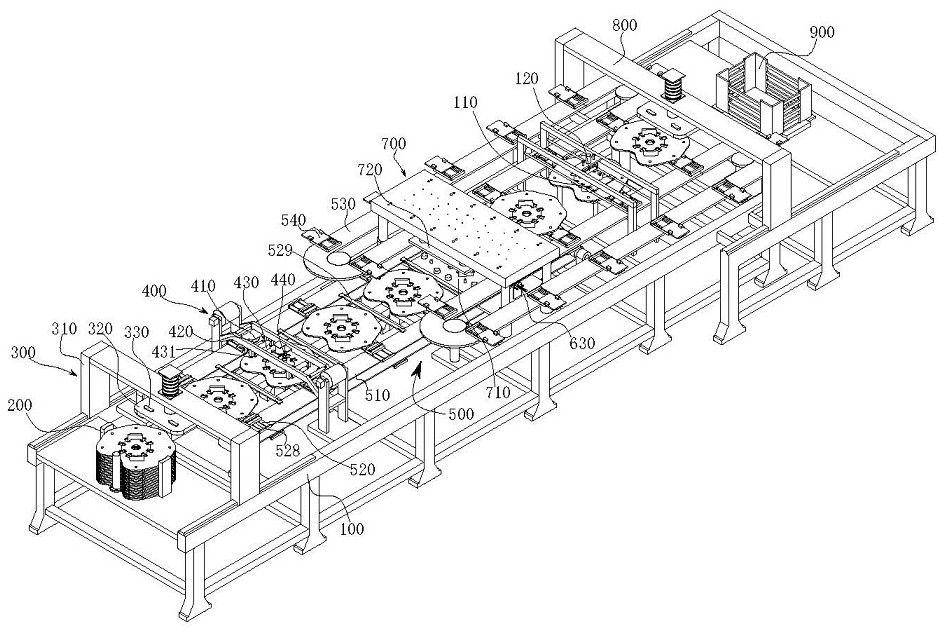

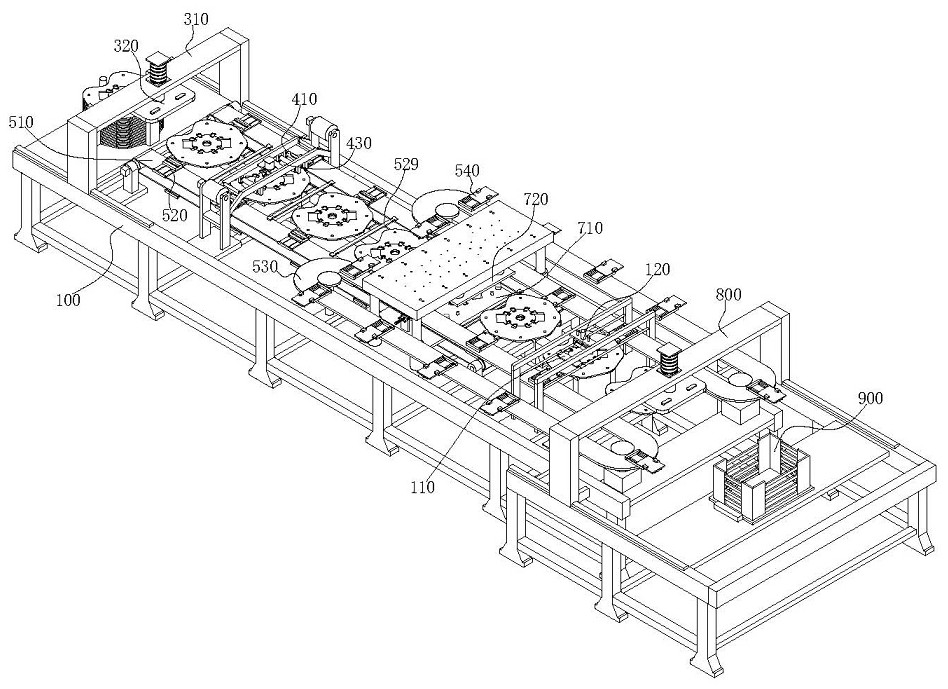

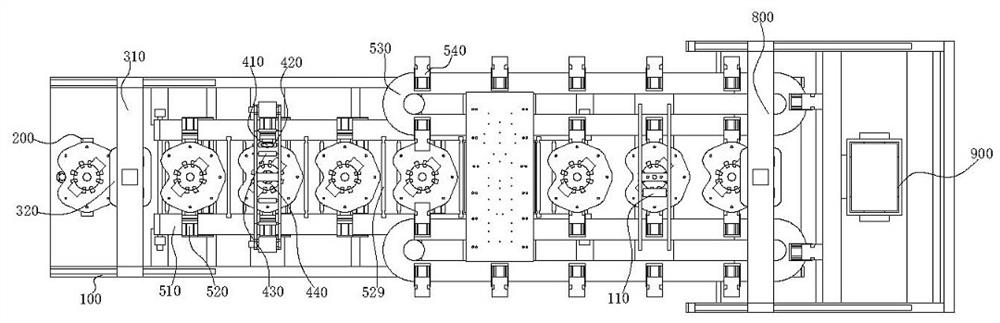

[0046]Refer toFigure 1 to Figure 9 The embodiment of the present application proposes an automated production equipment for stamping, drawing and flanging in the middle of a workpiece, which aims to solve the problem that in the prior art, in the production process of the reducer mount of a washing machine, it is necessary to manually coat and stamp the middle of the workpiece. Stretching oil, and after stamping and forming, it is necessary to manually clean the stamping and drawing oil, resulting in low efficiency and low level of automation.

[0047]Such asFigure 1 to Figure 9 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com