Package bottle code spraying machine

A technology for inkjet printers and packaging bottles, applied in typewriters, printing, etc., can solve problems such as incomplete inkjet, packaging bottles rolling, and packaging bottles falling on the ground, etc., to achieve clear inkjet, good quality, and inkjet position precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

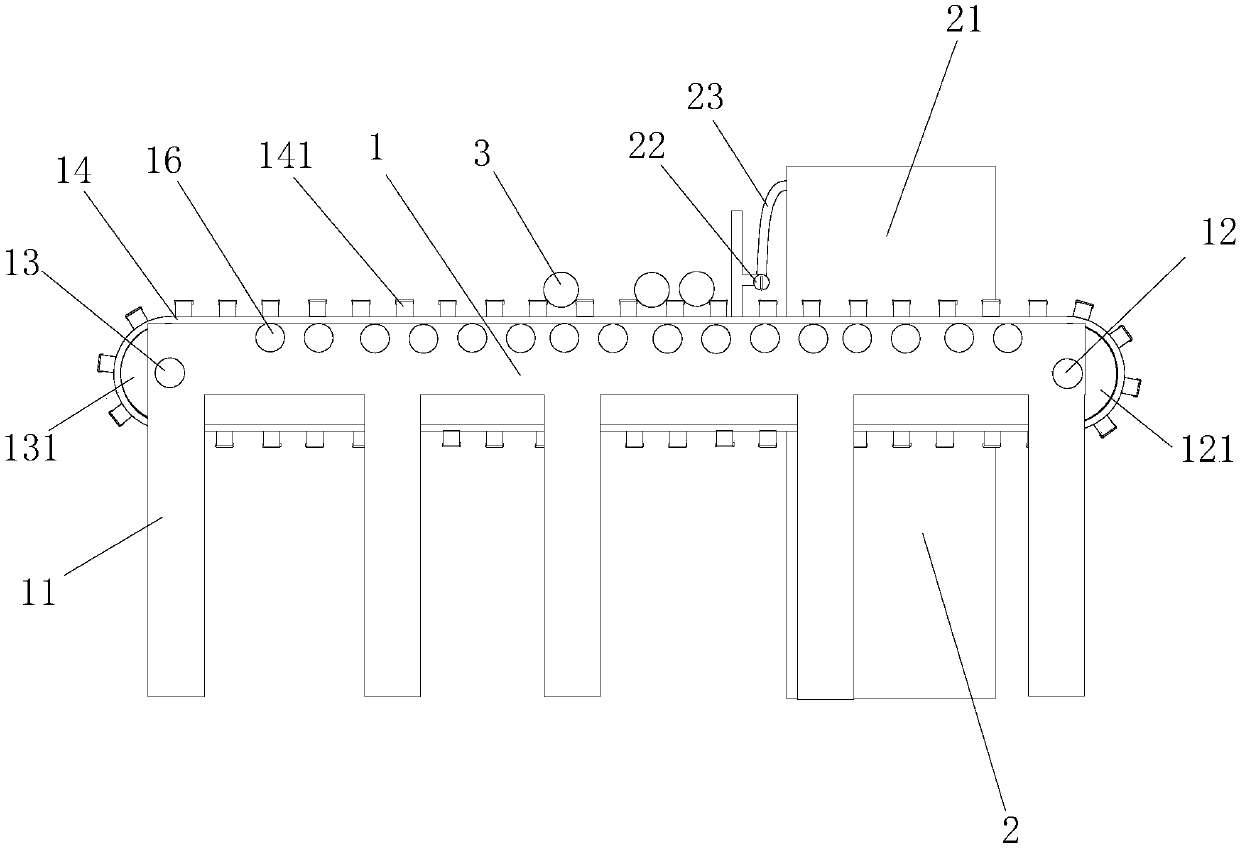

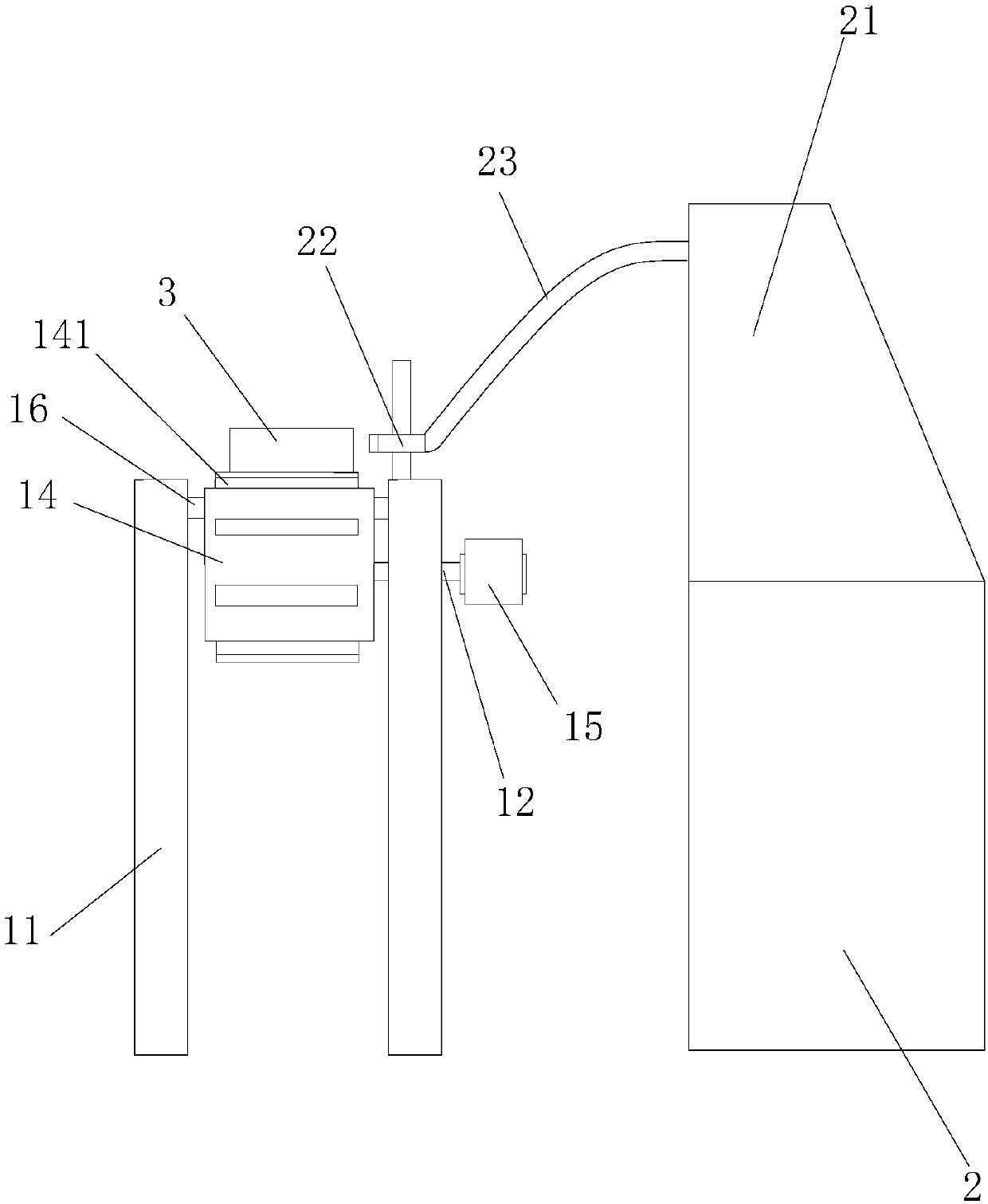

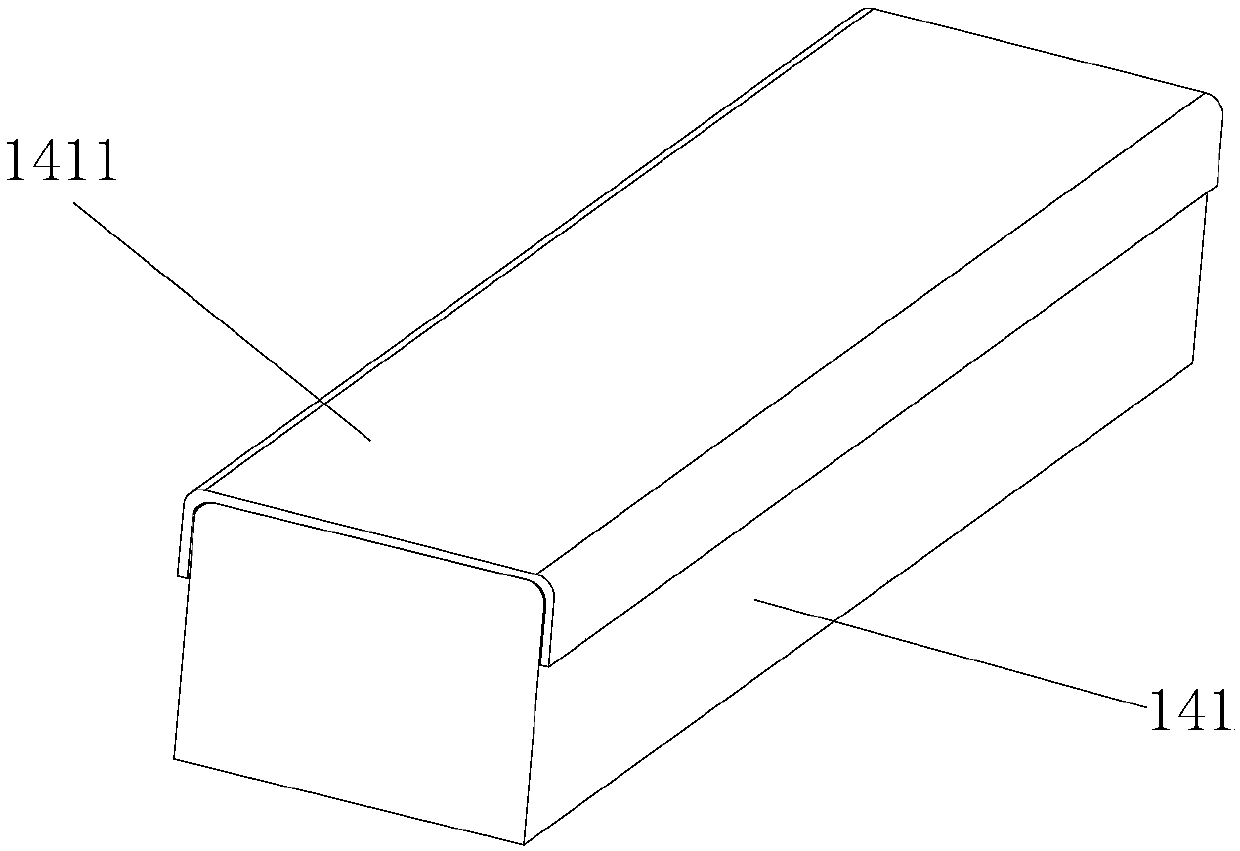

[0015] refer to figure 1 , figure 2 , a packaging bottle inkjet printer, including a conveying device 1 and a coding device 2, the conveying device 1 includes a support frame 11, a driving shaft 12 with a driving wheel 121, a driven shaft 13 with a driven wheel 131 , a conveyor belt 14, a driving device 15 for driving the driving shaft 12 to rotate, the driving shaft 12 and the driven shaft 13 are respectively located at the two ends of the support frame 11, and the driving wheel 121 passes through the conveyor belt 14 is connected with the driven wheel 131, the driving wheel 121 drives the driven wheel 131 to rotate through the conveyor belt 14, and the surface of the conveyor belt 14 is provided with a plurality of uniformly spaced The limit block 141, two adjacent limit blocks 141 cooperate with the conveyor belt to form a limit groove, the coding device 2 includes a coding box 21, a coding gun 22, and an ink delivery tube 23 , the coding gun 22 communicates with the cod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com