Expansion clasping hydraulic mould locking mechanism

A hydraulic lock and clasp technology, applied in the field of hydraulic mold clamping mechanism, can solve the problems of complex precise brake action, lower pull rod strength, slow mold moving speed, etc., achieve lower precision requirements, lower overall machine cost, and oil The effect of less compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

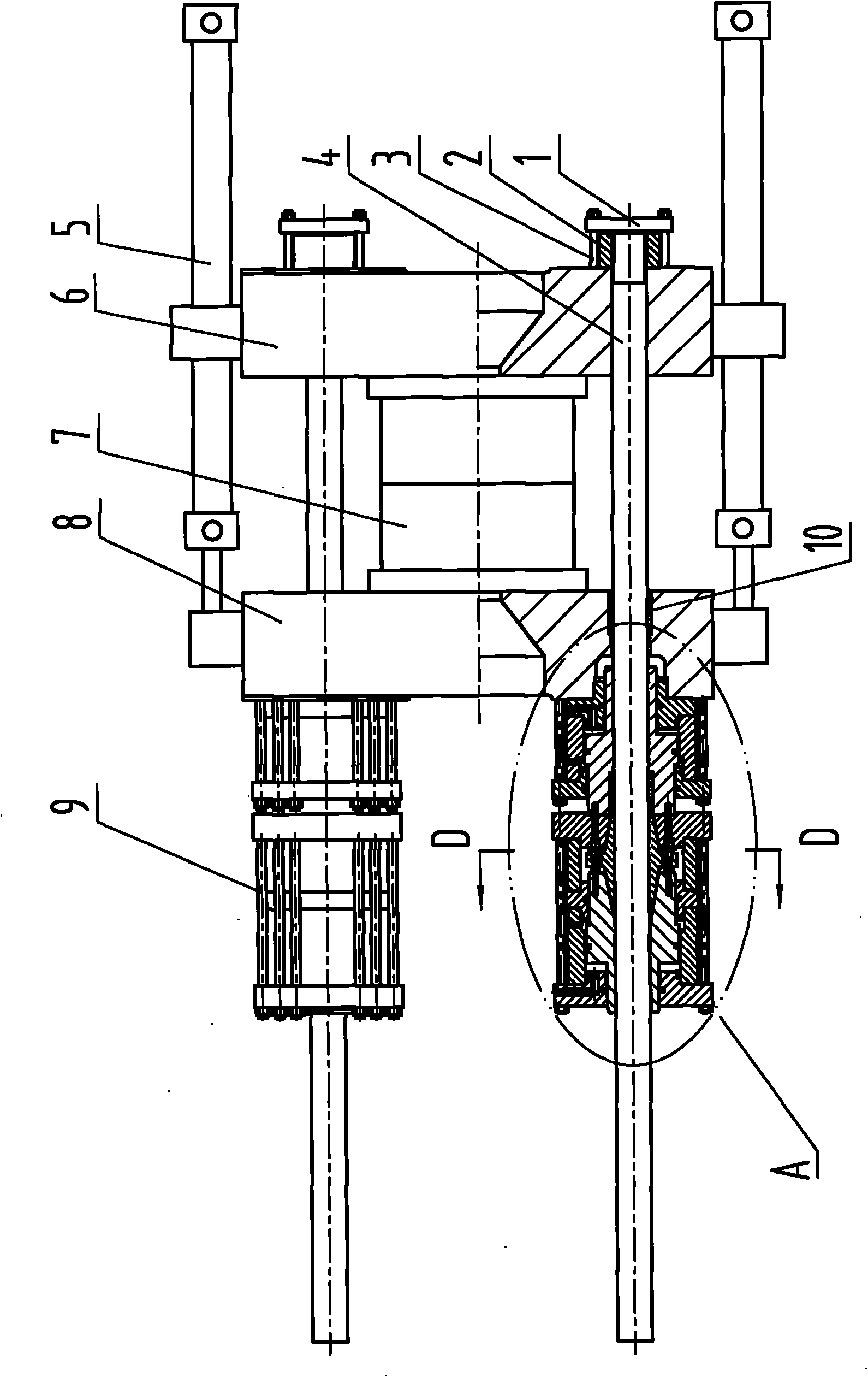

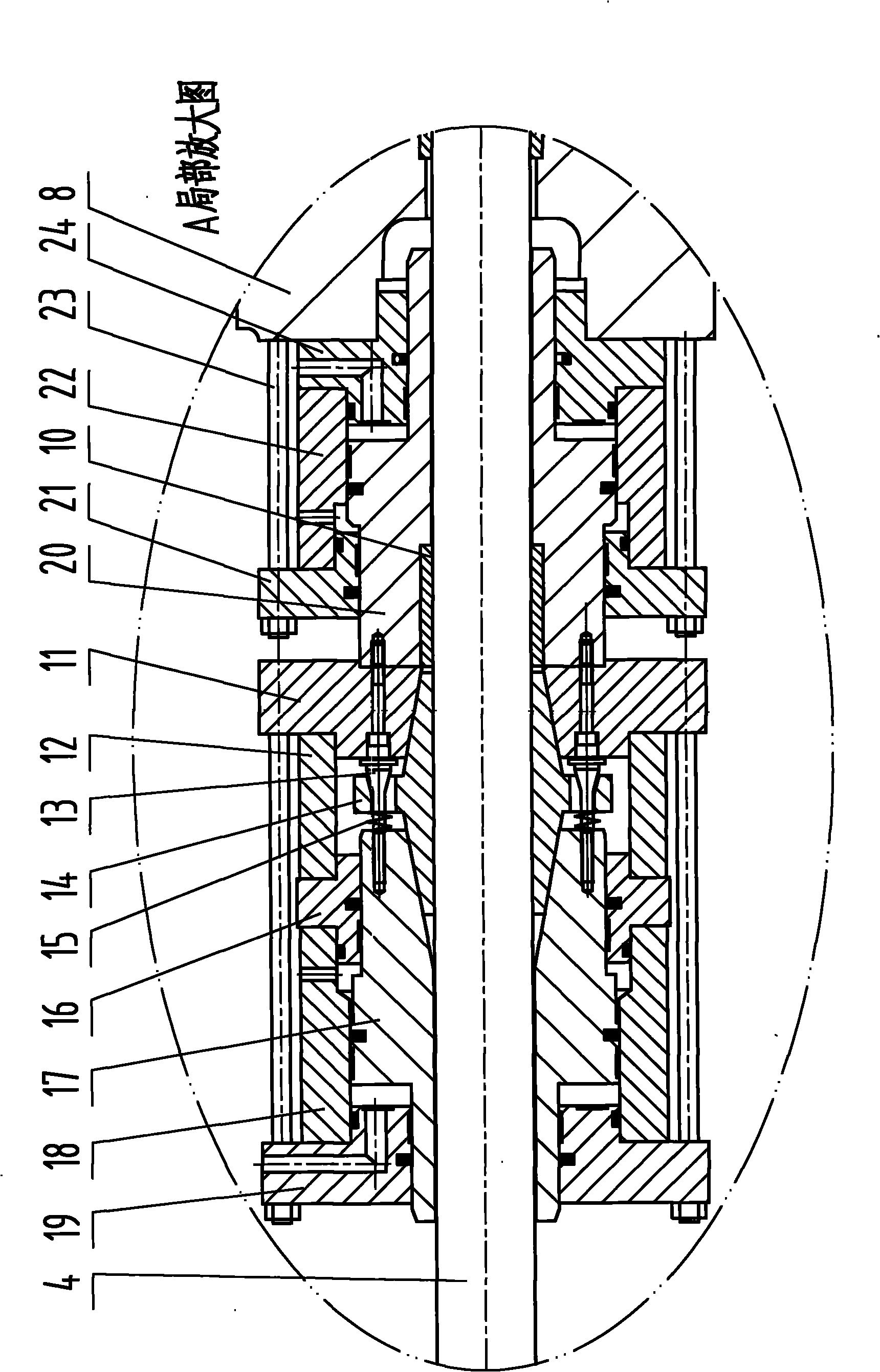

