Process for producing high-strength spring

一种高强度、表面温度的技术,应用在制造工具、热处理设备、炉等方向,达到高耐久性的效果

Inactive Publication Date: 2006-04-26

CHUO SPRING

View PDF0 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These past technologies have not always met the performance requirements of the latest springs applied at higher levels of operating stress

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

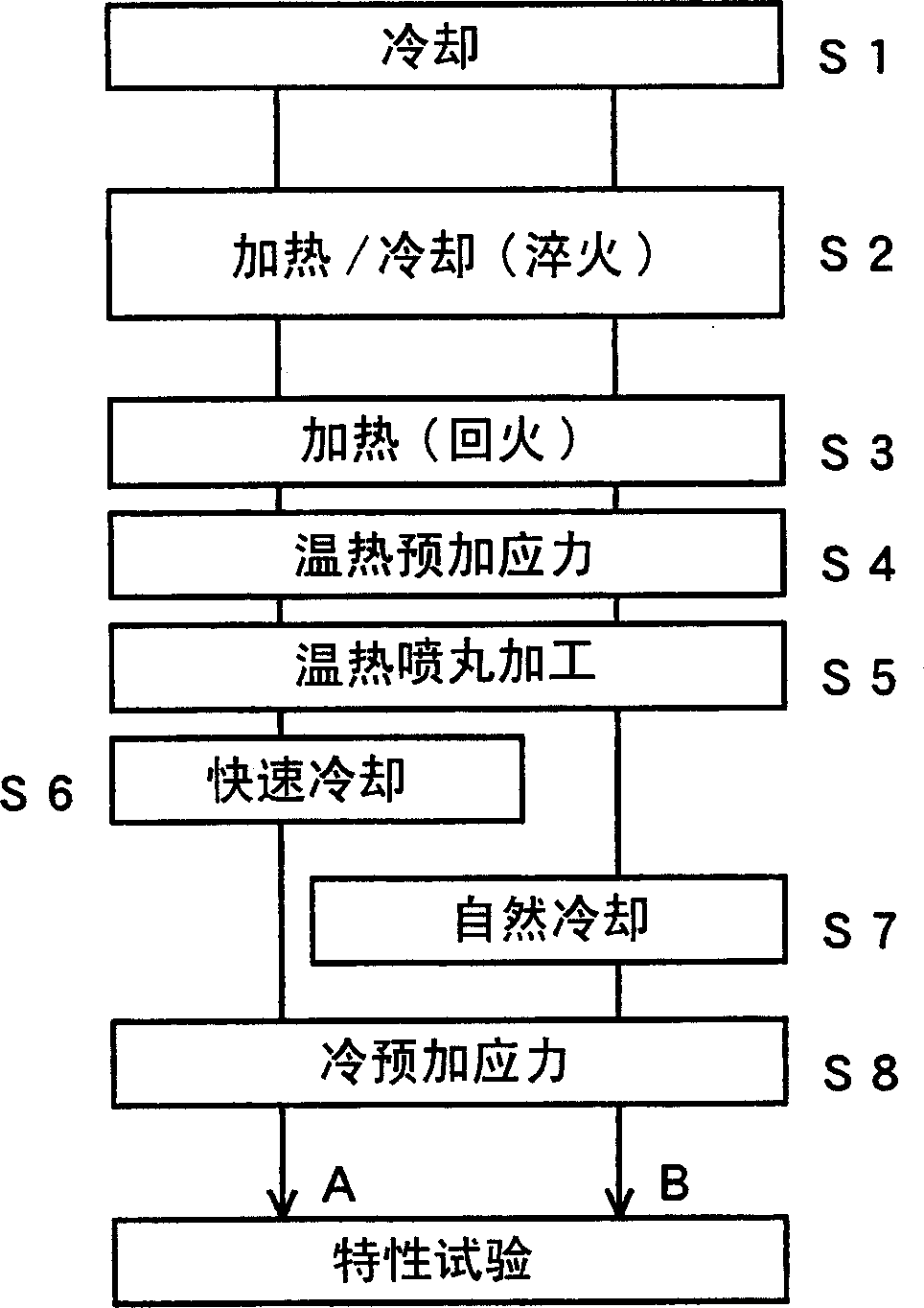

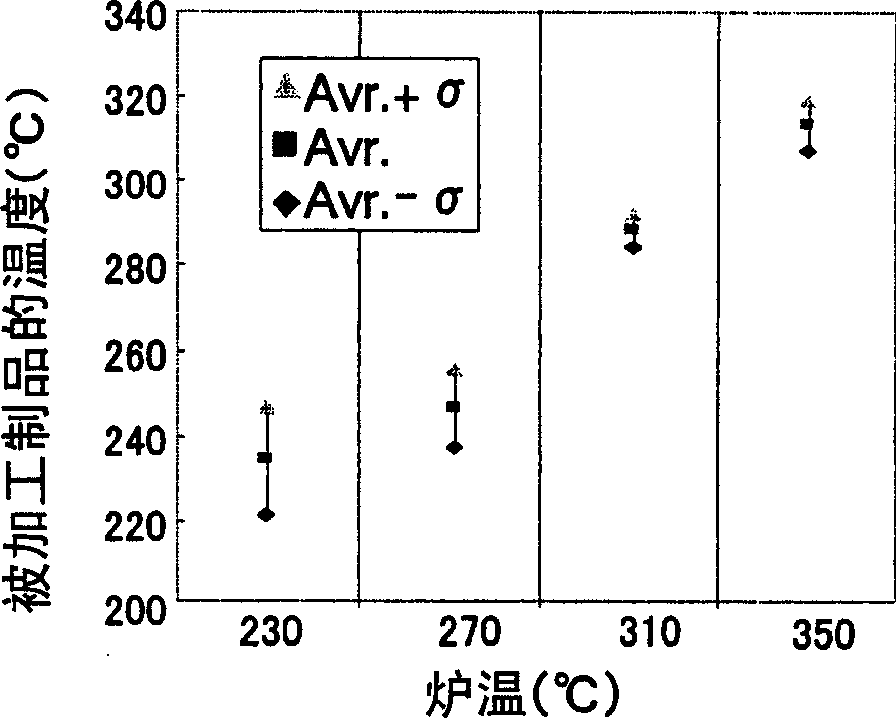

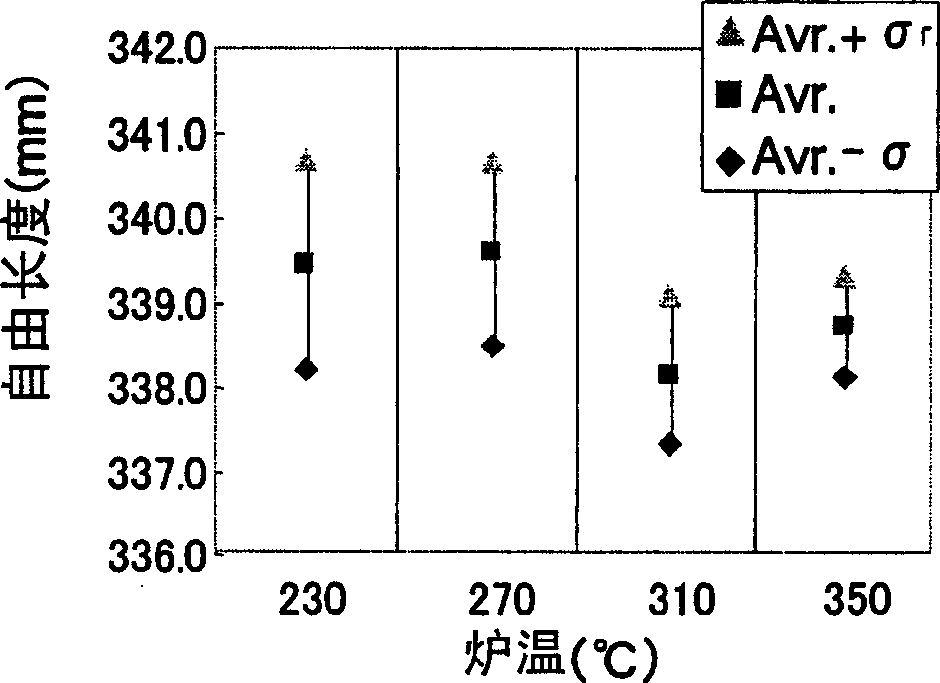

The present invention provides a process for producing a high-strength spring capable of having a compressive residual stress greater than in the prior art. In particular, the process comprises subjecting to shotpeening a spring having undergone final heating, such as tempering (for heat-treated spring) or stress relieving annealing (for cold formed spring), while the surface temperature of the spring is in the range of 265 to 340 DEG C (preferably 300 to 340 DEG C). The spring after shotpeening is quenched. It is preferred that setting be performed prior to shotpeening, or after shotpeening but before quenching. The quenching can be accomplished by water cooling or oil cooling with no preference. When the wire diameter of the spring is small, forced air cooling can be used.

Description

technical field The present invention relates to a shot peening method for producing springs, especially suspension springs, which have a high level of durability (or fatigue resistance) and sag resistance. Background technique As a method for significantly improving spring durability, shot peening is an indispensable method for high-strength springs, especially for suspension springs used in automobiles or valve springs used in engines. In the shot peening method, a large number of small particles are projected onto the surface of a target object. The process is superficially the same as shot blasting, which removes burrs (or knurling) from cutting or forming the article, or scale (ie, a hard oxide layer) from heat treatment. Surface cleaning process. However, the two processes differ significantly from each other in terms of strength and other conditions; for shot peening, the determined condition is that the plastic deformation is only on the surface of the spring, so...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21D8/00C21D7/06C21D9/02

CPCC21D9/02C21D8/00C21D7/06Y10T29/479Y10S148/908

Inventor 中野智弘榊原隆之胁田将见

Owner CHUO SPRING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com