Stretchable punch pin mechanism for thermal stamping die

A technology for hot stamping dies and punches is applied in the field of telescopic punch mechanisms of hot stamping dies, which can solve the problems of inconvenient disassembly and assembly of punch mechanisms, affecting work continuity and efficiency, and long time for replacement. Enhanced connection stability, easy adjustment, scientific and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

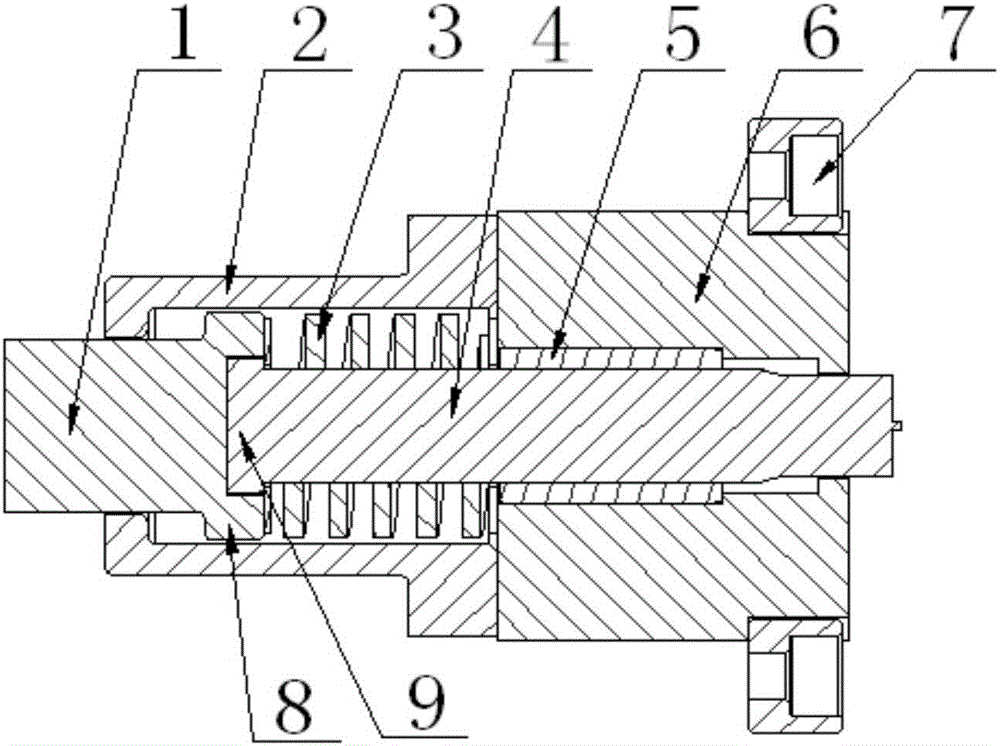

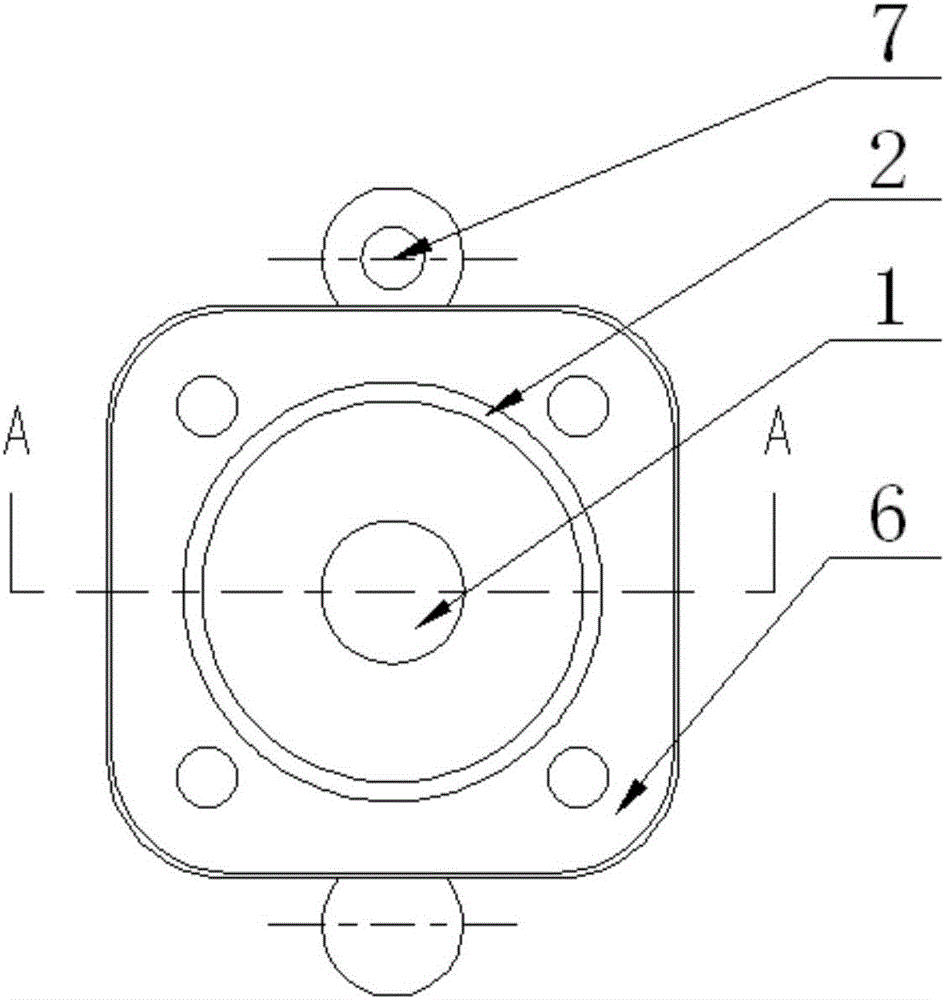

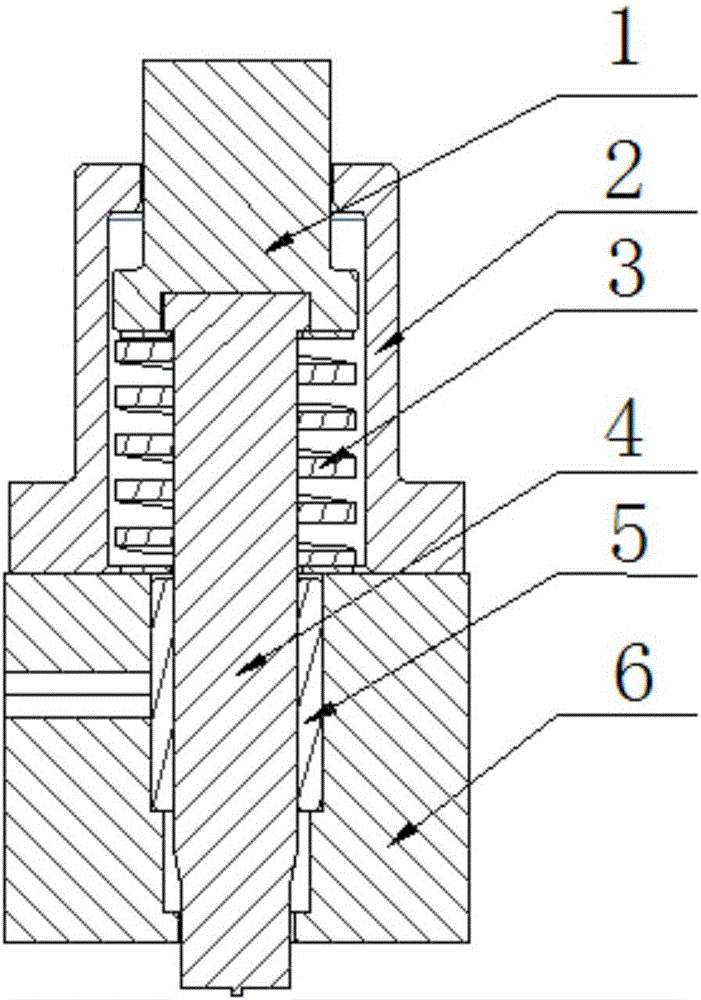

[0022] A retractable punch mechanism for a hot stamping die, the innovation of which is that it includes a punch sleeve 6, a spring sleeve 2, a punch 4, an impact block 1, a spring 3, a guide sleeve 5, and a base fixing block 7. The front end of the punch sleeve is coaxially fixed with the spring sleeve, the punch is coaxially installed in the punch sleeve and the spring sleeve, the front end of the punch is fixed with an impact block, the rear end of the impact block is located in the spring sleeve, and the impact block The front end of the punch sticks out of the spring sleeve, the spring is coaxially set between the punch and the spring sleeve, the guide sleeve is installed between the punch and the punch sleeve, and the base is symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com