Wallpaper with gold stamping effect and preparation method thereof

A wallpaper and imitation bronzing technology, applied in the field of wallpaper printing, can solve the problems of the glossiness being difficult to achieve bronzing foil, the adhesion is not strong, etc., and achieve the effects of superior washing fastness, good adhesion performance and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

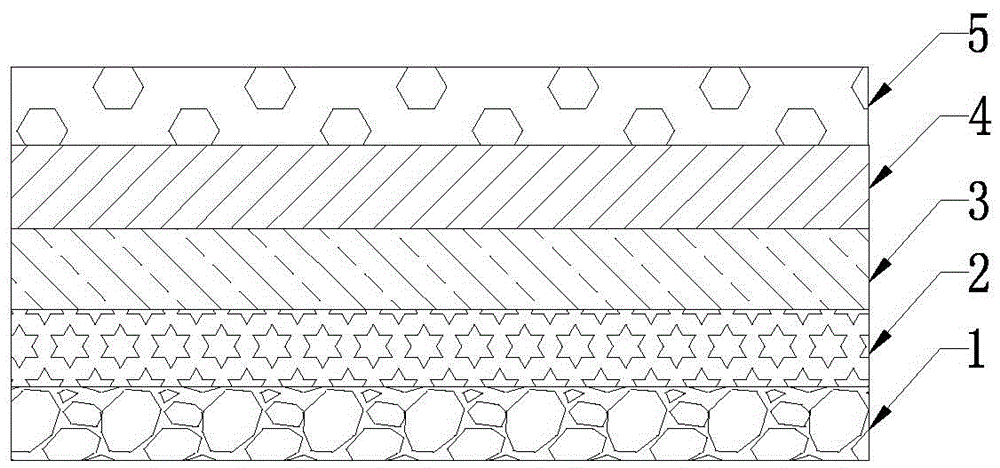

[0067] like figure 1 As shown, a wallpaper with bronzing effect includes a substrate layer 1, a water-based ink layer 3, and a bronzing imitation layer 4 connected in sequence from bottom to top.

[0068] Wherein, the thickness of the imitation bronzing layer is 0.01 mm.

[0069] Wherein, a substrate treatment layer 2 is also included between the substrate layer 1 and the water-based ink layer 3, the thickness of the substrate treatment layer 2 is 0.02mm, and the main material of the substrate treatment layer 2 is acrylic resin.

[0070] Wherein, the surface of the imitation bronzing layer 4 is also provided with a mica cover protection layer 5, and the mica cover protection layer 5 is a thin film layer formed by mixing a water-based acrylic resin emulsion with a pearl powder pigment.

[0071] Wherein, the thickness of the mica cover protective layer 5 is 0.08mm.

Embodiment 2

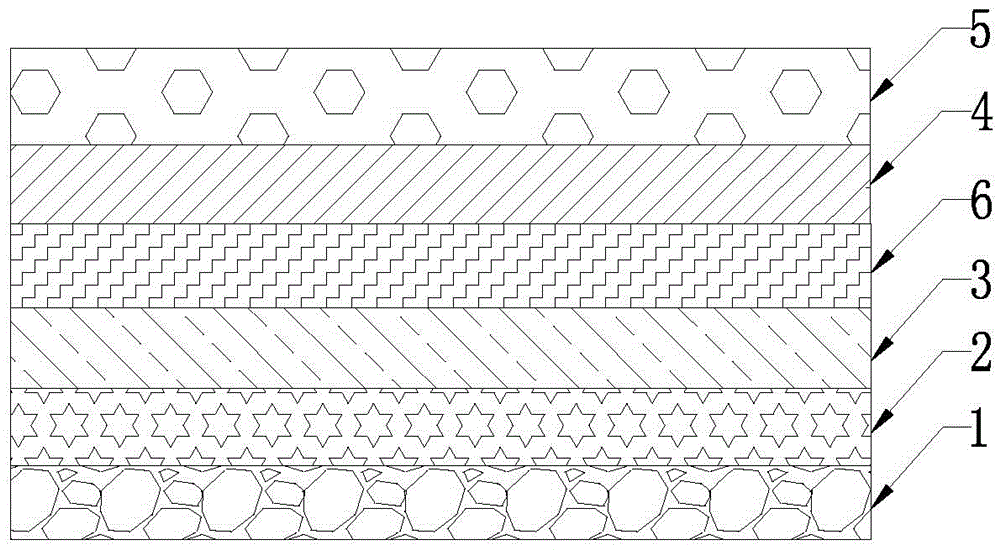

[0073] like figure 2 As shown, a wallpaper with bronzing effect includes a substrate layer 1, a water-based ink layer 3, and a bronzing imitation layer 4 connected in sequence from bottom to top.

[0074] Wherein, the thickness of the imitation bronzing layer is 0.5 mm.

[0075] Wherein, a substrate treatment layer 2 is also included between the substrate layer 1 and the water-based ink layer 3, the thickness of the substrate treatment layer 2 is 0.1 mm, and the main material of the substrate treatment layer 2 is polyvinyl chloride.

[0076] Wherein, a primer adhesive layer 6 is also included between the water-based ink layer 3 and the bronzing imitation layer 4, and the primer adhesive layer 6 is a colorless and transparent resin material.

[0077] Wherein, the thickness of the primer adhesive layer 6 is 0.02mm.

[0078] Wherein, the surface of the imitation bronzing layer 4 is also provided with a mica cover protection layer 5, and the mica cover protection layer 5 is a t...

Embodiment 3

[0081] A preparation method of wallpaper with bronzing effect, comprising the following preparation steps:

[0082] A. Substrate pretreatment: Put the prepared wallpaper substrate into the conveying device, and adjust the conveying tension and conveying speed of the substrate. The conveying tension is 200N / m, and the printing speed is 150m / min;

[0083] B, water-based ink layer 3 printing: water-based ink is printed on the surface of the substrate and dried;

[0084] C, imitation bronzing layer 4: print imitation bronzing layer on the surface of water-based ink layer 3, bake and dry, described printing method can adopt screen printing; Silk screen mesh number is 300 orders, and the refractive index of described imitation bronzing layer 4 1.93, the baking temperature is 30°C.

[0085] The obtained wallpaper ink with bronzing effect has good bonding performance, strong metallic feeling, high gloss, simple preparation process, and is safe and pollution-free to the environment. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com