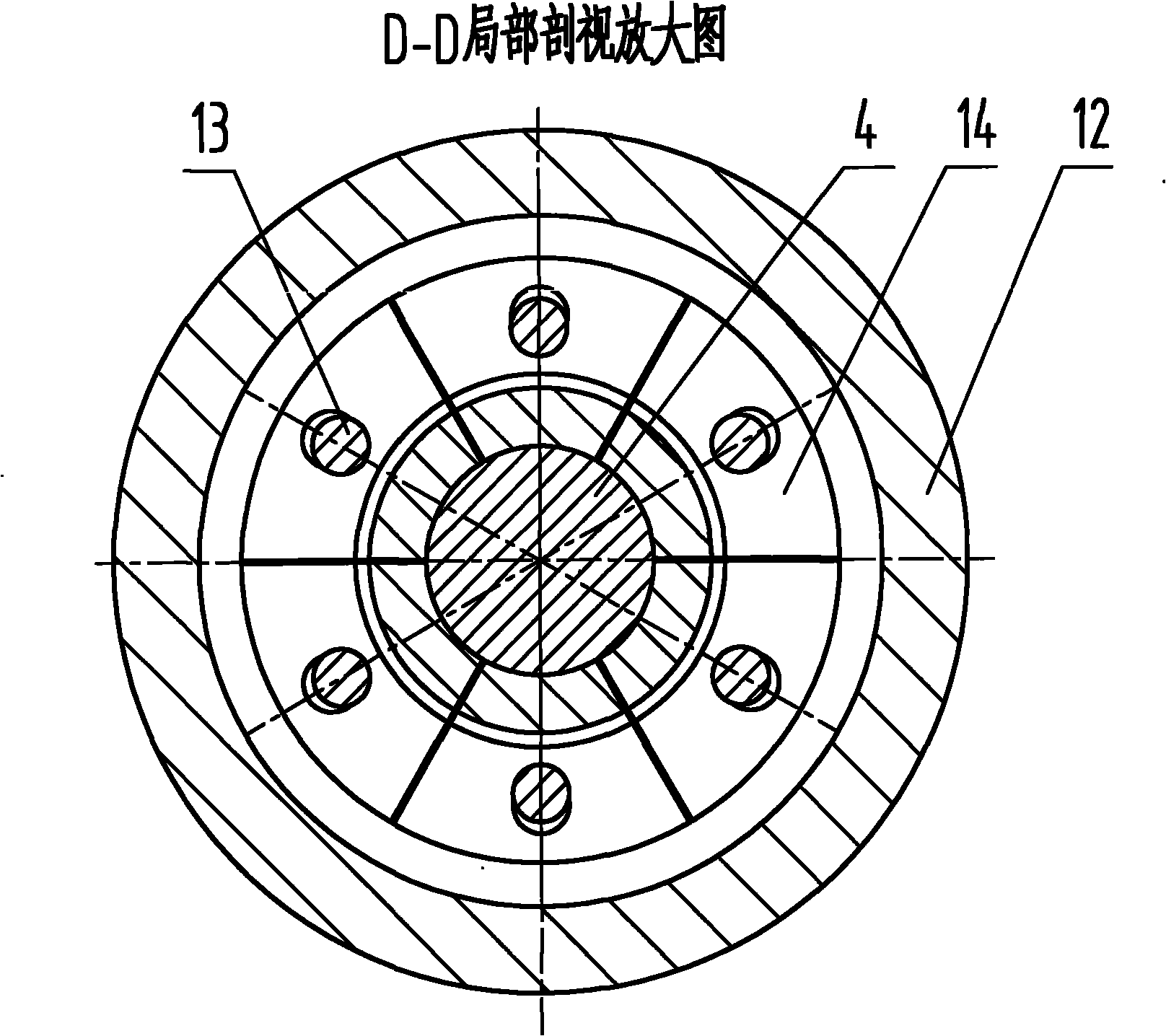

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown in the figure, a hydraulic mold clamping mechanism of the expansion-tightening type, which includes a tie rod clamp (1), a draw rod nut (2), a draw rod clamp screw (3), a draw rod (4), a mold transfer cylinder (5), a fixed template (6), mold (7), movable formwork (8), expansion joint cylinder pull rod (9), guide sleeve (10), expansion support seat (11), support body (12), pull screw (13) , expansion and tight oblique block (14), compression spring (15), expansion and tight engagement oil cylinder back cover (16), expansion and tight engagement oil cylinder piston rod (17), expansion and tight engagement oil cylinder body (18), expansion and tight engagement oil cylinder front cover (19), high pressure mold clamping cylinder piston rod (20), high pressure mold clamping cylinder rear cover (21), high pressure mold clamping cylinder body (22), high pressure mold clamping cylinder pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com