Forming method and forming device for powder metallurgy part

A technology of powder metallurgy and forming method, which is applied in the field of forming method and forming device of powder metallurgy parts, which can solve the problems of density reduction and achieve the effects of small relative density difference, high relative density and improved green body performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

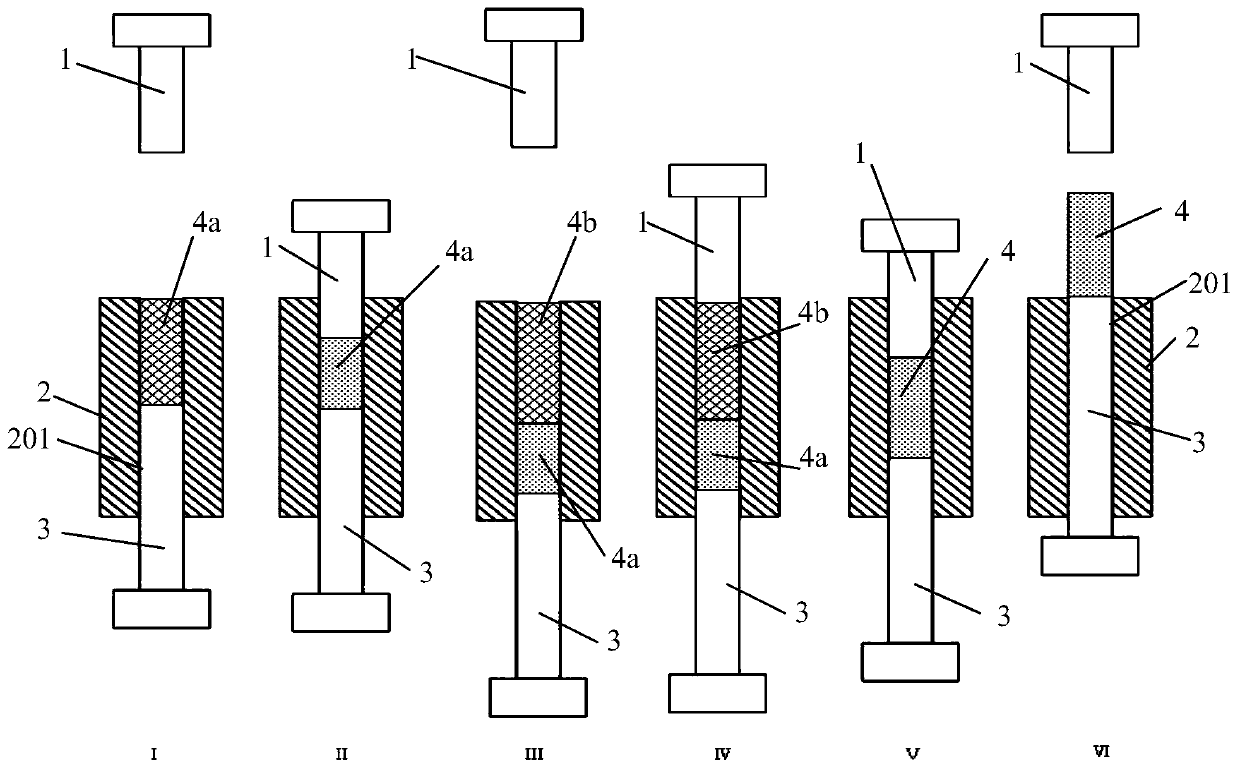

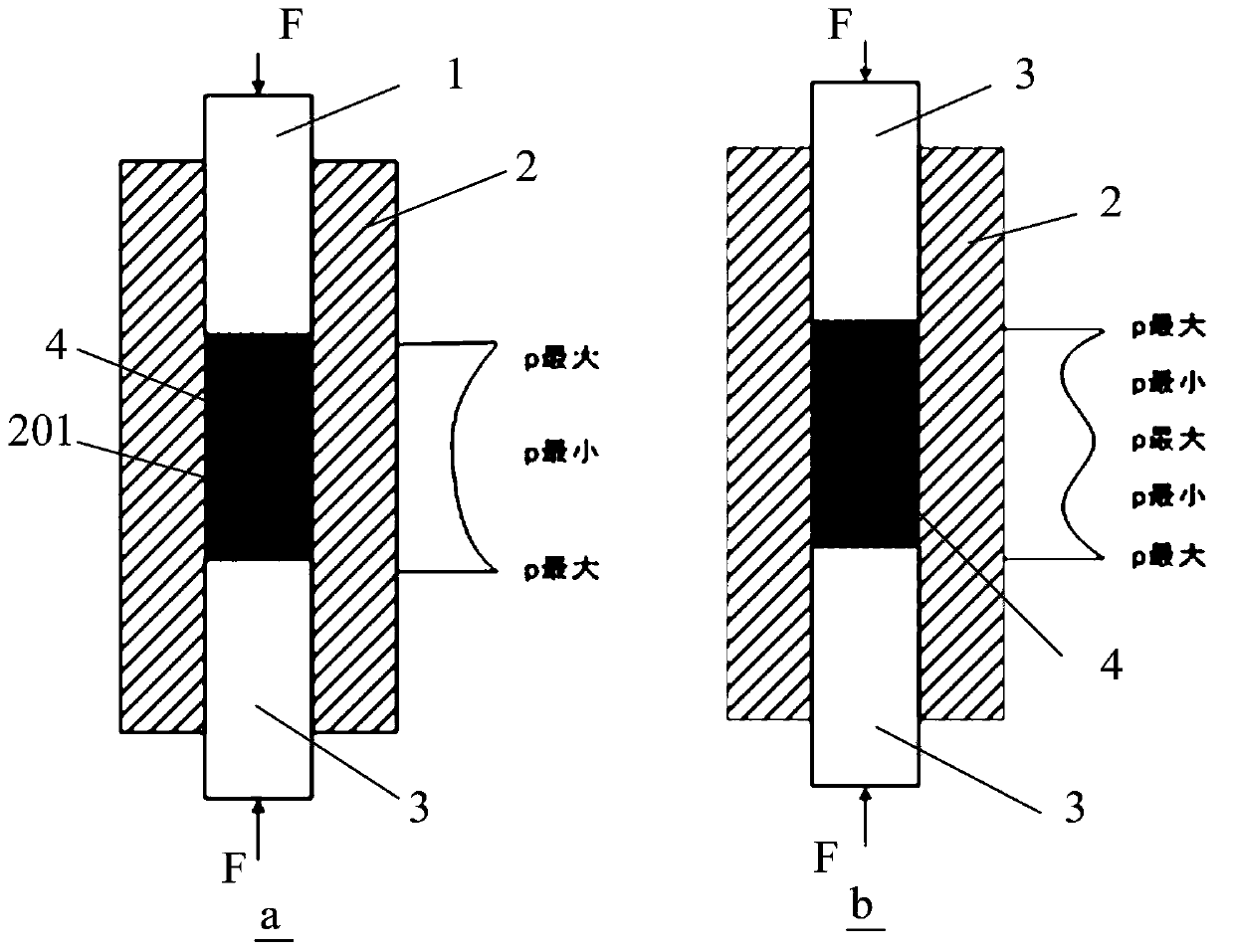

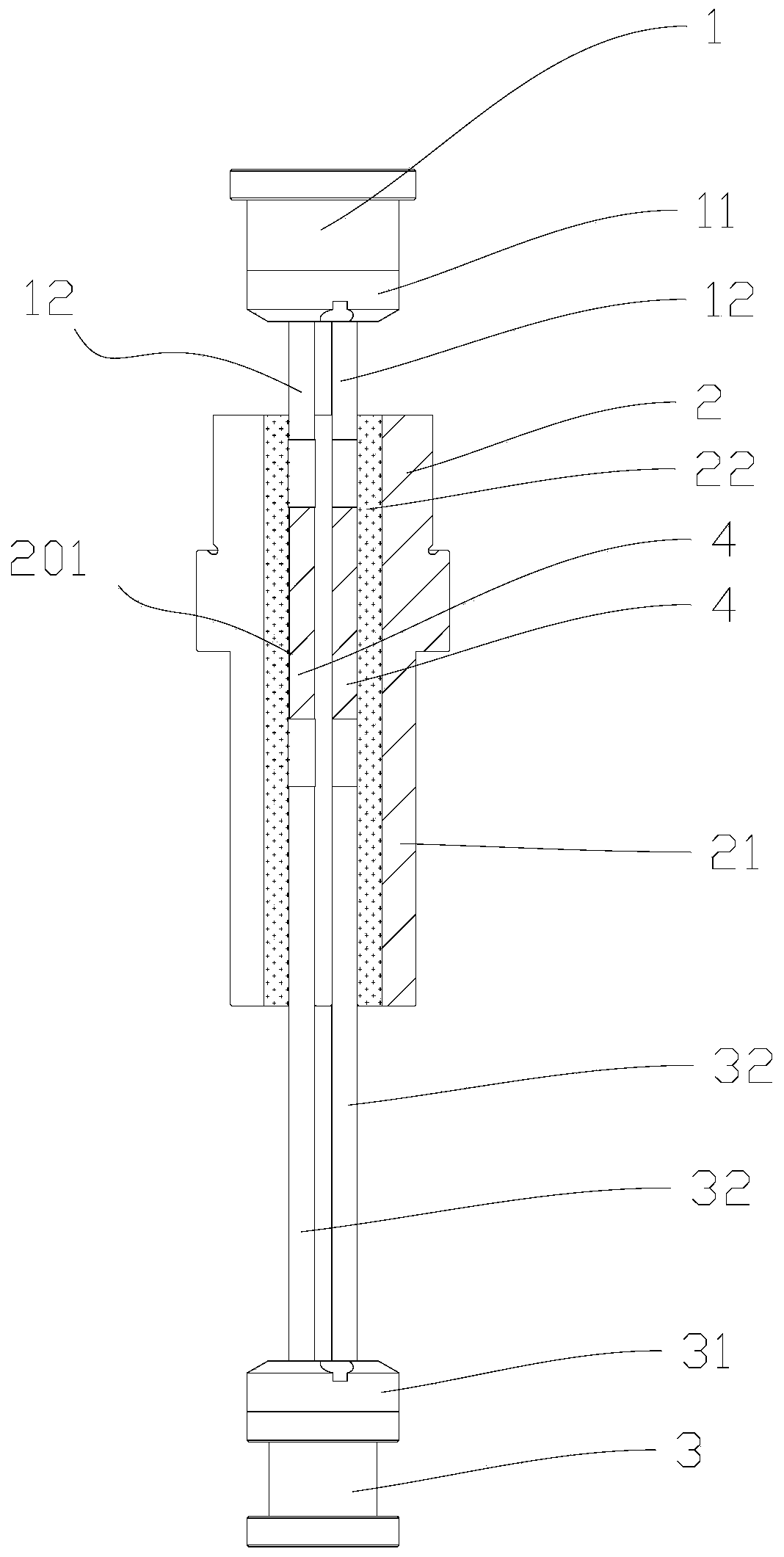

Method used

Image

Examples

Embodiment 2

[0049] The forming method of the powder metallurgy part of the present embodiment is different from Embodiment 1 in that:

[0050] The forming method of this implementation also includes an intermediate pressing between the first pressing of step S1 and the last pressing of step S2. The method of intermediate pressing is the same as the first pressing method: the upper die punch 1 moves upward and leaves the female mold cavity 201 of the female die 2 , the lower die punch 3 descends and remains in the female mold cavity 201, and sends the powder into the female mold cavity 201, and the filling height is lower than the height of the female mold cavity 201. The powder is pressed, the lower die punch 3 remains still, and when the upper die punch 1 descends to the designated position, the pressing is completed. Then do the final pressing.

[0051] The rest of the molding method is basically the same as that of Embodiment 1, and will not be repeated here.

[0052] It should be no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com