Loop-type heat exchange device

a heat exchange device and loop-type technology, applied in the direction of semiconductor devices, lighting and heating apparatus, electrical apparatus, etc., can solve the problems of reducing the workability and stability affecting the workability of the heat exchange device, and the cooling device such as the heat sink plus the cooling fan is no longer qualified or desirable for removing the heat from these electronic components, so as to reduce the amount of vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

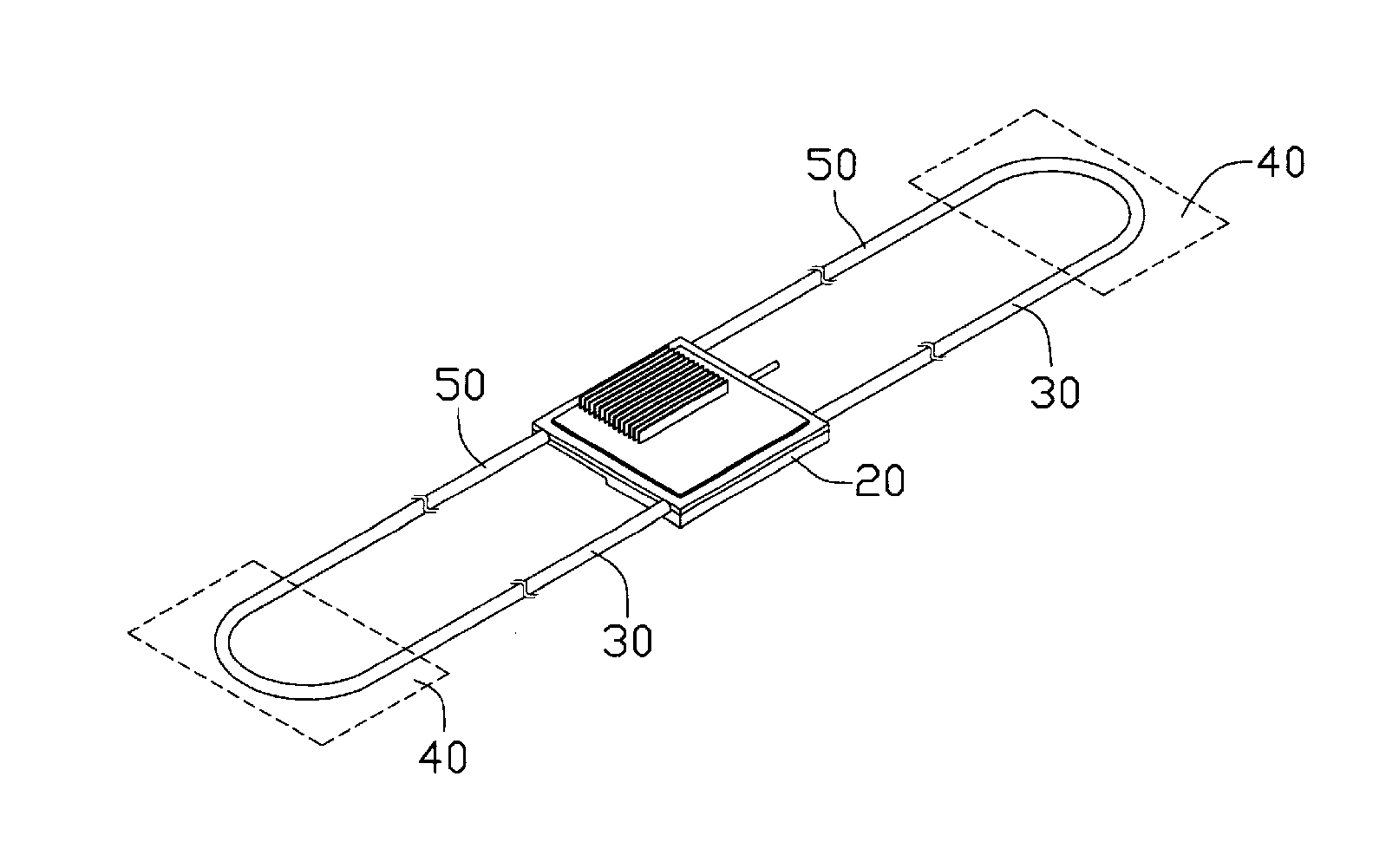

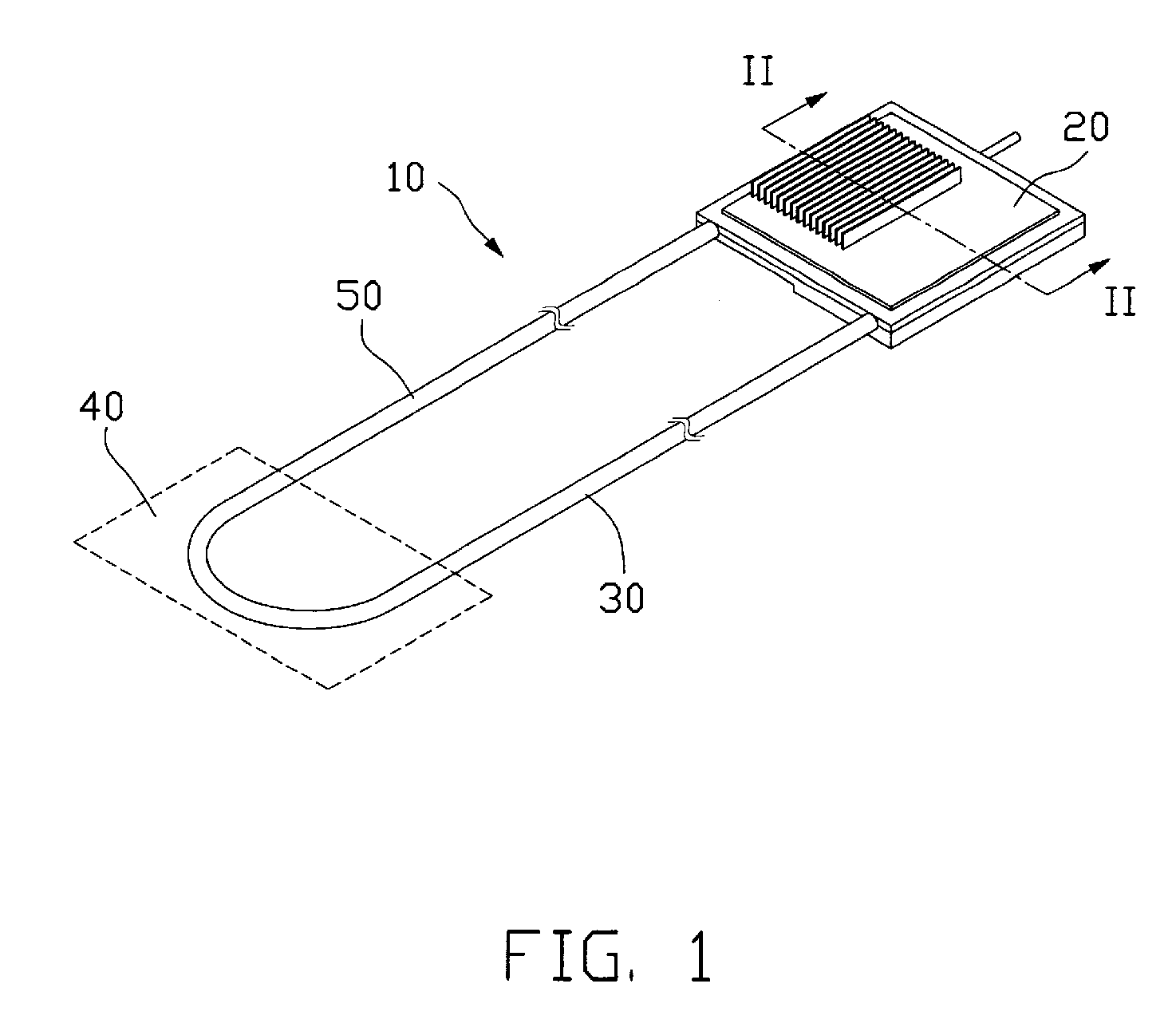

[0017]FIG. 1 illustrates a loop-type heat exchange device 10 in accordance with the present invention. The heat exchange device 10 includes an evaporator 20, a vapor conduit 30, a condenser 40 (shown in broken lines) and a liquid conduit 50. The evaporator 20 preferably is made of two separable portions connected together, as will be discussed in more detail later. The vapor and liquid conduits 30, 50 lie in parallel to each other, although they are not limited to this relationship. Two ends of each of the vapor and liquid conduits 30, 50 are respectively connected to the evaporator 20 and the condenser 40. The vapor and liquid conduits 30, 50 preferably are made of flexible metal or non-metal materials so that they could be bent or flattened easily in order to cause the heat exchange device 10 to be applicable in electronic products having a limited mounting space such as notebook computers.

