Prefabricated skirt type pipe pile used for drainage and added with pile body inclined support and construction method thereof

A prefabricated skirt type and oblique support technology, applied in sheet pile walls, soil protection, foundation structure engineering, etc., can solve problems such as limited bearing capacity, increased depth and pile diameter, mud pollution, etc., to achieve bearing capacity and settlement The effects of improvement, ultimate bearing capacity increase, and shear strength increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

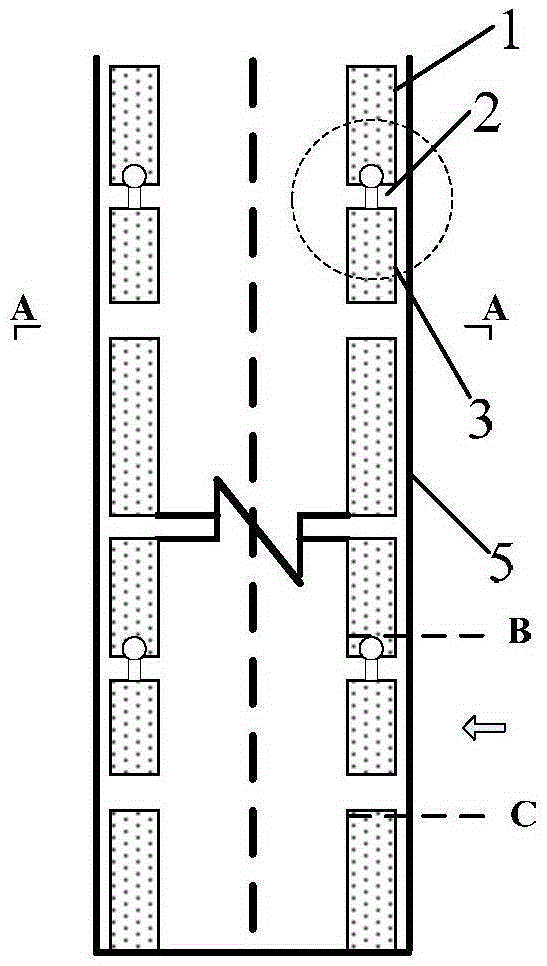

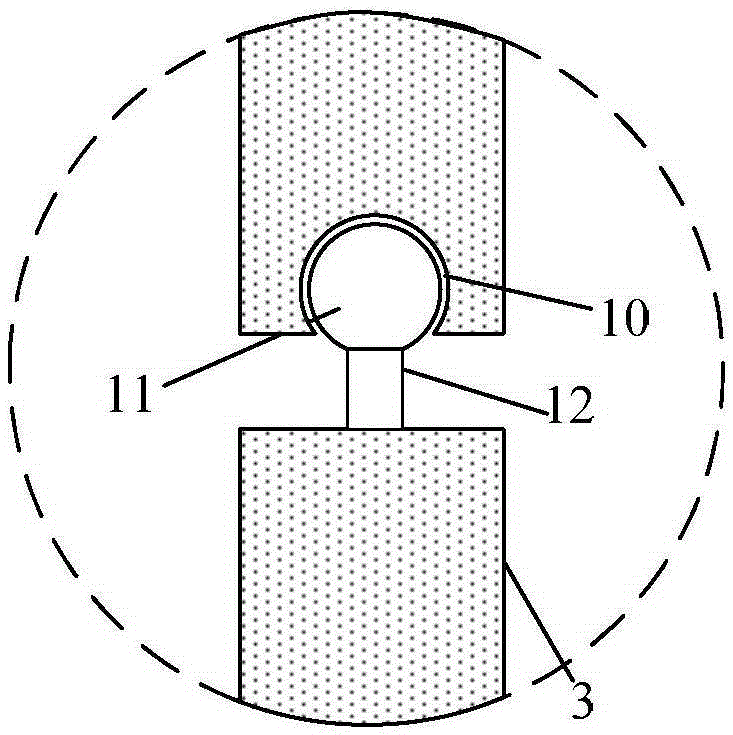

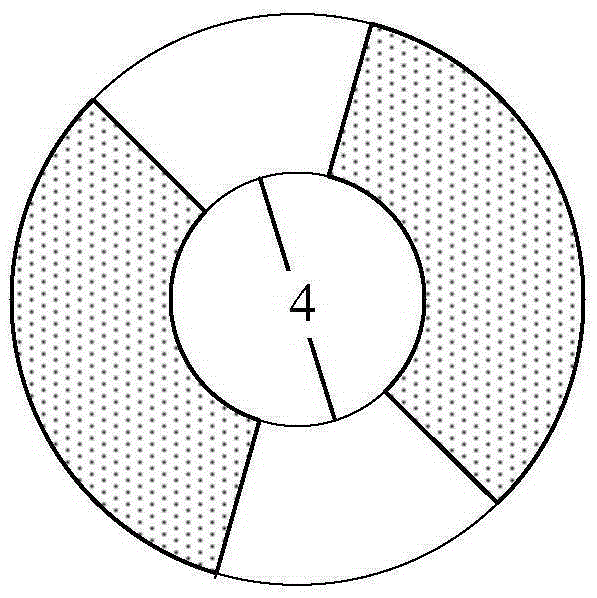

Embodiment 1

[0088] The soil at the test site is silt, and the test adopts a simplified pile shape instead of the prefabricated pipe pile in the present invention. Simplified pile shape: a pipe pile with an outer diameter of 150mm, an inner diameter of 130mm, and a length of 1.5m. The material is carbon steel. There is no oblique support within 30cm from the pile top along the pile body. Starting from the 30cm of the pile body, a circle of welded steel bars is installed every 20cm to replace the oblique support of prefabricated concrete blocks. There is no installation at the bottom of the pile, and a total of 6 circles are installed. . The diameter of the steel bar is 20mm, the length is 80mm, and the included angle with the pile body is 45 degrees. Using the control test, three piles were made, namely steel pipe piles without welded steel bars, steel pipe piles with only one pair of steel bars welded in each circle, and steel pipe piles with two pairs of steel bars welded in each circle...

Embodiment 2

[0091] The engineering geological conditions of the test site were changed to silty clay, and the test still adopted a simplified pile shape instead of the prefabricated pipe pile in the present invention. The simplified pile shape is consistent with the parameters in the first embodiment. Also compare the steel pipe piles with no welded steel bars, the steel pipe piles with only one pair of steel bars welded per circle, and the steel pipe piles with two pairs of steel bars welded per circle. The vertical static load test results of single piles show that: under the condition of silty clay, the bearing capacity of prefabricated tubular piles with oblique supports is more obvious than that of silt. The bearing capacity of steel pipe piles welded to one pair of steel bars is increased by nearly 15%, while the bearing capacity of steel pipe piles welded to two pairs of steel bars is increased by about 20%.

[0092] In contrast to formula 1 and formula 2 in the principle analysis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com