Compound sound insulation-absorption barrier board

A barrier board and sound-absorbing technology, which is applied in noise-absorbing devices and buildings, can solve the problems that the porosity of sound-absorbing materials cannot meet the requirements of low-frequency noise control, low-frequency noise cannot be effectively controlled, and material pore changes, etc., so as to avoid self-weight Increase, avoid capillarity, long fiber length effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

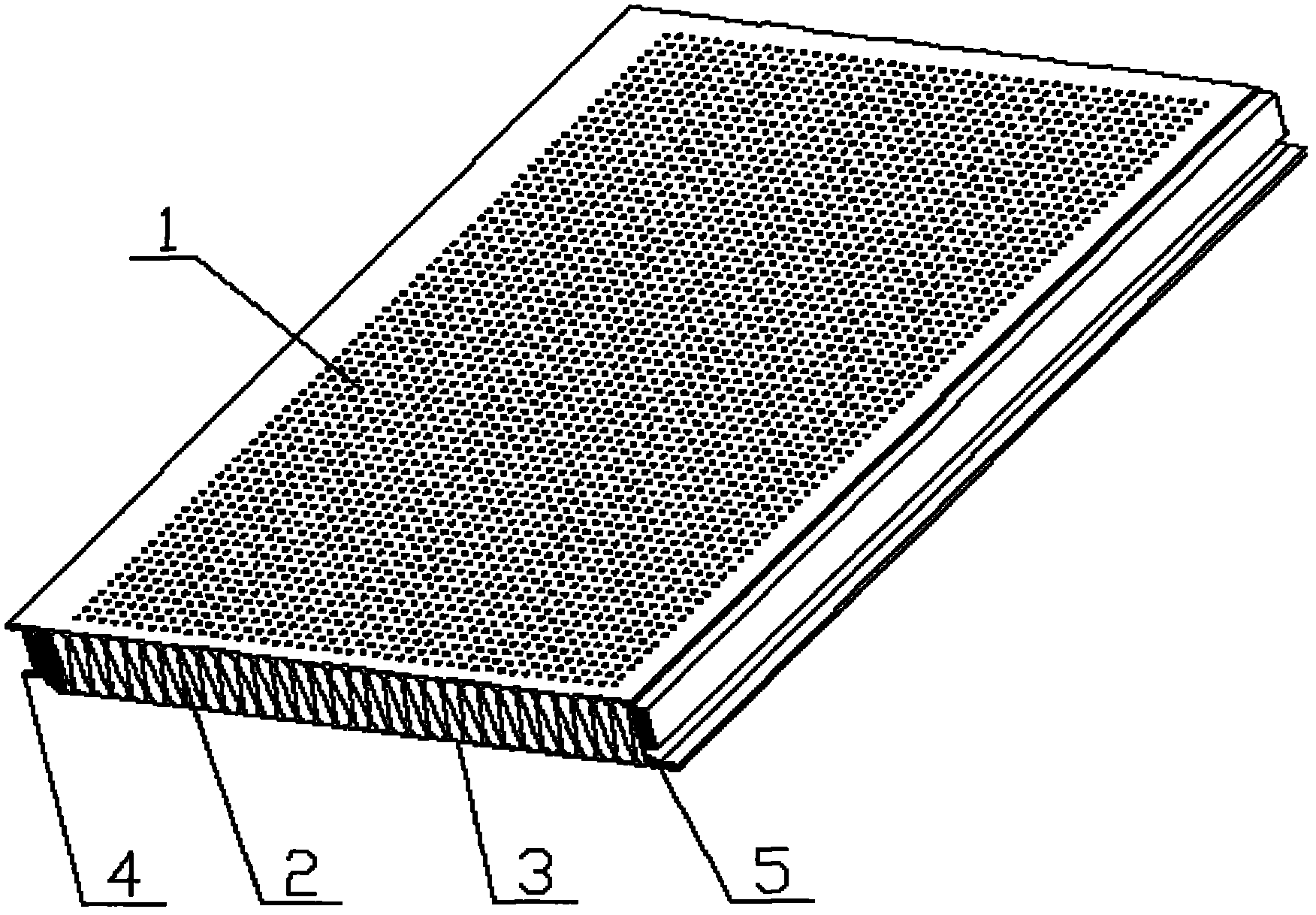

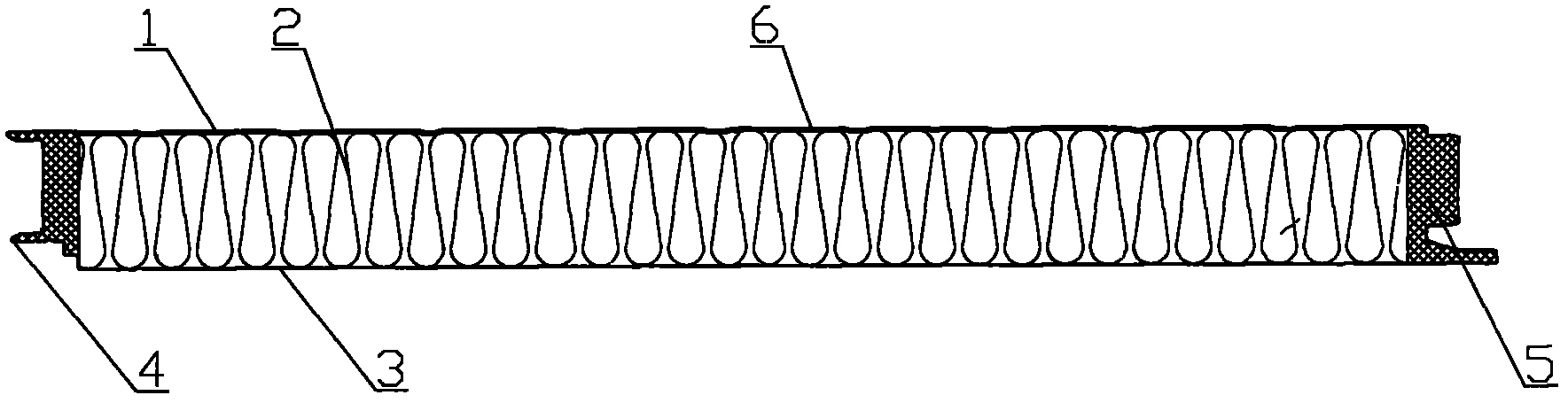

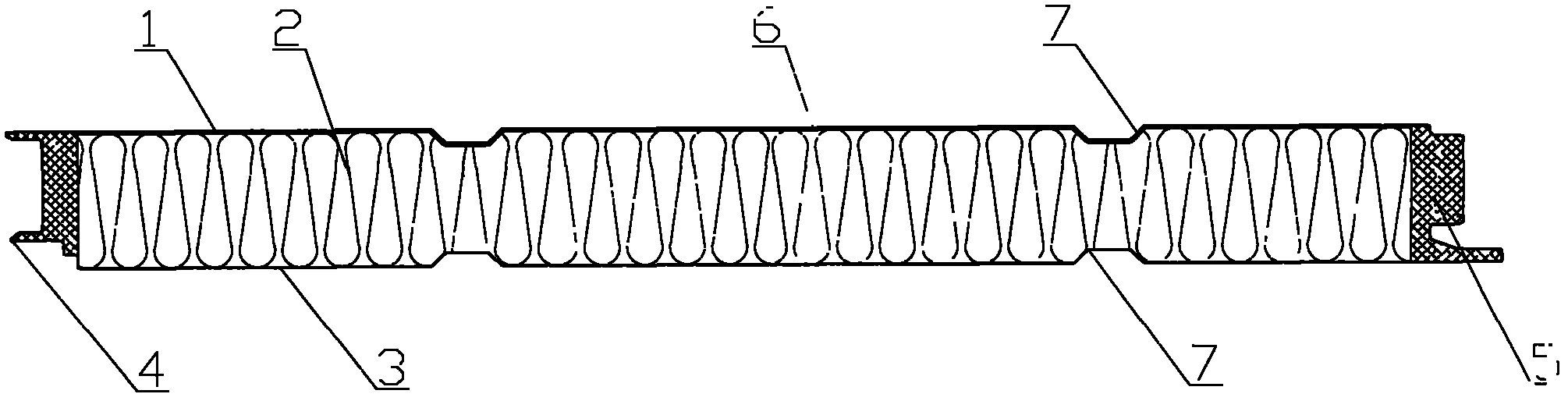

[0042] Such as figure 1 As shown, a composite sound-absorbing barrier panel includes a front panel 1, a back panel 3 and a core material 2 bonded and fixed between the two panels. The core material 2 is a centrifugal glass wool sound-absorbing material, and the centrifugal The glass wool sound-absorbing material is arranged in strips, and its fiber direction is perpendicular to the front panel 1 and the back panel 3, and the two sides of the composite sound-absorbing barrier board at the junction of the front panel 1 and the back panel 3 are provided with multiple tongues. mouth 4, the multi-tongue tongue and groove 4 on the two sides can be inserted into each other, the front panel is a perforated panel, and micropores with a perforation rate of 20% are distributed on it; the porosity of the core material is 97.44%, The average diameter of the fibers is 5-6 microns, and the fiber length is 150-200 mm; the noise enters the core material through the micropores and is absorbed ...