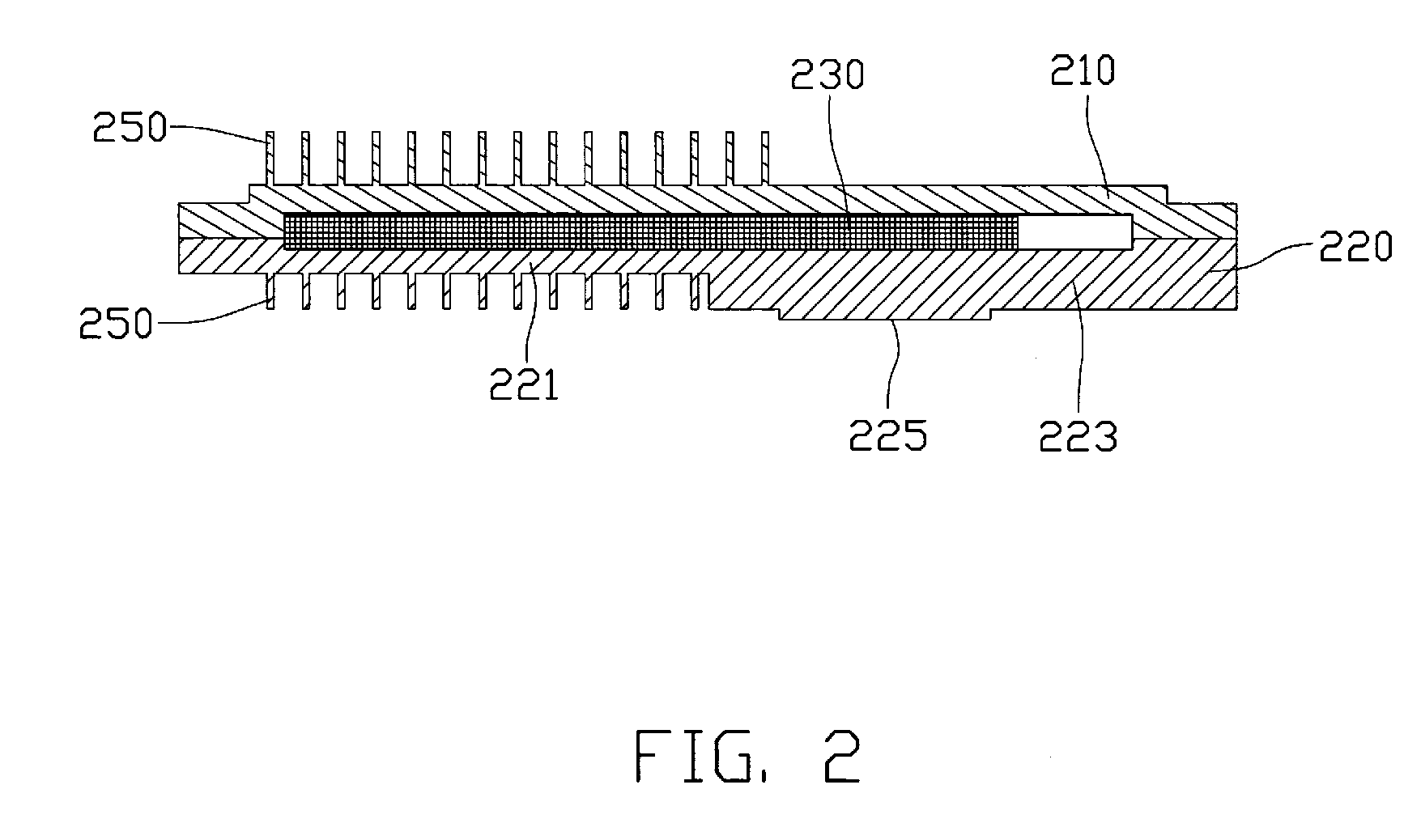

[0018] The evaporator 20 contains therein a working fluid (not shown). As heat from a heat s...

second embodiment

[0027]FIG. 5 shows a loop-type heat exchange device (not labeled) in accordance with the present invention. In this embodiment, the heat exchange device is provided with two heat transfer loops in order to increase its heat removal capacity, thus making it applicable for removing heat from heat-generating components with a high cooling requirement.

third embodiment

[0028]FIG. 6 shows a loop-type heat exchange device (not labeled) in accordance with the present invention. In this embodiment, the heat exchange device includes two heat transfer loops and in each heat transfer loop two vapor conduits 30 are provided so as to reduce a resistance to the vapor generated in the evaporator 20 as it flows towards the condenser 40. To attain this purpose (i.e., reducing resistance to the vapor), the vapor conduit 30 may also be made to have a larger diameter than the liquid conduit 50 so as to enable the generated vapor to move towards the condenser 40 effectively and smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com