Embodiment 2

[0059] The structure of the composite sound-absorbing barrier board is the same as in Example 1. Wherein the front panel is distributed with micropores with a perforation rate of 4%; the porosity of the core material is 98%, the average diameter of its fibers is 5-6 microns, and the fiber length is 160-180 mm; The material is a centrifugal glass wool sound-absorbing material containing a water-repellent agent, and the water-repellent agent is 0.3% of the weight of the centrifugal glass wool. The hydrophobicity of the material is 98%. The water-repellent agent is a silicone resin, which is obtained by modifying a phenolic resin with tricarboxypolydimethylsiloxane. For the modification method, see Example 1 described in CN101531893A.

Embodiment 3

[0061] The structure of the composite sound-absorbing barrier board is the same as in Example 1. Wherein the front panel is distributed with micropores with a perforation rate of 30%; the porosity of the core material is 98.4%, the average diameter of its fibers is 5-6 microns, and the fiber length is 160-180 mm; the core material The material is a centrifugal glass wool sound-absorbing material containing a water-repellent agent, and the water-repellent agent is 0.8% of the weight of the centrifugal glass wool. The hydrophobicity of the material is 99.95%. The water-repellent agent is an organosilicon polymer surfactant α, ω-dihydroxypolydimethylsiloxane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com